Delta-Pi Endstop Problem in Repeteir

Posted by runninfarmer

|

Delta-Pi Endstop Problem in Repeteir November 25, 2013 10:39AM |

Registered: 10 years ago Posts: 105 |

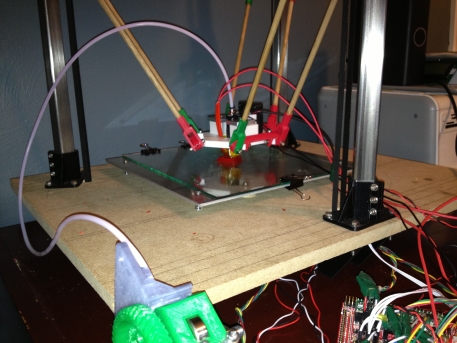

I have assembled Mike's Delta-pi design and am using repeteir host with repeteir firmware. Mike would you be willing to please share your firmware? My electronics are Ramps 1.4. I am very new to this so I've been learning on the fly. I initially had problems wiring the motors but now I have everything wired correctly, since I can independently move all three motors in the correct directions. My problem though is that when I go to print something, the axes home and activate the endstops, but the carrariages then keep crashing into the endstops. The x-axis will come down, but then the x-axis motor will move slowly. My endstops have three wires and blink red when activated.

I'm using the RostockMax firmware from thingverse, which I have attached. I have held down each endstop while sending M119 command, and repeteir shows the endstops are activating by displaying the "H" next to the one being tested. Is there something I'm overlooking? I have set all feedrates, steprates, and accelerations to be equal. I aprreciate the help! Sorry if this has been covered before but I've tried searching threads to no avail.

Edited 1 time(s). Last edit at 11/25/2013 10:40AM by runninfarmer.

I'm using the RostockMax firmware from thingverse, which I have attached. I have held down each endstop while sending M119 command, and repeteir shows the endstops are activating by displaying the "H" next to the one being tested. Is there something I'm overlooking? I have set all feedrates, steprates, and accelerations to be equal. I aprreciate the help! Sorry if this has been covered before but I've tried searching threads to no avail.

Edited 1 time(s). Last edit at 11/25/2013 10:40AM by runninfarmer.

|

Re: Delta-Pi Endstop Problem in Repeteir November 25, 2013 10:09PM |

Registered: 10 years ago Posts: 105 |

I was able to get the homing to work and endstops to work properly. Now my trouble is when I got to do a dry run of a simple object, the motors are really slow. It seems to home much faster than traveling in X/Y dimensions, even though I have my travel feedrates set higher than my homing feedrates. Here's a video on youtube to demonstrate my problem:

[www.youtube.com]

Again, thank you for the help!

[www.youtube.com]

Again, thank you for the help!

|

Re: Delta-Pi Endstop Problem in Repeteir November 26, 2013 01:18PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Delta-Pi Endstop Problem in Repeteir November 26, 2013 01:54PM |

Registered: 10 years ago Posts: 105 |

Thanks, for the info, I tried some higher speeds in the Slicr and noticed some improvement. But when I use manual controls the Z-axis moves fine, I get the slow, noisy moves in the X/Y directions. With the faster speeds in slicr, the motors are also much more noisier. I have the voltages on the drivers set around 0.22-0.30 volts. What I noticed though if change the drive system in the firmware from Delta to Cartesian, all three motors will independently move smoothly without a hitch, which seems odd to me. I hope I can get this resolved, since I feel so close to getting it running,

Edited 1 time(s). Last edit at 11/26/2013 01:55PM by runninfarmer.

Edited 1 time(s). Last edit at 11/26/2013 01:55PM by runninfarmer.

|

Re: Delta-Pi Endstop Problem in Repeteir November 26, 2013 07:52PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: Delta-Pi Endstop Problem in Repeteir November 26, 2013 09:10PM |

Registered: 10 years ago Posts: 105 |

The motors are rated for 1.2A at 57oz of torque. Do you think the delta configuration is requiring more torque than the Cartesian setup? I tried vrefs at .4 or .5 volts but that seemed to make the motors louder. I was afraid to increase the voltage and burn up the drivers, but they still felt cool to the touch. ARe higher vrefs required for delta printers? The Z axis moving sounds fine. Thanks again for all the help.

|

Re: Delta-Pi Endstop Problem in Repeteir November 27, 2013 08:12AM |

Registered: 10 years ago Posts: 1,433 |

The whole "how much torque?" thing is a matter of long debate. More or less - how much do you derate the design and in which directions?

You are not going to hurt the drivers or the motors by running the setup at 1A. That would at least rule out torque as the issue. You can then move on to checking other issues. I've assumed that the motions are all in the correct direction / correct distance. The next things on the list mostly relate to mechanical binding.

You are not going to hurt the drivers or the motors by running the setup at 1A. That would at least rule out torque as the issue. You can then move on to checking other issues. I've assumed that the motions are all in the correct direction / correct distance. The next things on the list mostly relate to mechanical binding.

|

Re: Delta-Pi Endstop Problem in Repeteir December 01, 2013 11:24PM |

Registered: 11 years ago Posts: 66 |

Hi Tyler,

Can I just cover off some basics with you first.

What brand of stepper drivers are you using? (Some brands use different sense resistors and require different voltages)

Are you using 0.9° or 1.8° motors? I used 0.9deg/step motors on the prototype and I found that with 1/16 microstepping the pulse frequency exceeded what the RAMPS could output.

What micro-stepping setting are you using?

What steps/mm did you calculate?

Now, I have been using Repetier firmware 0.82.2 IIRC

Recently I started trying out Johann's Marlin fork to get the bed levelling.

I still prefer Repetier but I have had both working.

One thing to be wary of with the stock delta code is that there isno inadequate limit checking and it is possible to send the head to unreachable positions with unpredictable results.

But I don't think that's what happens in your case.

I have seen this slow down though in my own printer. unfortunately I haven't seen it recently and I never found the cause.

I've made glacial progress on my printer since march but the good news is I have 2 weeks of vacation coming over Christmas and new year and the Delta-Pi is top of my list.

Regards,

Mike Paauwe

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

Can I just cover off some basics with you first.

What brand of stepper drivers are you using? (Some brands use different sense resistors and require different voltages)

Are you using 0.9° or 1.8° motors? I used 0.9deg/step motors on the prototype and I found that with 1/16 microstepping the pulse frequency exceeded what the RAMPS could output.

What micro-stepping setting are you using?

What steps/mm did you calculate?

Now, I have been using Repetier firmware 0.82.2 IIRC

Recently I started trying out Johann's Marlin fork to get the bed levelling.

I still prefer Repetier but I have had both working.

One thing to be wary of with the stock delta code is that there is

But I don't think that's what happens in your case.

I have seen this slow down though in my own printer. unfortunately I haven't seen it recently and I never found the cause.

I've made glacial progress on my printer since march but the good news is I have 2 weeks of vacation coming over Christmas and new year and the Delta-Pi is top of my list.

Regards,

Mike Paauwe

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

|

Re: Delta-Pi Endstop Problem in Repeteir December 01, 2013 11:34PM |

Registered: 11 years ago Posts: 66 |

Just watching your video again it looks like the non-printing moves are happening at high speed. I would be inclined to think that you have something set wrong in Slic3r

Check the 1st layer speed setting. This can be either a speed or a % depending on how you enter it.

Try sending the following Gcode from Repetier Host and timing the moves.

Check the 1st layer speed setting. This can be either a speed or a % depending on how you enter it.

Try sending the following Gcode from Repetier Host and timing the moves.

G29;HOME G01 X0 Y-50 Z100 F12000 G01 Y50 F1200; Should take 5 seconds to move 100mm G01 Y-50 F6000; Should take 1 second to move 100mm

|

Re: Delta-Pi Endstop Problem in Repeteir December 01, 2013 11:36PM |

Registered: 10 years ago Posts: 105 |

I got my motors on ebay here: [www.ebay.com]

They're 1.8 degree motors. I calculated 80 steps/mm with 1/16 stepping. Specifically in your movement settings in configuration.h, what values do you have for DELTA_SEGMENTS_PER_SECOND_PRINT, DELTA_SEGMENTS_PER_SECOND_MOVE, Printer radius, and effector/carriage offsets, etc?

Thanks again,

Tyler

Edited 2 time(s). Last edit at 12/02/2013 12:55AM by runninfarmer.

They're 1.8 degree motors. I calculated 80 steps/mm with 1/16 stepping. Specifically in your movement settings in configuration.h, what values do you have for DELTA_SEGMENTS_PER_SECOND_PRINT, DELTA_SEGMENTS_PER_SECOND_MOVE, Printer radius, and effector/carriage offsets, etc?

Thanks again,

Tyler

Edited 2 time(s). Last edit at 12/02/2013 12:55AM by runninfarmer.

|

Re: Delta-Pi Endstop Problem in Repeteir December 02, 2013 04:19AM |

Registered: 11 years ago Posts: 66 |

So I have the offsets commented out and just define the DELTA_RADIUS directly.

Leave the DELTA_DIAGONAL_ROD set to the length you made the rods to. This is a known and hopefully accurate measurement after all.

You need to adjust DELTA_RADIUS so that the build plane is flat. The theoretical value if you build to the plans is 125mm. But as you can see my printer needs 126.77mm

Typically I think this will be larger than theoretical because the printed parts you use to make your printer will usually be slightly undersize due to shrinkage as they cool.

I suspect your problem actually lies in your Slic3r settings but you'll want this info sooner or later.

Excerpt from Repetier Firmware 0.82.2 - configuration.h

Edited 1 time(s). Last edit at 12/02/2013 04:20AM by mikep-nz.

Leave the DELTA_DIAGONAL_ROD set to the length you made the rods to. This is a known and hopefully accurate measurement after all.

You need to adjust DELTA_RADIUS so that the build plane is flat. The theoretical value if you build to the plans is 125mm. But as you can see my printer needs 126.77mm

Typically I think this will be larger than theoretical because the printed parts you use to make your printer will usually be slightly undersize due to shrinkage as they cool.

I suspect your problem actually lies in your Slic3r settings but you'll want this info sooner or later.

Excerpt from Repetier Firmware 0.82.2 - configuration.h

/** \brief Delta rod length */ #define DELTA_DIAGONAL_ROD 250.0 // mm /** \brief Number of segments to generate for delta conversions per second of move */ #define DELTA_SEGMENTS_PER_SECOND_PRINT 200 // Move accurate setting for print moves #define DELTA_SEGMENTS_PER_SECOND_MOVE 70 // Less accurate setting for other moves /** \brief Horizontal offset of the universal joints on the end effector (moving platform). */ //#define END_EFFECTOR_HORIZONTAL_OFFSET 33 /** \brief Horizontal offset of the universal joints on the vertical carriages. */ //#define CARRIAGE_HORIZONTAL_OFFSET 18 /** \brief Printer radius in mm, measured from the center of the print area to the vertical smooth rod. */ //#define PRINTER_RADIUS 175 /** \brief Horizontal distance bridged by the diagonal push rod when the end effector is in the center. It is pretty close to 50% of the push rod length (250 mm). */ //#define DELTA_RADIUS (PRINTER_RADIUS-END_EFFECTOR_HORIZONTAL_OFFSET-CARRIAGE_HORIZONTAL_OFFSET) #define DELTA_RADIUS 126.77

Edited 1 time(s). Last edit at 12/02/2013 04:20AM by mikep-nz.

|

Re: Delta-Pi Endstop Problem in Repeteir December 02, 2013 10:26AM |

Registered: 10 years ago Posts: 105 |

Thanks for all the info Mike. I was able to run your Gcode twice and I've posted a video of it here: [www.youtube.com]

It makes a lot of noise, but it looked like it took 5 seconds for the first move after positioning in the z-direction.

Do the Slic3r settings affect the manual Gcode inputs? If so how do you modify the slic3r settings for that? I see how to modify settings for slicing the actual print. What are the optimum Slic3r settings for your printer?

Thanks again,

Tyler

It makes a lot of noise, but it looked like it took 5 seconds for the first move after positioning in the z-direction.

Do the Slic3r settings affect the manual Gcode inputs? If so how do you modify the slic3r settings for that? I see how to modify settings for slicing the actual print. What are the optimum Slic3r settings for your printer?

Thanks again,

Tyler

|

Re: Delta-Pi Endstop Problem in Repeteir December 02, 2013 03:41PM |

Registered: 11 years ago Posts: 66 |

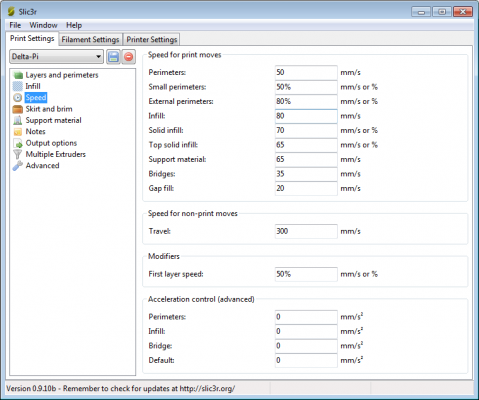

Here's a screen shot of my Slic3r speeds tab. The speeds are the same as I use on my Prusa-Mendel

So I'm doing perimeters at 50mm/s and infill at 80mm/s

But then the outermost (external) perimeter is set to 80% = 40mm/s

And the first layer speed is set to 50% so for the first layer the perimeters will be done at 25mm/s except for the external perimeter which will be at 20mm/s and the infill will be at 40mm/s.

These speeds are not the result of hours of experimentation so they may not be optimised. I got them from a forum post, (maybe by Nophead, not sure) and they worked quite well so I haven't messed with them.

I use the same speeds on my Prusa-Mendel It2.

So I'm doing perimeters at 50mm/s and infill at 80mm/s

But then the outermost (external) perimeter is set to 80% = 40mm/s

And the first layer speed is set to 50% so for the first layer the perimeters will be done at 25mm/s except for the external perimeter which will be at 20mm/s and the infill will be at 40mm/s.

These speeds are not the result of hours of experimentation so they may not be optimised. I got them from a forum post, (maybe by Nophead, not sure) and they worked quite well so I haven't messed with them.

I use the same speeds on my Prusa-Mendel It2.

|

Re: Delta-Pi Endstop Problem in Repeteir December 03, 2013 12:28AM |

Registered: 10 years ago Posts: 105 |

I've updated my firmware to match yours and I've matched my Slic3r settings to yours. I also slowed down the first layer speed from 200% to 50%. I still think I'm having problems though. It seems to start out all right with the first layer, but then after that it goes to making occasionally loud clicking noises. I think it's the motor(s) skipping? Or are the carriages catching somewhere? Here's an updated dry run with the current settings: [www.youtube.com]

You can hear the clicking noises and you can also hear the loud motors in general. I'm also stuck with the E0 extruder. I can't get it to go and I think I may have the wrong pins configuration, but I don't know how to go about determining the correct ones. Here's my current pins.h:

#define E0_STEP_PIN 11

#define E0_DIR_PIN 12

#define E0_ENABLE_PIN -1

You can hear the clicking noises and you can also hear the loud motors in general. I'm also stuck with the E0 extruder. I can't get it to go and I think I may have the wrong pins configuration, but I don't know how to go about determining the correct ones. Here's my current pins.h:

#define E0_STEP_PIN 11

#define E0_DIR_PIN 12

#define E0_ENABLE_PIN -1

|

Re: Delta-Pi Endstop Problem in Repeteir December 03, 2013 03:08AM |

Registered: 11 years ago Posts: 66 |

You shouldn't need to mess with the PINS settings. RAMPS1.4 is covered by #define MOTHERBOARD 33

If you use this then in pins.h it is already configured as this:

Here's a couple of other settings I think I may have changed from default.(can't remember for sure)

As for the clicking noise, It could be very high speed short moves and a small amount of play in one of the linkages.

Also, check you have got the carriages preloaded sufficiently. You should be able to press your finger on one of the top bearings and when you move the carriage the bearing should roll on the tube and slip against your finger, not slip on the tube.

Did you see the flickr stream? I have a few pictures there of the current state. I added bracing panels to two of the back corners. These stiffened the whole assembly up and make if far more robust. I was always worried about the tube mounts breaking till I added the braces.

I also added a small coin under the end of the carriage preload bolt to stop it digging in to the plastic. See the flickr stream for photos.

If you use this then in pins.h it is already configured as this:

#define E0_STEP_PIN 26 #define E0_DIR_PIN 28 #define E0_ENABLE_PIN 24

Here's a couple of other settings I think I may have changed from default.(can't remember for sure)

#define ENDSTOP_X_RETEST_REDUCTION_FACTOR 8 #define ENDSTOP_Y_RETEST_REDUCTION_FACTOR 8 #define ENDSTOP_Z_RETEST_REDUCTION_FACTOR 8 #define X_MAX_LENGTH 200 #define Y_MAX_LENGTH 200 #define Z_MAX_LENGTH 344 #define X_MIN_POS -100 #define Y_MIN_POS -100 #define Z_MIN_POS 0 #define MAX_FEEDRATE_X 300 #define MAX_FEEDRATE_Y 300 #define MAX_FEEDRATE_Z 300 #define HOMING_FEEDRATE_X 40 #define HOMING_FEEDRATE_Y 40 #define HOMING_FEEDRATE_Z 40 #define STEP_DOUBLER_FREQUENCY 10000 #define ALLOW_QUADSTEPPING true #define MAX_ACCELERATION_UNITS_PER_SQ_SECOND_X 1500 #define MAX_ACCELERATION_UNITS_PER_SQ_SECOND_Y 1500 #define MAX_ACCELERATION_UNITS_PER_SQ_SECOND_Z 1500 #define MAX_TRAVEL_ACCELERATION_UNITS_PER_SQ_SECOND_X 3000 #define MAX_TRAVEL_ACCELERATION_UNITS_PER_SQ_SECOND_Y 3000 #define MAX_TRAVEL_ACCELERATION_UNITS_PER_SQ_SECOND_Z 3000

As for the clicking noise, It could be very high speed short moves and a small amount of play in one of the linkages.

Also, check you have got the carriages preloaded sufficiently. You should be able to press your finger on one of the top bearings and when you move the carriage the bearing should roll on the tube and slip against your finger, not slip on the tube.

Did you see the flickr stream? I have a few pictures there of the current state. I added bracing panels to two of the back corners. These stiffened the whole assembly up and make if far more robust. I was always worried about the tube mounts breaking till I added the braces.

I also added a small coin under the end of the carriage preload bolt to stop it digging in to the plastic. See the flickr stream for photos.

|

Re: Delta-Pi Endstop Problem in Repeteir December 03, 2013 11:11AM |

Registered: 10 years ago Posts: 105 |

I will work on getting the carriages preloaded. I must have something weird going on in my configuration/pins because I have motherboard 33 defined in configuration.h, but the only way I could get my endstops to work was by modifying the first set of pins under where it says:

#if MOTHERBOARD == 0

#define KNOWN_BOARD 1

#ifndef __AVR_ATmega168__

#error Oops! Make sure you have 'Arduino Diecimila' selected from the boards menu.

#endif

Is there another place where I'm missing to define motherboard 33?

#if MOTHERBOARD == 0

#define KNOWN_BOARD 1

#ifndef __AVR_ATmega168__

#error Oops! Make sure you have 'Arduino Diecimila' selected from the boards menu.

#endif

Is there another place where I'm missing to define motherboard 33?

|

Re: Delta-Pi Endstop Problem in Repeteir December 03, 2013 02:19PM |

Registered: 11 years ago Posts: 66 |

|

Re: Delta-Pi Endstop Problem in Repeteir December 05, 2013 10:30AM |

Registered: 10 years ago Posts: 105 |

I figured out how to get the extruder working. I'm still having problems with noisy motors though. I have the 57 oz-in ones, should I upgrade to higher torque motors? Just seems like the motors are whining and not happy when moving. I've tried preloading the bearings as best as I can. I will try messing with the trimpots again. How much torque do your motors have? Do you remember doing anything to reduce motor noise? Also did you notice a difference between using Marlin vs Repeteir?

Thanks

Thanks

|

Re: Delta-Pi Endstop Problem in Repeteir December 05, 2013 10:11PM |

Registered: 11 years ago Posts: 66 |

Stepper motors are noisy. The step frequency is normally right across the audible range.

Having said that if you feel your printer is too noisy you can try these things:

Put some squares of carpet or foam between your printer and the table it's sitting on. It's amazing how effective this can be. The table top can act like a speaker, amplifying the vibrations from the printer.

Reduce the stepper drive current. Ideally you want the stepper drive current just high enough to prevent the motors from slipping. Higher step currents than this only make more noise and more heat in the stepper motors.

I don't think you want a higher current or bigger motors.

Plug the ends of the stainless tubes. Maybe with some dense foam. anything that can make a reasonably air tight seal. I haven't tried this myself yet but it is possible that the walls of the tube are transmitting the vibrations.

Cheers,

MikeP

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

Having said that if you feel your printer is too noisy you can try these things:

Put some squares of carpet or foam between your printer and the table it's sitting on. It's amazing how effective this can be. The table top can act like a speaker, amplifying the vibrations from the printer.

Reduce the stepper drive current. Ideally you want the stepper drive current just high enough to prevent the motors from slipping. Higher step currents than this only make more noise and more heat in the stepper motors.

I don't think you want a higher current or bigger motors.

Plug the ends of the stainless tubes. Maybe with some dense foam. anything that can make a reasonably air tight seal. I haven't tried this myself yet but it is possible that the walls of the tube are transmitting the vibrations.

Cheers,

MikeP

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

|

Re: Delta-Pi Endstop Problem in Repeteir December 10, 2013 01:06AM |

Registered: 10 years ago Posts: 105 |

Mike,

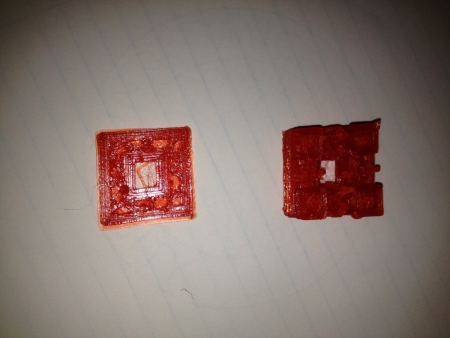

I've been able to do some test printing but am having problems with getting the bed level and also getting the Delta_Print_Radius just right. I'm also having problems with getting my bowden wade's extruder to have a consistent output. It seems like it's pulling the PLA into a very thin, stringy line, as oppossed to constant thickness. What routine do you use to get your bed fully leveled as well as calibrating your extruder? I've attached a pic of a first layer test print of a hollow cube:

I've been able to do some test printing but am having problems with getting the bed level and also getting the Delta_Print_Radius just right. I'm also having problems with getting my bowden wade's extruder to have a consistent output. It seems like it's pulling the PLA into a very thin, stringy line, as oppossed to constant thickness. What routine do you use to get your bed fully leveled as well as calibrating your extruder? I've attached a pic of a first layer test print of a hollow cube:

|

Re: Delta-Pi Endstop Problem in Repeteir December 10, 2013 04:27AM |

Registered: 11 years ago Posts: 66 |

Calibration of Delta-Pi is no different to any other delta printer. There are several good posts already on how to do the calibration so I will just give you a quick version here.

It will take you at least an hour to do it properly. Maybe longer the first time.

There are 5 stages you need to go through in order.

You adjust the tower end stops by driving the printer to positions in front of each tower and adjusting the end stops until all 3 positions are the same height. From memory X0 Y-90, X45 Y78 and X-45 Y78 are about as close as you can get with Marlin firmware due to internal limit checking.

These positions are for Delta-Pi which has 1 tower in front and 2 towers at the back. Normal Rostock is the other way round.

You need to do a home after each adjustment and recheck the height.

Once this stage is complete your build plane is parallel with your build surface.

After adjusting the end stops you need to readjust the Z_MAX_LENGTH (with the head at X0 Y0)

The next stage is to adjust PRINTER_RADIUS so that the height in the centre (X0 Y0) matches the height in front of the 3 towers. Only adjust PRINTER_RADIUS. You should leave DELTA_DIAGONAL_ROD set to the length you made the delta arms. After all you did make them accurately and you know their length.

Increasing PRINTER_RADIUS will lower the head in front of the towers. It will not affect the height at the X0 Y0.

With the 3 tower positions and the center now all at the same height the build plane should be flat and the print head should be just touching the surface at each position at Z0.

Just the extruder feed rate to calibrate and you're done.

I have been working on adding the bed leveling to Delta-Pi and I have a working probe and firmware. I am in the process of replacing the hot end that has given me so much trouble and when that is complete I'll publish details.

The bed leveling is a MAJOR advance for the delta designs because it practically eliminates the need for the above calibration process.

Edited 1 time(s). Last edit at 12/10/2013 04:43AM by mikep-nz.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

It will take you at least an hour to do it properly. Maybe longer the first time.

There are 5 stages you need to go through in order.

- Adjust Z_MAX_LENGTH

- Adjusting the tower end stops

- Readjust Z_MAX_LENGTH

- Adjusting the delta_radius

- Calibrating your extruder steps per mm

You adjust the tower end stops by driving the printer to positions in front of each tower and adjusting the end stops until all 3 positions are the same height. From memory X0 Y-90, X45 Y78 and X-45 Y78 are about as close as you can get with Marlin firmware due to internal limit checking.

These positions are for Delta-Pi which has 1 tower in front and 2 towers at the back. Normal Rostock is the other way round.

You need to do a home after each adjustment and recheck the height.

Once this stage is complete your build plane is parallel with your build surface.

After adjusting the end stops you need to readjust the Z_MAX_LENGTH (with the head at X0 Y0)

The next stage is to adjust PRINTER_RADIUS so that the height in the centre (X0 Y0) matches the height in front of the 3 towers. Only adjust PRINTER_RADIUS. You should leave DELTA_DIAGONAL_ROD set to the length you made the delta arms. After all you did make them accurately and you know their length.

Increasing PRINTER_RADIUS will lower the head in front of the towers. It will not affect the height at the X0 Y0.

With the 3 tower positions and the center now all at the same height the build plane should be flat and the print head should be just touching the surface at each position at Z0.

Just the extruder feed rate to calibrate and you're done.

I have been working on adding the bed leveling to Delta-Pi and I have a working probe and firmware. I am in the process of replacing the hot end that has given me so much trouble and when that is complete I'll publish details.

The bed leveling is a MAJOR advance for the delta designs because it practically eliminates the need for the above calibration process.

Edited 1 time(s). Last edit at 12/10/2013 04:43AM by mikep-nz.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

|

Re: Delta-Pi Endstop Problem in Repeteir December 17, 2013 10:21AM |

Registered: 10 years ago Posts: 105 |

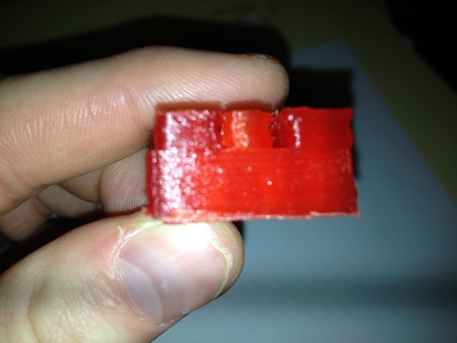

I had my first semi-successful print. Still struggling with the clicking/stepper skipping noise, but I'm ignoring it for the moment. I printed halfway through a hollow calibration cube. I noticed when I pulled it off it was more of a parraellogram shape. Also, two oppossing corners next to the holes were printed offset. Is this due to my towers being off, or I need to level the bed better? I also noticed the motors were having a hard time printing a straight line on a small print, such as one of the clevis arms. Thanks again for helping get on track. Here are the pics:

Edited 2 time(s). Last edit at 12/17/2013 10:58AM by runninfarmer.

Edited 2 time(s). Last edit at 12/17/2013 10:58AM by runninfarmer.

|

Re: Delta-Pi Endstop Problem in Repeteir December 17, 2013 02:10PM |

Registered: 11 years ago Posts: 66 |

Congratulations on the milestone. I don't know why the print would be distorted like that but having a tower out of position would be my first guess too.

It would pay to recheck the tower positions.

As a verify check you can measure between any convenient point on one tower and a point on the next tower (not necessarily the same point). Make the same measurement on the 3 towers and the distances should be the same.

That will tell you if there's something out of position.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

It would pay to recheck the tower positions.

As a verify check you can measure between any convenient point on one tower and a point on the next tower (not necessarily the same point). Make the same measurement on the 3 towers and the distances should be the same.

That will tell you if there's something out of position.

+++++++++++++++++++++++++++++++++++++++++++++

[www.makershop.co.nz]

Makershop - Reprap parts, adding new stock almost daily.

+++++++++++++++++++++++++++++++++++++++++++++

Sorry, only registered users may post in this forum.