New Own Design Printer 'Cherry Pi'

Posted by AndyCart

|

New Own Design Printer 'Cherry Pi' December 04, 2013 06:07PM |

Registered: 10 years ago Posts: 515 |

Hi Guys

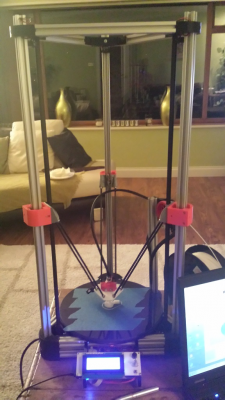

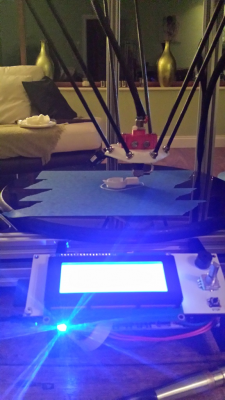

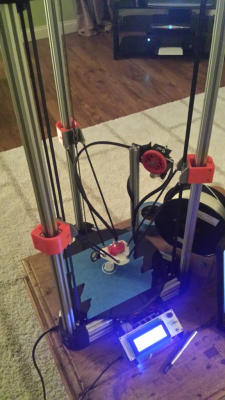

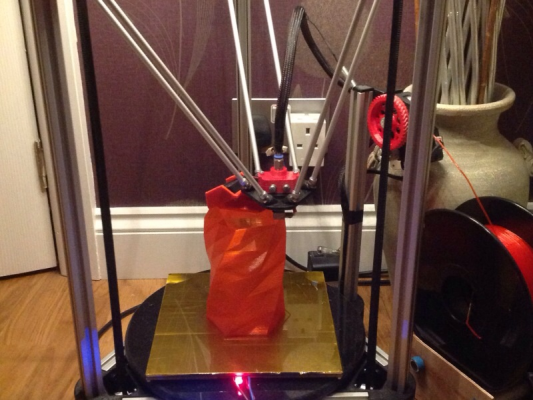

I thought you might be interested in my new printer design. It's a delta based on Rostock, 3DR, Delta Pi and a host of others, hence the name. I've 'cherry picked' everyone elses good ideas!

It's printing it's first print as we speak. It took me about a month to draw the design up in Sketchup and about another month to get the bits together, print the parts and build it.

Obviously I'm still in the commissioning stage but so far I love it.

Andy

Edited 1 time(s). Last edit at 12/05/2013 10:41AM by AndyCart.

|

Re: New Own Design Printer 'Cherry Pi' December 05, 2013 09:47AM |

Registered: 10 years ago Posts: 145 |

|

Re: New Own Design Printer 'Cherry Pi' December 05, 2013 10:41AM |

Registered: 10 years ago Posts: 515 |

|

Re: New Own Design Printer 'Cherry Pi' December 21, 2013 06:04PM |

Registered: 12 years ago Posts: 82 |

|

Re: New Own Design Printer 'Cherry Pi' December 21, 2013 06:25PM |

Registered: 10 years ago Posts: 515 |

Hi Rick

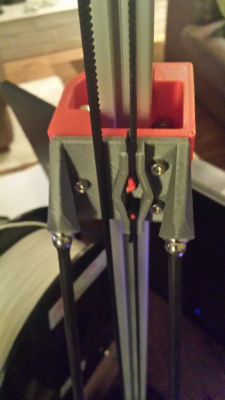

Yes, I'll post them tomorrow along with my other .stl files. I saw in your thread that you have your framing components sorted. You may want to look at my .stl files for the bearing holder that slides up and down the extrusion, they use 6 623 bearings each and have nut traps for all the M3 screws required. I also have a separate .stl for the diagonal rod carrier that bolts to the bearing housing. It's set up for magnetic connection. The rods are at 43mm centres. I will also post the Sketchup files on Thingiverse. If you use my rod carriers then my effector plate may be useful. It's designed to carry Richrap's Jhead mount from the 3DR. The only other file you may want is my microswitch endstop mount. It uses an M3 screw to lock it in place in a slot in the extrusion and ensure the button on the switch lines up with the top face of the bearing housing. The rod carriers also have a neat way to attach your GT2 belt that I pinched off another design, Delta Pi I think. If you need any detail photos of my build just let me know.

Andy

Yes, I'll post them tomorrow along with my other .stl files. I saw in your thread that you have your framing components sorted. You may want to look at my .stl files for the bearing holder that slides up and down the extrusion, they use 6 623 bearings each and have nut traps for all the M3 screws required. I also have a separate .stl for the diagonal rod carrier that bolts to the bearing housing. It's set up for magnetic connection. The rods are at 43mm centres. I will also post the Sketchup files on Thingiverse. If you use my rod carriers then my effector plate may be useful. It's designed to carry Richrap's Jhead mount from the 3DR. The only other file you may want is my microswitch endstop mount. It uses an M3 screw to lock it in place in a slot in the extrusion and ensure the button on the switch lines up with the top face of the bearing housing. The rod carriers also have a neat way to attach your GT2 belt that I pinched off another design, Delta Pi I think. If you need any detail photos of my build just let me know.

Andy

|

Re: New Own Design Printer 'Cherry Pi' December 22, 2013 02:22AM |

Registered: 10 years ago Posts: 515 |

Files now on Thingiverse :- [www.thingiverse.com]

Sketchup Files on my Github :- [github.com]

Andy

Edited 1 time(s). Last edit at 12/22/2013 04:40AM by AndyCart.

Sketchup Files on my Github :- [github.com]

Andy

Edited 1 time(s). Last edit at 12/22/2013 04:40AM by AndyCart.

|

Re: New Own Design Printer 'Cherry Pi' December 23, 2013 05:13AM |

Registered: 10 years ago Posts: 153 |

Quote

mikep-nz

The problem with using Aluminium tube as a bearing surface is that the soft aluminium surface is so easily damaged by dust and dirt and once it gets damaged it quickly deteriorates to the point of being useless.

The usual solution is to use rollers made of something even softer than the aluminium eg. delrin. But I preferred to stick with a hard steel surface and the polished stainless tube is cheap and readily available.

Are your extrusions are holding up pretty well?

I had the idea to put electrical heatshrink around the bearings. I found one case were a person tried it, they said the issue was that the shrink moved around on the bearing as his shrink wasn't wider than the bearing so the plastic didn't go around the edges of the bearings and didn't holding them in place.

|

Re: New Own Design Printer 'Cherry Pi' December 23, 2013 06:05AM |

Registered: 12 years ago Posts: 82 |

I know size wise this is probably useless, but how about something like this to wrap around the outside of the bearing: [www.ebay.com]

It's basically just a rubber casing, presumably to fit right on top of a standard metal bearing. If the correct size could be found, surely that'd work pretty well against the metal surface and should not only prevent wear, but also reduce sound. This is of course if we can figure out the size needed.

It's basically just a rubber casing, presumably to fit right on top of a standard metal bearing. If the correct size could be found, surely that'd work pretty well against the metal surface and should not only prevent wear, but also reduce sound. This is of course if we can figure out the size needed.

|

Re: New Own Design Printer 'Cherry Pi' December 23, 2013 03:16PM |

Registered: 10 years ago Posts: 1,381 |

Not related, idea:

You could use two of the rubber bearing covers with a Dia 22 mm, 608 bearing to create a self aligning system, and/or absorb vibration.

A means to hold the bearing within the bearing cover is needed, a flat head screw off to one side would work.

Repair Component Rubber Bearing Cover for Bosch GWS20-180 Angle Grinder

Product Name Bearing Cover

Fit Bosch GWS20-180 Angle Grinder

Inner Diameter 22mm/ 0.87"

Outer Diameter 25mm/ 0.98"

Hight 10mm/ 0.39"

Material Rubber

You could use two of the rubber bearing covers with a Dia 22 mm, 608 bearing to create a self aligning system, and/or absorb vibration.

A means to hold the bearing within the bearing cover is needed, a flat head screw off to one side would work.

Repair Component Rubber Bearing Cover for Bosch GWS20-180 Angle Grinder

Product Name Bearing Cover

Fit Bosch GWS20-180 Angle Grinder

Inner Diameter 22mm/ 0.87"

Outer Diameter 25mm/ 0.98"

Hight 10mm/ 0.39"

Material Rubber

|

Re: New Own Design Printer 'Cherry Pi' December 23, 2013 06:17PM |

Registered: 10 years ago Posts: 515 |

Hi guys. The bearing on extrusion noise is actually fairly minimal. I've put about 1.5 kgs of filament through the printer and there is no sign of wear. The majority of the noise is from the belts, the motors a close second. Overall the printer sits between the 3DR I built (filament drive, very quiet) and my Huxley which is very noisy, I can't run prints overnight on the Huxley as it's heard through the house. The Cherry Pi is fine. You could run the 3DR in the room you sleep in though ! If you look at the amount of up and down movement on the towers during a print it's actually quite small. I am running at about 80mm/sec overall with 250mm/sec travel moves. I'm sure it will run faster. It is very accurate. I have had some stunning results using spiral vase. A full size (300mm tall) twisted vase came out with out a blemish, it's difficult to tell it was 3D printed and that was with cheapo Chinese filament.

Andy

Andy

|

Re: New Own Design Printer 'Cherry Pi' December 24, 2013 06:16PM |

Registered: 10 years ago Posts: 153 |

|

Re: New Own Design Printer 'Cherry Pi' December 24, 2013 08:11PM |

Registered: 10 years ago Posts: 515 |

|

Re: New Own Design Printer 'Cherry Pi' December 25, 2013 05:52AM |

Registered: 10 years ago Posts: 153 |

|

Re: New Own Design Printer 'Cherry Pi' January 03, 2014 08:09AM |

Registered: 10 years ago Posts: 515 |

I've updated my design a little around the delta rods and magnets. The original design was o.k but I felt a stronger attachment method would be better. I am now using 10mm spherical magnets and M5 socket head cap screws. I have milled the heads of the cap screws with a 10mm ball end mill in my pillar drill. I am using 6mm aluminium tube for the rods. I found that if i drilled the inner of the tube with a 5mm drill then the M5 cap screws naturally self threaded for a secure, adjustable fit. The magnets were secured with viscous CA adhesive into the cups on the new effector plate. Pictures and new .stl are on the Thingiverse page.

Andy

Andy

|

Re: New Own Design Printer 'Cherry Pi' January 05, 2014 12:22AM |

Registered: 10 years ago Posts: 105 |

Andy,

I like your design and am thinking about adapting some aspects of it to my Delta-Pi that I've constructed. One question I have is what is the best way to achieve equal length for your aluminum arms with screws? Did you use a tube cutter/jig to somehow get equal lengths?

Edited 1 time(s). Last edit at 01/05/2014 12:22AM by runninfarmer.

I like your design and am thinking about adapting some aspects of it to my Delta-Pi that I've constructed. One question I have is what is the best way to achieve equal length for your aluminum arms with screws? Did you use a tube cutter/jig to somehow get equal lengths?

Edited 1 time(s). Last edit at 01/05/2014 12:22AM by runninfarmer.

|

Re: New Own Design Printer 'Cherry Pi' January 05, 2014 06:20PM |

Registered: 10 years ago Posts: 515 |

Hi runninfarmer

I'm lucky enough to have a fully equipped workshop, my other hobby is building aeroplanes, I used my chop saw to cut the 6mm tube, and the aluminium extrusion actually, after first clamping an end stop to the saw bed at 250mm from the edge of the blade. It was then simply a matter of putting the tube end on the endstop and using the saw. All my rods came out within .1mm. I got them all exactly to the same length by turning the cap screw magnet cups as required and then fixing the threads with CA.

Andy

I'm lucky enough to have a fully equipped workshop, my other hobby is building aeroplanes, I used my chop saw to cut the 6mm tube, and the aluminium extrusion actually, after first clamping an end stop to the saw bed at 250mm from the edge of the blade. It was then simply a matter of putting the tube end on the endstop and using the saw. All my rods came out within .1mm. I got them all exactly to the same length by turning the cap screw magnet cups as required and then fixing the threads with CA.

Andy

|

Re: New Own Design Printer 'Cherry Pi' January 12, 2014 11:35AM |

Registered: 10 years ago Posts: 903 |

Quote

TheTechnicalNoob

I had the idea to put electrical heatshrink around the bearings. I found one case were a person tried it, they said the issue was that the shrink moved around on the bearing as his shrink wasn't wider than the bearing so the plastic didn't go around the edges of the bearings and didn't holding them in place.

I have a dumb question for my first post on this forum. Instead of trying to wrap the bearing surface, how about applying a strip of PVC electrical tape to the extrusion surfaces that the bearings roll on? If it is durable enough, it could address the extrusion wear and possibly the metal-on-metal noise issue as well.....

|

Re: New Own Design Printer 'Cherry Pi' January 12, 2014 12:15PM |

Registered: 10 years ago Posts: 903 |

Andy,

Since you cherry picked several good ideas from other designs, I'm curious about your opinion on the spherical ball setup used on the SpiderBot effector plate. Instead of 6 spherical magnets, they used only three spherical steel balls, with rods from two neighboring risers both sharing a ball at the effector end. They embedded cylindrical magnets into the rods themselves, and it appears that the (tapered) rod end caps are printed cups. Assuming that the two rod ends never collide on the same ball at any point in the effector's possible motion range, the only pitfall that I can see would be if the magnets in the two rods somehow tried to stick to each other, or possibly their fields interacted to weaken their combined grip. Based on your experiences so far with the different magnets that you've tried, do you think that this is a viable option to decrease the parts count...especially for folks who want to have a collection of different quick-swap hot ends?????

Since you cherry picked several good ideas from other designs, I'm curious about your opinion on the spherical ball setup used on the SpiderBot effector plate. Instead of 6 spherical magnets, they used only three spherical steel balls, with rods from two neighboring risers both sharing a ball at the effector end. They embedded cylindrical magnets into the rods themselves, and it appears that the (tapered) rod end caps are printed cups. Assuming that the two rod ends never collide on the same ball at any point in the effector's possible motion range, the only pitfall that I can see would be if the magnets in the two rods somehow tried to stick to each other, or possibly their fields interacted to weaken their combined grip. Based on your experiences so far with the different magnets that you've tried, do you think that this is a viable option to decrease the parts count...especially for folks who want to have a collection of different quick-swap hot ends?????

|

Re: New Own Design Printer 'Cherry Pi' January 12, 2014 05:30PM |

Registered: 10 years ago Posts: 515 |

Hi vreihen

I toyed with the spider bot design but gave it up in favour of the one I finally went with. I got my 10mm spherical magnets very cheap from firstformagnets.com in the UK.

I am very happy with my current setup. I have made a couple of alternate effectors as I am experimenting with my own design hot ends. All my hotend wiring is via plug and socket and as six ball magnets are so cheap it wasn't an issue. I have squeezed about 1kg of pla through my current design with never a problem of the rods coming unstuck. Unlike my countersunk magnet a steel ball initial designs.

That said the spider bot design looks very cool..

As to noise levels it's really not that bad and after a couple of kgs of pla printed there is no sign of wear.

Andy

Edited 1 time(s). Last edit at 01/12/2014 05:32PM by AndyCart.

I toyed with the spider bot design but gave it up in favour of the one I finally went with. I got my 10mm spherical magnets very cheap from firstformagnets.com in the UK.

I am very happy with my current setup. I have made a couple of alternate effectors as I am experimenting with my own design hot ends. All my hotend wiring is via plug and socket and as six ball magnets are so cheap it wasn't an issue. I have squeezed about 1kg of pla through my current design with never a problem of the rods coming unstuck. Unlike my countersunk magnet a steel ball initial designs.

That said the spider bot design looks very cool..

As to noise levels it's really not that bad and after a couple of kgs of pla printed there is no sign of wear.

Andy

Edited 1 time(s). Last edit at 01/12/2014 05:32PM by AndyCart.

|

Re: New Own Design Printer 'Cherry Pi' January 15, 2014 05:34PM |

Registered: 10 years ago Posts: 515 |

|

Re: New Own Design Printer 'Cherry Pi' January 16, 2014 04:34AM |

Registered: 10 years ago Posts: 732 |

|

Re: New Own Design Printer 'Cherry Pi' January 16, 2014 06:18PM |

Registered: 10 years ago Posts: 515 |

Hi Hercek

I've done a couple of prints of the same object (tree frog) with and without the fan. It's definitely better with. The previous effector had three 25mm fans just angled towards the nozzle. No duct. They worked well too but reduced my printable radius. I actually think the single 40mm fan moves more air than the 3 x 25mm fans did. You can definitely feel cool air blowing from the duct on the back of your hand. All in all I like it.

Andy

I've done a couple of prints of the same object (tree frog) with and without the fan. It's definitely better with. The previous effector had three 25mm fans just angled towards the nozzle. No duct. They worked well too but reduced my printable radius. I actually think the single 40mm fan moves more air than the 3 x 25mm fans did. You can definitely feel cool air blowing from the duct on the back of your hand. All in all I like it.

Andy

|

Re: New Own Design Printer 'Cherry Pi' February 03, 2014 09:26AM |

Registered: 10 years ago Posts: 11 |

Hey Andy,

Could supply me with the delta dimensions you used in your configuration.h? (even better if you could post your configuration.h so i can have a look!)

• Center-to-center distance of the holes in the diagonal push rods. (i appreciate that my rods will differ slightly here)

• Horizontal offset from middle of printer to smooth rod center.

• Horizontal offset of the universal joints on the end effector.

• Horizontal offset of the universal joints on the carriages.

I believe these are the only cherry pi specific dimensions needed for the firmware?

I've collected most of the hardware and i'm waiting on some of the printed parts. While i'm waiting i'm planning of getting my firmware set up to a basic level.

Many thanks,

Charlie

Could supply me with the delta dimensions you used in your configuration.h? (even better if you could post your configuration.h so i can have a look!)

• Center-to-center distance of the holes in the diagonal push rods. (i appreciate that my rods will differ slightly here)

• Horizontal offset from middle of printer to smooth rod center.

• Horizontal offset of the universal joints on the end effector.

• Horizontal offset of the universal joints on the carriages.

I believe these are the only cherry pi specific dimensions needed for the firmware?

I've collected most of the hardware and i'm waiting on some of the printed parts. While i'm waiting i'm planning of getting my firmware set up to a basic level.

Many thanks,

Charlie

|

Re: New Own Design Printer 'Cherry Pi' February 04, 2014 06:30PM |

Registered: 10 years ago Posts: 515 |

Hi Charlie here you go :-

#ifndef CONFIGURATION_H

#define CONFIGURATION_H

// This configuration file contains the basic settings.

// Advanced settings can be found in Configuration_adv.h

// BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration

// User-specified version info of this build to display in [Pronterface, etc] terminal window during

// startup. Implementation of an idea by Prof Braino to inform user that any changes made to this

// build by the user have been successfully uploaded into firmware.

#define STRING_VERSION_CONFIG_H __DATE__ " " __TIME__ // build date and time

#define STRING_CONFIG_H_AUTHOR "(Andy, Erik Zalm M666)" // Who made the changes.

// SERIAL_PORT selects which serial port should be used for communication with the host.

// This allows the connection of wireless adapters (for instance) to non-default port pins.

// Serial port 0 is still used by the Arduino bootloader regardless of this setting.

#define SERIAL_PORT 0

// This determines the communication speed of the printer

#define BAUDRATE 250000

//#define BAUDRATE 115200

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// 10 = Gen7 custom (Alfons3 Version) "https://github.com/Alfons3/Generation_7_Electronics"

// 11 = Gen7 v1.1, v1.2 = 11

// 12 = Gen7 v1.3

// 13 = Gen7 v1.4

// 3 = MEGA/RAMPS up to 1.2 = 3

// 33 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Bed)

// 34 = RAMPS 1.3 / 1.4 (Power outputs: Extruder0, Extruder1, Bed)

// 35 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Fan)

// 4 = Duemilanove w/ ATMega328P pin assignment

// 5 = Gen6

// 51 = Gen6 deluxe

// 6 = Sanguinololu < 1.2

// 62 = Sanguinololu 1.2 and above

// 63 = Melzi

// 64 = STB V1.1

// 65 = Azteeg X1

// 66 = Melzi with ATmega1284 (MaKr3d version)

// 7 = Ultimaker

// 71 = Ultimaker (Older electronics. Pre 1.5.4. This is rare)

// 77 = 3Drag Controller

// 8 = Teensylu

// 80 = Rumba

// 81 = Printrboard (AT90USB1286)

// 82 = Brainwave (AT90USB646)

// 9 = Gen3+

// 70 = Megatronics

// 701= Megatronics v2.0

// 702= Minitronics v1.0

// 90 = Alpha OMCA board

// 91 = Final OMCA board

// 301 = Rambo

// 21 = Elefu Ra Board (v3)

#ifndef MOTHERBOARD

#define MOTHERBOARD 80

#endif

// Define this to set a custom name for your generic Mendel,

// #define CUSTOM_MENDEL_NAME "This Mendel"

// This defines the number of extruders

#define EXTRUDERS 1

//// The following define selects which power supply you have. Please choose the one that matches your setup

// 1 = ATX

// 2 = X-Box 360 203Watts (the blue wire connected to PS_ON and the red wire to VCC)

#define POWER_SUPPLY 1

//===========================================================================

//============================== Delta Settings =============================

//===========================================================================

// Enable DELTA kinematics and most of the default configuration for Deltas

#define DELTA

// Make delta curves from many straight lines (linear interpolation).

// This is a trade-off between visible corners (not enough segments)

// and processor overload (too many expensive sqrt calls).

#define DELTA_SEGMENTS_PER_SECOND 200

// NOTE NB all values for DELTA_* values MOUST be floating point, so always have a decimal point in them

// Center-to-center distance of the holes in the diagonal push rods.

#define DELTA_DIAGONAL_ROD 270.9876 // mm

// Horizontal offset from middle of printer to smooth rod center.

#define DELTA_SMOOTH_ROD_OFFSET 202.25// mm

// If your print head is too high or low in the middle of the print surface, adjust DELTA_SMOOTH_ROD_OFFSET by half mm and try again.

// Horizontal offset of the universal joints on the end effector.

#define DELTA_EFFECTOR_OFFSET 37.0 // mm

// Horizontal offset of the universal joints on the carriages.

#define DELTA_CARRIAGE_OFFSET 40.0 // mm

// Effective horizontal distance bridged by diagonal push rods.

#define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET)

#define DELTA_DIAGONAL_ROD_2 sq(DELTA_DIAGONAL_ROD)

// Effective X/Y positions of the three vertical towers.

#define SIN_60 0.8660254037844386

#define COS_60 0.5

#define DELTA_TOWER1_X -SIN_60*DELTA_RADIUS // front left tower

#define DELTA_TOWER1_Y -COS_60*DELTA_RADIUS

#define DELTA_TOWER2_X SIN_60*DELTA_RADIUS // front right tower

#define DELTA_TOWER2_Y -COS_60*DELTA_RADIUS

#define DELTA_TOWER3_X 0.0 // back middle tower

#define DELTA_TOWER3_Y DELTA_RADIUS

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

// 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup)

// 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup)

// 10 is 100k RS thermistor 198-961 (4.7k pullup)

// 60 is 100k Maker's Tool Works Kapton Bed Thermister

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup)

#define TEMP_SENSOR_0 5

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1

// This makes temp sensor 1 a redundant sensor for sensor 0. If the temperatures difference between these sensors is to high the print will be aborted.

//#define TEMP_SENSOR_1_AS_REDUNDANT

#define MAX_REDUNDANT_TEMP_SENSOR_DIFF 10

// Actual temperature must be close to target for this long before M109 returns success

#define TEMP_RESIDENCY_TIME 10 // (seconds)

#define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one

#define TEMP_WINDOW 1 // (degC) Window around target to start the residency timer x degC early.

// The minimal temperature defines the temperature below which the heater will not be enabled It is used

// to check that the wiring to the thermistor is not broken.

// Otherwise this would lead to the heater being powered on all the time.

#define HEATER_0_MINTEMP 5

#define HEATER_1_MINTEMP 5

#define HEATER_2_MINTEMP 5

#define BED_MINTEMP 5

// When temperature exceeds max temp, your heater will be switched off.

// This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure!

// You should use MINTEMP for thermistor short/failure protection.

#define HEATER_0_MAXTEMP 350

#define HEATER_1_MAXTEMP 255

#define HEATER_2_MAXTEMP 255

#define BED_MAXTEMP 120

// If your bed has low resistance e.g. .6 ohm and throws the fuse you can duty cycle it to reduce the

// average current. The value should be an integer and the heat bed will be turned on for 1 interval of

// HEATER_BED_DUTY_CYCLE_DIVIDER intervals.

//#define HEATER_BED_DUTY_CYCLE_DIVIDER 4

// PID settings:

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define BANG_MAX 255 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX 255 // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

//#define PID_DEBUG // Sends debug data to the serial port.

//#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX

#define PID_FUNCTIONAL_RANGE 10 // If the temperature difference between the target temperature and the actual temperature

// is more then PID_FUNCTIONAL_RANGE then the PID will be shut off and the heater will be set to min/max.

#define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term

#define K1 0.95 //smoothing factor within the PID

#define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the temperature routine

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

// #define DEFAULT_Kp 22.2

// #define DEFAULT_Ki 1.08

// #define DEFAULT_Kd 114

// Makergear

// #define DEFAULT_Kp 7.0

// #define DEFAULT_Ki 0.1

// #define DEFAULT_Kd 12

// Mendel Parts V9 on 12V

// #define DEFAULT_Kp 63.0

// #define DEFAULT_Ki 2.25

// #define DEFAULT_Kd 440

//V2 of 3DR - Using Official J-head with1.75mm insert from UK clone supplier

// bias: 41 d: 41 min: 147.71 max: 152.60

// Ku: 21.38 Tu: 31.72

// Clasic PID

// Kp: 12.83

// Ki: 0.81

// Kd: 50.87

#define DEFAULT_Kp 10.22

#define DEFAULT_Ki 0.45

#define DEFAULT_Kd 57.43

#endif // PIDTEMP

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// Uncomment this to enable PID on the bed. It uses the same frequency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you probably

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

//#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delivered to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, aggressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 10.00

#define DEFAULT_bedKi .023

#define DEFAULT_bedKd 305.4

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

//this prevents dangerous Extruder moves, i.e. if the temperature is under the limit

//can be software-disabled for whatever purposes by

#define PREVENT_DANGEROUS_EXTRUDE

//if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately.

#define PREVENT_LENGTHY_EXTRUDE

#define EXTRUDE_MINTEMP 160

#define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances.

//===========================================================================

//=============================Mechanical Settings===========================

//===========================================================================

// Uncomment the following line to enable CoreXY kinematics

// #define COREXY

// coarse Endstop Settings

#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors

#ifndef ENDSTOPPULLUPS

// fine Enstop settings: Individual Pullups. will be ignored if ENDSTOPPULLUPS is defined

// #define ENDSTOPPULLUP_XMAX

// #define ENDSTOPPULLUP_YMAX

// #define ENDSTOPPULLUP_ZMAX

// #define ENDSTOPPULLUP_XMIN

// #define ENDSTOPPULLUP_YMIN

// #define ENDSTOPPULLUP_ZMIN

#endif

#ifdef ENDSTOPPULLUPS

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Y_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool X_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Y_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Z_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

// deltas never have min endstops

#define DISABLE_MIN_ENDSTOPS

// Disable max endstops for compatibility with endstop checking routine

#if defined(COREXY) && !defined(DISABLE_MAX_ENDSTOPS)

#define DISABLE_MAX_ENDSTOPS

#endif

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z false

#define DISABLE_E false // For all extruders

#define INVERT_X_DIR false // DELTA does not invert

#define INVERT_Y_DIR false

#define INVERT_Z_DIR false

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

// deltas always home to max

#define X_HOME_DIR 1

#define Y_HOME_DIR 1

#define Z_HOME_DIR 1

#define min_software_endstops true // If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

// Travel limits after homing

#define X_MAX_POS 106

#define X_MIN_POS -106

#define Y_MAX_POS 106

#define Y_MIN_POS -106

#define Z_MAX_POS MANUAL_Z_HOME_POS

#define Z_MIN_POS 0

#define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS)

#define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS)

#define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS)

// The position of the homing switches

//#define MANUAL_HOME_POSITIONS // If defined, MANUAL_*_HOME_POS below will be used

//#define BED_CENTER_AT_0_0 // If defined, the center of the bed is at (X=0, Y=0)

//Manual homing switch locations:

#define MANUAL_HOME_POSITIONS // MANUAL_*_HOME_POS below will be used

// For deltabots this means top and center of the cartesian print volume.

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS 0

#define MANUAL_Z_HOME_POS 317.15// For delta: Distance between nozzle and print surface after homing.

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

// delta homing speeds must be the same on xyz

#define HOMING_FEEDRATE {100*40, 100*40, 100*40, 0} // set the homing speeds (mm/min)

// default settings

// delta speeds must be the same on xyz

#define DEFAULT_AXIS_STEPS_PER_UNIT {160,160,160,1263.43158} // default steps per unit for Kossel (GT2, 20 tooth)

#define DEFAULT_MAX_FEEDRATE {300,300,300,29} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000, 1000, 1000, 300} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 1000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

// Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing).

// The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder).

// For the other hotends it is their distance from the extruder 0 hotend.

// #define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis

// #define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 14.0 // (mm/sec)

#define DEFAULT_ZJERK 14.0 // (mm/sec) Must be same as XY for delta

#define DEFAULT_EJERK 6.0 // (mm/sec)

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// EEPROM

// the microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores paramters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

//define this to enable eeprom support

#define EEPROM_SETTINGS

//to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out:

// please keep turned on if you can.

#define EEPROM_CHITCHAT

// Preheat Constants

#define PLA_PREHEAT_HOTEND_TEMP 200

#define PLA_PREHEAT_HPB_TEMP 60

#define PLA_PREHEAT_FAN_SPEED 0 // Insert Value between 0 and 255

#define ABS_PREHEAT_HOTEND_TEMP 240

#define ABS_PREHEAT_HPB_TEMP 100

#define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

//LCD and SD support

//#define ULTRA_LCD //general lcd support, also 16x2

//#define DOGLCD // Support for SPI LCD 128x64 (Controller ST7565R graphic Display Family)

//#define SDSUPPORT // Enable SD Card Support in Hardware Console

//#define SDSLOW // Use slower SD transfer mode (not normally needed - uncomment if you're getting volume init error)

//#define ULTIMAKERCONTROLLER //as available from the ultimaker online store.

//#define ULTIPANEL //the ultipanel as on thingiverse

// The MaKr3d Makr-Panel with graphic controller and SD support

// [reprap.org]

//#define MAKRPANEL

// The RepRapDiscount Smart Controller (white PC

// [reprap.org]

#define REPRAP_DISCOUNT_SMART_CONTROLLER

// The GADGETS3D G3D LCD/SD Controller (blue PC

// [reprap.org]

//#define G3D_PANEL

// The RepRapDiscount FULL GRAPHIC Smart Controller (quadratic white PC

// [reprap.org]

//

// ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [code.google.com]

//#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

// The RepRapWorld REPRAPWORLD_KEYPAD v1.1

// [reprapworld.com]

//#define REPRAPWORLD_KEYPAD

//#define REPRAPWORLD_KEYPAD_MOVE_STEP 10.0 // how much should be moved when a key is pressed, eg 10.0 means 10mm per click

// The Elefu RA Board Control Panel

// [www.elefu.com]

// REMEMBER TO INSTALL LiquidCrystal_I2C.h in your ARUDINO library folder: [github.com]

//#define RA_CONTROL_PANEL

//automatic expansion

#if defined (MAKRPANEL)

#define DOGLCD

#define SDSUPPORT

#define ULTIPANEL

#define NEWPANEL

#define DEFAULT_LCD_CONTRAST 17

#endif

#if defined (REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER)

#define DOGLCD

#define U8GLIB_ST7920

#define REPRAP_DISCOUNT_SMART_CONTROLLER

#endif

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER) || defined(G3D_PANEL)

#define ULTIPANEL

#define NEWPANEL

#endif

#if defined(REPRAPWORLD_KEYPAD)

#define NEWPANEL

#define ULTIPANEL

#endif

#if defined(RA_CONTROL_PANEL)

#define ULTIPANEL

#define NEWPANEL

#define LCD_I2C_TYPE_PCA8574

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#endif

//I2C PANELS

//#define LCD_I2C_SAINSMART_YWROBOT

#ifdef LCD_I2C_SAINSMART_YWROBOT

// This uses the LiquidCrystal_I2C library ( [bitbucket.org] )

// Make sure it is placed in the Arduino libraries directory.

#define LCD_I2C_TYPE_PCF8575

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#define NEWPANEL

#define ULTIPANEL

#endif

// PANELOLU2 LCD with status LEDs, separate encoder and click inputs

//#define LCD_I2C_PANELOLU2

#ifdef LCD_I2C_PANELOLU2

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// (v1.2.3 no longer requires you to define PANELOLU in the LiquidTWI2.h library header file)

// Note: The PANELOLU2 encoder click input can either be directly connected to a pin

// (if BTN_ENC defined to != -1) or read through I2C (when BTN_ENC == -1).

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD

#define NEWPANEL

#define ULTIPANEL

#endif

// Panucatt VIKI LCD with status LEDs, integrated click & L/R/U/P buttons, separate encoder inputs

//#define LCD_I2C_VIKI

#ifdef LCD_I2C_VIKI

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// Note: The pause/stop/resume LCD button pin should be connected to the Arduino

// BTN_ENC pin (or set BTN_ENC to -1 if not used)

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD (requires LiquidTWI2 v1.2.3 or later)

#define NEWPANEL

#define ULTIPANEL

#endif

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the DOG graphic display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#endif

#else //no panel but just lcd

#ifdef ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the 128x64 graphics display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

#endif

// default LCD contrast for dogm-like LCD displays

#ifdef DOGLCD

# ifndef DEFAULT_LCD_CONTRAST

# define DEFAULT_LCD_CONTRAST 32

# endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// Use software PWM to drive the fan, as for the heaters. This uses a very low frequency

// which is not ass annoying as with the hardware PWM. On the other hand, if this frequency

// is too low, you should also increment SOFT_PWM_SCALE.

//#define FAN_SOFT_PWM

// Incrementing this by 1 will double the software PWM frequency,

// affecting heaters, and the fan if FAN_SOFT_PWM is enabled.

// However, control resolution will be halved for each increment;

// at zero value, there are 128 effective control positions.

#define SOFT_PWM_SCALE 0

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

// Support for the BariCUDA Paste Extruder.

//#define BARICUDA

/*********************************************************************\

* R/C SERVO support

* Sponsored by TrinityLabs, Reworked by codexmas

**********************************************************************/

// Number of servos

//

// If you select a configuration below, this will receive a default value and does not need to be set manually

// set it manually if you have more servos than extruders and wish to manually control some

// leaving it undefined or defining as 0 will disable the servo subsystem

// If unsure, leave commented / disabled

//

//#define NUM_SERVOS 3 // Servo index starts with 0 for M280 command

// Servo Endstops

//

// This allows for servo actuated endstops, primary usage is for the Z Axis to eliminate calibration or bed height changes.

// Use M206 command to correct for switch height offset to actual nozzle height. Store that setting with M500.

//

//#define SERVO_ENDSTOPS {-1, -1, 0} // Servo index for X, Y, Z. Disable with -1

//#define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 70,0} // X,Y,Z Axis Extend and Retract angles

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

#ifndef CONFIGURATION_H

#define CONFIGURATION_H

// This configuration file contains the basic settings.

// Advanced settings can be found in Configuration_adv.h

// BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration

// User-specified version info of this build to display in [Pronterface, etc] terminal window during

// startup. Implementation of an idea by Prof Braino to inform user that any changes made to this

// build by the user have been successfully uploaded into firmware.

#define STRING_VERSION_CONFIG_H __DATE__ " " __TIME__ // build date and time

#define STRING_CONFIG_H_AUTHOR "(Andy, Erik Zalm M666)" // Who made the changes.

// SERIAL_PORT selects which serial port should be used for communication with the host.

// This allows the connection of wireless adapters (for instance) to non-default port pins.

// Serial port 0 is still used by the Arduino bootloader regardless of this setting.

#define SERIAL_PORT 0

// This determines the communication speed of the printer

#define BAUDRATE 250000

//#define BAUDRATE 115200

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// 10 = Gen7 custom (Alfons3 Version) "https://github.com/Alfons3/Generation_7_Electronics"

// 11 = Gen7 v1.1, v1.2 = 11

// 12 = Gen7 v1.3

// 13 = Gen7 v1.4

// 3 = MEGA/RAMPS up to 1.2 = 3

// 33 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Bed)

// 34 = RAMPS 1.3 / 1.4 (Power outputs: Extruder0, Extruder1, Bed)

// 35 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Fan)

// 4 = Duemilanove w/ ATMega328P pin assignment

// 5 = Gen6

// 51 = Gen6 deluxe

// 6 = Sanguinololu < 1.2

// 62 = Sanguinololu 1.2 and above

// 63 = Melzi

// 64 = STB V1.1

// 65 = Azteeg X1

// 66 = Melzi with ATmega1284 (MaKr3d version)

// 7 = Ultimaker

// 71 = Ultimaker (Older electronics. Pre 1.5.4. This is rare)

// 77 = 3Drag Controller

// 8 = Teensylu

// 80 = Rumba

// 81 = Printrboard (AT90USB1286)

// 82 = Brainwave (AT90USB646)

// 9 = Gen3+

// 70 = Megatronics

// 701= Megatronics v2.0

// 702= Minitronics v1.0

// 90 = Alpha OMCA board

// 91 = Final OMCA board

// 301 = Rambo

// 21 = Elefu Ra Board (v3)

#ifndef MOTHERBOARD

#define MOTHERBOARD 80

#endif

// Define this to set a custom name for your generic Mendel,

// #define CUSTOM_MENDEL_NAME "This Mendel"

// This defines the number of extruders

#define EXTRUDERS 1

//// The following define selects which power supply you have. Please choose the one that matches your setup

// 1 = ATX

// 2 = X-Box 360 203Watts (the blue wire connected to PS_ON and the red wire to VCC)

#define POWER_SUPPLY 1

//===========================================================================

//============================== Delta Settings =============================

//===========================================================================

// Enable DELTA kinematics and most of the default configuration for Deltas

#define DELTA

// Make delta curves from many straight lines (linear interpolation).

// This is a trade-off between visible corners (not enough segments)

// and processor overload (too many expensive sqrt calls).

#define DELTA_SEGMENTS_PER_SECOND 200

// NOTE NB all values for DELTA_* values MOUST be floating point, so always have a decimal point in them

// Center-to-center distance of the holes in the diagonal push rods.

#define DELTA_DIAGONAL_ROD 270.9876 // mm

// Horizontal offset from middle of printer to smooth rod center.

#define DELTA_SMOOTH_ROD_OFFSET 202.25// mm

// If your print head is too high or low in the middle of the print surface, adjust DELTA_SMOOTH_ROD_OFFSET by half mm and try again.

// Horizontal offset of the universal joints on the end effector.

#define DELTA_EFFECTOR_OFFSET 37.0 // mm

// Horizontal offset of the universal joints on the carriages.

#define DELTA_CARRIAGE_OFFSET 40.0 // mm

// Effective horizontal distance bridged by diagonal push rods.

#define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET)

#define DELTA_DIAGONAL_ROD_2 sq(DELTA_DIAGONAL_ROD)

// Effective X/Y positions of the three vertical towers.

#define SIN_60 0.8660254037844386

#define COS_60 0.5

#define DELTA_TOWER1_X -SIN_60*DELTA_RADIUS // front left tower

#define DELTA_TOWER1_Y -COS_60*DELTA_RADIUS

#define DELTA_TOWER2_X SIN_60*DELTA_RADIUS // front right tower

#define DELTA_TOWER2_Y -COS_60*DELTA_RADIUS

#define DELTA_TOWER3_X 0.0 // back middle tower

#define DELTA_TOWER3_Y DELTA_RADIUS

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

// 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup)

// 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup)

// 10 is 100k RS thermistor 198-961 (4.7k pullup)

// 60 is 100k Maker's Tool Works Kapton Bed Thermister

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup)

#define TEMP_SENSOR_0 5

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 1

// This makes temp sensor 1 a redundant sensor for sensor 0. If the temperatures difference between these sensors is to high the print will be aborted.

//#define TEMP_SENSOR_1_AS_REDUNDANT

#define MAX_REDUNDANT_TEMP_SENSOR_DIFF 10

// Actual temperature must be close to target for this long before M109 returns success

#define TEMP_RESIDENCY_TIME 10 // (seconds)

#define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one

#define TEMP_WINDOW 1 // (degC) Window around target to start the residency timer x degC early.

// The minimal temperature defines the temperature below which the heater will not be enabled It is used

// to check that the wiring to the thermistor is not broken.

// Otherwise this would lead to the heater being powered on all the time.

#define HEATER_0_MINTEMP 5

#define HEATER_1_MINTEMP 5

#define HEATER_2_MINTEMP 5

#define BED_MINTEMP 5

// When temperature exceeds max temp, your heater will be switched off.

// This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure!

// You should use MINTEMP for thermistor short/failure protection.

#define HEATER_0_MAXTEMP 350

#define HEATER_1_MAXTEMP 255

#define HEATER_2_MAXTEMP 255

#define BED_MAXTEMP 120

// If your bed has low resistance e.g. .6 ohm and throws the fuse you can duty cycle it to reduce the

// average current. The value should be an integer and the heat bed will be turned on for 1 interval of

// HEATER_BED_DUTY_CYCLE_DIVIDER intervals.

//#define HEATER_BED_DUTY_CYCLE_DIVIDER 4

// PID settings:

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define BANG_MAX 255 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX 255 // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

//#define PID_DEBUG // Sends debug data to the serial port.

//#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX

#define PID_FUNCTIONAL_RANGE 10 // If the temperature difference between the target temperature and the actual temperature

// is more then PID_FUNCTIONAL_RANGE then the PID will be shut off and the heater will be set to min/max.

#define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term

#define K1 0.95 //smoothing factor within the PID

#define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the temperature routine

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// Ultimaker

// #define DEFAULT_Kp 22.2

// #define DEFAULT_Ki 1.08

// #define DEFAULT_Kd 114

// Makergear

// #define DEFAULT_Kp 7.0

// #define DEFAULT_Ki 0.1

// #define DEFAULT_Kd 12

// Mendel Parts V9 on 12V

// #define DEFAULT_Kp 63.0

// #define DEFAULT_Ki 2.25

// #define DEFAULT_Kd 440

//V2 of 3DR - Using Official J-head with1.75mm insert from UK clone supplier

// bias: 41 d: 41 min: 147.71 max: 152.60

// Ku: 21.38 Tu: 31.72

// Clasic PID

// Kp: 12.83

// Ki: 0.81

// Kd: 50.87

#define DEFAULT_Kp 10.22

#define DEFAULT_Ki 0.45

#define DEFAULT_Kd 57.43

#endif // PIDTEMP

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// Uncomment this to enable PID on the bed. It uses the same frequency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you probably

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

//#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delivered to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, aggressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 10.00

#define DEFAULT_bedKi .023

#define DEFAULT_bedKd 305.4

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

//this prevents dangerous Extruder moves, i.e. if the temperature is under the limit

//can be software-disabled for whatever purposes by

#define PREVENT_DANGEROUS_EXTRUDE

//if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately.

#define PREVENT_LENGTHY_EXTRUDE

#define EXTRUDE_MINTEMP 160

#define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances.

//===========================================================================

//=============================Mechanical Settings===========================

//===========================================================================

// Uncomment the following line to enable CoreXY kinematics

// #define COREXY

// coarse Endstop Settings

#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors

#ifndef ENDSTOPPULLUPS

// fine Enstop settings: Individual Pullups. will be ignored if ENDSTOPPULLUPS is defined

// #define ENDSTOPPULLUP_XMAX

// #define ENDSTOPPULLUP_YMAX

// #define ENDSTOPPULLUP_ZMAX

// #define ENDSTOPPULLUP_XMIN

// #define ENDSTOPPULLUP_YMIN

// #define ENDSTOPPULLUP_ZMIN

#endif

#ifdef ENDSTOPPULLUPS

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Y_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool X_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Y_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Z_MAX_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

// deltas never have min endstops

#define DISABLE_MIN_ENDSTOPS

// Disable max endstops for compatibility with endstop checking routine

#if defined(COREXY) && !defined(DISABLE_MAX_ENDSTOPS)

#define DISABLE_MAX_ENDSTOPS

#endif

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z false

#define DISABLE_E false // For all extruders

#define INVERT_X_DIR false // DELTA does not invert

#define INVERT_Y_DIR false

#define INVERT_Z_DIR false

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

// deltas always home to max

#define X_HOME_DIR 1

#define Y_HOME_DIR 1

#define Z_HOME_DIR 1

#define min_software_endstops true // If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

// Travel limits after homing

#define X_MAX_POS 106

#define X_MIN_POS -106

#define Y_MAX_POS 106

#define Y_MIN_POS -106

#define Z_MAX_POS MANUAL_Z_HOME_POS

#define Z_MIN_POS 0

#define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS)

#define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS)

#define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS)

// The position of the homing switches

//#define MANUAL_HOME_POSITIONS // If defined, MANUAL_*_HOME_POS below will be used

//#define BED_CENTER_AT_0_0 // If defined, the center of the bed is at (X=0, Y=0)

//Manual homing switch locations:

#define MANUAL_HOME_POSITIONS // MANUAL_*_HOME_POS below will be used

// For deltabots this means top and center of the cartesian print volume.

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS 0

#define MANUAL_Z_HOME_POS 317.15// For delta: Distance between nozzle and print surface after homing.

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

// delta homing speeds must be the same on xyz

#define HOMING_FEEDRATE {100*40, 100*40, 100*40, 0} // set the homing speeds (mm/min)

// default settings

// delta speeds must be the same on xyz

#define DEFAULT_AXIS_STEPS_PER_UNIT {160,160,160,1263.43158} // default steps per unit for Kossel (GT2, 20 tooth)

#define DEFAULT_MAX_FEEDRATE {300,300,300,29} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {1000, 1000, 1000, 300} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 1000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 1000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

// Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing).

// The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder).

// For the other hotends it is their distance from the extruder 0 hotend.

// #define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis

// #define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 14.0 // (mm/sec)

#define DEFAULT_ZJERK 14.0 // (mm/sec) Must be same as XY for delta

#define DEFAULT_EJERK 6.0 // (mm/sec)

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// EEPROM

// the microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores paramters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

//define this to enable eeprom support

#define EEPROM_SETTINGS

//to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out:

// please keep turned on if you can.

#define EEPROM_CHITCHAT

// Preheat Constants

#define PLA_PREHEAT_HOTEND_TEMP 200

#define PLA_PREHEAT_HPB_TEMP 60

#define PLA_PREHEAT_FAN_SPEED 0 // Insert Value between 0 and 255

#define ABS_PREHEAT_HOTEND_TEMP 240

#define ABS_PREHEAT_HPB_TEMP 100

#define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

//LCD and SD support

//#define ULTRA_LCD //general lcd support, also 16x2

//#define DOGLCD // Support for SPI LCD 128x64 (Controller ST7565R graphic Display Family)

//#define SDSUPPORT // Enable SD Card Support in Hardware Console

//#define SDSLOW // Use slower SD transfer mode (not normally needed - uncomment if you're getting volume init error)

//#define ULTIMAKERCONTROLLER //as available from the ultimaker online store.

//#define ULTIPANEL //the ultipanel as on thingiverse

// The MaKr3d Makr-Panel with graphic controller and SD support

// [reprap.org]

//#define MAKRPANEL

// The RepRapDiscount Smart Controller (white PC

// [reprap.org]

#define REPRAP_DISCOUNT_SMART_CONTROLLER

// The GADGETS3D G3D LCD/SD Controller (blue PC

// [reprap.org]

//#define G3D_PANEL

// The RepRapDiscount FULL GRAPHIC Smart Controller (quadratic white PC

// [reprap.org]

//

// ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [code.google.com]

//#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

// The RepRapWorld REPRAPWORLD_KEYPAD v1.1

// [reprapworld.com]

//#define REPRAPWORLD_KEYPAD

//#define REPRAPWORLD_KEYPAD_MOVE_STEP 10.0 // how much should be moved when a key is pressed, eg 10.0 means 10mm per click

// The Elefu RA Board Control Panel

// [www.elefu.com]

// REMEMBER TO INSTALL LiquidCrystal_I2C.h in your ARUDINO library folder: [github.com]

//#define RA_CONTROL_PANEL

//automatic expansion

#if defined (MAKRPANEL)

#define DOGLCD

#define SDSUPPORT

#define ULTIPANEL

#define NEWPANEL

#define DEFAULT_LCD_CONTRAST 17

#endif

#if defined (REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER)

#define DOGLCD

#define U8GLIB_ST7920

#define REPRAP_DISCOUNT_SMART_CONTROLLER

#endif

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER) || defined(G3D_PANEL)

#define ULTIPANEL

#define NEWPANEL

#endif

#if defined(REPRAPWORLD_KEYPAD)

#define NEWPANEL

#define ULTIPANEL

#endif

#if defined(RA_CONTROL_PANEL)

#define ULTIPANEL

#define NEWPANEL

#define LCD_I2C_TYPE_PCA8574

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#endif

//I2C PANELS

//#define LCD_I2C_SAINSMART_YWROBOT

#ifdef LCD_I2C_SAINSMART_YWROBOT

// This uses the LiquidCrystal_I2C library ( [bitbucket.org] )

// Make sure it is placed in the Arduino libraries directory.

#define LCD_I2C_TYPE_PCF8575

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#define NEWPANEL

#define ULTIPANEL

#endif

// PANELOLU2 LCD with status LEDs, separate encoder and click inputs

//#define LCD_I2C_PANELOLU2

#ifdef LCD_I2C_PANELOLU2

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// (v1.2.3 no longer requires you to define PANELOLU in the LiquidTWI2.h library header file)

// Note: The PANELOLU2 encoder click input can either be directly connected to a pin

// (if BTN_ENC defined to != -1) or read through I2C (when BTN_ENC == -1).

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD

#define NEWPANEL

#define ULTIPANEL

#endif

// Panucatt VIKI LCD with status LEDs, integrated click & L/R/U/P buttons, separate encoder inputs

//#define LCD_I2C_VIKI

#ifdef LCD_I2C_VIKI

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// Note: The pause/stop/resume LCD button pin should be connected to the Arduino

// BTN_ENC pin (or set BTN_ENC to -1 if not used)

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD (requires LiquidTWI2 v1.2.3 or later)

#define NEWPANEL

#define ULTIPANEL

#endif

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the DOG graphic display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#endif

#else //no panel but just lcd

#ifdef ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the 128x64 graphics display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

#endif

// default LCD contrast for dogm-like LCD displays

#ifdef DOGLCD

# ifndef DEFAULT_LCD_CONTRAST

# define DEFAULT_LCD_CONTRAST 32

# endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// Use software PWM to drive the fan, as for the heaters. This uses a very low frequency

// which is not ass annoying as with the hardware PWM. On the other hand, if this frequency

// is too low, you should also increment SOFT_PWM_SCALE.

//#define FAN_SOFT_PWM

// Incrementing this by 1 will double the software PWM frequency,

// affecting heaters, and the fan if FAN_SOFT_PWM is enabled.

// However, control resolution will be halved for each increment;

// at zero value, there are 128 effective control positions.

#define SOFT_PWM_SCALE 0

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

// Support for the BariCUDA Paste Extruder.

//#define BARICUDA

/*********************************************************************\

* R/C SERVO support

* Sponsored by TrinityLabs, Reworked by codexmas

**********************************************************************/

// Number of servos

//

// If you select a configuration below, this will receive a default value and does not need to be set manually

// set it manually if you have more servos than extruders and wish to manually control some

// leaving it undefined or defining as 0 will disable the servo subsystem

// If unsure, leave commented / disabled

//

//#define NUM_SERVOS 3 // Servo index starts with 0 for M280 command

// Servo Endstops

//

// This allows for servo actuated endstops, primary usage is for the Z Axis to eliminate calibration or bed height changes.

// Use M206 command to correct for switch height offset to actual nozzle height. Store that setting with M500.

//

//#define SERVO_ENDSTOPS {-1, -1, 0} // Servo index for X, Y, Z. Disable with -1

//#define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 70,0} // X,Y,Z Axis Extend and Retract angles

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

|

Re: New Own Design Printer 'Cherry Pi' February 08, 2014 05:09PM |

Registered: 10 years ago Posts: 515 |

Hi guys. A quick update. I have recently replaced my Jhead hotend with an E3D mk5. I took the opportunity to also drop from 0.5 to 0.4 for the nozzle and I have a 0.3 nozzle spare to try. The new hotend is simply superb. The Jhead was ok but I got tired of the yards of ooze that dripped from it during warmup. It made unattended print virtually impossible for me as I had to be there to keep wiping the nozzle. So far I've pushed both PLA and ABS through the E3D and the results from both are good. One downside is that I've lost about 20mm of build height but as I still have 320mm it's not really an issue. I could always redesign the groove mount to fit above the effector anyway.

Andy

Andy

|

Re: New Own Design Printer 'Cherry Pi' February 08, 2014 08:48PM |

Registered: 10 years ago Posts: 903 |

Will this help you get your build height back (and then some) with the E3D hotend?

http://www.thingiverse.com/thing:189393

(I don't know if mashing the hotend tip into the build plate as a Z-probe is going to have any effect on the orifice size over time, but it is an interesting concept that I just stumbled on for the first time today.)

Out of curiosity, have you had any problems with the E3D and PLA? I have seen mixed reports about problems printing PLA with it, and the authorized reseller that I purchased mine from strongly advised against using it with PLA.....

http://www.thingiverse.com/thing:189393

(I don't know if mashing the hotend tip into the build plate as a Z-probe is going to have any effect on the orifice size over time, but it is an interesting concept that I just stumbled on for the first time today.)

Out of curiosity, have you had any problems with the E3D and PLA? I have seen mixed reports about problems printing PLA with it, and the authorized reseller that I purchased mine from strongly advised against using it with PLA.....

|

Re: New Own Design Printer 'Cherry Pi' February 08, 2014 09:57PM |

Registered: 10 years ago Posts: 732 |

If you are afraid of that then it should be possible to modify it so that it works like capacitive displacement sensor. It would be more expensive though.Quote

vreihen

I don't know if mashing the hotend tip into the build plate as a Z-probe is going to have any effect on the orifice size over time, but it is an interesting concept that I just stumbled on for the first time today.

|

Re: New Own Design Printer 'Cherry Pi' February 09, 2014 09:09AM |

Registered: 10 years ago Posts: 903 |

Quote

hercek

[If you are afraid of that then it should be possible to modify it so that it works like capacitive displacement sensor. It would be more expensive though.

If expense was a concern, I would have picked up a $299 printer kit from Amazon instead of spending three times more than that for the best-of-breed parts and design.

I wonder if hotend heat would be an issue with a capacitive displacement setup?

I wonder if hotend heat would be an issue with a capacitive displacement setup?My thought is to borrow a tip from the RAF's WW-II dam-buster bomber. They had to fly *real* low at night, so they put downward-pointing spotlights on two different parts of the plane aimed at angles. When the two light beams intersected on the water's surface, they were at the proper height to drop the bouncing bomb. Too high or too low meant that the light beams wouldn't touch. Anyway, with a laser shining down at a 45 degree angle focused just under the tip of the hotend on one side, and an optical pinhole sensor at a 45 degree angle on the other side looking for the laser reflection from the print surface, it should work the same way with no mechanical contacts or even touching the print surface required. In theory, anyway.....

|

Re: New Own Design Printer 'Cherry Pi' February 09, 2014 06:10PM |

Registered: 10 years ago Posts: 732 |

Some people at delta bot google group tried to use optical approach and they failed. The angles to achieve total reflexion are too low. Problems with varying optical properties of bed over the area. It does not mean it is not possilbe. But it probably will not be that easy.

For capacitive aproach you need a conductive bed but it does not need to be optically uniform. It needs to be rather clean, but heatbed needs to be already clean for filament to stick. Well maybe it will not work well for people who use glue sticks or abs juice.

As for as uniformly conductive layer in the bed, maybe a mirror would do. Though not sure how to make a reliable electrical connection to the aluminium layer of the mirror. If the aluminium layer is too thin then its resistance may be a problem too.

I think it is worth a try but I'm not expert in the area of capacitive displacement sensors. I do not know about anybody who already tried this.