GUS Simpson

Posted by nicholas.seward

|

GUS Simpson January 10, 2014 04:30AM |

Registered: 10 years ago Posts: 979 |

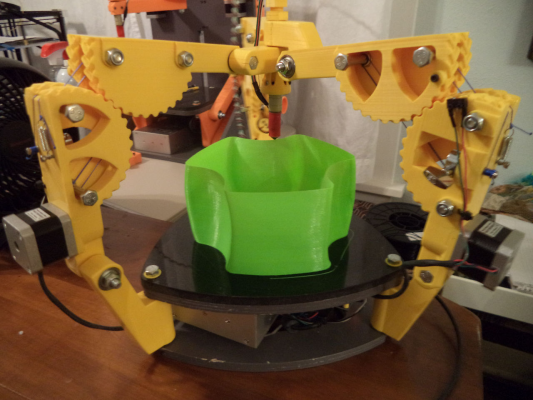

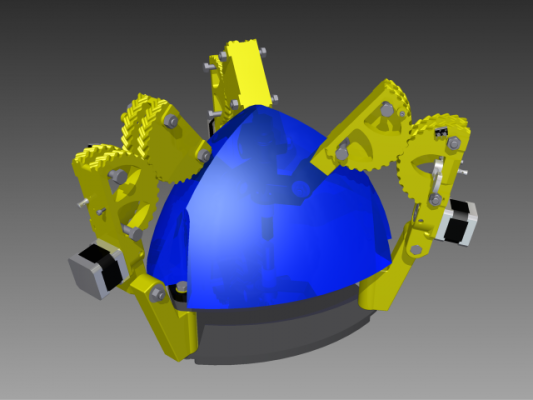

I figure it is about time for GUS (Geared Up Simpson) to get his own thread. As of today, as far as I am concerned, he has arrived. He can consistently (calibration between every few runs may be needed) make big beautiful prints.

His first print.

Movement demo.

His first print.

Movement demo.

|

Re: GUS Simpson January 10, 2014 09:00AM |

Registered: 10 years ago Posts: 100 |

|

Re: GUS Simpson January 10, 2014 09:37AM |

Registered: 11 years ago Posts: 58 |

Not only that, but there will shortly* be at least three more GUS Simpsons out there, testimony to how much we all like cool printers with gears and waving arms  I think that rate of adoption says a lot about the promise of the design.

I think that rate of adoption says a lot about the promise of the design.

* shortly == just few days, perhaps even this weekend, at the rate people are going. Two are already moving and just need calibration to make test prints, another is waiting for vitamins. Still more are at earlier stages of progress. . .

I think that rate of adoption says a lot about the promise of the design.

I think that rate of adoption says a lot about the promise of the design.* shortly == just few days, perhaps even this weekend, at the rate people are going. Two are already moving and just need calibration to make test prints, another is waiting for vitamins. Still more are at earlier stages of progress. . .

|

Re: GUS Simpson January 10, 2014 10:51AM |

Registered: 10 years ago Posts: 150 |

Thanks for the videos Nicholas, looks very promising !

If I remember correctly, at the very beginning of Simpson develoment you talked about a "parametric" design, for building larger Simpson.

Is that still in your plans ?

I think you could open a bounty for this, as a lot of people should be interested too ;-)

Edited 1 time(s). Last edit at 01/10/2014 10:51AM by Mikadoh.

If I remember correctly, at the very beginning of Simpson develoment you talked about a "parametric" design, for building larger Simpson.

Is that still in your plans ?

I think you could open a bounty for this, as a lot of people should be interested too ;-)

Edited 1 time(s). Last edit at 01/10/2014 10:51AM by Mikadoh.

|

Re: GUS Simpson January 10, 2014 10:56AM |

Registered: 10 years ago Posts: 979 |

|

Re: GUS Simpson January 10, 2014 11:09AM |

Registered: 10 years ago Posts: 145 |

|

Re: GUS Simpson January 10, 2014 11:36AM |

Registered: 10 years ago Posts: 979 |

|

Re: GUS Simpson January 10, 2014 01:21PM |

Registered: 10 years ago Posts: 100 |

Quote

nicholas.seward

I have some wobble being introduced from the printed spools. I will try to address that. Other than that it seems pretty spot on. More testing needed but I will try for self replication just as soon as I feel that I am ready.

This is a hard one to overcome with consistency. Engaging brainstorming mode:

One simple possibility is to make the spools a vitamin out of metal.

Another is to print a fixture that makes perfect spools by:

1) The fixture spins the spools and holds a [ file, sand paper, or Dremel ] so that they can be filed own to a precise round dimension.

2) The fixture is a rotary table for GUS that adds a precise way to make perfectly round prints (another axis.

Would it be cool to put a stepper motor on the bed and print a spool right on the shaft as it spins (Temp 4th axis)?

|

Re: GUS Simpson January 10, 2014 01:32PM |

Registered: 10 years ago Posts: 979 |

|

Re: GUS Simpson January 10, 2014 01:53PM |

Registered: 10 years ago Posts: 1,381 |

Quote

nicholas.seward

I am ordering metal spools. They are cheap enough. In the meantime I am also looking at making a error map of the spools I have. If the error is a nice enough sin function then I will incorporate this into my preprocessor to eliminate the error.

I've read quite a few post in the RepRap forums about 3d printed spools, they are rubbish, and to be avoided.

I wouldn't waste your time, just buy the metal version.

Unless your plans are to reduce purchased vitamins,

which is a different goal than building a bot that can print accurately.

|

Re: GUS Simpson January 10, 2014 02:04PM |

Registered: 10 years ago Posts: 979 |

@A2: I couldn't disagree more. You CAN make a bot that reduces the vitamin count and prints accurately. I will probably suggest the metal spools for those that want the easy road. I am going to see if I can get my printed ones to work. (I really have no double. They already work pretty darn good. I just need to map the error and then they will work better than pretty darn good.) This will help me as I gear up to make BOB Simpson.

Edited 1 time(s). Last edit at 01/10/2014 02:50PM by nicholas.seward.

Edited 1 time(s). Last edit at 01/10/2014 02:50PM by nicholas.seward.

|

Re: GUS Simpson January 10, 2014 02:43PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: GUS Simpson January 10, 2014 02:50PM |

Registered: 10 years ago Posts: 979 |

|

Re: GUS Simpson January 10, 2014 03:01PM |

Registered: 10 years ago Posts: 1,381 |

Ah, OK, I see what your doing now, tks!

I think a key, or some kind of physical feature will be required to orientate the spool relative to the end stops.

Maybe on the arm that the motor is mounted to (upper arm) you print a scale, and on the spool you print an arrow.

Home the arms against the end stop, then adjust the location of the spool, repeat a couple of times to verify.

I think a key, or some kind of physical feature will be required to orientate the spool relative to the end stops.

Maybe on the arm that the motor is mounted to (upper arm) you print a scale, and on the spool you print an arrow.

Home the arms against the end stop, then adjust the location of the spool, repeat a couple of times to verify.

|

Re: GUS Simpson January 10, 2014 03:10PM |

Registered: 10 years ago Posts: 979 |

|

Re: GUS Simpson January 22, 2014 04:16PM |

Registered: 10 years ago Posts: 3 |

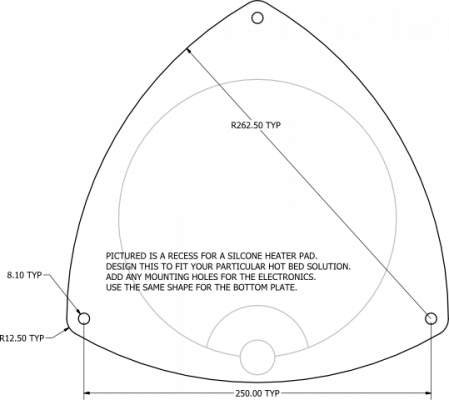

I have been preparing to build my first RepRap, and I want it to be a GUS Simpson. I've run into a small stumbling block regarding the bottom and top plates. The only person I know with a large enough CNC router lives all the way across the country. Is there a way to get dimensions from the DXF files so that I can cut the support plates by hand? Or is there another solution that I should consider? Any suggestions or advice will be greatly appreciated!

I sorry for posting what I'm sure is a trivial problem. Thank you for your help!

- Sy.

I sorry for posting what I'm sure is a trivial problem. Thank you for your help!

- Sy.

|

Re: GUS Simpson January 22, 2014 05:21PM |

Registered: 10 years ago Posts: 979 |

No worries! I am slowly adding all the necessary information to my GitHub.

The only thing that is really important is that you have the M8 holes located on the verticies of a equilateral triangle with 250mm sides. (You can actually change that dimension. Smaller=Bigger Work Envelope. However, the bigger work envelope starts to get harder to use for standard parts.) It is also important to have room for the shoulders to rotate through 60 degrees. Other than that you can make some fun shaped GUS beds. I just happen to like constant width shapes.

The work envelope will get wider and taller the closer the shoulders are together. However, you start losing the area behind each shoulder.

The only thing that is really important is that you have the M8 holes located on the verticies of a equilateral triangle with 250mm sides. (You can actually change that dimension. Smaller=Bigger Work Envelope. However, the bigger work envelope starts to get harder to use for standard parts.) It is also important to have room for the shoulders to rotate through 60 degrees. Other than that you can make some fun shaped GUS beds. I just happen to like constant width shapes.

The work envelope will get wider and taller the closer the shoulders are together. However, you start losing the area behind each shoulder.

|

Re: GUS Simpson February 26, 2014 09:30PM |

Registered: 10 years ago Posts: 1,381 |

Video of a Gus arm.

Gus Simpson RepRap Arm Test

[www.youtube.com]

Edited 1 time(s). Last edit at 02/26/2014 09:31PM by A2.

Gus Simpson RepRap Arm Test

[www.youtube.com]

Edited 1 time(s). Last edit at 02/26/2014 09:31PM by A2.

|

Re: GUS Simpson June 19, 2014 02:39PM |

Registered: 10 years ago Posts: 3 |

Every day I'm shufflin'

The base is just a hand cut job. I'm hoping to get a CNC cut MDF base made any day now. Anyone know where I can order a basalt base like I see on all the other GUS's? If I can't order a basalt base I'm going to see how badly my tile nipping skills have deteriorated and cut up some sort of a tile. I don't know how well a ceramic tile will function as a heated bed. I'm guessing quite spectacularly badly; might be fun. :-) Except for that and the limit switches, which are in the mail, I think I have everything. Now it's just a race to see what I break first as I learn how to use it.

- Sy

The base is just a hand cut job. I'm hoping to get a CNC cut MDF base made any day now. Anyone know where I can order a basalt base like I see on all the other GUS's? If I can't order a basalt base I'm going to see how badly my tile nipping skills have deteriorated and cut up some sort of a tile. I don't know how well a ceramic tile will function as a heated bed. I'm guessing quite spectacularly badly; might be fun. :-) Except for that and the limit switches, which are in the mail, I think I have everything. Now it's just a race to see what I break first as I learn how to use it.

- Sy

|

Re: GUS Simpson June 19, 2014 03:58PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: GUS Simpson June 22, 2014 10:40AM |

Registered: 10 years ago Posts: 67 |

Quote

I don't know how well a ceramic tile will function as a heated bed. I'm guessing quite spectacularly badly

Actually, it is probably one of the best beds to use. As a great discussion on another board, it is explained like this: The more heat conductive a bed material is, the worse it performs due to cooling too fast when the print is over. If the material is thermally resistive, then it takes longer to cool down, and helps eliminate edge curling on larger prints. The downside to ceramic tile is making sure to use a glazed one for flatness, and the fct that since it is thermally resistive, you need an adequate heater.

"Never argue with stupid people, they will drag you down to their level and then beat you with experience."

Sorry, only registered users may post in this forum.