NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!

Posted by LB-3D

NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 09, 2014 05:45PM |

Registered: 10 years ago Posts: 17 |

Dear Reprappers and experts

My first post (not the last off Corse)

Finished from my build of a standard rostock with original dimension

(RAMP 1.4 - INDUINO MEGA 2560 – MECHANICAL ENDSTOPS V1.2 – A4988 STEPPER DRIVER – T2 BELT – 20 TOOTH ALU PULLEY – NEMA 17 STEPPER MOTOR)

I download the latest marlin, adjust the value in (configuration.h) (configuration_adv.h) to match value of files inside (example_configurations) folder and edit the value corresponding to my build

I disabled

When I tried to compile, it gives the following error:

------------

------------

WHAT I DID I COMMENTED OUT ALL THOSE LINE:

I COMMENTED OUT ALL THOSE LINE:

---------

MAYBE THIS IS A MISTAKE BUT I THOUGHT ITS ONLY FOR AUTO BED LEVELING

But voila it compile

Then I succeeded to upload the firmware to my board

(very excited to see it moving but …)

…)

Now lets go to PRONTERFACE

***HOME ALL AXIS RESULT :***

even if its on middle of the tower far from endstops it wont move. each axe separately and by sequence jump up little bit and go back down to its original position with a buzzy sound coming from stepper motor like a noisy beep

***SENDING M119 result :***

All endstops free:

now I press X Y Z seperatly and send the commad for each so the result is :

-----------------------------------------------------------

If I move Z up in pronterface until hitting the endstops :

even when its showing hit , it wont stop

----------------------------------------------------------

Please if any one can guide me !!!!!!!!!

Its painful when its finished and not working

Please find attached my (configuration.h) (configuration_adv.h)

Many thanks in advance

My first post (not the last off Corse)

Finished from my build of a standard rostock with original dimension

(RAMP 1.4 - INDUINO MEGA 2560 – MECHANICAL ENDSTOPS V1.2 – A4988 STEPPER DRIVER – T2 BELT – 20 TOOTH ALU PULLEY – NEMA 17 STEPPER MOTOR)

I download the latest marlin, adjust the value in (configuration.h) (configuration_adv.h) to match value of files inside (example_configurations) folder and edit the value corresponding to my build

I disabled

//#define ENABLE_AUTO_BED_LEVELING // Delete the comment to enable (remove // at the start of the line)

When I tried to compile, it gives the following error:

------------

'ACCURATE_BED_LEVELING_POINTS' was not declared in this scope Marlin_main.cpp: In function 'void adjust_delta(float*)': Marlin_main.cpp:3287: error: 'ACCURATE_BED_LEVELING_POINTS' was not declared in this scope Marlin_main.cpp:3288: error: 'ACCURATE_BED_LEVELING_GRID_X' was not declared in this scope Marlin_main.cpp:3289: error: 'ACCURATE_BED_LEVELING_GRID_Y' was not declared in this scope Marlin_main.cpp:3294: error: 'bed_level' was not declared in this scope

------------

WHAT I DID

I COMMENTED OUT ALL THOSE LINE:

I COMMENTED OUT ALL THOSE LINE:

//{

//int half = (ACCURATE_BED_LEVELING_POINTS - 1) / 2;

//float grid_x = max(0.001-half, min(half-0.001, cartesian[X_AXIS] / ACCURATE_BED_LEVELING_GRID_X));

//float grid_y = max(0.001-half, min(half-0.001, cartesian[Y_AXIS] / ACCURATE_BED_LEVELING_GRID_Y));

//int floor_x = floor(grid_x);

//int floor_y = floor(grid_y);

//float ratio_x = grid_x - floor_x;

//float ratio_y = grid_y - floor_y;

// float z1 = bed_level[floor_x+half][floor_y+half];

//float z2 = bed_level[floor_x+half][floor_y+half+1];

//float z3 = bed_level[floor_x+half+1][floor_y+half];

// float z4 = bed_level[floor_x+half+1][floor_y+half+1];

// float left = (1-ratio_y)*z1 + ratio_y*z2;

//float right = (1-ratio_y)*z3 + ratio_y*z4;

//float offset = (1-ratio_x)*left + ratio_x*right;

// delta[X_AXIS] += offset;

// delta[Y_AXIS] += offset;

//delta[Z_AXIS] += offset;

//}

---------

MAYBE THIS IS A MISTAKE BUT I THOUGHT ITS ONLY FOR AUTO BED LEVELING

But voila it compile

Then I succeeded to upload the firmware to my board

(very excited to see it moving but

…)

…)Now lets go to PRONTERFACE

***HOME ALL AXIS RESULT :***

even if its on middle of the tower far from endstops it wont move. each axe separately and by sequence jump up little bit and go back down to its original position with a buzzy sound coming from stepper motor like a noisy beep

***SENDING M119 result :***

All endstops free:

Reporting endstop status x_max: open y_max: open z_max: open

now I press X Y Z seperatly and send the commad for each so the result is :

SENDING:M119 Reporting endstop status x_max: TRIGGERED y_max: open z_max: open >>>M119 SENDING:M119 Reporting endstop status x_max: open y_max: TRIGGERED z_max: open >>>M119 SENDING:M119 Reporting endstop status x_max: open y_max: open z_max: TRIGGERED

-----------------------------------------------------------

If I move Z up in pronterface until hitting the endstops :

echo:endstops hit: Y:1.78 echo:endstops hit: Y:1.81 echo:endstops hit: Y:1.84 Z:1.84 echo:endstops hit: X:1.94 Y:1.94 Z:1.94 echo:endstops hit: X:1.97 Y:1.97 Z:1.97 echo:endstops hit: X:2.00 Y:2.00 Z:2.00 echo:endstops hit: X:2.03 Y:2.03 Z:2.03

even when its showing hit , it wont stop

----------------------------------------------------------

Please if any one can guide me !!!!!!!!!

Its painful when its finished and not working

Please find attached my (configuration.h) (configuration_adv.h)

Many thanks in advance

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 03:24AM |

Registered: 10 years ago Posts: 29 |

I am just building my own version of a delta, and am using repetier firmware which deos config slightly differently.

However the issue you have seems to be familiar with many who build delta's, it is related to the endstop config, in that the end stops maybe set as normally open, but you have the config for normally closed, so the machine is trying to get a to a normally closd point,. Or you may have the config in the reverse, but the same is true in that the prog is looking for the wrong signal.

However the issue you have seems to be familiar with many who build delta's, it is related to the endstop config, in that the end stops maybe set as normally open, but you have the config for normally closed, so the machine is trying to get a to a normally closd point,. Or you may have the config in the reverse, but the same is true in that the prog is looking for the wrong signal.

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 04:33AM |

Registered: 10 years ago Posts: 12 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 07:02AM |

Registered: 10 years ago Posts: 17 |

daveb500 / imyz

many thanks for your replies

i tried REPETIER and face same exact problem

i cleared EEPROM nothing change

if i invert the logic of my endstops it seems the result not as expected

***SENDING M119 result :***

All endstops free:

in this case if i do homing all axes jump few mm and stop

any suggestion

thanks again

many thanks for your replies

i tried REPETIER and face same exact problem

i cleared EEPROM nothing change

if i invert the logic of my endstops it seems the result not as expected

***SENDING M119 result :***

All endstops free:

Reporting endstop status x_max: TRIGGERED y_max: TRIGGERED z_max: TRIGGERED

in this case if i do homing all axes jump few mm and stop

any suggestion

thanks again

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 07:42AM |

Registered: 10 years ago Posts: 515 |

Hi LB-3D

Your endstop configuration is working o.k although you seem to have your switches wired NO I.e they go closed circuit when you operate them. That's o.k though because you have the logic set to 'true'. The acid test is what happens when you send M119. As per your post all seems o.k. So it's not your endstop configuration causing the issue. You have your micro stepping set at 1/16. For your A4988 drivers that would mean all three jumpers under the driver on RAMPS being populated. Are they? Given that your end stops are operating correctly it must be something else. I would go back to a fresh copy of Marlin and just comment out #define ENABLE_AUTO_BED_LEVELING and #define ACCURATE_BED_LEVELLING and recompile

Andy

Your endstop configuration is working o.k although you seem to have your switches wired NO I.e they go closed circuit when you operate them. That's o.k though because you have the logic set to 'true'. The acid test is what happens when you send M119. As per your post all seems o.k. So it's not your endstop configuration causing the issue. You have your micro stepping set at 1/16. For your A4988 drivers that would mean all three jumpers under the driver on RAMPS being populated. Are they? Given that your end stops are operating correctly it must be something else. I would go back to a fresh copy of Marlin and just comment out #define ENABLE_AUTO_BED_LEVELING and #define ACCURATE_BED_LEVELLING and recompile

Andy

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 09:17AM |

Registered: 10 years ago Posts: 12 |

Do you have a thermistor connected? I cannot recall at the moment if the printer would run without the thermistor, if you have it defined in the firmware.

Try to define the temp sensor ar 0 and try again. It's this line:

#define TEMP_SENSOR_0 0 (you have 1 at the moment).

Sorry, I am not at the printer and cannot test it to be sure.

Try to define the temp sensor ar 0 and try again. It's this line:

#define TEMP_SENSOR_0 0 (you have 1 at the moment).

Sorry, I am not at the printer and cannot test it to be sure.

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 10:39AM |

Registered: 10 years ago Posts: 17 |

HOOOOORAY!!!!

ANDY U'R RIGHT - THANK YOU VERY MUCH - you saved me

i didn't know that those jumper are related to stepper driver

once installed - homing - and thats it homing very smoothly

homing very smoothly

THANKS AGAIN

/// imyz

u'r right, first it's always showing on my lcd an error about temp so i connect my thermistor and hotend to my ramp (its ready why not to connect )

)

really thank you all for your support and fast responce

(off corse i'll come back soon with calibration issue and update)

ANDY U'R RIGHT - THANK YOU VERY MUCH - you saved me

i didn't know that those jumper are related to stepper driver

once installed - homing - and thats it

homing very smoothly

homing very smoothlyTHANKS AGAIN

/// imyz

u'r right, first it's always showing on my lcd an error about temp so i connect my thermistor and hotend to my ramp (its ready why not to connect

)

)really thank you all for your support and fast responce

(off corse i'll come back soon with calibration issue and update)

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 10, 2014 11:24AM |

Registered: 10 years ago Posts: 515 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 11, 2014 09:34AM |

Registered: 10 years ago Posts: 17 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 12, 2014 01:16PM |

Registered: 10 years ago Posts: 12 |

Andy,

Great job. What would cause all switches to be triggered when one is triggered though?

Here is my issue where M119 shows all open, then I hold down X and M119 shows all triggered. Are they connected to the board wrong or share some sort of grounding issue?

Here is my post with video showing how odd my machine is: http://forums.reprap.org/read.php?178,336014

Thanks,

Mike

Great job. What would cause all switches to be triggered when one is triggered though?

Here is my issue where M119 shows all open, then I hold down X and M119 shows all triggered. Are they connected to the board wrong or share some sort of grounding issue?

Here is my post with video showing how odd my machine is: http://forums.reprap.org/read.php?178,336014

Thanks,

Mike

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 12, 2014 07:41PM |

Registered: 10 years ago Posts: 515 |

Hi Mike

That's weird! They must either be connected incorrectly or your pins.h file is designated wrong. I have a Sanguinololu board in another machine and the pins are different to RAMPS for the end stops. On RAMPS it's a centre pin and an outside pin that go to C and NC on the microswitch on Sanguinololu it's the outside two pins. Check your connectors with a meter before you do anything else. Good luck

Andy

That's weird! They must either be connected incorrectly or your pins.h file is designated wrong. I have a Sanguinololu board in another machine and the pins are different to RAMPS for the end stops. On RAMPS it's a centre pin and an outside pin that go to C and NC on the microswitch on Sanguinololu it's the outside two pins. Check your connectors with a meter before you do anything else. Good luck

Andy

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 12, 2014 07:45PM |

Registered: 10 years ago Posts: 515 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 05:40AM |

Registered: 10 years ago Posts: 17 |

Dear Andy

i tried to configured pronterface without any success

still considering center of the bed as origin

so i adjust slic3r and put a command in the starting of the G-code

and it works

maybe this is not the right way but at least i enjoined last night plotting with my printer with a pen (did't get my plastic yet )

)

Really its amazing

i will retry to adjust pronterface later and i will update

thanks again

i tried to configured pronterface without any success

still considering center of the bed as origin

so i adjust slic3r and put a command in the starting of the G-code

G1 X -100 Y -100

and it works

maybe this is not the right way but at least i enjoined last night plotting with my printer with a pen (did't get my plastic yet

)

) Really its amazing

i will retry to adjust pronterface later and i will update

thanks again

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 05:49AM |

Registered: 10 years ago Posts: 17 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 03:26PM |

Registered: 10 years ago Posts: 12 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 03:42PM |

Registered: 10 years ago Posts: 12 |

Andy,

Yep, you are right again. I'm using the following Sainsmart endstops and I just needed to choose one of the two GND wires in the middle to connect to my SIG and GND wires on the board.

Now I must figure out why my motors move way to harsh and far. The darn thing is going to vibrate off my table. Searching internet now...

Thanks again,

Mike

Yep, you are right again. I'm using the following Sainsmart endstops and I just needed to choose one of the two GND wires in the middle to connect to my SIG and GND wires on the board.

Now I must figure out why my motors move way to harsh and far. The darn thing is going to vibrate off my table. Searching internet now...

Thanks again,

Mike

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 06:02PM |

Registered: 10 years ago Posts: 515 |

Hi Mike

I suspect it's because you don't have the jumpers installed that tell your drivers what micro stepping mode you are using. If you have A4988 drivers and have set your steps per mm in Marlin to use 1/16 micro steps you need all three jumpers populated on the Sainsmart board. I believe they ship without them.

Or you have your homing federate set too high. Default in most Marlin forks is 200*60 changing hat to 100*60 for x,y and z may help

Andy

Edited 1 time(s). Last edit at 04/13/2014 06:04PM by AndyCart.

I suspect it's because you don't have the jumpers installed that tell your drivers what micro stepping mode you are using. If you have A4988 drivers and have set your steps per mm in Marlin to use 1/16 micro steps you need all three jumpers populated on the Sainsmart board. I believe they ship without them.

Or you have your homing federate set too high. Default in most Marlin forks is 200*60 changing hat to 100*60 for x,y and z may help

Andy

Edited 1 time(s). Last edit at 04/13/2014 06:04PM by AndyCart.

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 08:00PM |

Registered: 10 years ago Posts: 903 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 13, 2014 08:11PM |

Registered: 10 years ago Posts: 903 |

Here's a post from today, showing the RAMPS board with the micro-stepping jumpers installed:

http://forums.reprap.org/read.php?262,336883,339384#msg-339384

Edited 1 time(s). Last edit at 04/13/2014 08:12PM by vreihen.

http://forums.reprap.org/read.php?262,336883,339384#msg-339384

Edited 1 time(s). Last edit at 04/13/2014 08:12PM by vreihen.

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 15, 2014 06:42PM |

Registered: 10 years ago Posts: 12 |

Andy & vreihen,

You both are awesome! Missing jumpers were the issue. I must have been running full steps and almost vibrating my machine apart.

I know how this happened, too. I'm new to the board and the use of the Polu boards so I stuck them right in when I got the kit and had since then forgot that there are jumpers under the stepper boards.

Ran out to Radio Shack, bought the jumpers for 2 bucks and now it is running very smooth and homes well.

Next step for me is to configure the homing settings as I do not have a sensor for auto leveling. Perhaps I should invest in that as it seems that everyone uses one.

Thanks again you two!

Mike

You both are awesome! Missing jumpers were the issue. I must have been running full steps and almost vibrating my machine apart.

I know how this happened, too. I'm new to the board and the use of the Polu boards so I stuck them right in when I got the kit and had since then forgot that there are jumpers under the stepper boards.

Ran out to Radio Shack, bought the jumpers for 2 bucks and now it is running very smooth and homes well.

Next step for me is to configure the homing settings as I do not have a sensor for auto leveling. Perhaps I should invest in that as it seems that everyone uses one.

Thanks again you two!

Mike

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  April 15, 2014 06:48PM |

Registered: 10 years ago Posts: 515 |

You are most welcome sir.

If you are running Rich Cattell's Marlin then manual calibration is very easy as all the required values, endstop offsets, z height, delta radius and delta rod length can be changed from Pronterface with an M666 command so you don't need to continually upload changes via the IDE.

Check out this website for info on how to calibrate [minow.blogspot.co.uk]

Andy

If you are running Rich Cattell's Marlin then manual calibration is very easy as all the required values, endstop offsets, z height, delta radius and delta rod length can be changed from Pronterface with an M666 command so you don't need to continually upload changes via the IDE.

Check out this website for info on how to calibrate [minow.blogspot.co.uk]

Andy

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  July 12, 2014 10:20AM |

Registered: 10 years ago Posts: 17 |

Dear friends

First I want to thank you all for your support and for this Forum

Special thanks for JOHANN, RICHRAP, ~Russ and ANDY CART.

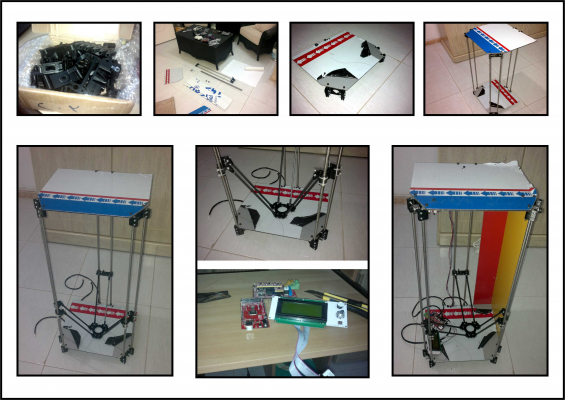

This is a fast log about my build and its capabilities for now (still improving)

Supplier of my kit forget 1 pulley and the belt is short

I find myself stack for 2 week until supplier send missing parts

Once received – installed – ready – and I face homing issue

After getting your help and pointing to missing jumper under stepper driver

Fix them and voila homing very smooth

I start, and first print was the cube 20*20*20

and first print was the cube 20*20*20

As you see in pic cube is almost very nice (H) is exact 20 but (L) 20.65 and (W) 20.25

The second print was 30*30*30 hollow cube and I was surprised with bridging quality but in that phase too much ooze from hot end going from side to side but it’s easy to clean with a knife (later after enable wiping and retract, problem solved)

Both print speed 60 mm (default silc3r setting)

My third print is hollow pyramid

Trying to reprint a cube, hot end temp increasing reach 140 and suddenly start decreasing

What’s wrong? Don’t know

After inspecting everything without noticing any loose in wiring I decide to check heater itself !!!

Yes, it’s burned out with hole in middle!!!

((No thermal paste between heat block and heater, I think it suffer very high temperature to heat my hot end and die early))

Again find myself waiting for parts

((I learned in a hard way to buy lot of replacement parts, and this what I did ))

))

After getting replacement (cover with aluminum foil) I continue my calibration

All printed parts I bought from e-bay are very week and start broken very easily even I am not working with it and without tightening screws.

So first things I decide to do is reprint my parts even without good calibration (I successes: D)

Now this is what my printer look like for now and what it can do

((bearing is moving directly))

((yes i am using the cover ))

))

Sorry for long post

Many thanks

LB-3D

First I want to thank you all for your support and for this Forum

Special thanks for JOHANN, RICHRAP, ~Russ and ANDY CART.

This is a fast log about my build and its capabilities for now (still improving)

Supplier of my kit forget 1 pulley and the belt is short

I find myself stack for 2 week until supplier send missing parts

Once received – installed – ready – and I face homing issue

After getting your help and pointing to missing jumper under stepper driver

Fix them and voila homing very smooth

I start,

and first print was the cube 20*20*20

and first print was the cube 20*20*20As you see in pic cube is almost very nice (H) is exact 20 but (L) 20.65 and (W) 20.25

The second print was 30*30*30 hollow cube and I was surprised with bridging quality but in that phase too much ooze from hot end going from side to side but it’s easy to clean with a knife (later after enable wiping and retract, problem solved)

Both print speed 60 mm (default silc3r setting)

My third print is hollow pyramid

Trying to reprint a cube, hot end temp increasing reach 140 and suddenly start decreasing

What’s wrong? Don’t know

After inspecting everything without noticing any loose in wiring I decide to check heater itself !!!

Yes, it’s burned out with hole in middle!!!

((No thermal paste between heat block and heater, I think it suffer very high temperature to heat my hot end and die early))

Again find myself waiting for parts

((I learned in a hard way to buy lot of replacement parts, and this what I did

))

))After getting replacement (cover with aluminum foil) I continue my calibration

All printed parts I bought from e-bay are very week and start broken very easily even I am not working with it and without tightening screws.

So first things I decide to do is reprint my parts even without good calibration (I successes: D)

Now this is what my printer look like for now and what it can do

((bearing is moving directly))

((yes i am using the cover

))

))Sorry for long post

Many thanks

LB-3D

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  July 12, 2014 06:35PM |

Registered: 10 years ago Posts: 515 |

Re: NEED HELP !!! ROSTOCK BUILD - WHATS WRONG !!!  July 14, 2014 08:30AM |

Registered: 10 years ago Posts: 172 |

Sorry, only registered users may post in this forum.