Waves in the build?

Posted by Artlav

|

Waves in the build? May 27, 2014 10:52AM |

Registered: 14 years ago Posts: 27 |

Hi all.

I'm making a Delta printer, based on Rostock Mini design, with Marlin firmware, and i'm getting a persisting problem.

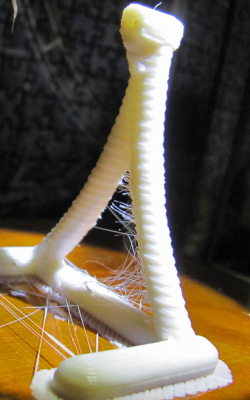

There are waves, mostly visible in vertical sections of the print.

What can be causing these?

They feel like rounding errors, but i'm not quite sure where to look for these.

The printer itself appears to be well tuned - the head moves flat in X-Y, positioning is repeatable, no skipped steps or anything, dimensions come out right.

I'm making a Delta printer, based on Rostock Mini design, with Marlin firmware, and i'm getting a persisting problem.

There are waves, mostly visible in vertical sections of the print.

What can be causing these?

They feel like rounding errors, but i'm not quite sure where to look for these.

The printer itself appears to be well tuned - the head moves flat in X-Y, positioning is repeatable, no skipped steps or anything, dimensions come out right.

|

Re: Waves in the build? May 27, 2014 10:59AM |

Registered: 10 years ago Posts: 469 |

Correct me if im wrong, but that looks to me to be some slack in the spider causing this.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Waves in the build? May 27, 2014 11:26AM |

Registered: 14 years ago Posts: 27 |

|

Re: Waves in the build? May 27, 2014 11:36AM |

Registered: 10 years ago Posts: 469 |

The spider may have some play in it. Even small amounts of slack in mounting it will result in a wavy print. At least my observation, however it could be slicer settings causing this as well.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Waves in the build? May 27, 2014 11:37AM |

Registered: 14 years ago Posts: 27 |

Ah, read your blog.

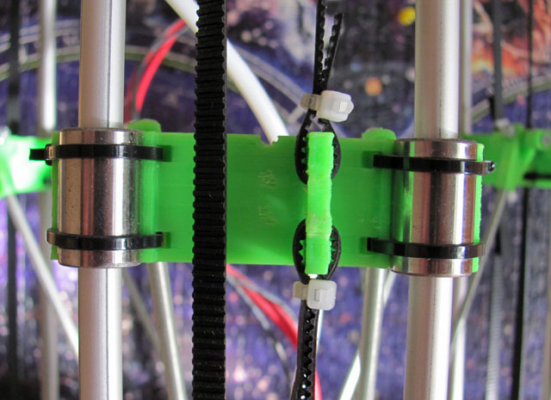

The only slack i can find is in the carriages - they rotate slightly in the plane of the picture below.

But AFAIK that is absolutely unavoidable without some magic-grade linear bearings.

Also, i don't quite see what kind of slack can produce a regular wave pattern like that.

It does not seem to add up.

The only slack i can find is in the carriages - they rotate slightly in the plane of the picture below.

But AFAIK that is absolutely unavoidable without some magic-grade linear bearings.

Also, i don't quite see what kind of slack can produce a regular wave pattern like that.

It does not seem to add up.

|

Re: Waves in the build? May 27, 2014 07:19PM |

Registered: 10 years ago Posts: 903 |

|

Re: Waves in the build? May 27, 2014 07:27PM |

Registered: 11 years ago Posts: 805 |

|

Re: Waves in the build? May 28, 2014 03:51AM |

Registered: 14 years ago Posts: 27 |

Problem is, it looks too regular to be caused by any slack.

If i print a vertical cylinder, it will have regular waves of being thinner and thicker along the Z axis.

No amount of slack can explain that, since every Z layer have exactly the same movements that the other.

Therefore, i'm confused.

If i print a vertical cylinder, it will have regular waves of being thinner and thicker along the Z axis.

No amount of slack can explain that, since every Z layer have exactly the same movements that the other.

Therefore, i'm confused.

|

Re: Waves in the build? May 28, 2014 01:12PM |

Registered: 10 years ago Posts: 469 |

The movement is not exactly the same on any layer. The movement of flatness is emulated, see if you can slow the print speed down a bit and see if the lines still appear, if the lines are not exactly the same then its slack that is causing resonant frequencies and that inconsistency. If it is the same, then your configuration may need to be tweaked.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Waves in the build? May 29, 2014 08:10PM |

Registered: 10 years ago Posts: 153 |

Check the frame for play, loose belts, loose pulleys, loose bearings, loose joints in the arms. Check the heck out of it

It could also be a plastic flow issue. If your hobbed bolt was not built properly and is eccentric it can cause this, but I doubt it.

It may be worth checking if you've tried everything and have run out of things to check.

If it's a plastic feed issue you'll get a wave every X mm of plastic that goes through the extruder.

If it's a mechanical issure I'd expect it to show every X mm of z height.

Thus if it is a plastic feed issue the waves will be closer together where the layers are wider and require more plastic, and further appart on taller thinner objects.

It could also be a plastic flow issue. If your hobbed bolt was not built properly and is eccentric it can cause this, but I doubt it.

It may be worth checking if you've tried everything and have run out of things to check.

If it's a plastic feed issue you'll get a wave every X mm of plastic that goes through the extruder.

If it's a mechanical issure I'd expect it to show every X mm of z height.

Thus if it is a plastic feed issue the waves will be closer together where the layers are wider and require more plastic, and further appart on taller thinner objects.

|

Re: Waves in the build? May 30, 2014 12:42PM |

Registered: 10 years ago Posts: 790 |

I've never touched a delta, so I may look like an ignorant fool [in the which case I look like I am], but isn't z-banding a result of miscalculated steps-per-mm?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 02, 2014 03:00PM |

Registered: 10 years ago Posts: 790 |

Could also be your heated bed expanding and contracting with the bang-bang on-off heating. I've read an experience or two about that recently.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 03, 2014 03:54PM |

Registered: 14 years ago Posts: 27 |

No, the heated bed is constantly on.Quote

MrDoctorDIV

Could also be your heated bed expanding and contracting with the bang-bang on-off heating. I've read an experience or two about that recently.

Then it would have slipped steps, causing catastrophic failures.Quote

vreihen

Check for loose motor mounts, or pulleys that don't have their set screw tightened all the way down.....

What should i be looking at in the configuration?Quote

jaguarking11

If it is the same, then your configuration may need to be tweaked.

This looks more and more like software issue to me.

Checked everything. Tried to mount both top and bottom of the frame to a wall to eliminate any possible shaking - no effect.Quote

TheTechnicalNoob

Check the frame for play, loose belts, loose pulleys, loose bearings, loose joints in the arms. Check the heck out of it

Tried to restrain the caret rotations - no effect. No other looseness i can see.

It's every some mm of height, and is perfectly repeatable from print to print of the same object, even if i change the slicing options to make the head go in a completely different direction.Quote

TheTechnicalNoob

If it's a plastic feed issue you'll get a wave every X mm of plastic that goes through the extruder.

If it's a mechanical issure I'd expect it to show every X mm of z height.

It feels like warped space, not warped build (if that makes sense).

|

Re: Waves in the build? June 03, 2014 04:23PM |

Registered: 10 years ago Posts: 153 |

The only thing I can think of is plastic flow, slicer software or a configuration issue. Those are the only things that haven't been ruled out entirely. Printing an object that transitions from a wide layers to narrow layers like a cone would tell you whether its every x mm of z height or a plastic flow depending on if the bands are spaced evenly on the cone, but you'd have to waste some fillament :/

Configuration: You could try get a fresh copy of marlin and start fresh.

What slicer software are you using? Perhaps it's generating messed up gcode. You can view the gcode in blender with an addon, or post the gcode file here and I'll take a look at it if you'd like.

Configuration: You could try get a fresh copy of marlin and start fresh.

What slicer software are you using? Perhaps it's generating messed up gcode. You can view the gcode in blender with an addon, or post the gcode file here and I'll take a look at it if you'd like.

|

Re: Waves in the build? June 03, 2014 06:00PM |

Registered: 14 years ago Posts: 27 |

Hm.

I just printed a hyperboloid vase. The head was basically doing circles all the time.

The waves are all on Z axis, very regular.

They are nearly invisible at the slopes, but are quite pronounced in the central part, where the walls are close to vertical.

The amplitude of the waves is less than on the original test piece - it's not the best shape to show the problem, i'll try to find a simple one with good effect.

So far that stand is the strongest case.

Plastic flow is unlikely to be a problem - i rebuilt the extruder recently, and so far it's nice and steady.

I'm using KISSlicer.

Slicing issues are unlikely, since i also have a mendel, and it prints the same parts sliced with similar settings perfectly.

I just printed a hyperboloid vase. The head was basically doing circles all the time.

The waves are all on Z axis, very regular.

They are nearly invisible at the slopes, but are quite pronounced in the central part, where the walls are close to vertical.

The amplitude of the waves is less than on the original test piece - it's not the best shape to show the problem, i'll try to find a simple one with good effect.

So far that stand is the strongest case.

Plastic flow is unlikely to be a problem - i rebuilt the extruder recently, and so far it's nice and steady.

I'm using KISSlicer.

Slicing issues are unlikely, since i also have a mendel, and it prints the same parts sliced with similar settings perfectly.

|

Re: Waves in the build? June 04, 2014 08:58AM |

Registered: 10 years ago Posts: 790 |

"Ok, turns out it was the heatbed expanding/contracting as it was being powered on/off maintaining the set temperature. Expanding would make the entire print raise closer to the hotend causing the filament to squish outwards, while contracting would move the print further away reducing the width of the extrude and likely overlapping the previous perimeter."

Example of the heated bed, his was "constantly on" as well. I bring my point back up, have you checked that it isn't the heated bed?

Are the waves the same distance from eachother on all models? Or closer together the longer it takes each layer?

Edited 1 time(s). Last edit at 06/04/2014 08:58AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Example of the heated bed, his was "constantly on" as well. I bring my point back up, have you checked that it isn't the heated bed?

Are the waves the same distance from eachother on all models? Or closer together the longer it takes each layer?

Edited 1 time(s). Last edit at 06/04/2014 08:58AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 04, 2014 09:21AM |

Registered: 14 years ago Posts: 27 |

Some more experiments:

-Printing the same hyperboloid off centre does not alter it's appearance, so it's not centre-specific.

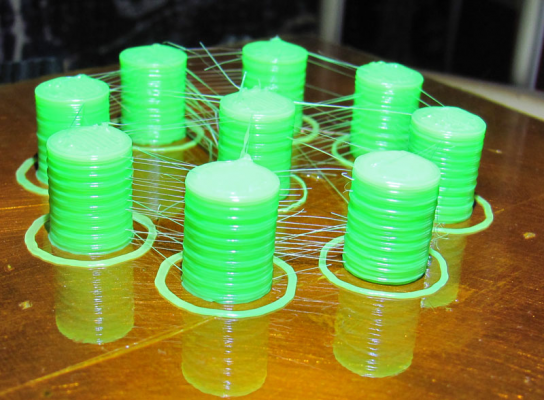

-Printing a set of cylinders show the waves nicely.

The cylinders are all nearly the same regardless of their position on the platform.

So, it appears to be a Z-related, not position related.

-Printing bars horizontally fail to reveal any waves.

There are some Z distortions, but they are noise, not waves.

-A simple diagonal cylinder, similar to the original, does show pronounced waves, but not as well as the original.

The waves seem to increase with height, somewhat counterintuitively.

In my case the heat bed is connected directly to the power supply, with no electronics in between but a mechanical switch.

It's always on.

-Printing the same hyperboloid off centre does not alter it's appearance, so it's not centre-specific.

-Printing a set of cylinders show the waves nicely.

The cylinders are all nearly the same regardless of their position on the platform.

So, it appears to be a Z-related, not position related.

-Printing bars horizontally fail to reveal any waves.

There are some Z distortions, but they are noise, not waves.

-A simple diagonal cylinder, similar to the original, does show pronounced waves, but not as well as the original.

The waves seem to increase with height, somewhat counterintuitively.

Unlikely, unless i don't understand the mechanics of the problem in the example.Quote

MrDoctorDIV

have you checked that it isn't the heated bed?

In my case the heat bed is connected directly to the power supply, with no electronics in between but a mechanical switch.

It's always on.

However, that's what i see on the cone-cylinder test piece (last image) - the waves get wider apart and more pronounced towards the top.Quote

MrDoctorDIV

Are the waves the same distance from eachother on all models? Or closer together the longer it takes each layer?

|

Re: Waves in the build? June 04, 2014 09:36AM |

Registered: 14 years ago Posts: 27 |

Ah, got it!

It's the extruder heater.

I tried printing a single small cylinder, and was watching it.

Heater LED goes on - the diameter increases, heater LED goes off - it starts decreasing.

With 20 seconds per layer the effect and correlation are obvious.

So, same thing as what MrDoctorDIV suspected, only with different heater being guilty.

And the mendel didn't have the same problem because it's hotend (Parcan) is not as powerful as the one here (J-head mk6, i think).

Ok, looks like i'll have to enable PIDTEMP and make it work...

That should do it, right?

It's the extruder heater.

I tried printing a single small cylinder, and was watching it.

Heater LED goes on - the diameter increases, heater LED goes off - it starts decreasing.

With 20 seconds per layer the effect and correlation are obvious.

So, same thing as what MrDoctorDIV suspected, only with different heater being guilty.

And the mendel didn't have the same problem because it's hotend (Parcan) is not as powerful as the one here (J-head mk6, i think).

Ok, looks like i'll have to enable PIDTEMP and make it work...

That should do it, right?

|

Re: Waves in the build? June 04, 2014 09:40AM |

Registered: 10 years ago Posts: 790 |

Yeah, PID controls it a lot more closely. In my opinion, PID should always be used for extruders.

Glad I could help, even if indirectly. I'll add that to my iddy biddy knowledge tree.

Edited 1 time(s). Last edit at 06/04/2014 09:41AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Glad I could help, even if indirectly. I'll add that to my iddy biddy knowledge tree.

Edited 1 time(s). Last edit at 06/04/2014 09:41AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 04, 2014 03:55PM |

Registered: 10 years ago Posts: 153 |

Good spotting!

I thought the defaults in marlin were set to pid already!

Some cool reading and calbrating you could look at to make it even better: [reprap.org]

I thought the defaults in marlin were set to pid already!

Some cool reading and calbrating you could look at to make it even better: [reprap.org]

|

Re: Waves in the build? June 04, 2014 04:08PM |

Registered: 10 years ago Posts: 790 |

Quote

TheTechnicalNoob

Good spotting!

I thought the defaults in marlin were set to pid already!

Some cool reading and calbrating you could look at to make it even better: [reprap.org]

I'm usually fairly stable, but I've never done a PID tuning. It will be interesting to see what kind of improvement, if any, I'll get out of my E3D.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 04, 2014 04:12PM |

Registered: 10 years ago Posts: 153 |

|

Re: Waves in the build? June 04, 2014 04:15PM |

Registered: 10 years ago Posts: 790 |

I've never overshot more than 6-7, usually about 3-4 on a high. Stable within +-2.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Waves in the build? June 26, 2014 02:14PM |

Registered: 9 years ago Posts: 569 |

Not to steal the thread, but are the strings between objects / edges normal? This is a constant issue with my Rostock Mini and I am not sure if I should speed it up, slow it down, are there minimum speeds needed for good prints, etc...

And at first when you mentioned waves in your prints, I was thinking something more along the horizontal axis rather than the vertical. The last time I tried to print anything, I was getting waves like the nozzle was digging into the print, forcing the plastic to wave out from the line being printed. This was resulting in my nozzle skipping on the next layer and ruining the print, hence the reason I tried to slow down my print speed.

|

Re: Waves in the build? June 26, 2014 02:56PM |

Registered: 10 years ago Posts: 469 |

The spider webbing comes from retraction speed on the extruder.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Waves in the build? June 26, 2014 03:54PM |

Registered: 14 years ago Posts: 27 |

|

Re: Waves in the build? June 26, 2014 04:19PM |

Registered: 10 years ago Posts: 153 |

|

Re: Waves in the build? June 26, 2014 07:31PM |

Registered: 10 years ago Posts: 732 |

Strings are about retraction length. They disappear for me at about 10 mm retraction length.

Retraction speed determines whether there are small blobs of additionally deposited material at the locations where there is a retract (or retract reverse). If you get the blobs then you need to increase the speed. They disappear for me at about 150 mm/s.

Retraction speed determines whether there are small blobs of additionally deposited material at the locations where there is a retract (or retract reverse). If you get the blobs then you need to increase the speed. They disappear for me at about 150 mm/s.

|

Re: Waves in the build? June 27, 2014 11:58AM |

Registered: 9 years ago Posts: 569 |

Sorry, only registered users may post in this forum.