Cherry Pi III Is Available

Posted by AndyCart

|

Re: Cherry Pi III Is Available August 12, 2014 10:53AM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available August 12, 2014 11:18AM |

Registered: 9 years ago Posts: 113 |

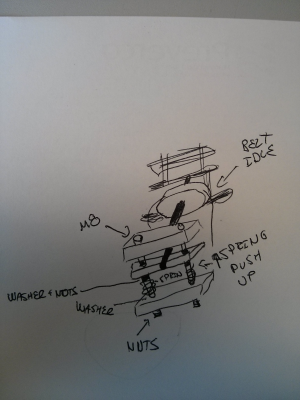

As for the spring loaded idle, I was thinking of something like this

(M8 is too big... M5 or even M3 should be okay).

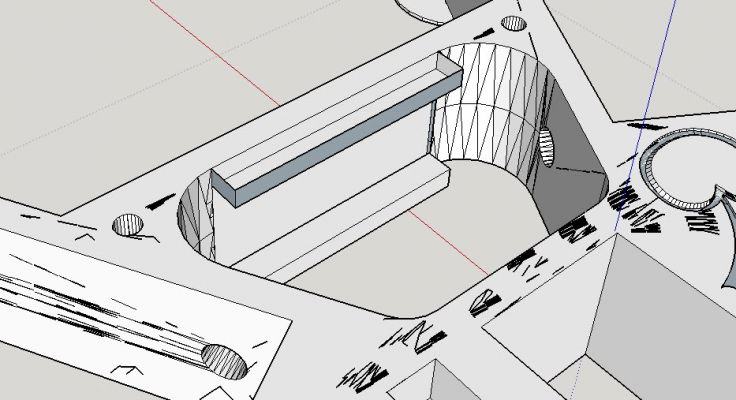

Installed like this

Two part would be fixed to the top braket, the middle one will be moving (spring loaded) with the bearing mount.

when you install the belt, you push the spring to the bottom and when you release it, the belt is loaded.

Edited 1 time(s). Last edit at 08/12/2014 11:19AM by nka.

- Sebastien Plante (nka)

(M8 is too big... M5 or even M3 should be okay).

Installed like this

Two part would be fixed to the top braket, the middle one will be moving (spring loaded) with the bearing mount.

when you install the belt, you push the spring to the bottom and when you release it, the belt is loaded.

Edited 1 time(s). Last edit at 08/12/2014 11:19AM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 12, 2014 10:07PM |

Registered: 9 years ago Posts: 83 |

I don't know how it would be applied to the Mini Kossel / Cherry Pi design (well, I do-- redesign the top bracket from scratch), but the belt tension mechanism on the Kossel Clear is nice-- the idler pulley is suspended from the top bracket by two bolts. Tighten / loosen the two bolts (equally) to set the tension on the belt exactly where you want it. Also makes the belt easier to remove from the carriage. As an aesthetic benefit, since each tower is tightened independently, you can cap off the extrusion with the top bracket. Not required, but looks slightly more elegant IMO.

|

Re: Cherry Pi III Is Available August 13, 2014 08:51AM |

Registered: 9 years ago Posts: 113 |

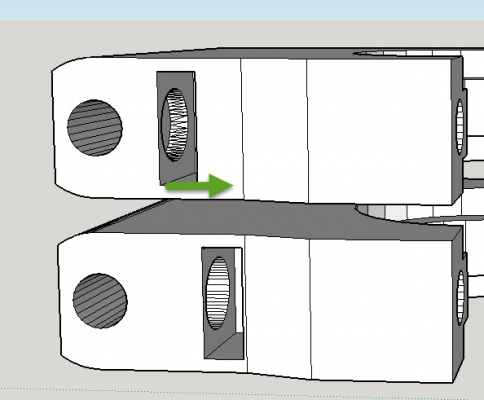

Just a little improvement I would do on the Effector Clamp

Moving the nuts hole a little would help to reach the nuts and then tight without going into the wall of the other screw (in case of a too-long screw).

- Sebastien Plante (nka)

Moving the nuts hole a little would help to reach the nuts and then tight without going into the wall of the other screw (in case of a too-long screw).

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 13, 2014 11:03AM |

Registered: 10 years ago Posts: 903 |

I second Sebastien's suggestion! My added rationale is that my bag of assorted Mini-Kossel M3 SHCS hardware only had two screw lengths in this range. One just reached the face of the nut when pushed in, and the longer one would have passed through the pivot hole as he pointed out. If the nut were forward a few millimeters, the shorter screw would work perfectly.....

|

Re: Cherry Pi III Is Available August 13, 2014 11:16AM |

Registered: 10 years ago Posts: 903 |

If you are considering a re-design of the bottom brackets, may I suggest cherry-picking this concept?

http://www.thingiverse.com/thing:340529

Instead of slotting the motor holes, just make the entire green plate a little bit shorter and slot the extrusion mounting holes so the whole plate/motor can slide to tension the belts without disturbing the frame geometry. My only concern is the ease of access to the front (shared) extrusion mounting holes with the motor installed.....

http://www.thingiverse.com/thing:340529

Instead of slotting the motor holes, just make the entire green plate a little bit shorter and slot the extrusion mounting holes so the whole plate/motor can slide to tension the belts without disturbing the frame geometry. My only concern is the ease of access to the front (shared) extrusion mounting holes with the motor installed.....

|

Re: Cherry Pi III Is Available August 13, 2014 05:05PM |

Registered: 10 years ago Posts: 515 |

Quote

nka

Just a little improvement I would do on the Effector Clamp

Moving the nuts hole a little would help to reach the nuts and then tight without going into the wall of the other screw (in case of a too-long screw).

It was designed for a 25mm screw. Mine all fit o.k ???

|

Re: Cherry Pi III Is Available August 13, 2014 07:30PM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available August 13, 2014 08:00PM |

Registered: 10 years ago Posts: 903 |

|

Re: Cherry Pi III Is Available August 15, 2014 05:13PM |

Registered: 9 years ago Posts: 113 |

woohooo !

[www.youtube.com]

10mm cube, is 10mm ! Moving to next print.

I also have to ajust my height, since I'm scratching the tape on the first layer! Easy way to do this without recalibratiing the whole thing?

edit:

M666 Hxxx

M500

Edited 1 time(s). Last edit at 08/15/2014 05:18PM by nka.

- Sebastien Plante (nka)

[www.youtube.com]

10mm cube, is 10mm ! Moving to next print.

I also have to ajust my height, since I'm scratching the tape on the first layer! Easy way to do this without recalibratiing the whole thing?

edit:

M666 Hxxx

M500

Edited 1 time(s). Last edit at 08/15/2014 05:18PM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 15, 2014 05:44PM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available August 15, 2014 06:41PM |

Registered: 10 years ago Posts: 515 |

|

Re: Cherry Pi III Is Available August 15, 2014 09:58PM |

Registered: 9 years ago Posts: 113 |

Yeah, I ajusted them, they seems to be more silent now too... didnt try a print, cause I was trying to fine tune the printer.

btw... glass just craked... :'( Need to get a new one... I'll get a strong one for a local shop, not a cheap ebay thing.

Dont know why it craked, why doing test, the nozzle it the glass and bam... supposed to be borosilicate glass !

Edited 1 time(s). Last edit at 08/15/2014 10:03PM by nka.

- Sebastien Plante (nka)

btw... glass just craked... :'( Need to get a new one... I'll get a strong one for a local shop, not a cheap ebay thing.

Dont know why it craked, why doing test, the nozzle it the glass and bam... supposed to be borosilicate glass !

Edited 1 time(s). Last edit at 08/15/2014 10:03PM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 16, 2014 01:27PM |

Registered: 9 years ago Posts: 113 |

Found a mirror to get me back on track, I'm calibrating right now. Hope people didnt think I was buying those to decorate, they are ugly... lol

Yesterday, I was looking at heatbed and I think the 220mm (180mm heated) heatbed used for the Orion could work very nicely (with some braket to hold it) : [seemecnc.com] . I might go this way if I dont go with the custom one.

I also got a question. I'm using the firmware for the Mini Kossel from Rich Cattell you provided me.

I was following this tutorial ( [www.youtube.com] ) to do a pre-calibration using M666.

I was ajusting the tower "X" at X-73.6 Y-42.5, I found that I touched the bed at 1.2mm, so I did "M666 X1.2", "G28" then "G0 X-73.6 Y-42.5" and used the Repetier-Host (also tried with the Pronterface) and I was touching the bed a 1.2 agains... I did this like 4 time, (I was at M666 X4.8) and I was still touching the bed at 1.2.

So I tried M500 and a reload... same thing.

It seems to be the same thing with the "M666 Hxxx". I was scraping the tape, so I removed some height and it was still scraping it... like it dosent use those? I Even tried "M666 H100" to see what would happen... and notthing. My max height is like 238.3 and I setted 240 into the firmware. Tried the same thing after a M502, M500 and reset of the printer.

What I was doing wrong? I'm lost.

I'm auto calibrating right now with the "G30 A", I'll tried to see if it does a better calibration than me!

- Sebastien Plante (nka)

Yesterday, I was looking at heatbed and I think the 220mm (180mm heated) heatbed used for the Orion could work very nicely (with some braket to hold it) : [seemecnc.com] . I might go this way if I dont go with the custom one.

I also got a question. I'm using the firmware for the Mini Kossel from Rich Cattell you provided me.

I was following this tutorial ( [www.youtube.com] ) to do a pre-calibration using M666.

I was ajusting the tower "X" at X-73.6 Y-42.5, I found that I touched the bed at 1.2mm, so I did "M666 X1.2", "G28" then "G0 X-73.6 Y-42.5" and used the Repetier-Host (also tried with the Pronterface) and I was touching the bed a 1.2 agains... I did this like 4 time, (I was at M666 X4.8) and I was still touching the bed at 1.2.

So I tried M500 and a reload... same thing.

It seems to be the same thing with the "M666 Hxxx". I was scraping the tape, so I removed some height and it was still scraping it... like it dosent use those? I Even tried "M666 H100" to see what would happen... and notthing. My max height is like 238.3 and I setted 240 into the firmware. Tried the same thing after a M502, M500 and reset of the printer.

What I was doing wrong? I'm lost.

I'm auto calibrating right now with the "G30 A", I'll tried to see if it does a better calibration than me!

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 16, 2014 01:50PM |

Registered: 10 years ago Posts: 515 |

Quote

nka

Found a mirror to get me back on track, I'm calibrating right now. Hope people didnt think I was buying those to decorate, they are ugly... lol

Yesterday, I was looking at heatbed and I think the 220mm (180mm heated) heatbed used for the Orion could work very nicely (with some braket to hold it) : [seemecnc.com] . I might go this way if I dont go with the custom one.

I also got a question. I'm using the firmware for the Mini Kossel from Rich Cattell you provided me.

I was following this tutorial ( [www.youtube.com] ) to do a pre-calibration using M666.

I was ajusting the tower "X" at X-73.6 Y-42.5, I found that I touched the bed at 1.2mm, so I did "M666 X1.2", "G28" then "G0 X-73.6 Y-42.5" and used the Repetier-Host (also tried with the Pronterface) and I was touching the bed a 1.2 agains... I did this like 4 time, (I was at M666 X4.8) and I was still touching the bed at 1.2.

So I tried M500 and a reload... same thing.

It seems to be the same thing with the "M666 Hxxx". I was scraping the tape, so I removed some height and it was still scraping it... like it dosent use those? I Even tried "M666 H100" to see what would happen... and notthing. My max height is like 238.3 and I setted 240 into the firmware. Tried the same thing after a M502, M500 and reset of the printer.

What I was doing wrong? I'm lost.

I'm auto calibrating right now with the "G30 A", I'll tried to see if it does a better calibration than me!

Check your EEPROM is enabled in the firmware

Edited 1 time(s). Last edit at 08/16/2014 01:51PM by AndyCart.

|

Re: Cherry Pi III Is Available August 16, 2014 02:02PM |

Registered: 9 years ago Posts: 113 |

yeah, it is... (#define EEPROM_SETTINGS). The settings are staying saved and I see them when I reload the printer, but it just dosent seems to listen to the adjustment I'm making using M666.

I'll wait till the end of Auto-Calibration and make some more test. I was just wondering if you had an idea since I have about 1h of "free time" waiting for the calibration! :p

btw, thanks for the tips about the stepper, I had those ajusted too hight, now it's working fine and no heat!

Edited 1 time(s). Last edit at 08/16/2014 02:03PM by nka.

- Sebastien Plante (nka)

I'll wait till the end of Auto-Calibration and make some more test. I was just wondering if you had an idea since I have about 1h of "free time" waiting for the calibration! :p

btw, thanks for the tips about the stepper, I had those ajusted too hight, now it's working fine and no heat!

Edited 1 time(s). Last edit at 08/16/2014 02:03PM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 16, 2014 02:33PM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available August 16, 2014 04:49PM |

Registered: 10 years ago Posts: 515 |

|

Re: Cherry Pi III Is Available August 16, 2014 04:53PM |

Registered: 9 years ago Posts: 113 |

I was browsing around for stuff to print and I found that... The idea is pretty good. Wonder if we can apply it to the Cherry.

[www.thingiverse.com]

Edited 1 time(s). Last edit at 08/16/2014 08:47PM by nka.

- Sebastien Plante (nka)

[www.thingiverse.com]

Edited 1 time(s). Last edit at 08/16/2014 08:47PM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 16, 2014 08:44PM |

Registered: 10 years ago Posts: 903 |

This is more or less what I am using:

http://www.thingiverse.com/thing:36813

My belt isn't continuous, so the yellow cable ties that they used in the picture above are on each end of the belt.

If I ever design my own carriages, it will probably incorporate something like this to pull one end of the belt:

http://www.thingiverse.com/thing:26361

http://www.thingiverse.com/thing:164339

http://www.thingiverse.com/thing:36813

My belt isn't continuous, so the yellow cable ties that they used in the picture above are on each end of the belt.

If I ever design my own carriages, it will probably incorporate something like this to pull one end of the belt:

http://www.thingiverse.com/thing:26361

http://www.thingiverse.com/thing:164339

|

Re: Cherry Pi III Is Available August 16, 2014 08:48PM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available August 17, 2014 01:46PM |

Registered: 10 years ago Posts: 903 |

Quote

maso

[attachment 36189 fanfit.jpg]

I can also confirm that the fan will work when it's that close to the magnet. Spins like a dream!

I am using 1/2 inch (12.7mm) spherical magnets, and just discovered that my E3Dv5 fan motor does *not* spin without a manual nudge with my finger to get it rotating. Even then, it only seems to be spinning at quarter of the speed it normally would.

Me thinks it's time to look at the non-magnetic setup again.....

|

Re: Cherry Pi III Is Available August 17, 2014 05:15PM |

Registered: 10 years ago Posts: 515 |

Quote

vreihen

Quote

maso

[attachment 36189 fanfit.jpg]

I can also confirm that the fan will work when it's that close to the magnet. Spins like a dream!

I am using 1/2 inch (12.7mm) spherical magnets, and just discovered that my E3Dv5 fan motor does *not* spin without a manual nudge with my finger to get it rotating. Even then, it only seems to be spinning at quarter of the speed it normally would.

Me thinks it's time to look at the non-magnetic setup again.....

Hi Arthur

If you rotate the magnets you will find a 'sweet spot' where they don't cause this issue. I had the same problem on the original Cherry Pi.

Andy

|

Re: Cherry Pi III Is Available August 18, 2014 10:08AM |

Registered: 9 years ago Posts: 113 |

So I have about 20 hours of print now, I can say it's working fine. I managed to fix most of the problems I found.

I also did a 8 hours non-stop printing as a stress test to the printer. Everything when fine, except I notice those :

- The belt are slipping. No mather how hard I tight them, the belt+screw will turn and they will loose. I noticed that since at about the end of the print, I saw that there was some wierd move when changing direction. At the end of the print, I checked the belt and they were loose. At first, I was thinking it was just "normal", belt get extension... but then I notice that on the top, my "U" was now pretty small... almost out.

-- I'll try to add something to "squeeze" them more. But I'm also thinking of another design, so they dont slip and also a belt tensioner would be nice. This is pretty nice ( [www.thingiverse.com] ), but I'm not sure it would be working since we need to move it on the other side, might not be as solid... dont know.

- Dont thight the spring too much, dosent need that much force and will eat the plastic if you do (not that bad, but it does).

- Try to align the miniwheel so they fit prefectly into the extrusion slow. I had one not straight and the will got eated by the extrusion (But still functionnal).

- Sebastien Plante (nka)

I also did a 8 hours non-stop printing as a stress test to the printer. Everything when fine, except I notice those :

- The belt are slipping. No mather how hard I tight them, the belt+screw will turn and they will loose. I noticed that since at about the end of the print, I saw that there was some wierd move when changing direction. At the end of the print, I checked the belt and they were loose. At first, I was thinking it was just "normal", belt get extension... but then I notice that on the top, my "U" was now pretty small... almost out.

-- I'll try to add something to "squeeze" them more. But I'm also thinking of another design, so they dont slip and also a belt tensioner would be nice. This is pretty nice ( [www.thingiverse.com] ), but I'm not sure it would be working since we need to move it on the other side, might not be as solid... dont know.

- Dont thight the spring too much, dosent need that much force and will eat the plastic if you do (not that bad, but it does).

- Try to align the miniwheel so they fit prefectly into the extrusion slow. I had one not straight and the will got eated by the extrusion (But still functionnal).

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 18, 2014 10:16AM |

Registered: 10 years ago Posts: 515 |

Quote

nka

So I have about 20 hours of print now, I can say it's working fine. I managed to fix most of the problems I found.

I also did a 8 hours non-stop printing as a stress test to the printer. Everything when fine, except I notice those :

- The belt are slipping. No mather how hard I tight them, the belt+screw will turn and they will loose. I noticed that since at about the end of the print, I saw that there was some wierd move when changing direction. At the end of the print, I checked the belt and they were loose. At first, I was thinking it was just "normal", belt get extension... but then I notice that on the top, my "U" was now pretty small... almost out.

-- I'll try to add something to "squeeze" them more. But I'm also thinking of another design, so they dont slip and also a belt tensioner would be nice. This is pretty nice ( [www.thingiverse.com] ), but I'm not sure it would be working since we need to move it on the other side, might not be as solid... dont know.

- Dont thight the spring too much, dosent need that much force and will eat the plastic if you do (not that bad, but it does).

- Try to align the miniwheel so they fit prefectly into the extrusion slow. I had one not straight and the will got eated by the extrusion (But still functionnal).

Hi Sebastien

I think you must have your belts the wrong way round in the 'loop' they should be tooth to tooth. It's impossible for them to slip! The screw is just there to make the loop big enough that it won't pull back through the channel. I used a screw because it looks better. I used to use a short piece of filament. You really shouldn't need a belt tensioner. Get them as tight as you can with the steppers at the top of their slots and then push the steppers down to fully tighten. My steppers are 1/2 way down the slot giving some more adjustment in the future if required without resorting to re doing the belt connections on the carriages. You are correct that the mini-wheels have to be square and true. I prefer the springs that hold the rods to be tight. A smear of silicone grease stops any wear.

Andy

Edited 1 time(s). Last edit at 08/18/2014 10:17AM by AndyCart.

|

Re: Cherry Pi III Is Available August 18, 2014 10:41AM |

Registered: 9 years ago Posts: 113 |

They are tooth to tooth, but I think they are not tight enough into the "slot". The lower one seems be okay, but not the upper one. If I pull very hard, I see them slip (even if the bolt is tight). I think that adding something to squeeze them more will help prevent the slip. As for the best tensioner. It's just becose it's easier than unscrewing the stepper!  I'll also use a spring like this ( [cdn1.bigcommerce.com] ) to keep the tension and still allow some play.

I'll also use a spring like this ( [cdn1.bigcommerce.com] ) to keep the tension and still allow some play.

The spring is tight, but not "too tight". Before, I had to push the effector for like 5cm to get the rods in. Now I push only about 2cm, it's tight, but not too much. I over did it the first time I think. I'll add some silicone grease! I was thinking of it, but wasnt sure about it... thanks!

- Sebastien Plante (nka)

I'll also use a spring like this ( [cdn1.bigcommerce.com] ) to keep the tension and still allow some play.

I'll also use a spring like this ( [cdn1.bigcommerce.com] ) to keep the tension and still allow some play.The spring is tight, but not "too tight". Before, I had to push the effector for like 5cm to get the rods in. Now I push only about 2cm, it's tight, but not too much. I over did it the first time I think. I'll add some silicone grease! I was thinking of it, but wasnt sure about it... thanks!

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 18, 2014 08:18PM |

Registered: 10 years ago Posts: 903 |

I like that tensioner for a new carriage design. Regarding the belts going slack, I noticed that my second printer's belts were stretching on the first few prints. It may just be normal with some belt material. My first printer's belt material came from Open Builds, and it didn't seem to stretch nearly as much. I have no idea if one or both have kevlar or other reinforcements.

I pried the hotend fan off yesterday, and re-glued it about 3mm above the effector plate. A little blue tape to fill the gap at the base, and it is now turning much faster. With all of the problems I have been having with getting magnets to stick, I did not want to break it free after getting it to stick looking for the sweet spot where it didn't interfere with the fan motor.....

I pried the hotend fan off yesterday, and re-glued it about 3mm above the effector plate. A little blue tape to fill the gap at the base, and it is now turning much faster. With all of the problems I have been having with getting magnets to stick, I did not want to break it free after getting it to stick looking for the sweet spot where it didn't interfere with the fan motor.....

|

Re: Cherry Pi III Is Available August 19, 2014 02:33PM |

Registered: 12 years ago Posts: 11 |

Quote

nka

They are tooth to tooth, but I think they are not tight enough into the "slot". The lower one seems be okay, but not the upper one. If I pull very hard, I see them slip (even if the bolt is tight). I think that adding something to squeeze them more will help prevent the slip. As for the best tensioner. It's just becose it's easier than unscrewing the stepper!I'll also use a spring like this ( [cdn1.bigcommerce.com] ) to keep the tension and still allow some play.

The spring is tight, but not "too tight". Before, I had to push the effector for like 5cm to get the rods in. Now I push only about 2cm, it's tight, but not too much. I over did it the first time I think. I'll add some silicone grease! I was thinking of it, but wasnt sure about it... thanks!

I found that the slots in the carrier where a little to wide for my belts and had issues with mine slipping to.

I modified them to reduce the gap and reprinted and they have been fine up till now.

Got my belts from china and I don't think all belts are the same quality.

Edited 2 time(s). Last edit at 08/19/2014 02:36PM by KtB.

|

Re: Cherry Pi III Is Available August 19, 2014 02:41PM |

Registered: 9 years ago Posts: 113 |

Awww... must be that. Mine came from AliExpress, might be cheap. I should have ordered those from Openbuild at the same time of the mini wheel.

btw, I fixed the problem, I just placed a small paper clip part between them !

I just have to figure out one problem. Sometime, I have wierd stuff on my print. Like there's a "hole" on a section, like if the extrusion stopped at this place or did the layer too low or too high...

I also have miss alignement at some place, it sound like it's when the layer begin, maybe the nozzle "kick" a little too far. Maybe my belt suck and I have backlasth (I dont know how to spell that?).

- Sebastien Plante (nka)

btw, I fixed the problem, I just placed a small paper clip part between them !

I just have to figure out one problem. Sometime, I have wierd stuff on my print. Like there's a "hole" on a section, like if the extrusion stopped at this place or did the layer too low or too high...

I also have miss alignement at some place, it sound like it's when the layer begin, maybe the nozzle "kick" a little too far. Maybe my belt suck and I have backlasth (I dont know how to spell that?).

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available August 20, 2014 01:59AM |

Registered: 10 years ago Posts: 515 |

Definitely must be various thicknesses of GT2 belt. My belts need to be forced into the slot on the rod carrier. To the point where the machine will operate ok without the screw in the belt loop. The teeth on each side of the loop mesh tightly together, hence my comment that it is impossible for them to slip. I didn't realise some belts were thinner. I got mine from AliExpress too, but they weren't the cheapest Chinese supplier. I've had several deliveries from them now and quality has been consistent

Sorry, only registered users may post in this forum.