Cherry Pi III Is Available

Posted by AndyCart

|

Re: Cherry Pi III Is Available November 02, 2014 06:15AM |

Registered: 10 years ago Posts: 903 |

The COM port name is what Windows calls the serial port in your PC. Whatever you were reading in the code 'serial port 1' is how the card's firmware references the serial port on your Mega 2560 board. Try setting the port on Windows back to COM3, which is the same port that you used to flash the firmware.

If all else fails, go back into the Arduino software and load the serial monitor. At the bottom of the window is a pick list for line terminators. I don't have a Windows computer handy to verify, but you need to change this to one of the other options. Type M119 and push [ENTER] or click on send. Keep changing the option until you get a response showing your endstop settings. Having verified the COM port settings using this tool, go back to debugging your host software du jour.....

If all else fails, go back into the Arduino software and load the serial monitor. At the bottom of the window is a pick list for line terminators. I don't have a Windows computer handy to verify, but you need to change this to one of the other options. Type M119 and push [ENTER] or click on send. Keep changing the option until you get a response showing your endstop settings. Having verified the COM port settings using this tool, go back to debugging your host software du jour.....

|

Re: Cherry Pi III Is Available November 02, 2014 06:36AM |

Registered: 9 years ago Posts: 164 |

Just tried everything again, from start to finish, for COM1, COM3 and COM5, with baud rate of 9600 and 115200 (so six complete attempts with those settings at the Windows level, Arduino IDE level and Repetier/Pronterface/Matter Control level). I've been changing the device name each time as well to make verify that the Arduino IDE write is working, and it's not failing at all. So far device names have included "My anus is" and "Something is" in an attempt to maintain humour.

But alas, no luck.

vreihen, I did try your suggestions, but I'm just getting no feedback at all from the serial monitor.

But alas, no luck.

vreihen, I did try your suggestions, but I'm just getting no feedback at all from the serial monitor.

|

Re: Cherry Pi III Is Available November 02, 2014 07:15AM |

Registered: 9 years ago Posts: 164 |

Okay, I've had some success! It's beeping and making noise and doing stuff, and there's comms coming back in Repetier! A very helpful forum member sent me a copy of his configuration.h and it worked first go. So, I highly recommend not using the config.h that's earlier in this thread.

.... next issue is that it's killing itself about 3 seconds into calibration hahaha. There's a fairly high whine like a motor is trying to work but it's not actually doing anything... Any ideas? Maybe I should check the wiring of my steppers. Is there a cheat sheet anyone has found super useful with quick commands I can shoot my printer to try and narrow down my troubleshooting? Or furthermore, know where I could get a reason why the kill() was executed? If not, I'll start troubleshooting tomorrow, but for now it's bed time.

EDIT: Because I couldn't leave it at that, I had to try the same command (G30 A) in Pronterface. It told me that the endstops were hit? Hmm. Maybe the steppers are fine, the end stops aren't... Always was going to be one of those two!

Edited 1 time(s). Last edit at 11/02/2014 07:20AM by pugzor.

.... next issue is that it's killing itself about 3 seconds into calibration hahaha. There's a fairly high whine like a motor is trying to work but it's not actually doing anything... Any ideas? Maybe I should check the wiring of my steppers. Is there a cheat sheet anyone has found super useful with quick commands I can shoot my printer to try and narrow down my troubleshooting? Or furthermore, know where I could get a reason why the kill() was executed? If not, I'll start troubleshooting tomorrow, but for now it's bed time.

EDIT: Because I couldn't leave it at that, I had to try the same command (G30 A) in Pronterface. It told me that the endstops were hit? Hmm. Maybe the steppers are fine, the end stops aren't... Always was going to be one of those two!

Edited 1 time(s). Last edit at 11/02/2014 07:20AM by pugzor.

|

Re: Cherry Pi III Is Available November 02, 2014 07:18AM |

Registered: 10 years ago Posts: 515 |

My understanding is that you can connect to your Arduino from the Arduino IDE using a particular baud rate and COM port and you can successfully upload the firmware? If this is the case then you HAVE to use the same COM port and baud rate for everything else. Have you tried a different USB lead. I know it sounds daft but some work and some don't!

|

Re: Cherry Pi III Is Available November 02, 2014 07:25AM |

Registered: 9 years ago Posts: 164 |

Haha, it's not daft, I did do that step! Fortunately I found a longer (more conveniently sized) cable.Quote

AndyCart

My understanding is that you can connect to your Arduino from the Arduino IDE using a particular baud rate and COM port and you can successfully upload the firmware? If this is the case then you HAVE to use the same COM port and baud rate for everything else. Have you tried a different USB lead. I know it sounds daft but some work and some don't!

But yeah, I found that the upload of firmware wasn't actually too fussed about which COM port and baud rate. Maybe some smarts in Win 8.1 or something? Who knows. I'm just happy that I'm pressing [ENTER] and something is happening now mechanically... even if it's failing haha.

|

Re: Cherry Pi III Is Available November 02, 2014 09:22AM |

Registered: 9 years ago Posts: 113 |

There's no Baud Rate into the IDE. Sadly, my Arduino is far from my computer, so I can't show you EXACTLY, but I'll try to help you the most I can.

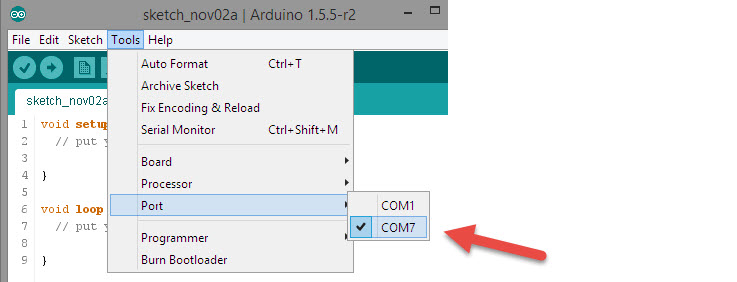

If you open the Marlin.ino for the Arduino, look at the COM port that allow you to flash the firmware sucessfully

(Board shoud also be set to Mega 2560)

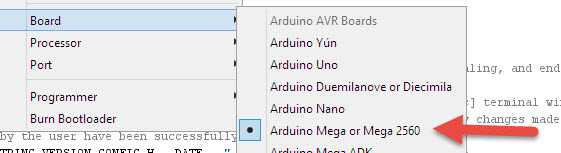

Then, open the tab "configuration.h" and make sure "Serial" is "0" and then look into the BAUD RATE

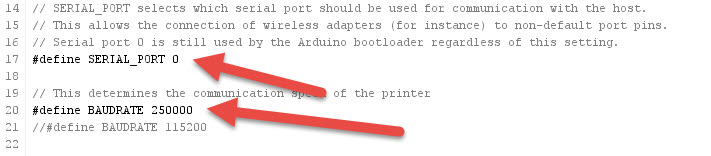

You'll have to use the same COM and Baud Rate into the hose (Repetier into this picture)

When it's done, "connect" to the printer and go into the terminal and send a M119 command to get the endstop status (you should only see four of them (x max, y max, z max, z min), if you see more of them, you need to disable them into the configuration.h). Then press each endstop one by one to make sure they work. They should be "TRIGGERED" only when you engage them. If they are TRIGGERED and go "OPEN" when you touch them, you'll have to reverse them into the "configuration.h" (search for #define ENDSTOPPULLUPS).

Then, send a G28. If the printer make noise but dosent move, you'll have to ajust the pot on the motor driver.

Edited 1 time(s). Last edit at 11/02/2014 09:23AM by nka.

- Sebastien Plante (nka)

If you open the Marlin.ino for the Arduino, look at the COM port that allow you to flash the firmware sucessfully

(Board shoud also be set to Mega 2560)

Then, open the tab "configuration.h" and make sure "Serial" is "0" and then look into the BAUD RATE

You'll have to use the same COM and Baud Rate into the hose (Repetier into this picture)

When it's done, "connect" to the printer and go into the terminal and send a M119 command to get the endstop status (you should only see four of them (x max, y max, z max, z min), if you see more of them, you need to disable them into the configuration.h). Then press each endstop one by one to make sure they work. They should be "TRIGGERED" only when you engage them. If they are TRIGGERED and go "OPEN" when you touch them, you'll have to reverse them into the "configuration.h" (search for #define ENDSTOPPULLUPS).

Then, send a G28. If the printer make noise but dosent move, you'll have to ajust the pot on the motor driver.

Edited 1 time(s). Last edit at 11/02/2014 09:23AM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available November 02, 2014 11:14AM |

Registered: 10 years ago Posts: 515 |

|

Re: Cherry Pi III Is Available November 03, 2014 05:44AM |

Registered: 9 years ago Posts: 164 |

Woo hoo, more noise and stuff! Unfortunately that's the extent of my success lol. It didn't go for the kill() after I inverted the endstops (thanks Sebastian) however it didn't move a whole lot. I issued a G28 and the motors were kind of jerky and didn't move much... maybe a step up and down? I don't know. Nothing's caught fire yet which is a positive. I'm just not sure on what the next step is...

|

Re: Cherry Pi III Is Available November 03, 2014 06:33AM |

Registered: 10 years ago Posts: 903 |

|

Re: Cherry Pi III Is Available November 03, 2014 07:14AM |

Registered: 9 years ago Posts: 164 |

|

Re: Cherry Pi III Is Available November 03, 2014 08:22AM |

Registered: 9 years ago Posts: 113 |

Your almost there. After that, you'll be able to print (if you're in a hurry), but you'll also need to do a calibration. As Andy said, trigger a "G30 A" and then fine tune with M666 ( [www.youtube.com] )

Edited 1 time(s). Last edit at 11/03/2014 08:22AM by nka.

- Sebastien Plante (nka)

Edited 1 time(s). Last edit at 11/03/2014 08:22AM by nka.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available November 04, 2014 02:19AM |

Registered: 10 years ago Posts: 515 |

Hi Andrew

You're nearly there. In terms of checking your stepper connections. I usually make a small 'U' of single core cable and insert it into first the left hand pair of holes in the stepper plug and then the right hand. In each case I move the corresponding carriage by hand (x front left, y front right, z rear). If the wiring is correct you will feel much more resistance to movement with the wire inserted than you do without it. This confirms the pairs are correct too. Always power down before you remove or plug in steppers or you will fry your stepper drivers.

Good luck

Andy

You're nearly there. In terms of checking your stepper connections. I usually make a small 'U' of single core cable and insert it into first the left hand pair of holes in the stepper plug and then the right hand. In each case I move the corresponding carriage by hand (x front left, y front right, z rear). If the wiring is correct you will feel much more resistance to movement with the wire inserted than you do without it. This confirms the pairs are correct too. Always power down before you remove or plug in steppers or you will fry your stepper drivers.

Good luck

Andy

|

Re: Cherry Pi III Is Available November 04, 2014 02:41AM |

Registered: 9 years ago Posts: 164 |

Thanks for the support guys.

Yep, I'm going to check my stepper connections again. Some of my earlier crimps were of questionable quality so that could be an issue for sure. Fortunately I got a bucket load of receptacles and housings off eBay so that's not an issue.

My X tower stepper did work well though; it was super cool see it run to the end stop and stop on a dime. The Y tower %$#^'d up though so I'll put a new receptacle on it tonight and give it another crack.

Out of interest, what's usually the best way to "fine tune" after an automagic calibration has been done? How do you know if a calibration is good or bad?

Already getting excited about the prospect of a 4XL Andy, haha, but I need to get the base system working first!

Yep, I'm going to check my stepper connections again. Some of my earlier crimps were of questionable quality so that could be an issue for sure. Fortunately I got a bucket load of receptacles and housings off eBay so that's not an issue.

My X tower stepper did work well though; it was super cool see it run to the end stop and stop on a dime. The Y tower %$#^'d up though so I'll put a new receptacle on it tonight and give it another crack.

Out of interest, what's usually the best way to "fine tune" after an automagic calibration has been done? How do you know if a calibration is good or bad?

Already getting excited about the prospect of a 4XL Andy, haha, but I need to get the base system working first!

|

Re: Cherry Pi III Is Available November 04, 2014 08:16AM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available November 05, 2014 07:27AM |

Registered: 9 years ago Posts: 164 |

And now, I shall express my current feelings through the medium of image.

|

Re: Cherry Pi III Is Available November 05, 2014 08:20AM |

Registered: 9 years ago Posts: 113 |

woah, that's a chair with 3 legs !

What is not working? Did you ajust the pot on the stepper driver? You need to turn the screw.

I found this video [youtu.be] or this page (step 16) [www.instructables.com]

- Sebastien Plante (nka)

What is not working? Did you ajust the pot on the stepper driver? You need to turn the screw.

I found this video [youtu.be] or this page (step 16) [www.instructables.com]

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available November 05, 2014 05:30PM |

Registered: 9 years ago Posts: 164 |

I know right! Maybe that's where I'm going wrong... maybe I need a chair with 4 legs?

Haven't tuned the steppers (will give that a go next) but I rewired all my stepper plugs that go to the board... was super careful to make sure all the receptacles pop into their sockets nicely... and was rewarded with carbon fibre arms flying around the room! Haha.

I bet it is the stepper drivers actually. You can hear them getting power and attempting to move but it's like they don't have quite enough to shift. Just a bit frustrating is all.

Haven't tuned the steppers (will give that a go next) but I rewired all my stepper plugs that go to the board... was super careful to make sure all the receptacles pop into their sockets nicely... and was rewarded with carbon fibre arms flying around the room! Haha.

I bet it is the stepper drivers actually. You can hear them getting power and attempting to move but it's like they don't have quite enough to shift. Just a bit frustrating is all.

|

Re: Cherry Pi III Is Available November 05, 2014 05:53PM |

Registered: 10 years ago Posts: 515 |

Just going back to basics. How many jumpers have you got under the stepper drivers and what type of drivers are they? What's your steps per mm setting for X Y Z in Marlin? I've built about 20 printers now all with RAMPS and 4988 drivers. I've always started with the driver pots centred and never had an issue. I normally wind them back to about '10 minutes to 12' during commissioning. Never resorted to a meter. If the steppers are quiet and the drivers cool and the machine doesn't miss steps during a print they are fine

|

Re: Cherry Pi III Is Available November 05, 2014 06:48PM |

Registered: 9 years ago Posts: 113 |

you said that one was moving. You can try to connect the others stepper to this driver to see if they move. If it's the case, then, you know the cabling is okay.

as Andy said, I do mine without the multimeter. I just turn them until the move freely. I apply a little pressure on them to see if they are okay, if yes, I move to the next one. If you push it too much, it will work, but they will also generate more heat.

- Sebastien Plante (nka)

as Andy said, I do mine without the multimeter. I just turn them until the move freely. I apply a little pressure on them to see if they are okay, if yes, I move to the next one. If you push it too much, it will work, but they will also generate more heat.

- Sebastien Plante (nka)

|

Re: Cherry Pi III Is Available November 06, 2014 09:48AM |

Registered: 10 years ago Posts: 903 |

|

Re: Cherry Pi III Is Available November 06, 2014 10:21AM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available November 07, 2014 06:50AM |

Registered: 9 years ago Posts: 164 |

Quote

vreihen

Quote

nka

woah, that's a chair with 3 legs !

It's a DELTA chair!!!!!

Nice.

Quote

AndyCart

Just going back to basics. How many jumpers have you got under the stepper drivers and what type of drivers are they? What's your steps per mm setting for X Y Z in Marlin? I've built about 20 printers now all with RAMPS and 4988 drivers. I've always started with the driver pots centred and never had an issue. I normally wind them back to about '10 minutes to 12' during commissioning. Never resorted to a meter. If the steppers are quiet and the drivers cool and the machine doesn't miss steps during a print they are fine

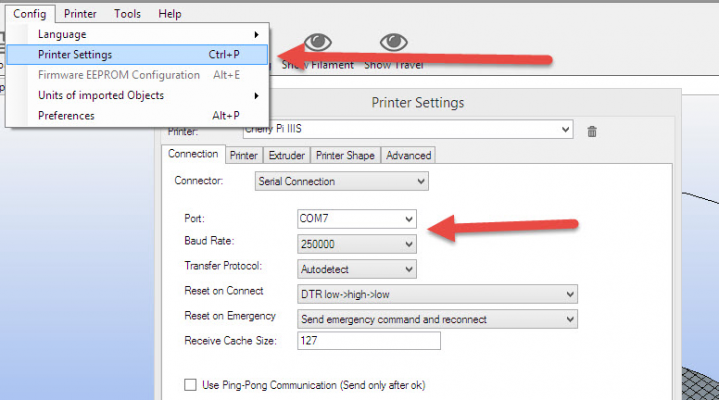

I used the exact same AliExpress kit that you linked me to, so I'm hoping I have the same kind of success you did! Here's my config.h.

#ifndef CONFIGURATION_H

#define CONFIGURATION_H

// This configuration file contains the basic settings.

// Advanced settings can be found in Configuration_adv.h

// BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration

// User-specified version info of this build to display in [Pronterface, etc] terminal window during

// startup. Implementation of an idea by Prof Braino to inform user that any changes made to this

// build by the user have been successfully uploaded into firmware.

#define STRING_VERSION_CONFIG_H __DATE__ " " __TIME__ // build date and time

#define STRING_CONFIG_H_AUTHOR "(Andy D, Awesomeness)" // Who made the changes.

// SERIAL_PORT selects which serial port should be used for communication with the host.

// This allows the connection of wireless adapters (for instance) to non-default port pins.

// Serial port 0 is still used by the Arduino bootloader regardless of this setting.

#define SERIAL_PORT 0

// This determines the communication speed of the printer

//#define BAUDRATE 250000

#define BAUDRATE 115200

//// The following define selects which electronics board you have. Please choose the one that matches your setup

// 10 = Gen7 custom (Alfons3 Version) "https://github.com/Alfons3/Generation_7_Electronics"

// 11 = Gen7 v1.1, v1.2 = 11

// 12 = Gen7 v1.3

// 13 = Gen7 v1.4

// 3 = MEGA/RAMPS up to 1.2 = 3

// 33 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Bed)

// 34 = RAMPS 1.3 / 1.4 (Power outputs: Extruder0, Extruder1, Bed)

// 35 = RAMPS 1.3 / 1.4 (Power outputs: Extruder, Fan, Fan)

// 4 = Duemilanove w/ ATMega328P pin assignment

// 5 = Gen6

// 51 = Gen6 deluxe

// 6 = Sanguinololu < 1.2

// 62 = Sanguinololu 1.2 and above

// 63 = Melzi

// 64 = STB V1.1

// 65 = Azteeg X1

// 66 = Melzi with ATmega1284 (MaKr3d version)

// 7 = Ultimaker

// 71 = Ultimaker (Older electronics. Pre 1.5.4. This is rare)

// 77 = 3Drag Controller

// 8 = Teensylu

// 80 = Rumba

// 81 = Printrboard (AT90USB1286)

// 82 = Brainwave (AT90USB646)

// 9 = Gen3+

// 70 = Megatronics

// 701= Megatronics v2.0

// 702= Minitronics v1.0

// 90 = Alpha OMCA board

// 91 = Final OMCA board

// 301 = Rambo

// 21 = Elefu Ra Board (v3)

#ifndef MOTHERBOARD

#define MOTHERBOARD 33

#endif

// Define this to set a custom name for your generic Mendel,

#define CUSTOM_MENDEL_NAME "My Anus is"

// This defines the number of extruders

#define EXTRUDERS 1

//// The following define selects which power supply you have. Please choose the one that matches your setup

// 1 = ATX

// 2 = X-Box 360 203Watts (the blue wire connected to PS_ON and the red wire to VCC)

#define POWER_SUPPLY 1

//===========================================================================

//============================== Delta Settings =============================

//===========================================================================

// Enable DELTA kinematics

#define DELTA

// Make delta curves from many straight lines (linear interpolation).

// This is a trade-off between visible corners (not enough segments)

// and processor overload (too many expensive sqrt calls).

#define DELTA_SEGMENTS_PER_SECOND 200

// Center-to-center distance of the holes in the diagonal push rods.

#define DEFAULT_DELTA_DIAGONAL_ROD 232.11 // mm

// Horizontal offset from middle of printer to smooth rod center.

#define DELTA_SMOOTH_ROD_OFFSET 190.8 // mm //158

// Horizontal offset of the universal joints on the end effector.

#define DELTA_EFFECTOR_OFFSET 37 // mm

// Horizontal offset of the universal joints on the carriages.

#define DELTA_CARRIAGE_OFFSET 35 // mm

// Effective horizontal distance bridged by diagonal push rods.

#define DEFAULT_DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET)

//Uncomment to enable autocalibration debug messages

//#define DEBUG_MESSAGES

// Precision for G30 delta autocalibration function

#define AUTOCALIBRATION_PRECISION 0.03 // mm

// Diameter of print bed - this is used to set the distance that autocalibration probes the bed at.

#define BED_DIAMETER 200 // mm

// Z-Probe variables

// Start and end location values are used to deploy/retract the probe (will move from start to end and back again)

#define PROBING_FEEDRATE 100/10*60 // Speed for individual probe Use: G30 A F600

#define Z_PROBE_OFFSET {0, 0, 0.8, 0} // X, Y, Z, E distance between hotend nozzle and deployed bed leveling probe.

#define Z_PROBE_DEPLOY_START_LOCATION {0, 0, 20, 0} // X, Y, Z, E start location for z-probe deployment sequence

#define Z_PROBE_DEPLOY_END_LOCATION {0, 0, 20, 0} // X, Y, Z, E end location for z-probe deployment sequence

#define Z_PROBE_RETRACT_START_LOCATION {0, 0, 20, 0} // X, Y, Z, E start location for z-probe retract sequence

#define Z_PROBE_RETRACT_END_LOCATION {0, 0, 20, 0} // X, Y, Z, E end location for z-probe retract sequence

#define AUTOLEVEL_GRID 24 // Distance between autolevel Z probing points, should be less than print surface radius/3.

//===========================================================================

//=============================Thermal Settings ============================

//===========================================================================

//

//--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table

//

//// Temperature sensor settings:

// -2 is thermocouple with MAX6675 (only for sensor 0)

// -1 is thermocouple with AD595

// 0 is not used

// 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup)

// 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup)

// 3 is mendel-parts thermistor (4.7k pullup)

// 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !!

// 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup)

// 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup)

// 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup)

// 71 is 100k Honeywell thermistor 135-104LAF-J01 (4.7k pullup)

// 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup)

// 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup)

// 10 is 100k RS thermistor 198-961 (4.7k pullup)

// 60 is 100k Maker's Tool Works Kapton Bed Thermister

//

// 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k

// (but gives greater accuracy and more stable PID)

// 51 is 100k thermistor - EPCOS (1k pullup)

// 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup)

// 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup)

#define TEMP_SENSOR_0 1

#define TEMP_SENSOR_1 0

#define TEMP_SENSOR_2 0

#define TEMP_SENSOR_BED 0

// This makes temp sensor 1 a redundant sensor for sensor 0. If the temperatures difference between these sensors is to high the print will be aborted.

//#define TEMP_SENSOR_1_AS_REDUNDANT

#define MAX_REDUNDANT_TEMP_SENSOR_DIFF 10

// Actual temperature must be close to target for this long before M109 returns success

#define TEMP_RESIDENCY_TIME 10 // (seconds)

#define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one

#define TEMP_WINDOW 1 // (degC) Window around target to start the residency timer x degC early.

// The minimal temperature defines the temperature below which the heater will not be enabled It is used

// to check that the wiring to the thermistor is not broken.

// Otherwise this would lead to the heater being powered on all the time.

#define HEATER_0_MINTEMP 5

#define HEATER_1_MINTEMP 5

#define HEATER_2_MINTEMP 5

#define BED_MINTEMP 5

// When temperature exceeds max temp, your heater will be switched off.

// This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure!

// You should use MINTEMP for thermistor short/failure protection.

#define HEATER_0_MAXTEMP 275

#define HEATER_1_MAXTEMP 275

#define HEATER_2_MAXTEMP 275

#define BED_MAXTEMP 150

// If your bed has low resistance e.g. .6 ohm and throws the fuse you can duty cycle it to reduce the

// average current. The value should be an integer and the heat bed will be turned on for 1 interval of

// HEATER_BED_DUTY_CYCLE_DIVIDER intervals.

//#define HEATER_BED_DUTY_CYCLE_DIVIDER 4

// PID settings:

// Comment the following line to disable PID and enable bang-bang.

#define PIDTEMP

#define BANG_MAX 255 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX 255 // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

//#define PID_DEBUG // Sends debug data to the serial port.

//#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX

#define PID_FUNCTIONAL_RANGE 10 // If the temperature difference between the target temperature and the actual temperature

// is more then PID_FUNCTIONAL_RANGE then the PID will be shut off and the heater will be set to min/max.

#define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term

#define K1 0.95 //smoothing factor within the PID

#define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the temperature routine

// If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it

// J-Head with 12v 40W heater cartridge

#define DEFAULT_Kp 26.82

#define DEFAULT_Ki 1.66

#define DEFAULT_Kd 108.54

// Makergear

// #define DEFAULT_Kp 7.0

// #define DEFAULT_Ki 0.1

// #define DEFAULT_Kd 12

// Mendel Parts V9 on 12V

// #define DEFAULT_Kp 63.0

// #define DEFAULT_Ki 2.25

// #define DEFAULT_Kd 440

#endif // PIDTEMP

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// Uncomment this to enable PID on the bed. It uses the same frequency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you probably

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

//#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delivered to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, aggressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 10.00

#define DEFAULT_bedKi .023

#define DEFAULT_bedKd 305.4

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

//this prevents dangerous Extruder moves, i.e. if the temperature is under the limit

//can be software-disabled for whatever purposes by

#define PREVENT_DANGEROUS_EXTRUDE

//if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately.

#define PREVENT_LENGTHY_EXTRUDE

#define EXTRUDE_MINTEMP 170

#define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances.

//===========================================================================

//=============================Mechanical Settings===========================

//===========================================================================

// Uncomment the following line to enable CoreXY kinematics

// #define COREXY

// coarse Endstop Settings

#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors

#ifndef ENDSTOPPULLUPS

// fine Enstop settings: Individual Pullups. will be ignored if ENDSTOPPULLUPS is defined

// #define ENDSTOPPULLUP_XMAX

// #define ENDSTOPPULLUP_YMAX

// #define ENDSTOPPULLUP_ZMAX

// #define ENDSTOPPULLUP_XMIN

// #define ENDSTOPPULLUP_YMIN

// #define ENDSTOPPULLUP_ZMIN

#endif

#ifdef ENDSTOPPULLUPS

#define ENDSTOPPULLUP_XMAX

#define ENDSTOPPULLUP_YMAX

#define ENDSTOPPULLUP_ZMAX

#define ENDSTOPPULLUP_XMIN

#define ENDSTOPPULLUP_YMIN

#define ENDSTOPPULLUP_ZMIN

#endif

// The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins.

const bool X_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Y_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool Z_MIN_ENDSTOP_INVERTING = false; // set to true to invert the logic of the endstop.

const bool X_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Y_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

const bool Z_MAX_ENDSTOP_INVERTING = true; // set to true to invert the logic of the endstop.

//#define DISABLE_MAX_ENDSTOPS

//#define DISABLE_MIN_ENDSTOPS

// Disable max endstops for compatibility with endstop checking routine

#if defined(COREXY) && !defined(DISABLE_MAX_ENDSTOPS)

#define DISABLE_MAX_ENDSTOPS

#endif

// For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1

#define X_ENABLE_ON 0

#define Y_ENABLE_ON 0

#define Z_ENABLE_ON 0

#define E_ENABLE_ON 0 // For all extruders

// Disables axis when it's not being used.

#define DISABLE_X false

#define DISABLE_Y false

#define DISABLE_Z false

#define DISABLE_E false // For all extruders

#define INVERT_X_DIR false // for Mendel set to false, for Orca set to true

#define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false

#define INVERT_Z_DIR false // for Mendel set to false, for Orca set to true

#define INVERT_E0_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

#define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false

// ENDSTOP SETTINGS:

// Sets direction of endstops when homing; 1=MAX, -1=MIN

#define X_HOME_DIR 1

#define Y_HOME_DIR 1

#define Z_HOME_DIR 1

#define min_software_endstops true // If true, axis won't move to coordinates less than HOME_POS.

#define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below.

// Travel limits after homing

#define X_MAX_POS 100

#define X_MIN_POS -100

#define Y_MAX_POS 100

#define Y_MIN_POS -100

#define Z_MAX_POS MANUAL_Z_HOME_POS

#define Z_MIN_POS 0

#define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS)

#define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS)

#define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS)

// The position of the homing switches

#define MANUAL_HOME_POSITIONS // If defined, MANUAL_*_HOME_POS below will be used

#define BED_CENTER_AT_0_0 // If defined, the center of the bed is at (X=0, Y=0)

//Manual homing switch locations:

// For deltabots this means top and center of the cartesian print volume.

#define MANUAL_X_HOME_POS 0

#define MANUAL_Y_HOME_POS 0

#define MANUAL_Z_HOME_POS 251.2 // For delta: Distance between nozzle and print surface after homing.

//// MOVEMENT SETTINGS

#define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E

#define HOMING_FEEDRATE {150*60, 150*60, 150*60, 0} // set the homing speeds (mm/min)

// default settings

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 700}

#define DEFAULT_MAX_FEEDRATE {200, 200, 200, 200} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,9000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for retracts

// Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing).

// The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder).

// For the other hotends it is their distance from the extruder 0 hotend.

// #define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis

// #define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis

// The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously)

#define DEFAULT_XYJERK 20.0 // (mm/sec)

#define DEFAULT_ZJERK 20.0 // (mm/sec)

#define DEFAULT_EJERK 20.0 // (mm/sec)

//===========================================================================

//=============================Additional Features===========================

//===========================================================================

// EEPROM

// the microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores paramters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

//define this to enable eeprom support

#define EEPROM_SETTINGS

//to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out:

// please keep turned on if you can.

#define EEPROM_CHITCHAT

// Preheat Constants

#define PLA_PREHEAT_HOTEND_TEMP 185

#define PLA_PREHEAT_HPB_TEMP 70

#define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

#define ABS_PREHEAT_HOTEND_TEMP 240

#define ABS_PREHEAT_HPB_TEMP 100

#define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255

//LCD and SD support

//#define ULTRA_LCD //general lcd support, also 16x2

//#define DOGLCD // Support for SPI LCD 128x64 (Controller ST7565R graphic Display Family)

//#define SDSUPPORT // Enable SD Card Support in Hardware Console

//#define SDSLOW // Use slower SD transfer mode (not normally needed - uncomment if you're getting volume init error)

//#define ULTIMAKERCONTROLLER //as available from the ultimaker online store.

//#define ULTIPANEL //the ultipanel as on thingiverse

// The MaKr3d Makr-Panel with graphic controller and SD support

// [reprap.org]

//#define MAKRPANEL

// The RepRapDiscount Smart Controller (white PC // [reprap.org]

#define REPRAP_DISCOUNT_SMART_CONTROLLER

// The GADGETS3D G3D LCD/SD Controller (blue PC

// [reprap.org]

#define REPRAP_DISCOUNT_SMART_CONTROLLER

// The GADGETS3D G3D LCD/SD Controller (blue PC // [reprap.org]

//#define G3D_PANEL

// The RepRapDiscount FULL GRAPHIC Smart Controller (quadratic white PC

// [reprap.org]

//#define G3D_PANEL

// The RepRapDiscount FULL GRAPHIC Smart Controller (quadratic white PC // [reprap.org]

//

// ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [code.google.com]

//#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

// The RepRapWorld REPRAPWORLD_KEYPAD v1.1

// [reprapworld.com]

//#define REPRAPWORLD_KEYPAD

//#define REPRAPWORLD_KEYPAD_MOVE_STEP 10.0 // how much should be moved when a key is pressed, eg 10.0 means 10mm per click

// The Elefu RA Board Control Panel

// [www.elefu.com]

// REMEMBER TO INSTALL LiquidCrystal_I2C.h in your ARUDINO library folder: [github.com]

//#define RA_CONTROL_PANEL

//automatic expansion

#if defined (MAKRPANEL)

#define DOGLCD

#define SDSUPPORT

#define ULTIPANEL

#define NEWPANEL

#define DEFAULT_LCD_CONTRAST 17

#endif

#if defined (REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER)

#define DOGLCD

#define U8GLIB_ST7920

#define REPRAP_DISCOUNT_SMART_CONTROLLER

#endif

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER) || defined(G3D_PANEL)

#define ULTIPANEL

#define NEWPANEL

#endif

#if defined(REPRAPWORLD_KEYPAD)

#define NEWPANEL

#define ULTIPANEL

#endif

#if defined(RA_CONTROL_PANEL)

#define ULTIPANEL

#define NEWPANEL

#define LCD_I2C_TYPE_PCA8574

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#endif

//I2C PANELS

//#define LCD_I2C_SAINSMART_YWROBOT

#ifdef LCD_I2C_SAINSMART_YWROBOT

// This uses the LiquidCrystal_I2C library ( [bitbucket.org] )

// Make sure it is placed in the Arduino libraries directory.

#define LCD_I2C_TYPE_PCF8575

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#define NEWPANEL

#define ULTIPANEL

#endif

// PANELOLU2 LCD with status LEDs, separate encoder and click inputs

//#define LCD_I2C_PANELOLU2

#ifdef LCD_I2C_PANELOLU2

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// (v1.2.3 no longer requires you to define PANELOLU in the LiquidTWI2.h library header file)

// Note: The PANELOLU2 encoder click input can either be directly connected to a pin

// (if BTN_ENC defined to != -1) or read through I2C (when BTN_ENC == -1).

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD

#define NEWPANEL

#define ULTIPANEL

#endif

// Panucatt VIKI LCD with status LEDs, integrated click & L/R/U/P buttons, separate encoder inputs

//#define LCD_I2C_VIKI

#ifdef LCD_I2C_VIKI

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// Note: The pause/stop/resume LCD button pin should be connected to the Arduino

// BTN_ENC pin (or set BTN_ENC to -1 if not used)

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD (requires LiquidTWI2 v1.2.3 or later)

#define NEWPANEL

#define ULTIPANEL

#endif

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the DOG graphic display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#endif

#else //no panel but just lcd

#ifdef ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the 128x64 graphics display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

#endif

// default LCD contrast for dogm-like LCD displays

#ifdef DOGLCD

# ifndef DEFAULT_LCD_CONTRAST

# define DEFAULT_LCD_CONTRAST 32

# endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// Use software PWM to drive the fan, as for the heaters. This uses a very low frequency

// which is not ass annoying as with the hardware PWM. On the other hand, if this frequency

// is too low, you should also increment SOFT_PWM_SCALE.

//#define FAN_SOFT_PWM

// Incrementing this by 1 will double the software PWM frequency,

// affecting heaters, and the fan if FAN_SOFT_PWM is enabled.

// However, control resolution will be halved for each increment;

// at zero value, there are 128 effective control positions.

#define SOFT_PWM_SCALE 0

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

// Support for the BariCUDA Paste Extruder.

//#define BARICUDA

/*********************************************************************\

* R/C SERVO support

* Sponsored by TrinityLabs, Reworked by codexmas

**********************************************************************/

// Number of servos

//

// If you select a configuration below, this will receive a default value and does not need to be set manually

// set it manually if you have more servos than extruders and wish to manually control some

// leaving it undefined or defining as 0 will disable the servo subsystem

// If unsure, leave commented / disabled

//

//#define NUM_SERVOS 3 // Servo index starts with 0 for M280 command

// Servo Endstops

//

// This allows for servo actuated endstops, primary usage is for the Z Axis to eliminate calibration or bed height changes.

// Use M206 command to correct for switch height offset to actual nozzle height. Store that setting with M500.

//

//#define SERVO_ENDSTOPS {-1, -1, 0} // Servo index for X, Y, Z. Disable with -1

//#define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 70,0} // X,Y,Z Axis Extend and Retract angles

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

// [reprap.org]

//

// ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [code.google.com]

//#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER

// The RepRapWorld REPRAPWORLD_KEYPAD v1.1

// [reprapworld.com]

//#define REPRAPWORLD_KEYPAD

//#define REPRAPWORLD_KEYPAD_MOVE_STEP 10.0 // how much should be moved when a key is pressed, eg 10.0 means 10mm per click

// The Elefu RA Board Control Panel

// [www.elefu.com]

// REMEMBER TO INSTALL LiquidCrystal_I2C.h in your ARUDINO library folder: [github.com]

//#define RA_CONTROL_PANEL

//automatic expansion

#if defined (MAKRPANEL)

#define DOGLCD

#define SDSUPPORT

#define ULTIPANEL

#define NEWPANEL

#define DEFAULT_LCD_CONTRAST 17

#endif

#if defined (REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER)

#define DOGLCD

#define U8GLIB_ST7920

#define REPRAP_DISCOUNT_SMART_CONTROLLER

#endif

#if defined(ULTIMAKERCONTROLLER) || defined(REPRAP_DISCOUNT_SMART_CONTROLLER) || defined(G3D_PANEL)

#define ULTIPANEL

#define NEWPANEL

#endif

#if defined(REPRAPWORLD_KEYPAD)

#define NEWPANEL

#define ULTIPANEL

#endif

#if defined(RA_CONTROL_PANEL)

#define ULTIPANEL

#define NEWPANEL

#define LCD_I2C_TYPE_PCA8574

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#endif

//I2C PANELS

//#define LCD_I2C_SAINSMART_YWROBOT

#ifdef LCD_I2C_SAINSMART_YWROBOT

// This uses the LiquidCrystal_I2C library ( [bitbucket.org] )

// Make sure it is placed in the Arduino libraries directory.

#define LCD_I2C_TYPE_PCF8575

#define LCD_I2C_ADDRESS 0x27 // I2C Address of the port expander

#define NEWPANEL

#define ULTIPANEL

#endif

// PANELOLU2 LCD with status LEDs, separate encoder and click inputs

//#define LCD_I2C_PANELOLU2

#ifdef LCD_I2C_PANELOLU2

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// (v1.2.3 no longer requires you to define PANELOLU in the LiquidTWI2.h library header file)

// Note: The PANELOLU2 encoder click input can either be directly connected to a pin

// (if BTN_ENC defined to != -1) or read through I2C (when BTN_ENC == -1).

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD

#define NEWPANEL

#define ULTIPANEL

#endif

// Panucatt VIKI LCD with status LEDs, integrated click & L/R/U/P buttons, separate encoder inputs

//#define LCD_I2C_VIKI

#ifdef LCD_I2C_VIKI

// This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] )

// Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory.

// Note: The pause/stop/resume LCD button pin should be connected to the Arduino

// BTN_ENC pin (or set BTN_ENC to -1 if not used)

#define LCD_I2C_TYPE_MCP23017

#define LCD_I2C_ADDRESS 0x20 // I2C Address of the port expander

#define LCD_USE_I2C_BUZZER //comment out to disable buzzer on LCD (requires LiquidTWI2 v1.2.3 or later)

#define NEWPANEL

#define ULTIPANEL

#endif

#ifdef ULTIPANEL

// #define NEWPANEL //enable this if you have a click-encoder panel

#define SDSUPPORT

#define ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the DOG graphic display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 20

#define LCD_HEIGHT 4

#endif

#else //no panel but just lcd

#ifdef ULTRA_LCD

#ifdef DOGLCD // Change number of lines to match the 128x64 graphics display

#define LCD_WIDTH 20

#define LCD_HEIGHT 5

#else

#define LCD_WIDTH 16

#define LCD_HEIGHT 2

#endif

#endif

#endif

// default LCD contrast for dogm-like LCD displays

#ifdef DOGLCD

# ifndef DEFAULT_LCD_CONTRAST

# define DEFAULT_LCD_CONTRAST 32

# endif

#endif

// Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino

//#define FAST_PWM_FAN

// Use software PWM to drive the fan, as for the heaters. This uses a very low frequency

// which is not ass annoying as with the hardware PWM. On the other hand, if this frequency

// is too low, you should also increment SOFT_PWM_SCALE.

//#define FAN_SOFT_PWM

// Incrementing this by 1 will double the software PWM frequency,

// affecting heaters, and the fan if FAN_SOFT_PWM is enabled.

// However, control resolution will be halved for each increment;

// at zero value, there are 128 effective control positions.

#define SOFT_PWM_SCALE 0

// M240 Triggers a camera by emulating a Canon RC-1 Remote

// Data from: [www.doc-diy.net]

// #define PHOTOGRAPH_PIN 23

// SF send wrong arc g-codes when using Arc Point as fillet procedure

//#define SF_ARC_FIX

// Support for the BariCUDA Paste Extruder.

//#define BARICUDA

/*********************************************************************\

* R/C SERVO support

* Sponsored by TrinityLabs, Reworked by codexmas

**********************************************************************/

// Number of servos

//

// If you select a configuration below, this will receive a default value and does not need to be set manually

// set it manually if you have more servos than extruders and wish to manually control some

// leaving it undefined or defining as 0 will disable the servo subsystem

// If unsure, leave commented / disabled

//

//#define NUM_SERVOS 3 // Servo index starts with 0 for M280 command

// Servo Endstops

//

// This allows for servo actuated endstops, primary usage is for the Z Axis to eliminate calibration or bed height changes.

// Use M206 command to correct for switch height offset to actual nozzle height. Store that setting with M500.

//

//#define SERVO_ENDSTOPS {-1, -1, 0} // Servo index for X, Y, Z. Disable with -1

//#define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 70,0} // X,Y,Z Axis Extend and Retract angles

#include "Configuration_adv.h"

#include "thermistortables.h"

#endif //__CONFIGURATION_H

Anything blatantly bad in that?

Is there any such command where I can tell X axis to go up 2mm? I'd just like to test components one by one to see if they respond to commands...

Edited 1 time(s). Last edit at 11/07/2014 06:58AM by pugzor.

|

Re: Cherry Pi III Is Available November 07, 2014 07:40AM |

Registered: 10 years ago Posts: 515 |

Hi Andrew

Nothing looks way out in your config.h. How many jumpers have you got on your RAMPS board under each stepper driver board? There should be three under each driver to set the 1/16th microstepping that you have your config.h set to '#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 700}' assuming you are using GT2 belt, 20 tooth pulleys and 200 steps per revolution stepper motors ((200 x 16) /2)/20 = 80 i.e ((steps per rev x microstepping) /belt pitch)/pulley teeth.

I assume you meant have the Z axis go up 2mm? X is the left to right axis (Y is the front to back axis)

The command would be G0 Z2 F6000 (F sets the speed in mm/minute) if your head started at Z0 then it will move up to Z2. Easier to use the buttons in RH to move Z in defined steps (or lower it)

Andy

Nothing looks way out in your config.h. How many jumpers have you got on your RAMPS board under each stepper driver board? There should be three under each driver to set the 1/16th microstepping that you have your config.h set to '#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 700}' assuming you are using GT2 belt, 20 tooth pulleys and 200 steps per revolution stepper motors ((200 x 16) /2)/20 = 80 i.e ((steps per rev x microstepping) /belt pitch)/pulley teeth.

I assume you meant have the Z axis go up 2mm? X is the left to right axis (Y is the front to back axis)

The command would be G0 Z2 F6000 (F sets the speed in mm/minute) if your head started at Z0 then it will move up to Z2. Easier to use the buttons in RH to move Z in defined steps (or lower it)

Andy

|

Re: Cherry Pi III Is Available November 07, 2014 07:53AM |

Registered: 9 years ago Posts: 164 |

... nope. That could be one of the reasons things are being not great for me.  I bet there's more but that'd be a start!

I bet there's more but that'd be a start!

Tomorrow I need to get 12 jumpers. I bet it's going to cost me like $1. Such a complicated mistake to have made, haha.

Edited 1 time(s). Last edit at 11/07/2014 07:53AM by pugzor.

I bet there's more but that'd be a start!

I bet there's more but that'd be a start!Tomorrow I need to get 12 jumpers. I bet it's going to cost me like $1. Such a complicated mistake to have made, haha.

Edited 1 time(s). Last edit at 11/07/2014 07:53AM by pugzor.

|

Re: Cherry Pi III Is Available November 07, 2014 08:33AM |

Registered: 9 years ago Posts: 113 |

|

Re: Cherry Pi III Is Available November 07, 2014 10:12AM |

Registered: 10 years ago Posts: 515 |

You could use '#define DEFAULT_AXIS_STEPS_PER_UNIT {5, 5, 5, 700}' just to get things moving, (200/2)/20. The other option would be to just solder a bridge across the jumpers on the basis that you are never going to change them anyway!

If you bought the same kit that I sent you the links for the jumpers are included in a seperate plastic bag with the RAMPS

Edited 1 time(s). Last edit at 11/07/2014 10:14AM by AndyCart.

If you bought the same kit that I sent you the links for the jumpers are included in a seperate plastic bag with the RAMPS

Edited 1 time(s). Last edit at 11/07/2014 10:14AM by AndyCart.

|

Re: Cherry Pi III Is Available November 07, 2014 05:38PM |

Registered: 9 years ago Posts: 164 |

|

Re: Cherry Pi III Is Available November 07, 2014 09:01PM |

Registered: 9 years ago Posts: 164 |

|

Re: Cherry Pi III Is Available November 07, 2014 09:32PM |

Registered: 9 years ago Posts: 164 |

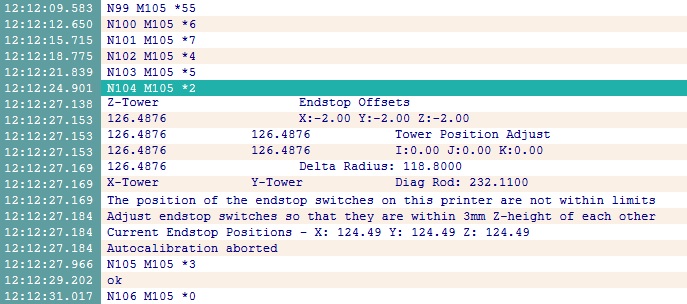

Okay, so autocalibration is actually doing something now! Woo!

Problem is now that it's saying my endstops aren't within 3mm of each other, which I'm thinking is a damn lie. The tower heights were awesomely close to being equal length. Is there anything else that may be giving this error?

Also, what parameter might I have to adjust given that I added ~50mm to my build height? Is it possible that it's erroring out because it tried to find a bottom but couldn't?

Edited 1 time(s). Last edit at 11/07/2014 09:32PM by pugzor.

Problem is now that it's saying my endstops aren't within 3mm of each other, which I'm thinking is a damn lie. The tower heights were awesomely close to being equal length. Is there anything else that may be giving this error?

Also, what parameter might I have to adjust given that I added ~50mm to my build height? Is it possible that it's erroring out because it tried to find a bottom but couldn't?

Edited 1 time(s). Last edit at 11/07/2014 09:32PM by pugzor.

|

Re: Cherry Pi III Is Available November 08, 2014 02:45AM |

Registered: 10 years ago Posts: 515 |

Sorry, only registered users may post in this forum.