Cherry Pi III Is Available

Posted by AndyCart

|

Re: Cherry Pi III Is Available March 14, 2015 08:23AM |

Registered: 9 years ago Posts: 164 |

*sigh* My hotend keeps getting clogged.

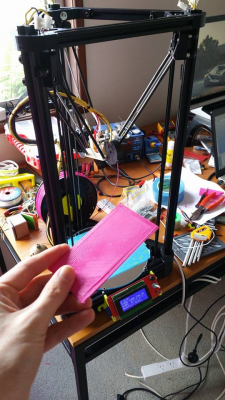

Got this far on my test print and then the filament seized within the hotend again, above the nozzle. Really freaking annoying because I need to take apart the effector and recalibrate again. The print above is how much I got out of it before it clogged.

Any ideas why? As you can see, the print quality seems pretty good. Maybe a bit under-extruding if anything because there are some slight gaps between the tracks here and there.

Got this far on my test print and then the filament seized within the hotend again, above the nozzle. Really freaking annoying because I need to take apart the effector and recalibrate again. The print above is how much I got out of it before it clogged.

Any ideas why? As you can see, the print quality seems pretty good. Maybe a bit under-extruding if anything because there are some slight gaps between the tracks here and there.

|

Re: Cherry Pi III Is Available March 14, 2015 10:52AM |

Registered: 10 years ago Posts: 903 |

|

Re: Cherry Pi III Is Available March 14, 2015 02:29PM |

Registered: 9 years ago Posts: 5 |

I'm making a variation of the CPII but using conventional ball links.

I'm a little confused on the delta rod lengths

In the description for CPII on thingiverse Andy says he used 250mm rod length but further down it says 200mm rod length

My cross brace extrusions are 250mm but what would be a good length for the delta rods?

Stu

I'm a little confused on the delta rod lengths

In the description for CPII on thingiverse Andy says he used 250mm rod length but further down it says 200mm rod length

My cross brace extrusions are 250mm but what would be a good length for the delta rods?

Stu

|

Re: Cherry Pi III Is Available March 14, 2015 03:59PM |

Registered: 9 years ago Posts: 164 |

|

Re: Cherry Pi III Is Available March 14, 2015 04:11PM |

Registered: 10 years ago Posts: 14,672 |

The hot end fan must be wired directly to 12V so that it runs all the time. It's purpose is to keep the top end of the nozzle assembly cool, to avoid the filament melting too high up.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi III Is Available March 14, 2015 04:25PM |

Registered: 9 years ago Posts: 68 |

Day 14

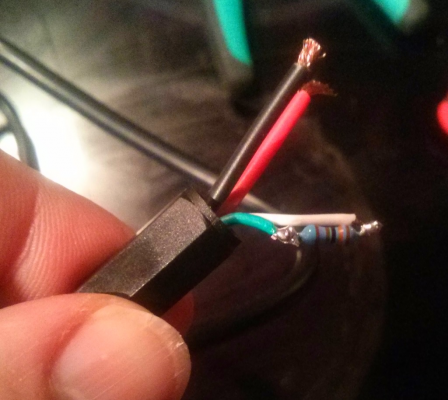

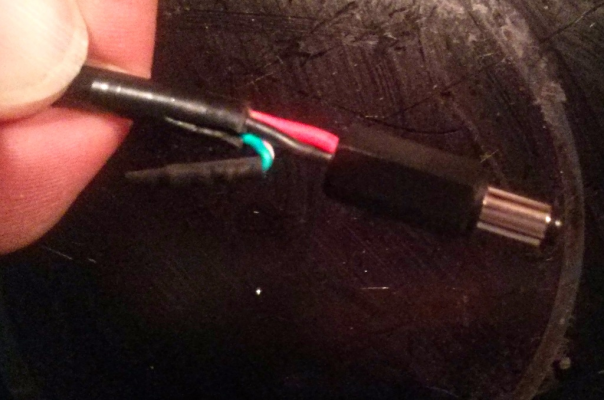

Thanks Andy. That worked a treat. I could find details of the first XBox 360 power supply with about 10 pins, but nothing came up for the slim or the XBox ONE.

After checking it would work, I used a spare resistor to connect the white and green wires instead of having a dead short. No doubt there is one there internally already, but its not doing any harm. With it all soldered together, I encased it in heat shrink to insulate it and provide some strain relief.

Quote

AndyCart

When you plug the PSU into the mains there should be a red led illuminated on the unit. If you short the green and white wires together it should turn green, at which point you should have 12V on the red and black wires.

Thanks Andy. That worked a treat. I could find details of the first XBox 360 power supply with about 10 pins, but nothing came up for the slim or the XBox ONE.

After checking it would work, I used a spare resistor to connect the white and green wires instead of having a dead short. No doubt there is one there internally already, but its not doing any harm. With it all soldered together, I encased it in heat shrink to insulate it and provide some strain relief.

|

Re: Cherry Pi III Is Available March 14, 2015 04:26PM |

Registered: 9 years ago Posts: 164 |

Really? I've only got a centrifugal fan on mine which blows air only onto the nozzle tip. This one should be on all the time? I thought this was more for solidifying extruded plastic quickly.Quote

dc42

The hot end fan must be wired directly to 12V so that it runs all the time. It's purpose is to keep the top end of the nozzle assembly cool, to avoid the filament melting too high up.

Edited 1 time(s). Last edit at 03/14/2015 04:27PM by pugzor.

|

Re: Cherry Pi III Is Available March 14, 2015 04:37PM |

Registered: 9 years ago Posts: 68 |

Quote

pugzor

Really? I've only got a centrifugal fan on mine which blows air only onto the nozzle tip. This one should be on all the time? I thought this was more for solidifying extruded plastic quickly.

I notice that pugzor is not using an E3D. Andy's Cherry Pi III images on Thingiverse with the previous hot end don't show a fan, but there was some discussion near the start of this thread about adding one.

Edited 1 time(s). Last edit at 03/14/2015 04:38PM by gowen.

|

Re: Cherry Pi III Is Available March 14, 2015 05:41PM |

Registered: 10 years ago Posts: 14,672 |

Your centrifugal blower sounds good as a print cooling fan. You need a separate hot end fan to blow air over the cooling fins of the hot end assembly. Usual choice is a 40mmx10mm PC fan.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi III Is Available March 14, 2015 06:31PM |

Registered: 10 years ago Posts: 903 |

Quote

dc42

Your centrifugal blower sounds good as a print cooling fan. You need a separate hot end fan to blow air over the cooling fins of the hot end assembly. Usual choice is a 40mmx10mm PC fan.

He has a PEEK J-head clone, not an E3D. I have never read anywhere about those needing a cooling fan. Can't say from experience though, as my only experience with a J-head was watching a brand new one melt down after a minute due to thermistor separation while doing PID tuning.....

|

Re: Cherry Pi III Is Available March 14, 2015 07:14PM |

Registered: 10 years ago Posts: 515 |

Quote

stuuk

I'm making a variation of the CPII but using conventional ball links.

I'm a little confused on the delta rod lengths

In the description for CPII on thingiverse Andy says he used 250mm rod length but further down it says 200mm rod length

My cross brace extrusions are 250mm but what would be a good length for the delta rods?

Stu

Hi Stu

There have been a few iterations. The current CP IIIS rod length, that's the actual tube length before the balls are attached, is 225mm.

Andy

|

Re: Cherry Pi III Is Available March 14, 2015 07:25PM |

Registered: 10 years ago Posts: 515 |

@ Puzgor

You shouldn't need a cooling fan for your JHead. The centrifugal fan is purely for part cooling. It sounds like you have got some debris in the nozzle. Given that the print looked under extruded and them jammed I suspect that is the problem. If you take the Bowden tube out of the hot end and put a short length, about 50cm, of PTFE tube in its place. Get the nozzle to 210 and see it you can manually push filament into the hot end through the short length of tube. It shouldn't require much force. If it does push the filament in and pull it out quite sharply, then discard that bit and repeat. The object is to try and pull the debris out stuck in the melted filament. As soon as you get it you will find the next bit of filament goes through o.k. The other thing to check is the actual temperature. If your thermistor is off it may read 210 but it could be much lower. A cheap IR thermometer is a useful diagnostic tool. Or just increase the temp in 5 degree increments until it's easy to push filament through. Record that temp and use it moving forward.

You shouldn't need a cooling fan for your JHead. The centrifugal fan is purely for part cooling. It sounds like you have got some debris in the nozzle. Given that the print looked under extruded and them jammed I suspect that is the problem. If you take the Bowden tube out of the hot end and put a short length, about 50cm, of PTFE tube in its place. Get the nozzle to 210 and see it you can manually push filament into the hot end through the short length of tube. It shouldn't require much force. If it does push the filament in and pull it out quite sharply, then discard that bit and repeat. The object is to try and pull the debris out stuck in the melted filament. As soon as you get it you will find the next bit of filament goes through o.k. The other thing to check is the actual temperature. If your thermistor is off it may read 210 but it could be much lower. A cheap IR thermometer is a useful diagnostic tool. Or just increase the temp in 5 degree increments until it's easy to push filament through. Record that temp and use it moving forward.

|

Re: Cherry Pi III Is Available March 15, 2015 02:40PM |

Registered: 9 years ago Posts: 893 |

I'm planning to start printing parts for a Cherry Pi IIIS very soon - I have just one question - what filament is recommended for the parts? PLA is easy, but I'm sure that ABS is needed for the effector. I was just wondering if there was any mechanical/physical advantage in using certain plastics for some parts.

I really don't care which I use, as I can print either on my Prusa i3!

D'oh! I've just looked at the STL filenames, and they show it all... if in doubt, RTFFNs!

Edited 3 time(s). Last edit at 03/15/2015 04:38PM by David J.

I really don't care which I use, as I can print either on my Prusa i3!

D'oh! I've just looked at the STL filenames, and they show it all... if in doubt, RTFFNs!

Edited 3 time(s). Last edit at 03/15/2015 04:38PM by David J.

|

Re: Cherry Pi III Is Available March 15, 2015 05:52PM |

Registered: 9 years ago Posts: 893 |

OK - a more sensible question (or seeking clarification, anyway) - am I right in thinking that the Z-probe is activated by the tip of the hot-end touching the bed, and lifting the hot-end support off a microswitch?

It's just that I was looking for something complicated like the one found on a mini kossel, where a probe is set and 'put away' after use, but I couldn't see anything like that in the Thingiverse pictures. This way seems simpler, as long as the hot-end tip is clean...

Also, looking at the effector that came along later for the E3D v6, does that have the Z-probe? I have an E3Dv6 on my Prusa i3, and I'd hope to use another on this printer - but I also wish to use auto-levelling.

Edited 2 time(s). Last edit at 03/15/2015 05:59PM by David J.

It's just that I was looking for something complicated like the one found on a mini kossel, where a probe is set and 'put away' after use, but I couldn't see anything like that in the Thingiverse pictures. This way seems simpler, as long as the hot-end tip is clean...

Also, looking at the effector that came along later for the E3D v6, does that have the Z-probe? I have an E3Dv6 on my Prusa i3, and I'd hope to use another on this printer - but I also wish to use auto-levelling.

Edited 2 time(s). Last edit at 03/15/2015 05:59PM by David J.

|

Re: Cherry Pi III Is Available March 15, 2015 06:02PM |

Registered: 9 years ago Posts: 67 |

Hi

I have now wired up everything on my cherry pi but I am having a bit of an issue with the stepper motors.

My pairs are Red, Blue and Green, Black. I have wired them Red, Blue, Green, Black in the plugs. When I advance the motor it make a noise and sometimes spins a bit but not consistently every time, adjusting the pot doesn't appear to make much of a difference, the tiutorials say you should wind the pot all the way down, then gradually up. the pots on mine appear to go all the way round without stopping

Any suggestions would be appreciated.

I have now wired up everything on my cherry pi but I am having a bit of an issue with the stepper motors.

My pairs are Red, Blue and Green, Black. I have wired them Red, Blue, Green, Black in the plugs. When I advance the motor it make a noise and sometimes spins a bit but not consistently every time, adjusting the pot doesn't appear to make much of a difference, the tiutorials say you should wind the pot all the way down, then gradually up. the pots on mine appear to go all the way round without stopping

Any suggestions would be appreciated.

|

Re: Cherry Pi III Is Available March 15, 2015 06:18PM |

Registered: 9 years ago Posts: 111 |

|

Re: Cherry Pi III Is Available March 15, 2015 06:24PM |

Registered: 10 years ago Posts: 515 |

Quote

David J

OK - a more sensible question (or seeking clarification, anyway) - am I right in thinking that the Z-probe is activated by the tip of the hot-end touching the bed, and lifting the hot-end support off a microswitch?

It's just that I was looking for something complicated like the one found on a mini kossel, where a probe is set and 'put away' after use, but I couldn't see anything like that in the Thingiverse pictures. This way seems simpler, as long as the hot-end tip is clean...

Also, looking at the effector that came along later for the E3D v6, does that have the Z-probe? I have an E3Dv6 on my Prusa i3, and I'd hope to use another on this printer - but I also wish to use auto-levelling.

Hi David

That version of the effector has a micro switch built into it. The hot end is held in a hinge that is held closed by springs and so keeps the microswitch closed. As the tip touches the bed it pushes the hinge against the springs and the switch opens to register the bed. It isn't relying on the nozzle to bed electrical connection to act as a switch.

Andy

|

Re: Cherry Pi III Is Available March 15, 2015 06:27PM |

Registered: 10 years ago Posts: 515 |

Quote

Matt,Wheatley

Hi

I have now wired up everything on my cherry pi but I am having a bit of an issue with the stepper motors.

My pairs are Red, Blue and Green, Black. I have wired them Red, Blue, Green, Black in the plugs. When I advance the motor it make a noise and sometimes spins a bit but not consistently every time, adjusting the pot doesn't appear to make much of a difference, the tiutorials say you should wind the pot all the way down, then gradually up. the pots on mine appear to go all the way round without stopping

Any suggestions would be appreciated.

Hi Matt

Check that you have all three jumpers installed under your stepper drivers on the RAMPS board. If you haven't, and have the firmware set to 1/16 microsteps, which is normal, then you end up sending more pulses than the driver can handle and get the effect you describe. Or you may have a duff stepper driver. Just plugging or unplugging a motor with power on will trash them!

Andy

|

Re: Cherry Pi III Is Available March 15, 2015 06:28PM |

Registered: 9 years ago Posts: 893 |

Andy,

That's what I thought! I guessed that it was a mechanical system - I didn't think that it made an electrical connection.

Does the E3D version work in the same way? Or is that the one you're talking about!

I'd really like to see a picture or two of the E3D effector fully assembled, just to get my head around it.

That's what I thought! I guessed that it was a mechanical system - I didn't think that it made an electrical connection.

Does the E3D version work in the same way? Or is that the one you're talking about!

I'd really like to see a picture or two of the E3D effector fully assembled, just to get my head around it.

|

Re: Cherry Pi III Is Available March 15, 2015 06:35PM |

Registered: 10 years ago Posts: 515 |

Quote

David J

Andy,

That's what I thought! I guessed that it was a mechanical system - I didn't think that it made an electrical connection.

Does the E3D version work in the same way? Or is that the one you're talking about!

I'd really like to see a picture or two of the E3D effector fully assembled, just to get my head around it.

No. The E3D version doesn't have a microswitch, or any form of bed probing. After a lot of heartache with auto calibration I came to the conclusion that once the machine is set up properly you don't need to probe the bed for each print. I purposely designed both effectors to be inter changeable so people could choose either or both. I still carry out an initial auto calibration with the E3D version but that involves a flying lead, two croc clips and relies on the electrical connection between the nozzle and the aluminium build plate. As delta's bed don't move they don't seem to go out of true. My own Cherry Pi has been printing for weeks without me touching the calibration settings. It just works.

There are numerous pictures of the E3D effector further up the thread.

Edited 1 time(s). Last edit at 03/15/2015 06:36PM by AndyCart.

|

Re: Cherry Pi III Is Available March 15, 2015 06:38PM |

Registered: 9 years ago Posts: 67 |

|

Re: Cherry Pi III Is Available March 15, 2015 06:38PM |

Registered: 9 years ago Posts: 893 |

|

Re: Cherry Pi III Is Available March 15, 2015 06:40PM |

Registered: 9 years ago Posts: 68 |

Quote

David J

Andy,

That's what I thought! I guessed that it was a mechanical system - I didn't think that it made an electrical connection.

Does the E3D version work in the same way? Or is that the one you're talking about!

I'd really like to see a picture or two of the E3D effector fully assembled, just to get my head around it.

Hi David,

I've just built the current hot end. You can see some pictures of it back a few pages.

Cheers. Gary.

Edited 2 time(s). Last edit at 03/15/2015 06:44PM by gowen.

|

Re: Cherry Pi III Is Available March 15, 2015 06:56PM |

Registered: 9 years ago Posts: 164 |

Quote

AndyCart

My own Cherry Pi has been printing for weeks without me touching the calibration settings. It just works.

This is what I'm aiming for!

Quote

AndyCart

You shouldn't need a cooling fan for your JHead. The centrifugal fan is purely for part cooling. It sounds like you have got some debris in the nozzle. Given that the print looked under extruded and them jammed I suspect that is the problem. If you take the Bowden tube out of the hot end and put a short length, about 50cm, of PTFE tube in its place. Get the nozzle to 210 and see it you can manually push filament into the hot end through the short length of tube. It shouldn't require much force. If it does push the filament in and pull it out quite sharply, then discard that bit and repeat. The object is to try and pull the debris out stuck in the melted filament. As soon as you get it you will find the next bit of filament goes through o.k. The other thing to check is the actual temperature. If your thermistor is off it may read 210 but it could be much lower. A cheap IR thermometer is a useful diagnostic tool. Or just increase the temp in 5 degree increments until it's easy to push filament through. Record that temp and use it moving forward.

Okay, I'll muck around with all of that next.

Personally, I think that's unlikely to be debris in the nozzle because I've cleared out the blockages further up in the PEEK tube, without clearing out the nozzle at all, then it's flowed okay for a while then blocked again.

More likely to be an issue with the thermistor I reckon. I'll try everything I can before putting it back together though. I don't mind calibrating but it's a bit annoying to do.

On the bright side, I didn't know people were using compression springs to hold down the bearing onto the hobbed bolt, so I picked up some on the weekend. Cost me a whole $3 from Bunnings (super useful for any Aussies watching this). I've also found a local supply of "secret sauce" as the HV stuff isn't terribly easy to find.

|

Re: Cherry Pi III Is Available March 15, 2015 07:09PM |

Registered: 9 years ago Posts: 67 |

|

Re: Cherry Pi III Is Available March 16, 2015 03:21AM |

Registered: 10 years ago Posts: 515 |

|

Re: Cherry Pi III Is Available March 16, 2015 03:27AM |

Registered: 10 years ago Posts: 515 |

@ Puzgor

Where exactly in the PEEK fitting is the blockage occurring? Sometimes the PTFE liner isn't pressed tightly enough against the top of the thread from the heat block and this causes plastic to pool in the gap under pressure. I have sometimes had to cut a spacer from the same 6mm tube I use for the delta rods to fit inside the top of the PEEK between the pneumatic fitting and the top of the PTFE. This clamps everything in place when the pneumatic fitting is tightened up. It all needs to be cleaned out first though.

Where exactly in the PEEK fitting is the blockage occurring? Sometimes the PTFE liner isn't pressed tightly enough against the top of the thread from the heat block and this causes plastic to pool in the gap under pressure. I have sometimes had to cut a spacer from the same 6mm tube I use for the delta rods to fit inside the top of the PEEK between the pneumatic fitting and the top of the PTFE. This clamps everything in place when the pneumatic fitting is tightened up. It all needs to be cleaned out first though.

|

Re: Cherry Pi III Is Available March 16, 2015 03:43AM |

Registered: 9 years ago Posts: 164 |

Originally it blocked at the bottom of the PTFE and there was a small gap between the PTFE and the thread of the nozzle. Well, by gap I mean there was a space between where the PLA had solidified in the two pieces. That was my first indication it had melted too high and cooled. The second time it jammed I'm not sure, but the nozzle and the plumbing fitting had both been done up tight to the PEEK but there was a bit of my bright magenta plastic leaking through the thread on the nozzle (rectified by using plumbing tape this time!).

Either way, it does really seem it's melting too high up.

I might actually dial down my nozzle to 150°C and progressively heat it up until I find a sweet spot for this plastic.

Either way, it does really seem it's melting too high up.

I might actually dial down my nozzle to 150°C and progressively heat it up until I find a sweet spot for this plastic.

|

Re: Cherry Pi III Is Available March 16, 2015 04:50AM |

Registered: 9 years ago Posts: 893 |

Thanks Gary,

I had seen those pictures (although I was suffering from 'long topic fatigue' by then). Trouble is, I was looking for details of a z-probe mechanism that wasn't there...

Anyway, despite a number of wrong turns while I tried to understand how things fit together, I plan to start printing parts later on today.

David

Edited 1 time(s). Last edit at 03/16/2015 04:52AM by David J.

|

Re: Cherry Pi III Is Available March 16, 2015 03:24PM |

Registered: 9 years ago Posts: 67 |

Pictures of My Cherry Pi IIIS+

(260mm Diameter Build Platform, 170mm Build Height)

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

Thanks to everybody on this forum and to Andy for all the work on the PI.

All I have to do is calibrate the air tipper extruder and I might be able to print with it

(260mm Diameter Build Platform, 170mm Build Height)

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

[drive.google.com]

Thanks to everybody on this forum and to Andy for all the work on the PI.

All I have to do is calibrate the air tipper extruder and I might be able to print with it

Sorry, only registered users may post in this forum.