Cherry Pi III Is Available

Posted by AndyCart

|

Re: Cherry Pi III Is Available April 04, 2015 05:44AM |

Registered: 10 years ago Posts: 44 |

OK new update - about ready to stab myself in the face after working on this for the last 4 hours or so.

The following is my latest M666 L:

04:17:30.479 : Current Delta geometry values:

04:17:30.479 : X (Endstop Adj): -4.00

04:17:30.479 : Y (Endstop Adj): -7.50

04:17:30.479 : Z (Endstop Adj): -5.75

04:17:30.484 : P (Z-Probe Offset): X0.00 Y0.00 Z0.80

04:17:30.484 : A (Tower A Position Correction): 0.00

04:17:30.484 : B (Tower B Position Correction): 0.00

04:17:30.489 : C (Tower C Position Correction): 0.00

04:17:30.489 : I (Tower A Radius Correction): 0.00

04:17:30.489 : J (Tower B Radius Correction): 0.00

04:17:30.489 : K (Tower C Radius Correction): 0.00

04:17:30.489 : R (Delta Radius): 120.00

04:17:30.494 : D (Diagonal Rod Length): 240.00

04:17:30.494 : H (Z-Height): 236.80

After I get script 4 to be appropriate, scripts 1/2/3 are above the platen - as in there is a "bowl" shape which needs to be compensated for.

Once I compensate for X/Y/Z, script 4 is now below the platen.

Any ideas?

The following is my latest M666 L:

04:17:30.479 : Current Delta geometry values:

04:17:30.479 : X (Endstop Adj): -4.00

04:17:30.479 : Y (Endstop Adj): -7.50

04:17:30.479 : Z (Endstop Adj): -5.75

04:17:30.484 : P (Z-Probe Offset): X0.00 Y0.00 Z0.80

04:17:30.484 : A (Tower A Position Correction): 0.00

04:17:30.484 : B (Tower B Position Correction): 0.00

04:17:30.489 : C (Tower C Position Correction): 0.00

04:17:30.489 : I (Tower A Radius Correction): 0.00

04:17:30.489 : J (Tower B Radius Correction): 0.00

04:17:30.489 : K (Tower C Radius Correction): 0.00

04:17:30.489 : R (Delta Radius): 120.00

04:17:30.494 : D (Diagonal Rod Length): 240.00

04:17:30.494 : H (Z-Height): 236.80

After I get script 4 to be appropriate, scripts 1/2/3 are above the platen - as in there is a "bowl" shape which needs to be compensated for.

Once I compensate for X/Y/Z, script 4 is now below the platen.

Any ideas?

|

Re: Cherry Pi III Is Available April 04, 2015 10:43AM |

Registered: 10 years ago Posts: 903 |

|

Re: Cherry Pi III Is Available April 04, 2015 04:06PM |

Registered: 9 years ago Posts: 67 |

|

Re: Cherry Pi III Is Available April 04, 2015 06:57PM |

Registered: 10 years ago Posts: 515 |

Quote

Matt,Wheatley

Andy,

I noticed on your PrntQB V5 your using a graphic display, what controller board do you use for your Core XY, also are you using the marlin firmware for it.

Thanks

Matt

Hi Matt

The full graphic display is fine on a coreXY machine. I'm using a standard Arduino Mega 2560 and RAMPS. The processor doesn't have to work much harder than for a Cartesisn machine. And yes, I'm using standard Marlin.

Andy

|

Re: Cherry Pi III Is Available April 04, 2015 07:03PM |

Registered: 10 years ago Posts: 515 |

Quote

Zzyzxx71

OK new update - about ready to stab myself in the face after working on this for the last 4 hours or so.

The following is my latest M666 L:

04:17:30.479 : Current Delta geometry values:

04:17:30.479 : X (Endstop Adj): -4.00

04:17:30.479 : Y (Endstop Adj): -7.50

04:17:30.479 : Z (Endstop Adj): -5.75

04:17:30.484 : P (Z-Probe Offset): X0.00 Y0.00 Z0.80

04:17:30.484 : A (Tower A Position Correction): 0.00

04:17:30.484 : B (Tower B Position Correction): 0.00

04:17:30.489 : C (Tower C Position Correction): 0.00

04:17:30.489 : I (Tower A Radius Correction): 0.00

04:17:30.489 : J (Tower B Radius Correction): 0.00

04:17:30.489 : K (Tower C Radius Correction): 0.00

04:17:30.489 : R (Delta Radius): 120.00

04:17:30.494 : D (Diagonal Rod Length): 240.00

04:17:30.494 : H (Z-Height): 236.80

After I get script 4 to be appropriate, scripts 1/2/3 are above the platen - as in there is a "bowl" shape which needs to be compensated for.

Once I compensate for X/Y/Z, script 4 is now below the platen.

Any ideas?

Further back in the thread I attached a copy of a calibration guide I put together. Just follow that and it should work out fine. Your endstop offsets look a bit odd. There shouldn't be much more than 1mm difference between them. Maybe measure from base to top bracket on each tower and adjust as necessary. Also check your delta rods are all the same length. If you built a 'standard' CPIII your Z height should be around 250mm. The delta rods should be 225 (tube length) towers are 600mm.

|

Re: Cherry Pi III Is Available April 05, 2015 09:44AM |

Registered: 9 years ago Posts: 164 |

Pretty sure I've conquered the filament jamming issue! Soooo close to being happy...

Taking a look at this, what would you say is the issue? Under-extrusion seems possible... Also, any tips for adhesion to the bed? Just printing Colorfabb PLA to an unheated bed with blue tape.

Taking a look at this, what would you say is the issue? Under-extrusion seems possible... Also, any tips for adhesion to the bed? Just printing Colorfabb PLA to an unheated bed with blue tape.

|

Re: Cherry Pi III Is Available April 05, 2015 10:24AM |

Registered: 10 years ago Posts: 903 |

Does your slicer du jour's settings include a different layer height for the first layer? It seems like the nozzle is a smidge too high, which impacts extrusion thickness and also bed adhesion. It also seems like your extruder is either slipping on the filament or missing steps. If it has a spring or screws on the pinch roller, try tightening them a bit more. Otherwise, it may be the stepper motor current being set a little bit low.

Silly question - Did you do the calibration with the nozzle at operating temperature?????

Silly question - Did you do the calibration with the nozzle at operating temperature?????

|

Re: Cherry Pi III Is Available April 05, 2015 06:33PM |

Registered: 9 years ago Posts: 164 |

Hey vreihen, nah didn't do calibration with the nozzle at operating temp... Should I have?

Yeah my first layer was set at 0.3mm with every other layer at 0.1mm. I changed this to 0.1mm but it seems to ball up a bit now. Is that an issue with temp being too low? I also notice a lot of dripping meaning that it doesn't actually start extruding until half way through the first layer... Maybe my temp is too high? It's at 210c.

Here's a pic of the latest settings print.

Edit: I did tighten up my springs on the extruder. Seems okay now? I'm using Cura too. For some reason it takes like 3 minutes to travel from home to the print bed... Anyone else had that?

Edited 1 time(s). Last edit at 04/05/2015 06:35PM by pugzor.

Yeah my first layer was set at 0.3mm with every other layer at 0.1mm. I changed this to 0.1mm but it seems to ball up a bit now. Is that an issue with temp being too low? I also notice a lot of dripping meaning that it doesn't actually start extruding until half way through the first layer... Maybe my temp is too high? It's at 210c.

Here's a pic of the latest settings print.

Edit: I did tighten up my springs on the extruder. Seems okay now? I'm using Cura too. For some reason it takes like 3 minutes to travel from home to the print bed... Anyone else had that?

Edited 1 time(s). Last edit at 04/05/2015 06:35PM by pugzor.

|

Re: Cherry Pi III Is Available April 05, 2015 09:25PM |

Registered: 9 years ago Posts: 76 |

I read some where you need stepper torque of at least 4600 g/cm, I was looking at the datasheet and noticed that I have 4587 g/cm (45Ncm or 63.7oz.in) is this to low, should I return them?

( The motor [www.omc-stepperonline.com] )

( The motor [www.omc-stepperonline.com] )

|

Re: Cherry Pi III Is Available April 05, 2015 09:36PM |

Registered: 10 years ago Posts: 903 |

You should always do calibrations at full operating temperature. Metal expands. I've seen someone claim that they measured a 2mm rise (warp) on a square Mk2 heatbed with all four corners firmly anchored just from thermal expansion, which is why some people either use loose bed screws or else torque the bed down at operating temperature. The glass won't warp, but it will rise up if the bed bows when it expands.

My two cents USD is that 0.2mm or even 0.3mm is a better layer height to start with (on *all* layers) when running a 0.4mm nozzle. It took me several iterations of fine-tweaking the extruder steps/mm to get acceptable prints at 0.1mm, but I could crank out usable parts at 0.3mm.

Regarding the travel speed, I'm sure there's a setting for maximum travel speeds in the firmware and/or your slicer that needs some attention. If it isn't somewhere near 100mm/second, it is probably set too slow.....

My two cents USD is that 0.2mm or even 0.3mm is a better layer height to start with (on *all* layers) when running a 0.4mm nozzle. It took me several iterations of fine-tweaking the extruder steps/mm to get acceptable prints at 0.1mm, but I could crank out usable parts at 0.3mm.

Regarding the travel speed, I'm sure there's a setting for maximum travel speeds in the firmware and/or your slicer that needs some attention. If it isn't somewhere near 100mm/second, it is probably set too slow.....

|

Re: Cherry Pi III Is Available April 06, 2015 04:29AM |

Registered: 9 years ago Posts: 164 |

@mikes3ds, that torque seems pretty bloody close... I wouldn't worry about it... but then again I've had so many issues I wouldn't trust anything I say!

@vreihen, hmm, fair enough. I don't have a printed bed but I guess it makes sense to calibrate as much under operating conditions as possible. Would it be suggested to calibrate with blue tape on the bed too? My Cura settings are as follows:

Speeds (I've got the same for slow and fast)

Print 80mm/s

Travel 150mm/s

First layed 65mm/s

Outer perimeter 60mm/s

Inner perimeter 70mm/s

Infill 100mm/s

Layer height 0.2mm

First layer height 0.2mm

First layer extrusion width 100%

Structures

Infill shell thickess 0.8mm

Top/bottom thickness 0.6mm

Infill overlap 15%

Infill pattern Grid

Solid top infill and solid bottom infill both checked

Support pattern Lines

Overhang angle 46%

Fill amount 15%

Distance XY 0.7mm

Distance Z 0.15mm

Skirt line count 5

Brim width 5mm

Skirt distance 10mm

Minimum skirt length 150mm

Raft extra margin 5mm

Base line thickness 0.3mm

Interface thickness 0.2mm

Air gap layer 0 0mm

Air gap 0

Line spacing 1mm

Base line width 0.7mm

Interface line width 0.2mm

Num surface layer 1

Gcode flavour RepRap

General extruder settings

Minimize crossing perimeters and enable retraction cecked

Retraction speed 20mm/s

Retraction distance 3mm

Minimum travel before retract 1.5mm

Minimum extrusion before retract 0.02mm

Zhop 0.1mm

Cut off object bottom 0mm

Nozzle diameter 0.4mm

Create wipe and prime tower checked

Support extruder as any extruder

Retraction on extruder switch 16mm

Wipe and prime volume 15mm^2

Volume overlap 0mm

Fan full at height 0.5mm

Minimum speed 0mm/s

G-Codes tab unmodified

Everything on advanced tab unchecked

Filament

Filament diameter 1.75mm

Flow 100%

Print temperature 210°C

Bed temperature 0°C

Min fan speed 50%

Max fan speed 100%

Minimum layer time 5s

@vreihen, hmm, fair enough. I don't have a printed bed but I guess it makes sense to calibrate as much under operating conditions as possible. Would it be suggested to calibrate with blue tape on the bed too? My Cura settings are as follows:

Speeds (I've got the same for slow and fast)

Print 80mm/s

Travel 150mm/s

First layed 65mm/s

Outer perimeter 60mm/s

Inner perimeter 70mm/s

Infill 100mm/s

Layer height 0.2mm

First layer height 0.2mm

First layer extrusion width 100%

Structures

Infill shell thickess 0.8mm

Top/bottom thickness 0.6mm

Infill overlap 15%

Infill pattern Grid

Solid top infill and solid bottom infill both checked

Support pattern Lines

Overhang angle 46%

Fill amount 15%

Distance XY 0.7mm

Distance Z 0.15mm

Skirt line count 5

Brim width 5mm

Skirt distance 10mm

Minimum skirt length 150mm

Raft extra margin 5mm

Base line thickness 0.3mm

Interface thickness 0.2mm

Air gap layer 0 0mm

Air gap 0

Line spacing 1mm

Base line width 0.7mm

Interface line width 0.2mm

Num surface layer 1

Gcode flavour RepRap

General extruder settings

Minimize crossing perimeters and enable retraction cecked

Retraction speed 20mm/s

Retraction distance 3mm

Minimum travel before retract 1.5mm

Minimum extrusion before retract 0.02mm

Zhop 0.1mm

Cut off object bottom 0mm

Nozzle diameter 0.4mm

Create wipe and prime tower checked

Support extruder as any extruder

Retraction on extruder switch 16mm

Wipe and prime volume 15mm^2

Volume overlap 0mm

Fan full at height 0.5mm

Minimum speed 0mm/s

G-Codes tab unmodified

Everything on advanced tab unchecked

Filament

Filament diameter 1.75mm

Flow 100%

Print temperature 210°C

Bed temperature 0°C

Min fan speed 50%

Max fan speed 100%

Minimum layer time 5s

|

Re: Cherry Pi III Is Available April 06, 2015 04:32AM |

Registered: 9 years ago Posts: 164 |

|

Re: Cherry Pi III Is Available April 06, 2015 09:40AM |

Registered: 10 years ago Posts: 903 |

Quote

pugzor

Would it be suggested to calibrate with blue tape on the bed too?

According to the listing on Amazon, 3M/Scotch blue painters tape is 0.1mm thick. What layer height were you using on your first attempts? I think you can see my point. Bigger nozzles or thicker layer heights let you be a little bit sloppy with the precision, but you still want to be measuring with every variable as close to the actual printing conditions as possible when you're playing with precisions specified in fractions of a millimeter (0.1mm) or 100 microns.

I'll share a tip for slicing that I use and it doesn't seem like anyone else does. I do not specify temperatures in my slicer, but rather set them manually on the printer before starting each job. Especially with a new printer/hotend/filament combination, you really need to try varying the temperature to find what works best, With PLA through an E3Dv5, I tried everything from 180-215C before settling on 190C for that spool. (Haven't run PLA since.) For ABS, I tried everything from 220-245C before settling on 230C for one roll and 235C for a different color/brand. There was a test print object on Thingiverse that consisted of a tall rectangle block, which you are supposed to print with 5C temperature steps to see the difference. Once you get the first layer worked out, you may want to find/print it to figure out your best temperature.

Unfortunately, there is a lot of trial-and-error involved with commissioning a new printer or even changing brands/spools of filament. After a few times, it becomes almost second nature as you gain the experience. Do not take anyone's settings as gospel, because they might not line up with your printer/hardware/hotend/filament. For example, my best extruder setting for not getting blobs on retract is 6.5mm retraction @ 100mm/second, with the extruder maximum acceleration limit raised in firmware to actually do 100mm/second. It took me almost a day to determine just this one setting.....

|

Re: Cherry Pi III Is Available April 06, 2015 11:54AM |

Registered: 9 years ago Posts: 893 |

When you say "balling up", do you mean that it puts down nothing for a few millimetres, then drops a big blob, over and over?

If that's the case then I suggest that your nozzle is too close to the bed - the bed itself is blocking the nozzle, until something has to give and all the backed-up plastic is pushed out. This is something my Prusa does with monotonous regularity when the auto-tramming doesn't want to play nicely...

...ignore me if this isn't the problem...

If that's the case then I suggest that your nozzle is too close to the bed - the bed itself is blocking the nozzle, until something has to give and all the backed-up plastic is pushed out. This is something my Prusa does with monotonous regularity when the auto-tramming doesn't want to play nicely...

...ignore me if this isn't the problem...

|

Re: Cherry Pi III Is Available April 06, 2015 05:10PM |

Registered: 10 years ago Posts: 515 |

@Puzgor, I would wind your first layer speed down a bit 65 is pretty fast. Try 25 for first layer speed. I would agree with Vreihen regarding layer heights. For your first few prints go with 0.3 for everything. When you get some Kgs of plastic under your belt start playing around with smaller layers. Calibrate with the blue tape on and the nozzle at printing temp and do the 'photocopier paper is a firm sliding fit' test on all four points (in front of each tower and centre) 0.3 layer height, certainly for your first layer, should just print at that point.

|

Re: Cherry Pi III Is Available April 07, 2015 07:37PM |

Registered: 9 years ago Posts: 76 |

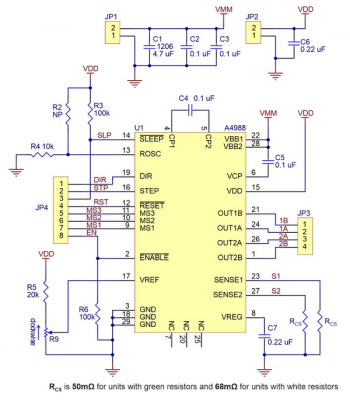

I was looking at the schematic, so you say short R4 to ground (The 10K resistor)

|

Re: Cherry Pi III Is Available April 08, 2015 02:44AM |

Registered: 10 years ago Posts: 515 |

Quote

mikes3ds

I was looking at the schematic, so you say short R4 to ground (The 10K resistor)

Yes. This is a section of Nophead's blog ( [hydraraptor.blogspot.co.uk] ) on the subject :-

Low Current Microstepping. Intended for applications where the minimum on-time prevents the output current from regulating to the programmed current level at low current steps. To prevent this, the device can be set to operate in Mixed decay mode on both rising and falling portions of the current waveform. This feature is implemented by shorting the ROSC pin to ground. In this state, the off-time is internally set to 30 μs.

|

Re: Cherry Pi III Is Available April 08, 2015 08:11AM |

Registered: 9 years ago Posts: 164 |

Build a 3D printer, they said... It'll be fun, they said...

But in all seriousness, slowing down the first layer helped a lot. I think I've got issues with it adhering to the print bed though, or filament getting stuck on the nozzle. Maybe it's too close to the bed? I'll keep mucking with the settings... I'll surely stumble across something that works one day. Maybe on the next roll of filament lol.

But in all seriousness, slowing down the first layer helped a lot. I think I've got issues with it adhering to the print bed though, or filament getting stuck on the nozzle. Maybe it's too close to the bed? I'll keep mucking with the settings... I'll surely stumble across something that works one day. Maybe on the next roll of filament lol.

|

Re: Cherry Pi III Is Available April 08, 2015 10:17AM |

Registered: 10 years ago Posts: 903 |

Some day, you will be looking at a plastic frog that just finished printing perfectly and laugh about all of the failures that you learned from to get that frog. Then, you'll put a price tag on that plastic frog and realize why I keep stressing that 3D printer parts should come with warning labels that stress the fine line between hobby and mental obsession.  I threw away my first roll of PLA just trying to figure out slicer settings and temperatures, and only have a handful of stringy pyramids to show for it.....

I threw away my first roll of PLA just trying to figure out slicer settings and temperatures, and only have a handful of stringy pyramids to show for it.....

I threw away my first roll of PLA just trying to figure out slicer settings and temperatures, and only have a handful of stringy pyramids to show for it.....

I threw away my first roll of PLA just trying to figure out slicer settings and temperatures, and only have a handful of stringy pyramids to show for it.....

|

Re: Cherry Pi III Is Available April 08, 2015 11:59AM |

Registered: 10 years ago Posts: 515 |

You may be better trying a glue stick (Pritt Stick in the UK) the thing that looks like a white lipstick and is used to stick bits of paper together. Just smear it all over your bed and let it dry for a bit. Holds PLA like s#!t to a blanket. Looking at you pile of strands I would actually say your nozzle is too far away from the bed as there are gaps between the strands. You need them to be just touching each other with a little overlap. Start with something small too, like a 20 x 20 x 20 cube.

Edited 1 time(s). Last edit at 04/08/2015 12:00PM by AndyCart.

Edited 1 time(s). Last edit at 04/08/2015 12:00PM by AndyCart.

|

Re: Cherry Pi III Is Available April 08, 2015 11:14PM |

Registered: 9 years ago Posts: 164 |

Haha, thanks guys. Admittedly I'm very %$#&ing happy that at least I did sort out my issue with the hot end jamming. That was worrying me greatly because I didn't want to spend more money before getting some results.

The ironic thing is that when I first got my printer working I actually had a reasonable print using slic3r, but now that I've been using Cura I haven't been able to get as good even with a bit of tweaking. I might try slic3r again and if I don't have any luck, go back to tweaking Cura (I know that's what you recommend Andy!). Might actually make a post in the printing issues forum too with a more comprehensive log of my attempts. When I get some solid settings I'll post on here what they were (just as another starting point for anyone else having issues).

There are a couple of things I want to try before messing with more settings in Cura.

a) Use a glue stick

Glue stick should work well on top of the blue tape, right? I'm not sure if it'll be as good just on the glass.

b) Up the temperature a tiny bit (~5°C)

I'm going to add a few degrees on to my extruder too because I noticed it's not as fluid as I've seen it at slightly higher temps, so a couple more degrees might be enough to increase adhesion.

c) Try printing a smaller object

Admittedly this will help to iron out some of the fundamental bugs, as I've only faced issues when long, straight lines are printed and maybe one line bows out for a few millimetres, causing the hot end to hit it and drag on the next pass.

I have to ask and maybe you've experienced this Andy, but does Cura take a long time to go from home to the print bed? Mine takes like 3-4 minutes every time I start a print. In that time I get filament leaking, not to mention a lot of frustration.

The ironic thing is that when I first got my printer working I actually had a reasonable print using slic3r, but now that I've been using Cura I haven't been able to get as good even with a bit of tweaking. I might try slic3r again and if I don't have any luck, go back to tweaking Cura (I know that's what you recommend Andy!). Might actually make a post in the printing issues forum too with a more comprehensive log of my attempts. When I get some solid settings I'll post on here what they were (just as another starting point for anyone else having issues).

There are a couple of things I want to try before messing with more settings in Cura.

a) Use a glue stick

Glue stick should work well on top of the blue tape, right? I'm not sure if it'll be as good just on the glass.

b) Up the temperature a tiny bit (~5°C)

I'm going to add a few degrees on to my extruder too because I noticed it's not as fluid as I've seen it at slightly higher temps, so a couple more degrees might be enough to increase adhesion.

c) Try printing a smaller object

Admittedly this will help to iron out some of the fundamental bugs, as I've only faced issues when long, straight lines are printed and maybe one line bows out for a few millimetres, causing the hot end to hit it and drag on the next pass.

I have to ask and maybe you've experienced this Andy, but does Cura take a long time to go from home to the print bed? Mine takes like 3-4 minutes every time I start a print. In that time I get filament leaking, not to mention a lot of frustration.

|

Re: Cherry Pi III Is Available April 09, 2015 04:31AM |

Registered: 9 years ago Posts: 67 |

#pugzor

Glue stick on glass or blue tape. When I print PLA, glue stick on glass works great. With ABS I found blue tape without glue stick worked best. I wouldn't start mixing them.

A smaller object can help if your bed isn't level, and when I was having first layer issues, I kept upping the temp, I now print PLA at 210, but I don't know how accurate that is, but it works for me.

Matt

Glue stick on glass or blue tape. When I print PLA, glue stick on glass works great. With ABS I found blue tape without glue stick worked best. I wouldn't start mixing them.

A smaller object can help if your bed isn't level, and when I was having first layer issues, I kept upping the temp, I now print PLA at 210, but I don't know how accurate that is, but it works for me.

Matt

|

Re: Cherry Pi III Is Available April 09, 2015 11:20AM |

Registered: 9 years ago Posts: 893 |

When I was printing PLA onto glass I found that cleaning the bed with something like meths (methyl alcohol) or acetone, followed by a light spray of the cheapest hairspray I could find, nearly always did the trick. Each spraying would last for quite a few prints as long as I kept my fingers off it. And I mean "the cheapest hairspray" - you need something without additives such as 'added vitamins' or 'conditioner'. Mine cost me about 75p (50c perhaps?) in Sainsburys.

For ABS I used 'ABS juice', which is a short length of ABS filament dissolved in acetone - this is wiped over the glass leaving a barely visible thin film. Don't make it too strong, else you'll never get the print off the glass!

Now I have an aluminium heated bed so I cover that with kapton tape. All I do with that is keep it clean with acetone, and I have no adhesion problems with PLA or ABS... well, I say 'no problems', but often I have a wrestling match getting ABS prints off! When this happens I just leave the bed to get cold and the print frees itself (often with a clearly audible click).

As for the other comments above - many of my first prints were test pieces, some of which I'd drawn up in FreeCAD. All were quite small, printed at 0.3, with temperatures that were mid-range for the filament in use. This meant that when things went wrong I hadn't wasted too much time and filament. I used this time to learn how Slic3r and Cura worked, and how changing settings affected the print.

HTH,

David

For ABS I used 'ABS juice', which is a short length of ABS filament dissolved in acetone - this is wiped over the glass leaving a barely visible thin film. Don't make it too strong, else you'll never get the print off the glass!

Now I have an aluminium heated bed so I cover that with kapton tape. All I do with that is keep it clean with acetone, and I have no adhesion problems with PLA or ABS... well, I say 'no problems', but often I have a wrestling match getting ABS prints off! When this happens I just leave the bed to get cold and the print frees itself (often with a clearly audible click).

As for the other comments above - many of my first prints were test pieces, some of which I'd drawn up in FreeCAD. All were quite small, printed at 0.3, with temperatures that were mid-range for the filament in use. This meant that when things went wrong I hadn't wasted too much time and filament. I used this time to learn how Slic3r and Cura worked, and how changing settings affected the print.

HTH,

David

|

Re: Cherry Pi III Is Available April 09, 2015 12:57PM |

Registered: 10 years ago Posts: 92 |

I have a heated borosilicate glass bed, and I use hairspray for everything. I've used it with success for PLA, ABS, and HIPS. For ABS I have Slic3r make a brim of about 4mm to really give it some surface area to prevent it from warping off the bed.

Cheap unscented Aqua Net works fantastic! And it leaves a very glossy finish on the part too.

I've found that if you print a second piece after the first, there can be a little shadow of the first piece on the second, so I clean the hairspray off between prints.

All it takes is another spray of hairspray and the old stuff softens up to be easily removed. I use one of these printable razor blade handles:

as a sort of a squeegee to scrape the old hairspray off. Plus it makes a nice part removal tool.

Cheap unscented Aqua Net works fantastic! And it leaves a very glossy finish on the part too.

I've found that if you print a second piece after the first, there can be a little shadow of the first piece on the second, so I clean the hairspray off between prints.

All it takes is another spray of hairspray and the old stuff softens up to be easily removed. I use one of these printable razor blade handles:

as a sort of a squeegee to scrape the old hairspray off. Plus it makes a nice part removal tool.

|

Re: Cherry Pi III Is Available April 10, 2015 01:47AM |

Registered: 10 years ago Posts: 515 |

Quote

pugzor

I have to ask and maybe you've experienced this Andy, but does Cura take a long time to go from home to the print bed? Mine takes like 3-4 minutes every time I start a print. In that time I get filament leaking, not to mention a lot of frustration.

Cura shouldn't cause a 3-4 minute home to start of print issue. I assume you mean the time it takes for the effector to move down once the nozzle has reached temperature? This problem is most likely caused by an incorrect setting in your Start Gcode. Can you post a copy?

|

Re: Cherry Pi III Is Available April 10, 2015 10:09AM |

Registered: 9 years ago Posts: 893 |

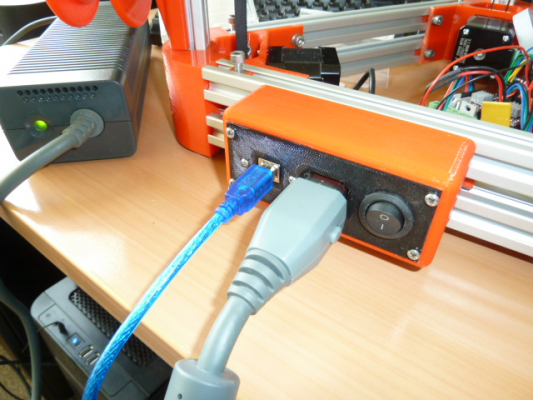

I've been busy - following on from my previous posting about the XBox PSU socket, I decided to make a little enclosure to neaten up the wiring.

It has a changeover switch - setting it to 'on'/'1' connects the PSU's +5v to its power-enable pin, which turns on the 12v supply. Setting it to 'off'/'0' connects the PSU's power-enable pin to PS-ON on the RAMPS board, allowing software like Repetier Host to control the 12v supply. This arrangement means that the 5v from the PSU never gets mixed up with the 5v of the RAMPS board. The USB outlet is a short extension lead off the Arduino USB type A socket.

I'm not 100% happy with the design - it's only fastened to the top rail with two M5 screws, and if I was doing it again I would have used two screws into each rail. I'd also have made the plinth for the XBox socket 10mm high instead of 5mm, to make more room for the wiring. However, I won't bother because I've run out of 3mm red* filament, and as the Cherry Pi is going to be using 1.75mm filament I don't want to buy any more of the old size!

I have put the STL files up on Thingiverse as this box could be used on any delta printer that uses 20x20 extrusion (and probably others too). Perhaps it will be useful to someone.

All I need now is for my heatbed to arrive from China - everything else is finished.

David

* It's what e-sun call red, but it's distinctly orange, especially with the flash lighting. A fair description is 'Chinese red' - look at the bits in the back of the photos to see the true colour.

Edited 5 time(s). Last edit at 04/10/2015 01:47PM by David J.

It has a changeover switch - setting it to 'on'/'1' connects the PSU's +5v to its power-enable pin, which turns on the 12v supply. Setting it to 'off'/'0' connects the PSU's power-enable pin to PS-ON on the RAMPS board, allowing software like Repetier Host to control the 12v supply. This arrangement means that the 5v from the PSU never gets mixed up with the 5v of the RAMPS board. The USB outlet is a short extension lead off the Arduino USB type A socket.

I'm not 100% happy with the design - it's only fastened to the top rail with two M5 screws, and if I was doing it again I would have used two screws into each rail. I'd also have made the plinth for the XBox socket 10mm high instead of 5mm, to make more room for the wiring. However, I won't bother because I've run out of 3mm red* filament, and as the Cherry Pi is going to be using 1.75mm filament I don't want to buy any more of the old size!

I have put the STL files up on Thingiverse as this box could be used on any delta printer that uses 20x20 extrusion (and probably others too). Perhaps it will be useful to someone.

All I need now is for my heatbed to arrive from China - everything else is finished.

David

* It's what e-sun call red, but it's distinctly orange, especially with the flash lighting. A fair description is 'Chinese red' - look at the bits in the back of the photos to see the true colour.

Edited 5 time(s). Last edit at 04/10/2015 01:47PM by David J.

|

Re: Cherry Pi III Is Available April 11, 2015 11:20AM |

Registered: 10 years ago Posts: 515 |

Hi Guys

I've designed a new (oh no not another one !!!) effector. It's a variant of the E3D V5 version that allows a 12mm inductive probe to be fitted for auto calibration. I know, I've previously said it's not worth the bother but this probe in conjunction with Rich Cattell's latest version of Marlin (on his 'Testing' fork) seems to work really well. There's a video here of it in operation :-

[www.youtube.com]

If you want the effector .stl it's attached.

EffectorForAllMetalHotEndwithProbeV2.stl

Enjoy

Andy

I've designed a new (oh no not another one !!!) effector. It's a variant of the E3D V5 version that allows a 12mm inductive probe to be fitted for auto calibration. I know, I've previously said it's not worth the bother but this probe in conjunction with Rich Cattell's latest version of Marlin (on his 'Testing' fork) seems to work really well. There's a video here of it in operation :-

[www.youtube.com]

If you want the effector .stl it's attached.

EffectorForAllMetalHotEndwithProbeV2.stl

Enjoy

Andy

|

Re: Cherry Pi III Is Available April 11, 2015 12:43PM |

Registered: 9 years ago Posts: 76 |

The video is pretty cool!!!

A couple questions--

Where did you get that probe from?

Is it better than using the other designs where it uses the effector as Z probe?

Is it worth having a Z probe? (Can you manually calibrate with the z-probe easily, I was not going to have z-probe on mine unless I thought it was useful)

A couple questions--

Where did you get that probe from?

Is it better than using the other designs where it uses the effector as Z probe?

Is it worth having a Z probe? (Can you manually calibrate with the z-probe easily, I was not going to have z-probe on mine unless I thought it was useful)

|

Re: Cherry Pi III Is Available April 11, 2015 01:01PM |

Registered: 10 years ago Posts: 515 |

Quote

mikes3ds

The video is pretty cool!!!

A couple questions--

Where did you get that probe from?

Is it better than using the other designs where it uses the effector as Z probe?

Is it worth having a Z probe? (Can you manually calibrate with the z-probe easily, I was not going to have z-probe on mine unless I thought it was useful)

Hi Mike

The probe is from Ebay [www.ebay.co.uk]

It's the most accurate system I have used to date (microswitch in effector, microswitch with Allen key & FSR all tried previously) the inductive sensor gets the same reading from just two tries about 99% of the time.

No problem manually calibrating with the probe attached.

The only doubt I have about it is the added weight on the effector. Time will tell. So far so good.

Andy

|

Re: Cherry Pi III Is Available April 11, 2015 01:58PM |

Registered: 9 years ago Posts: 893 |

Sorry, only registered users may post in this forum.