Effector "Rocking"

Posted by Parabolic

|

Effector "Rocking" August 03, 2014 05:33PM |

Registered: 12 years ago Posts: 141 |

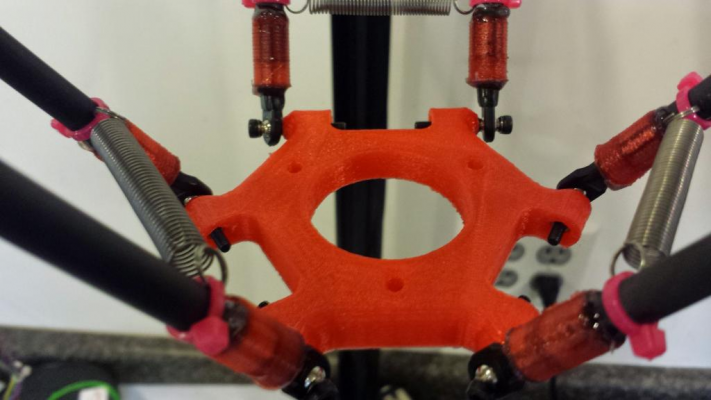

Hey guys - Im having a slight issue on my Delta. The Effector "rocks" ever so slightly when its moving. its easier to see on the infill movements as it moves back and fourth quickly. As a better example, when one carriage moves up, that side of the effector is "pulled" up compared to the others in that direction of travel. Is this a geometry issue or a firmware/ calculation issue? My towers are exactly 120 deg apart and square to each other. all of my rods are the same length, as well as the magnetic ball mounts on the effector and carriages. If it is a setting, WHICH of the settings would change it.

It will print, however I get a bit nervous of the print head hitting the print if it rocks too much.

Thanks!

Jeff

It will print, however I get a bit nervous of the print head hitting the print if it rocks too much.

Thanks!

Jeff

|

Re: Effector "Rocking" August 03, 2014 05:36PM |

Registered: 10 years ago Posts: 515 |

|

Re: Effector "Rocking" August 03, 2014 05:38PM |

Registered: 12 years ago Posts: 141 |

|

Re: Effector "Rocking" August 04, 2014 10:21AM |

Registered: 9 years ago Posts: 79 |

When I had this issue, it was a mechanical issue. The culprit: the diagonal rods were not precisely equal.

I too believed that they were equal, but when I took the machine apart and used a caliber on them, they were different. Give it a try, if it is not the issue then at least this step is checked.

You can also feel that the arms are off if you take the moving parts out of the machine: the carriages, arms, and effector--all still connected. Then try to move the carriages in a circular movement. If they are equal it will be easy to make a full circle. If they are not equal you will feel a rigid sort of slam when doing the circle. You will feel it move in a straight line rather than a circular motion. The slam will be akin to a tire rolling with a flat spot on it. It be incapable of making a perfect circular motion and you will feel when it changes from circular to flat--it will be apparent. To be clear the circle motion will be disrupted and the circle will be similar to a circle with a flat side somewhere on one section.

If you get similar results with the circular motion test, then check your rod length with a caliber.

After I checked this with this method and checked my rods with a caliber, I had to rebuild my rods and the difference was that instead of preparing each rod at a time I did everything at once. I cut all of the rods at the exact same time- just taped them together and put it in my bandsaw (if you have too cut carbon fiber, use some sort of protection: respirator, mask....). Then I made a massive jig with magnets adhered to a piece of wood and I set them with epoxy all at once. I learned that making them individually allows a risk for some variation between the parts.

With the new parts my effector does not raise up when the effector is closest to that carriage (carriage is the the highest of the three). However, if this is your issue you should be able to see the effector rise when doing a tower calibration. It will lift up on whichever tower the rods are not correct. Mine was near the y tower.

If you cannot duplicate the rocking in situations other than when the machine is doing infill, then it may be speed related.

If that was the case, I would be looking at the strength of the magnets. If your magnets are n35, I would try to increase the magnet to n42 or n52 and see if the problem subsides. If the power of the magnets is already sufficient, then I would see if the setup had a proper ball and socket joint. A ball and socket joint would help to keep the joint in the correct axis during all of the movements. It could be that during the infill motions the magnets may slip from the proper axis, resulting in a rocking effect.

Edited 2 time(s). Last edit at 08/04/2014 10:32AM by Wildcard.

I too believed that they were equal, but when I took the machine apart and used a caliber on them, they were different. Give it a try, if it is not the issue then at least this step is checked.

You can also feel that the arms are off if you take the moving parts out of the machine: the carriages, arms, and effector--all still connected. Then try to move the carriages in a circular movement. If they are equal it will be easy to make a full circle. If they are not equal you will feel a rigid sort of slam when doing the circle. You will feel it move in a straight line rather than a circular motion. The slam will be akin to a tire rolling with a flat spot on it. It be incapable of making a perfect circular motion and you will feel when it changes from circular to flat--it will be apparent. To be clear the circle motion will be disrupted and the circle will be similar to a circle with a flat side somewhere on one section.

If you get similar results with the circular motion test, then check your rod length with a caliber.

After I checked this with this method and checked my rods with a caliber, I had to rebuild my rods and the difference was that instead of preparing each rod at a time I did everything at once. I cut all of the rods at the exact same time- just taped them together and put it in my bandsaw (if you have too cut carbon fiber, use some sort of protection: respirator, mask....). Then I made a massive jig with magnets adhered to a piece of wood and I set them with epoxy all at once. I learned that making them individually allows a risk for some variation between the parts.

With the new parts my effector does not raise up when the effector is closest to that carriage (carriage is the the highest of the three). However, if this is your issue you should be able to see the effector rise when doing a tower calibration. It will lift up on whichever tower the rods are not correct. Mine was near the y tower.

If you cannot duplicate the rocking in situations other than when the machine is doing infill, then it may be speed related.

If that was the case, I would be looking at the strength of the magnets. If your magnets are n35, I would try to increase the magnet to n42 or n52 and see if the problem subsides. If the power of the magnets is already sufficient, then I would see if the setup had a proper ball and socket joint. A ball and socket joint would help to keep the joint in the correct axis during all of the movements. It could be that during the infill motions the magnets may slip from the proper axis, resulting in a rocking effect.

Edited 2 time(s). Last edit at 08/04/2014 10:32AM by Wildcard.

|

Re: Effector "Rocking" August 04, 2014 11:20AM |

Registered: 12 years ago Posts: 141 |

Thanks so much for the input!!

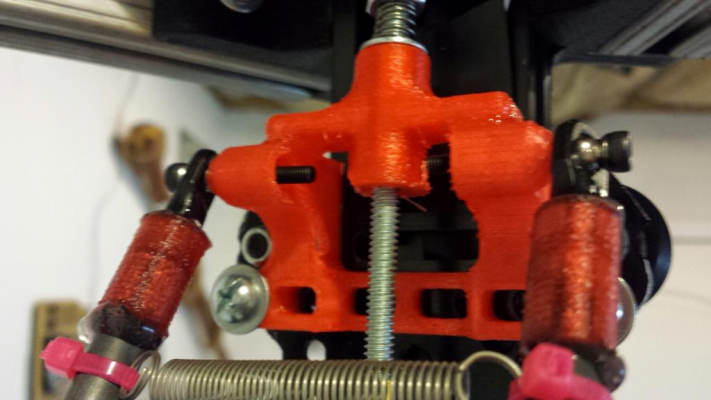

I think youre right in the last few statements - I think its my sockets. I "machined" them by hand and they may not be totally accurate between all of them. (ball hone on a drill). They are socket head bolts I tried to round out.

What is a good solution for a socket on a 1/2" magnet then? How about a threaded rod coupler that can be adjusted?

Thanks!

Jeff

I think youre right in the last few statements - I think its my sockets. I "machined" them by hand and they may not be totally accurate between all of them. (ball hone on a drill). They are socket head bolts I tried to round out.

What is a good solution for a socket on a 1/2" magnet then? How about a threaded rod coupler that can be adjusted?

Thanks!

Jeff

|

Re: Effector "Rocking" August 04, 2014 08:22PM |

Registered: 10 years ago Posts: 903 |

|

Re: Effector "Rocking" August 05, 2014 12:29PM |

Registered: 9 years ago Posts: 79 |

I used finishing washers when I made a magnetic effector for my rostock. If you are thinking about rebuilding the magnetic setup, there is a nice listing on the delta group for magnetic balls. [groups.google.com].

You can also use Redcat racing 02152 m5 ball screws, and counter sunk magnets.

You can also use Redcat racing 02152 m5 ball screws, and counter sunk magnets.

|

Re: Effector "Rocking" August 05, 2014 01:27PM |

Registered: 12 years ago Posts: 141 |

Well, I rebuilt all my rods yesterday and set them in a jig for accuracy between them. Still have the rocking when changing directions. There is no play in anything so im unsure where this is coming from now. Is there any possibility this could be an incorrect setting in marlin? Im thinking that if my homing is off that it wouldnt be an issue as it would just be slanted...?

Thanks!

Jeff

Thanks!

Jeff

|

Re: Effector "Rocking" August 05, 2014 02:46PM |

Registered: 10 years ago Posts: 515 |

|

Re: Effector "Rocking" August 05, 2014 03:15PM |

Registered: 12 years ago Posts: 141 |

|

Re: Effector "Rocking" August 05, 2014 05:53PM |

Registered: 10 years ago Posts: 515 |

|

Re: Effector "Rocking" August 10, 2014 03:34PM |

Registered: 12 years ago Posts: 141 |

Sure I can!

[youtu.be]

Sorry it took so long - been busy at work.

As you can see its not excessive but it is apparent.

No I have NOT calibrated this as of yet - just the basic measurements entered into marlin.

Again - all my towers are at a perfect 120 degree separation and parallel. all the pullys are the same (20 tooth aluminum), and the stepper motor steps is at 80 in Marlin.

All 6 rods are exact length (done in a jig)

Thanks!

Jeff

[youtu.be]

Sorry it took so long - been busy at work.

As you can see its not excessive but it is apparent.

No I have NOT calibrated this as of yet - just the basic measurements entered into marlin.

Again - all my towers are at a perfect 120 degree separation and parallel. all the pullys are the same (20 tooth aluminum), and the stepper motor steps is at 80 in Marlin.

All 6 rods are exact length (done in a jig)

Thanks!

Jeff

|

Re: Effector "Rocking" August 11, 2014 11:51PM |

Registered: 9 years ago Posts: 79 |

|

Re: Effector "Rocking" August 13, 2014 10:28AM |

Registered: 12 years ago Posts: 141 |

Nope, Sockets are good - there is nothing loose at all. I reprinted a new effector as My carriages were found to be a bit wider - but that didnt change anything. Ive checked and checked all my measurements and EVERYTHING is equal! Its almost as the firmware calibration is off. If I move it by hand theres no apparent rocking seen. IDK - Im at a loss.

|

Re: Effector "Rocking" August 13, 2014 11:13AM |

Registered: 9 years ago Posts: 79 |

What about slop? What if the problem that you are seeing is similar to the traxxas joints where the effector will still have small movement on the joints. Magnetic joints seem to suffer from the same occurrence.

You may try adding springs to tie the arms together. Other people use rubber ands or print out connectors that clip onto the rods. [dustsreprap.blogspot.com]

Edited 1 time(s). Last edit at 08/13/2014 11:18AM by Wildcard.

You may try adding springs to tie the arms together. Other people use rubber ands or print out connectors that clip onto the rods. [dustsreprap.blogspot.com]

Edited 1 time(s). Last edit at 08/13/2014 11:18AM by Wildcard.

|

Re: Effector "Rocking" August 14, 2014 09:17PM |

Registered: 12 years ago Posts: 141 |

|

Re: Effector "Rocking" August 15, 2014 01:34AM |

Registered: 10 years ago Posts: 469 |

I dislike the magnet solution. Traxxas joints are ok. I think a different joint with less slop is in order.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Effector "Rocking" August 15, 2014 10:27AM |

Registered: 9 years ago Posts: 79 |

I recently just put springs on my traxxas arms to take the slop away. There is also a heating solution that was discussed on the google group on how to make he joints slop free without springs or bands. The steps were:

Jun 14Doug LaRue

since I've not seen it posted anywhere and had to figure this out here is how you assemble the traxxas joints( metal into plastic ).

Put all the metal parts in a glass container in the freezer for about 15minutes

place cereal box cardboard down on stone countertop for insulation

boil a pot of water after the 15 minutes

You will need 2 pair of tweesers. one for the hot parts, one for the cold part

drop one plastic piece in the boiling water and count to 30(seconds) while also pulling out one metal piece which is put on the cardboard

place another plastic part int the water and pull out the first one

quickly place the hot plastic piece over the metal part( shinny ring down ) and using another blank plastic piece to apply force push the plastic onto the metal

repeat

Doing this you should get tight traxxas joints instead of loose sloppy ones which require springs and rubber bands to keep the slop out.

Traxxas joint assembly magic

Edited 1 time(s). Last edit at 08/15/2014 10:30AM by Wildcard.

Jun 14Doug LaRue

since I've not seen it posted anywhere and had to figure this out here is how you assemble the traxxas joints( metal into plastic ).

Put all the metal parts in a glass container in the freezer for about 15minutes

place cereal box cardboard down on stone countertop for insulation

boil a pot of water after the 15 minutes

You will need 2 pair of tweesers. one for the hot parts, one for the cold part

drop one plastic piece in the boiling water and count to 30(seconds) while also pulling out one metal piece which is put on the cardboard

place another plastic part int the water and pull out the first one

quickly place the hot plastic piece over the metal part( shinny ring down ) and using another blank plastic piece to apply force push the plastic onto the metal

repeat

Doing this you should get tight traxxas joints instead of loose sloppy ones which require springs and rubber bands to keep the slop out.

Traxxas joint assembly magic

Edited 1 time(s). Last edit at 08/15/2014 10:30AM by Wildcard.

|

Re: Effector "Rocking" August 15, 2014 10:46AM |

Registered: 10 years ago Posts: 469 |

I might give that a shot. I will be replacing my solid aluminum arms with CF rods at some point. I will be buying new joints for those arms anyway so I might give that a shot. My initial idea was to use 3mm ID bearnings and make my own universal joints.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Effector "Rocking" August 15, 2014 12:45PM |

Registered: 10 years ago Posts: 732 |

If you are in EU try these: MP JET Ball Link (Ø7 mm, M3, M3 short)

[bigplanes.nl]

They are sold assembled and tight. No need for rubber bands.

No way I would go with magnetic joints instead of good ball joints.

Edited 1 time(s). Last edit at 08/15/2014 12:46PM by hercek.

[bigplanes.nl]

They are sold assembled and tight. No need for rubber bands.

No way I would go with magnetic joints instead of good ball joints.

Edited 1 time(s). Last edit at 08/15/2014 12:46PM by hercek.

|

Re: Effector "Rocking" August 15, 2014 02:43PM |

Registered: 9 years ago Posts: 79 |

|

Re: Effector "Rocking" August 15, 2014 06:59PM |

Registered: 12 years ago Posts: 141 |

Thats what I ended up doing... pressed in the "balls" and used springs - so far so good!

What about the all aluminum ones Ive seen? Would these be a better and tighter solution?

What about the all aluminum ones Ive seen? Would these be a better and tighter solution?

|

Re: Effector "Rocking" August 15, 2014 07:48PM |

Registered: 10 years ago Posts: 153 |

I'm betting the radius of your rod ends was greater than the radius of the balls. I'm surprised people are glad to switch to traxxas rods, as theoretically they wear out over time and have slop and get more as time goes on. Whereas the magnets are tight from the start and still are ages later, assuming they are well made. Either or, both work.

Edited 1 time(s). Last edit at 08/15/2014 07:48PM by TheTechnicalNoob.

Edited 1 time(s). Last edit at 08/15/2014 07:48PM by TheTechnicalNoob.

|

Re: Effector "Rocking" August 16, 2014 10:06AM |

Registered: 9 years ago Posts: 79 |

Different strokes for different folks. Everything needs maintenance after awhile and even a magnetic setup can have slop, or may break down after awhile because you have metal on metal or plastic on metal which may wear down overtime.

Edited 1 time(s). Last edit at 08/16/2014 07:12PM by Wildcard.

Edited 1 time(s). Last edit at 08/16/2014 07:12PM by Wildcard.

|

Re: Effector "Rocking" August 16, 2014 10:17AM |

Registered: 9 years ago Posts: 79 |

|

Re: Effector "Rocking" August 16, 2014 04:57PM |

Registered: 10 years ago Posts: 515 |

I don't use magnets or Traxas. I print 8mm 'cups' in the plastic parts and my rods have 8mm balls on the end. The rods are held in place with a piece of Spectra line and a spring. No backlash or slop and really easy to dis-assemble if required. Cheap too!

[forums.reprap.org]

Andy

[forums.reprap.org]

Andy

|

Re: Effector "Rocking" August 16, 2014 07:34PM |

Registered: 9 years ago Posts: 79 |

|

Re: Effector "Rocking" August 18, 2014 07:28AM |

Registered: 10 years ago Posts: 515 |

Sorry, only registered users may post in this forum.