Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 15, 2015 06:28PM |

Registered: 9 years ago Posts: 36 |

Quote

parco

Is anyone else experience this crazy wiggle: [www.youtube.com]

(I do realize it is printing higher than it should)

I'm trying to see what might be the cause, everything is tight and well built. The linear rails are definitely not "butter" smooth, and the other culprit may be the 36 tooth pulleys.

The Slic3r software might be the culprit. Double check your setting. It could be the fill-in or something straight like that. I'm using the 36-tooth pulleys and it's relatively smooth. My only problem is the webbing, probably too high of the temperature on the PLA causing drips, running at 220C which is normally used for ABS. Still a lot of fine tuning left. I'm also added a Greg Wade's filament extruder to increase the torque, and having trouble fine tuning the speed. So more fun and games...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 15, 2015 11:20PM |

Registered: 9 years ago Posts: 46 |

Quote

dnguyenai598

The Slic3r software might be the culprit. Double check your setting. It could be the fill-in or something straight like that. I'm using the 36-tooth pulleys and it's relatively smooth. My only problem is the webbing, probably too high of the temperature on the PLA causing drips, running at 220C which is normally used for ABS. Still a lot of fine tuning left. I'm also added a Greg Wade's filament extruder to increase the torque, and having trouble fine tuning the speed. So more fun and games...

I too am using the Greg Wade's extruder. I am successfully printing in both PLA and ABS now. My steps in Configuration.h is 700 for the extruder. For the stringy prints, you may just have to play around with retraction in slic3r. It differs slightly on different brands. For Makerbot PLA, I have the retraction set to 3mm and for Shaxon PLA, I have it set to 4mm. You just have to find the sweet spot.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2015 09:38AM |

Registered: 9 years ago Posts: 6 |

Hello Reprappers

I got my FolgerTech Kossel 2020 a week ago, and the build went good. After some research i found the firmware, for Repetier Host (windows) 0.91.

My problem is that a the firmware seems "right", but the distance it travels when using manuel control is, way bigger in the Repetier program, whene going home, it looks more like a crash!

I run with 36 teeth pulley, GT2, 44,44 mm/step, the motors are 1.8 degree NEMA 17. (when traveling z up, at 0.1 it jumps over a step every second time)

I dont know which setting i should change, to configure the motors? Any information or if anybody has the same problem?

Thanks!

I got my FolgerTech Kossel 2020 a week ago, and the build went good. After some research i found the firmware, for Repetier Host (windows) 0.91.

My problem is that a the firmware seems "right", but the distance it travels when using manuel control is, way bigger in the Repetier program, whene going home, it looks more like a crash!

I run with 36 teeth pulley, GT2, 44,44 mm/step, the motors are 1.8 degree NEMA 17. (when traveling z up, at 0.1 it jumps over a step every second time)

I dont know which setting i should change, to configure the motors? Any information or if anybody has the same problem?

Thanks!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2015 12:13PM |

Registered: 9 years ago Posts: 17 |

Quote

bjoernkarmann

Hello Reprappers

I got my FolgerTech Kossel 2020 a week ago, and the build went good. After some research i found the firmware, for Repetier Host (windows) 0.91.

My problem is that a the firmware seems "right", but the distance it travels when using manuel control is, way bigger in the Repetier program, whene going home, it looks more like a crash!

I run with 36 teeth pulley, GT2, 44,44 mm/step, the motors are 1.8 degree NEMA 17. (when traveling z up, at 0.1 it jumps over a step every second time)

I dont know which setting i should change, to configure the motors? Any information or if anybody has the same problem?

Thanks!

I have this exact same issue, did someone mention going to 20 tooth pulleys can fix this?

EDIT: Can confirm, switching to 20 tooth pulleys and changing the DEFAULT_AXIS_STEPS_PER_UNIT in firmware does fix this problem.

Edited 3 time(s). Last edit at 01/17/2015 06:10PM by parco.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2015 07:15PM |

Registered: 11 years ago Posts: 69 |

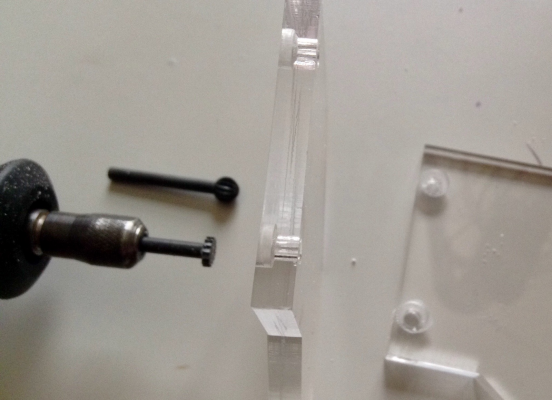

The acrylic parts are definitely beta. One of the hot bed mounting pieces was missing a hole completely.

Any piece that needed to be attached to the frame with t-nuts and the suggested M3x8 screwed barely got a thread to catch. I Dremeled them out so they could get a better bite. First I used a ball shaped reaming tool. Then a flat toothed disc to allow the screw to inset a millimeter or two.

The switches for the top of the slides needed to be offset a bit, so I use the included split lock washers but not used in the build manual to let the switches stick out without catching.

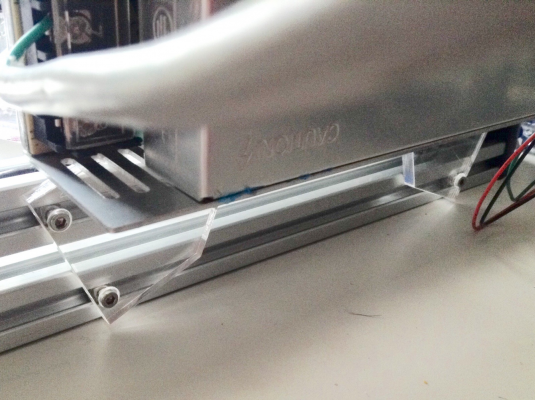

The power supply mounts were off by so much that I had to mount them at an angle to get them to work. Already reamed the holes for the M3x8s so didn't want to have to drill new holes. I put the frame on its side so I could work out attaching the power supply more easily.

Standing up, the corners luckily are not lower than the frame or could make a pivot point if there is any vibrations.

Drilling in acrylic can be a pain and chip or crack the part if the bit catches too much.

Any piece that needed to be attached to the frame with t-nuts and the suggested M3x8 screwed barely got a thread to catch. I Dremeled them out so they could get a better bite. First I used a ball shaped reaming tool. Then a flat toothed disc to allow the screw to inset a millimeter or two.

The switches for the top of the slides needed to be offset a bit, so I use the included split lock washers but not used in the build manual to let the switches stick out without catching.

The power supply mounts were off by so much that I had to mount them at an angle to get them to work. Already reamed the holes for the M3x8s so didn't want to have to drill new holes. I put the frame on its side so I could work out attaching the power supply more easily.

Standing up, the corners luckily are not lower than the frame or could make a pivot point if there is any vibrations.

Drilling in acrylic can be a pain and chip or crack the part if the bit catches too much.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2015 11:03PM |

Registered: 9 years ago Posts: 17 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 01:10AM |

Registered: 11 years ago Posts: 69 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 01:32AM |

Registered: 9 years ago Posts: 36 |

Quote

rtideas

And once again, coming up short with this kit. The leads for the hot end are too short. Grrrrrr.

What gauge wire do I need to add extensions to the hot end heater wires?

Needs about a 25-30cm more of wire.

[attachment 47343 image.jpg]

Already had to make extended leads for the fan.

If you don't mount the Arduino on acrylic bed support and leave it free-floating, it should just be long enough. I wouldn't blame Folger because the hot-ends come with this length of leads. Maybe try moving the leads to the other side. Yes, longer would be better; I would go with 16awg. For the hot bed, 14awg, or 12awg if you can get the wires into the terminals. Good luck.

Edited 1 time(s). Last edit at 01/18/2015 06:34PM by dnguyenai598.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 01:41AM |

Registered: 9 years ago Posts: 36 |

Quote

rtideas

The acrylic parts are definitely beta. One of the hot bed mounting pieces was missing a hole completely.

[attachment 47338 image.jpg]

Any piece that needed to be attached to the frame with t-nuts and the suggested M3x8 screwed barely got a thread to catch. I Dremeled them out so they could get a better bite. First I used a ball shaped reaming tool. Then a flat toothed disc to allow the screw to inset a millimeter or two.

[attachment 47339 image.jpg]

The switches for the top of the slides needed to be offset a bit, so I use the included split lock washers but not used in the build manual to let the switches stick out without catching.

[attachment 47340 image.jpg]

The power supply mounts were off by so much that I had to mount them at an angle to get them to work. Already reamed the holes for the M3x8s so didn't want to have to drill new holes. I put the frame on its side so I could work out attaching the power supply more easily.

[attachment 47341 image.jpg]

Standing up, the corners luckily are not lower than the frame or could make a pivot point if there is any vibrations.

[attachment 47342 image.jpg]

Drilling in acrylic can be a pain and chip or crack the part if the bit catches too much.

I think all the acrylic pieces got scaled to 105% so the hole alignment is a little off; on some pieces like the power supply mount, I drilled new holes. As for the three stop-end switches, you need to use the two round acrylic spacers with 18mm bolts (two lower ones and an 10mm on top). Did you have any 10mm bolts? These are for the acrylic pieces so that you don't have to countersink the 8mm ones.

Edited 1 time(s). Last edit at 01/18/2015 06:35PM by dnguyenai598.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 09:51AM |

Registered: 9 years ago Posts: 5 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 06:57PM |

Registered: 9 years ago Posts: 36 |

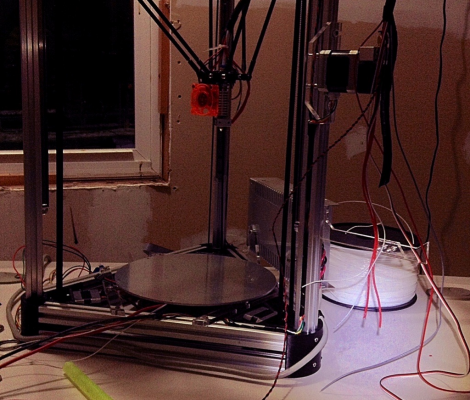

New idea, remounting the Arduino on the top side using the acrylic pieces that were originally for the bed and filament spool arm. So I discovered a couple of things. As the bed heats up, it warps and the acrylic support won't hold it flat, and the filament spool arm won't allow the spool to turn smoothly, sometimes getting caught. I'm rebuilding the bed and the arm, and re-purposing the other parts and using them to mount the Arduino on top.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2015 07:17PM |

Registered: 11 years ago Posts: 69 |

Trying to use what came with the kit. Was missing the 30mm tensioner bolts listed in the Build Manual. After searching my local hardware store (limited metric), Lowe's (too short), my favorite hobby shop, another hardware store recommended by the hobby shop (same selection as Lowe's), I found the bolts at another hobby shop across town.

They manual should recommend 35mm or longer. Also, the nylock nuts spun freely. My guess, the plastic parts scaled up for the 20x20 frame also scaled the nut holes. Had to jam a small flathead screwdriver to tighten the tensioner bolts.

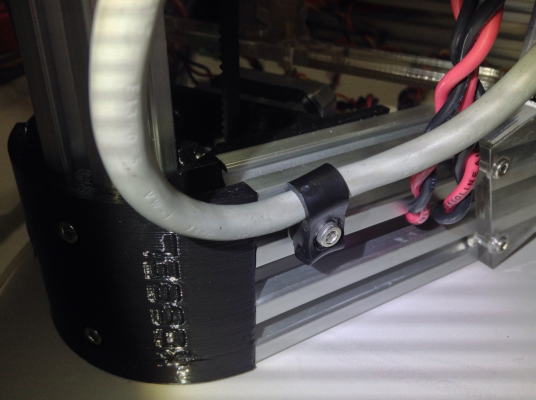

I also attached a coax cable mount I took from my basement to attach the power cord to the frame to keep tension off the power supply connections.

Yeah, Dnguyenai598, I wonder about the hot bed on an acrylic mount. Did it even warp with the spacers?

Edited 1 time(s). Last edit at 01/18/2015 07:51PM by rtideas.

They manual should recommend 35mm or longer. Also, the nylock nuts spun freely. My guess, the plastic parts scaled up for the 20x20 frame also scaled the nut holes. Had to jam a small flathead screwdriver to tighten the tensioner bolts.

I also attached a coax cable mount I took from my basement to attach the power cord to the frame to keep tension off the power supply connections.

Yeah, Dnguyenai598, I wonder about the hot bed on an acrylic mount. Did it even warp with the spacers?

Edited 1 time(s). Last edit at 01/18/2015 07:51PM by rtideas.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 02:02AM |

Registered: 9 years ago Posts: 46 |

Quote

rtideas

Trying to use what came with the kit. Was missing the 30mm tensioner bolts listed in the Build Manual. After searching my local hardware store (limited metric), Lowe's (too short), my favorite hobby shop, another hardware store recommended by the hobby shop (same selection as Lowe's), I found the bolts at another hobby shop across town.

They manual should recommend 35mm or longer. Also, the nylock nuts spun freely. My guess, the plastic parts scaled up for the 20x20 frame also scaled the nut holes. Had to jam a small flathead screwdriver to tighten the tensioner bolts.

I also attached a coax cable mount I took from my basement to attach the power cord to the frame to keep tension off the power supply connections.

[attachment 47400 image.jpg]

Yeah, Dnguyenai598, I wonder about the hot bed on an acrylic mount. Did it even warp with the spacers?

I realized by having to buy so many metric bolts, Home Depot has better selection than Lowes. I'm lucky enough to have 3 of them within 7 miles from home. I am now in the process of the final modifications and build of my kit. Bear in mind that I have dismantled this at least 3 times...don't ask me why. After this, it should be just all business and no more tinkering. I bough the kit as a baseline kit and had low expectations about the build quality and support, so I really cannot complain.

I have cut two acrylic pieces that would fit the top and under the bed. Unfotunately, I'm not home right now to take photos of my modifications. They do make the whole thing more rigid. I have placed the RAMPS on the top acrylic because even with fiberglass insulation, the bottom of the acrylic still gets pretty warm. Not a good place for a very touchy piece of electronics.

On another note, while I am able to print ABS parts, there is a need for an enclosure when printing tall parts, so I guess this printer will only be seeing PLA from me from now on.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 02:07AM |

Registered: 9 years ago Posts: 46 |

Quote

parco

Quote

bjoernkarmann

Hello Reprappers

I got my FolgerTech Kossel 2020 a week ago, and the build went good. After some research i found the firmware, for Repetier Host (windows) 0.91.

My problem is that a the firmware seems "right", but the distance it travels when using manuel control is, way bigger in the Repetier program, whene going home, it looks more like a crash!

I run with 36 teeth pulley, GT2, 44,44 mm/step, the motors are 1.8 degree NEMA 17. (when traveling z up, at 0.1 it jumps over a step every second time)

I dont know which setting i should change, to configure the motors? Any information or if anybody has the same problem?

Thanks!

I have this exact same issue, did someone mention going to 20 tooth pulleys can fix this?

EDIT: Can confirm, switching to 20 tooth pulleys and changing the DEFAULT_AXIS_STEPS_PER_UNIT in firmware does fix this problem.

You would have to ask dnguyenai598 how his kit is running smoothly with the 36-tooth pulleys if you want to go with that. I had 20-teeth lying around while I was building it so I swapped them out because I did notice that at 0.1 mm increments, the motors only move every other step. I now have 16-tooth installed, but have yet to test it. We'll see the results soon enough.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 12:47PM |

Registered: 9 years ago Posts: 6 |

Thanks!, maybe i will just go for the 20 or 16 let me know how it goes with your 16-tooth  and if you changed the steps pr mm perhaps.

and if you changed the steps pr mm perhaps.

And for rtideas, i have the same problem with the acrylic (i also had a "home button holder" cracking, and had to mount the power supply sideways. so you defiantly have de be carefull with the screws. even my bed holder did't fit .

and if you changed the steps pr mm perhaps.

and if you changed the steps pr mm perhaps.And for rtideas, i have the same problem with the acrylic (i also had a "home button holder" cracking, and had to mount the power supply sideways. so you defiantly have de be carefull with the screws. even my bed holder did't fit .

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 01:37PM |

Registered: 9 years ago Posts: 46 |

Yes, I did have to change the steps to 100/mm. If you go to any prusa calculator, you can input your setup and it gives you the proper steps and also see how it affects your resolution. I would just pull more effort from your motors, but so far I haven't had any problems. You just have to set your driver voltages properly. At 0.6 volts, I haven't had a missed step and the motors are staying cool. I am not running the Folger's firmware though, since they came in late with that and I had already done so many modifications to the firmware I had.Quote

bjoernkarmann

Thanks!, maybe i will just go for the 20 or 16 let me know how it goes with your 16-toothand if you changed the steps pr mm perhaps.

And for rtideas, i have the same problem with the acrylic (i also had a "home button holder" cracking, and had to mount the power supply sideways. so you defiantly have de be carefull with the screws. even my bed holder did't fit .

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 09:05PM |

Registered: 11 years ago Posts: 69 |

Closer. At least it's moving. Installed 0.91 Repetier firmware. I matched all the settings to the configuration file in the FolgerTech Google Drive except for rod length and my added LCD screen.

Googe Drive--FolgerTech Kossel 2020 software package.zip.

The printer moves, but 0.1 mm steps are giant at 6 mm. 1mm are 60 mm. 10 mm are 600 -- I don't dare.

Using the 36 tooth pulleys. Also, the stepper motors get considerably hot.

Attached is my config file.

1. Did I miss something?

2. How hot are steppers when on?

3. Should I try switching to Marlin?

My steps: I used an online configurator for Repetier. Used the Arduino SDK to install. Used Repetier-Host on my Mac to connect. Tried micro 0.1 mm steps to test it. Instead, it moves at at 60x the distance.

Googe Drive--FolgerTech Kossel 2020 software package.zip.

The printer moves, but 0.1 mm steps are giant at 6 mm. 1mm are 60 mm. 10 mm are 600 -- I don't dare.

Using the 36 tooth pulleys. Also, the stepper motors get considerably hot.

Attached is my config file.

1. Did I miss something?

2. How hot are steppers when on?

3. Should I try switching to Marlin?

My steps: I used an online configurator for Repetier. Used the Arduino SDK to install. Used Repetier-Host on my Mac to connect. Tried micro 0.1 mm steps to test it. Instead, it moves at at 60x the distance.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 11:43PM |

Registered: 9 years ago Posts: 36 |

Quote

rtideas

Closer. At least it's moving. Installed 0.91 Repetier firmware. I matched all the settings to the configuration file in the FolgerTech Google Drive except for rod length and my added LCD screen.

Googe Drive--FolgerTech Kossel 2020 software package.zip.

The printer moves, but 0.1 mm steps are giant at 6 mm. 1mm are 60 mm. 10 mm are 600 -- I don't dare.

Using the 36 tooth pulleys. Also, the stepper motors get considerably hot.

Attached is my config file.

1. Did I miss something?

2. How hot are steppers when on?

3. Should I try switching to Marlin?

My steps: I used an online configurator for Repetier. Used the Arduino SDK to install. Used Repetier-Host on my Mac to connect. Tried micro 0.1 mm steps to test it. Instead, it moves at at 60x the distance.

The stepper shouldn't be hot at all; only hot if they are printing for a few hours. Frankly, there should be a fan(s) down by the stepper motors. They get hot enough that the bolt holes get soften. In the beginning, my "Y" motor did get really hot and a combinations of things (don't know which) helped: I switched out that driver module, and tweak the pot on each module down to about 0.4vdc (careful with this because you can easily short something out because of the small parts). There's a description on the internet as to how to do this.

I started off using Marlin because I got my kit before the all the instructions came out. There's a location to adjust all four stepper motors and I'm sure Repetier has this too. Mine is 44.44 for x, y, and z, and 625 for the Greg Wade's extruder.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2015 11:46PM |

Registered: 9 years ago Posts: 36 |

Quote

bjoernkarmann

Thanks!, maybe i will just go for the 20 or 16 let me know how it goes with your 16-toothand if you changed the steps pr mm perhaps.

And for rtideas, i have the same problem with the acrylic (i also had a "home button holder" cracking, and had to mount the power supply sideways. so you defiantly have de be carefull with the screws. even my bed holder did't fit .

I think this is where all those questionable lock washers are used, but it would be 10 or 12mm bolts that would reach the nuts, not 8mm.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 04:06AM |

Registered: 9 years ago Posts: 1,159 |

Quote

rtideas

Closer. At least it's moving. Installed 0.91 Repetier firmware. I matched all the settings to the configuration file in the FolgerTech Google Drive except for rod length and my added LCD screen.

Googe Drive--FolgerTech Kossel 2020 software package.zip.

The printer moves, but 0.1 mm steps are giant at 6 mm. 1mm are 60 mm. 10 mm are 600 -- I don't dare.

Using the 36 tooth pulleys. Also, the stepper motors get considerably hot.

Attached is my config file.

1. Did I miss something?

2. How hot are steppers when on?

3. Should I try switching to Marlin?

My steps: I used an online configurator for Repetier. Used the Arduino SDK to install. Used Repetier-Host on my Mac to connect. Tried micro 0.1 mm steps to test it. Instead, it moves at at 60x the distance.

You do have the 3 jumper fitted underneath all the Stepper driver modules don't you?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 05:48AM |

Registered: 11 years ago Posts: 69 |

Yes. All jumpers in place and configuration set to 44.44 mm/step. Are you allowed to use floating point values?Quote

dougal1957

You do have the 3 jumper fitted underneath all the Stepper driver modules don't you?

Another issue is my top endstop switches work in reverse. They stop the slide from moving down, not up.

The Build Manual suggested soldering connectors for the thermistors and auto leveler switch. Had solder seep down a bit too far so the connectors would not seat all the way down. Had to desolder two. Crimping, if done properly, should be fine.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 06:44AM |

Registered: 11 years ago Posts: 69 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 08:23AM |

Registered: 9 years ago Posts: 1,159 |

Quote

rtideas

Sent a M205 command and got:

Far greater than then the 44.44 mm I did set it to with the Arduino SDK.Quote

< 5:50:15 AM: EPR:3 11 2560.0000 Steps per mm

Need to dig to see where tis is getting changed.

Sounds like you have enabled the eeprom in the firmware (if you have the values stick in there and are not updated by the firmware took me a couple of weeks to discover that fact)

think you may have to use m500/m501/m502 (Can't remember which way round they work or the syntax now but sure you can find it with a search) to get those figures into the EEPROM or if you use Repetier Host you can do it from the EEPROM config in the Config drop down or use ALT+E to get to it.

Doug

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 08:30AM |

Registered: 11 years ago Posts: 69 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 08:39AM |

Registered: 9 years ago Posts: 1,159 |

Quote

rtideas

Awesome Doug! Thanks!

Was just about to switch to Marlin.

Glad to help.

I couldn't get marlin to even compile for me hence I went to Repetier which to be honest I prefer anyway now though next printer will be a 32 bit controller as it will be a semi large delta (400mm dia bed with 1000mm towers) should give me about 550 mm build height at 350mm diameter or so

just need to print all the parts for it now.

Doug

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 09:13AM |

Registered: 11 years ago Posts: 69 |

Quote

dougal1957

Glad to help.

I couldn't get marlin to even compile for me hence I went to Repetier which to be honest I prefer anyway now though next printer will be a 32 bit controller as it will be a semi large delta (400mm dia bed with 1000mm towers) should give me about 550 mm build height at 350mm diameter or so

just need to print all the parts for it now.

Doug

Good to know. I like the idea of larger deltas.

Care to share your Repetier config file?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 09:29AM |

Registered: 9 years ago Posts: 1,159 |

Quote

rtideas

Quote

dougal1957

Glad to help.

I couldn't get marlin to even compile for me hence I went to Repetier which to be honest I prefer anyway now though next printer will be a 32 bit controller as it will be a semi large delta (400mm dia bed with 1000mm towers) should give me about 550 mm build height at 350mm diameter or so

just need to print all the parts for it now.

Doug

Good to know. I like the idea of larger deltas.

Care to share your Repetier config file?

Unfortunately I don't have one for a delta my printer is an I3 next one will be a delta with a DUET Controller with DC42 firmware on it

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 20, 2015 10:21AM |

Registered: 9 years ago Posts: 36 |

Quote

rtideas

Yes. All jumpers in place and configuration set to 44.44 mm/step. Are you allowed to use floating point values?Quote

dougal1957

You do have the 3 jumper fitted underneath all the Stepper driver modules don't you?

Another issue is my top endstop switches work in reverse. They stop the slide from moving down, not up.

The Build Manual suggested soldering connectors for the thermistors and auto leveler switch. Had solder seep down a bit too far so the connectors would not seat all the way down. Had to desolder two. Crimping, if done properly, should be fine.

Endstop in reverse? You are off by one at the header; there are six inputs into that header, every other three are minimum endstops and every other three are maximum endstops, you want the maximum endstops. There should be a pic in the doc.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 21, 2015 12:54AM |

Registered: 11 years ago Posts: 69 |

It was these settings I had to set to 1 and now my endstops work properly:Quote

dnguyenai598

Endstop in reverse? You are off by one at the header; there are six inputs into that header, every other three are minimum endstops and every other three are maximum endstops, you want the maximum endstops. There should be a pic in the doc.

#define INVERT_X_DIR 1 #define INVERT_Y_DIR 1 #define INVERT_Z_DIR 1

Finally going in the right direction, err, stopping in the right direction.

Anyone actually get the hotbed to not warp over the acrylic? Should just scrap using it from the start?

Also, best to start with PLA, then move to ABS? I also have some T-Glase to eventually play with.

Thanks everyone for your posts, help and suggestions.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 21, 2015 03:46AM |

Registered: 9 years ago Posts: 36 |

Quote

rtideas

It was these settings I had to set to 1 and now my endstops work properly:Quote

dnguyenai598

Endstop in reverse? You are off by one at the header; there are six inputs into that header, every other three are minimum endstops and every other three are maximum endstops, you want the maximum endstops. There should be a pic in the doc.

#define INVERT_X_DIR 1 #define INVERT_Y_DIR 1 #define INVERT_Z_DIR 1

Finally going in the right direction, err, stopping in the right direction.

Anyone actually get the hotbed to not warp over the acrylic? Should just scrap using it from the start?

Also, best to start with PLA, then move to ABS? I also have some T-Glase to eventually play with.

Thanks everyone for your posts, help and suggestions.

Even with PLA, a heat bed helps. Or be prepare with a stick of superglue to help things from moving. But I'm not using the heat bed for the time being, I just wire tied it down using the three holes. I will eventually be using it if I can come up with a way to help the heat from dissipating so much.

Sorry, only registered users may post in this forum.