Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 03, 2015 04:06PM |

Registered: 11 years ago Posts: 69 |

I'm using 0.92 Repetier firmware.Quote

iceman62

Are you getting anything to work in the Repetier FW like Auto Leveling or the LCD cause I could not get either to work under Repetier FW.

The X and Y direction were swapped. I swapped the X- and Y-motor and the X- and Y-stop wiring. BUT I could have just swapped the angles for the columns--210 with 330 and vice versa.

I realized from the configuration wizard drawing that my towers were wrong from what was suggested in the build manual.

I have some weird limits when the head is at its lowest.

Currently, manually controlling it for testing using Reptier-Host and -Server on my iMac.

The 2004 LCD Display Controller does work fine.

The connector for D10 broke so I rerouted the hot end to D9 and soldered the hotend fan directly to D10. I altered the pins.h file to get it to work. And my config file for the fan.

The one of the biggest hurdles with Repetier was the EEPROM. Very confusing to start. Still confused. ALWAYS check the EEPROM settings to make the settings take.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 03, 2015 05:32PM |

Registered: 9 years ago Posts: 30 |

Quote

rtideas

I'm using 0.92 Repetier firmware.Quote

iceman62

Are you getting anything to work in the Repetier FW like Auto Leveling or the LCD cause I could not get either to work under Repetier FW.

The X and Y direction were swapped. I swapped the X- and Y-motor and the X- and Y-stop wiring. BUT I could have just swapped the angles for the columns--210 with 330 and vice versa.

I realized from the configuration wizard drawing that my towers were wrong from what was suggested in the build manual.

I have some weird limits when the head is at its lowest.

Currently, manually controlling it for testing using Reptier-Host and -Server on my iMac.

The 2004 LCD Display Controller does work fine.

The connector for D10 broke so I rerouted the hot end to D9 and soldered the hotend fan directly to D10. I altered the pins.h file to get it to work. And my config file for the fan.

The one of the biggest hurdles with Repetier was the EEPROM. Very confusing to start. Still confused. ALWAYS check the EEPROM settings to make the settings take.

So nothing on getting the Auto Leveling to work?

The FW I am using was attached to an eMail sent to me from Nate @ Folger Tech where I purchased my Kossel Printer from. I have it running and

and the LCD works but I am still having issues with the Auto Leveling.

Edited 1 time(s). Last edit at 02/03/2015 05:33PM by iceman62.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 03, 2015 06:40PM |

Registered: 11 years ago Posts: 69 |

Yeah, no auto-leveling yet. Still getting the regular movements dialed in. My extruder to moving about 4x the distance it is supposed to. telling it to move 10mm, actually moves about 38.5mm of filament.

Now I have my X direction moving right, I can go down my list of things to figure out:

Now I have my X direction moving right, I can go down my list of things to figure out:

- set range of movement

- make sure limits work

- do a manual bed levelling

- get extruder dialed in

- consider swapping out the 36T pulleys for 20T ones

- then get auto-leveler working

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 03, 2015 07:47PM |

Registered: 11 years ago Posts: 69 |

I did see they added new Z-probe manual and Autolevel firmware on one of their Google Drives:

https://drive.google.com/drive/#folders/0B_KUgGb2XPIXYnBmdHMxOUFBazQ

But i'd be very careful homing the head with their firmware. Haven't tested it just yet. The last one I tried from them tried to crash my head. Glad my hot bed was not installed yet and was able to hit the kill motors button in time.

At least to shows how to wire the servo. Will have to get parts

https://drive.google.com/drive/#folders/0B_KUgGb2XPIXYnBmdHMxOUFBazQ

But i'd be very careful homing the head with their firmware. Haven't tested it just yet. The last one I tried from them tried to crash my head. Glad my hot bed was not installed yet and was able to hit the kill motors button in time.

At least to shows how to wire the servo. Will have to get parts

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 04, 2015 10:44PM |

Registered: 9 years ago Posts: 2 |

"Yeah, no auto-leveling yet. Still getting the regular movements dialed in. My extruder to moving about 4x the distance it is supposed to. telling it to move 10mm, actually moves about 38.5mm of filament."

With the folger tech extruder and 1/16 microstepping. Set the extruder to 95 steps/mm

Edited 1 time(s). Last edit at 02/04/2015 10:51PM by Drago.

With the folger tech extruder and 1/16 microstepping. Set the extruder to 95 steps/mm

Edited 1 time(s). Last edit at 02/04/2015 10:51PM by Drago.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 06:58AM |

Registered: 11 years ago Posts: 69 |

Excellent. Thank you!Quote

Drago

"Yeah, no auto-leveling yet. Still getting the regular movements dialed in. My extruder to moving about 4x the distance it is supposed to. telling it to move 10mm, actually moves about 38.5mm of filament."

With the folger tech extruder and 1/16 microstepping. Set the extruder to 95 steps/mm

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 08:44AM |

Registered: 11 years ago Posts: 69 |

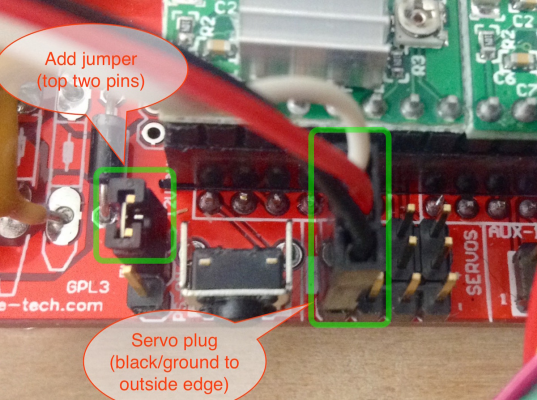

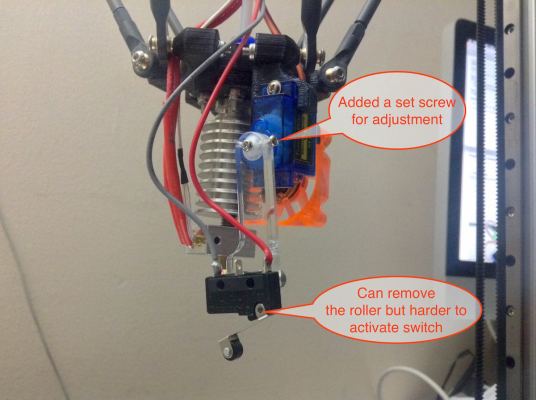

Closer. Got the servo to work at least.

Figured out the wiring from this:

[forums.reprap.org]

Here is a closeup of mine:

Since my drill bit had pilot hole tip and didn't allow for a tight fit, I added a set screw on the side so I could adjust the arm on the servo. Also, not certain where the servo would rotate to once turned on. Most other Kossels with this switch set up pop of the roller arm for the switch. Since the alignment is wonky until I can print a better servo holder, I left it on for now.

It is somewhat functioning--the arm moves up and down, but it does not sense the switch to stop it from jamming into the bed, YET.

G31 does show high and low. And M340 P0 SXXXX does work to rotate the servo. (corrected--thanks Drago)

Still not certain why they chose the servo over the hex wrench type probe. The servo method seems much less precise.

Edited 2 time(s). Last edit at 02/05/2015 10:35AM by rtideas.

Figured out the wiring from this:

[forums.reprap.org]

Here is a closeup of mine:

Since my drill bit had pilot hole tip and didn't allow for a tight fit, I added a set screw on the side so I could adjust the arm on the servo. Also, not certain where the servo would rotate to once turned on. Most other Kossels with this switch set up pop of the roller arm for the switch. Since the alignment is wonky until I can print a better servo holder, I left it on for now.

It is somewhat functioning--the arm moves up and down, but it does not sense the switch to stop it from jamming into the bed, YET.

G31 does show high and low. And M340 P0 SXXXX does work to rotate the servo. (corrected--thanks Drago)

Still not certain why they chose the servo over the hex wrench type probe. The servo method seems much less precise.

Edited 2 time(s). Last edit at 02/05/2015 10:35AM by rtideas.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 08:51AM |

Registered: 9 years ago Posts: 63 |

So did you have to activate the servo in the software anywhere? It looks to me like you do, but when I uncomment the servo line, I still cannot get the servo to rotate with the G340 command. I DO have the jumper accross Vcc and 5v. Since oyu are using G340 I assume oyu are using Repetier firmware?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 09:33AM |

Registered: 9 years ago Posts: 2 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 11:15AM |

Registered: 9 years ago Posts: 30 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 11:19AM |

Registered: 9 years ago Posts: 2 |

I had the servo working on the marlin FW, but removed the servo all together. The servo has 3xmm 3xmm X Y offset( I forgot the actual measurement ).

On my 190mm building area , it probes about 130mm of it.

Anyone printing at descent speed without the extruder skipping/slipping? like >35mm/s?

Tried increasing temp, lubing the filament with canola oil, increasing the extruder motor volt, but still skips

BTW why is everyone using the Repetier FW? Is it better?

On my 190mm building area , it probes about 130mm of it.

Anyone printing at descent speed without the extruder skipping/slipping? like >35mm/s?

Tried increasing temp, lubing the filament with canola oil, increasing the extruder motor volt, but still skips

BTW why is everyone using the Repetier FW? Is it better?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 11:36AM |

Registered: 9 years ago Posts: 30 |

Quote

kylaris

I had the servo working on the marlin FW, but removed the servo all together. The servo has 3xmm 3xmm X Y offset( I forgot the actual measurement ).

On my 190mm building area , it probes about 130mm of it.

Anyone printing at descent speed without the extruder skipping/slipping? like >35mm/s?

Tried increasing temp, lubing the filament with canola oil, increasing the extruder motor volt, but still skips

BTW why is everyone using the Repetier FW? Is it better?

I am trying both Firm Ware's because I want my auto leveling to work. I have only been able to print with Marlin though. With the Marlin FW I have the LCD

working and I can get movement with the auto leveling (but it's not working correctly) and I can print if I don't add the G-Start code for the auto leveling. I'll

attach a couple pics of something I have printed with Marlin FW.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 02:10PM |

Registered: 9 years ago Posts: 36 |

Quote

iceman62

Quote

kylaris

I had the servo working on the marlin FW, but removed the servo all together. The servo has 3xmm 3xmm X Y offset( I forgot the actual measurement ).

On my 190mm building area , it probes about 130mm of it.

Anyone printing at descent speed without the extruder skipping/slipping? like >35mm/s?

Tried increasing temp, lubing the filament with canola oil, increasing the extruder motor volt, but still skips

BTW why is everyone using the Repetier FW? Is it better?

I am trying both Firm Ware's because I want my auto leveling to work. I have only been able to print with Marlin though. With the Marlin FW I have the LCD

working and I can get movement with the auto leveling (but it's not working correctly) and I can print if I don't add the G-Start code for the auto leveling. I'll

attach a couple pics of something I have printed with Marlin FW.

Those are nice items...I've been printing quite a bit of everything to test and experiment, and just ran out of my first roll of filament (2.2lb). However, I get constant webbing on all my prints, what is your slic3r settings to get around that? Also, when printing big parts, does the outer edges lift (curl) on you? I stopped using the heatbed because it takes forever to heat up, maybe this is my problem.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 04:05PM |

Registered: 9 years ago Posts: 30 |

Here are snapshots of my slic3r settings... and remember to save each time you put new settings in.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 05, 2015 04:10PM |

Registered: 9 years ago Posts: 30 |

Yes I get a little bit of curling on large parts but less if I wait and let the bed heat up and the give it a minute or two after it has reach the desired temp.

I have a friends who has a Prusa i3 and swears by using Glass and spraying it with Hair Spray letting it dry and then printing. I have purchased the

glass to put on top of my heat bed but I haven't mounted it yet.

I have a friends who has a Prusa i3 and swears by using Glass and spraying it with Hair Spray letting it dry and then printing. I have purchased the

glass to put on top of my heat bed but I haven't mounted it yet.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 08, 2015 09:17AM |

Registered: 9 years ago Posts: 2 |

I am a little unclear about total rod length and would appreciate any insight i could get. I cut the rods at 250mm which I read here somewhere but that makes the total length center to center 300mm. It that too long and should I cut them to get a total center length of 250mm or 280mm.

Thanks

Thanks

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 08, 2015 08:34PM |

Registered: 9 years ago Posts: 30 |

Quote

djfriz

I am a little unclear about total rod length and would appreciate any insight i could get. I cut the rods at 250mm which I read here somewhere but that makes the total length center to center 300mm. It that too long and should I cut them to get a total center length of 250mm or 280mm.

Thanks

In the Build Manual that came with my Kossel it instructs that the total length of the rod including ball joints from bolt hole to bolt hole be 224mm and that is for a 210mm print bed

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 09, 2015 10:42AM |

Registered: 9 years ago Posts: 76 |

NEW UPDATED BUILD MANUAL AVAILABLE!!!!!!!

-Uploaded V2 firmware that includes autolevel and document to outline variables.

-Uploaded Cura profile with starting gCode

We are also working on an updated configuration manual to go with the new V2 firmware.

Stay tuned!

[drive.google.com]

Edited 2 time(s). Last edit at 02/09/2015 02:58PM by MakerFront.

-Uploaded V2 firmware that includes autolevel and document to outline variables.

-Uploaded Cura profile with starting gCode

We are also working on an updated configuration manual to go with the new V2 firmware.

Stay tuned!

[drive.google.com]

Edited 2 time(s). Last edit at 02/09/2015 02:58PM by MakerFront.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 09, 2015 11:15AM |

Registered: 9 years ago Posts: 76 |

The diagonal rod length seems to be a point of contention.

In the new build manual, we specify a total length of the rods (bolt center to bolt center) of 230mm, this yeilds a print volume to 6" diameter by 8.4" height. We assume people are looking at delta printers for the build height stability, so this was the compromise we made.

The config manual will have detailed instructions on how to modify the measurements for the rod lengths in the firmware.

Also, you can assemble another set of rods and swap them out if you want to change the build volume dimensions.

I attached an excerpt from the manual explaining the diagonal rod length changes.

Cheers!

Edited 1 time(s). Last edit at 02/09/2015 11:18AM by MakerFront.

In the new build manual, we specify a total length of the rods (bolt center to bolt center) of 230mm, this yeilds a print volume to 6" diameter by 8.4" height. We assume people are looking at delta printers for the build height stability, so this was the compromise we made.

The config manual will have detailed instructions on how to modify the measurements for the rod lengths in the firmware.

Also, you can assemble another set of rods and swap them out if you want to change the build volume dimensions.

I attached an excerpt from the manual explaining the diagonal rod length changes.

Cheers!

Edited 1 time(s). Last edit at 02/09/2015 11:18AM by MakerFront.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 09, 2015 06:25PM |

Registered: 9 years ago Posts: 63 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 09, 2015 11:11PM |

Registered: 9 years ago Posts: 30 |

Quote

mmcginnis9272

Step 27 in the v2 build manual states that the bed leveling servo arm is attached in the configuration manual. I do not see an updated configuration manual, nor do I see anywhere in the existing configuration manual where this is described. Any ideas?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 02:17AM |

Registered: 9 years ago Posts: 23 |

Hello. I'm new to 3D printers and just finished building this printer. I'm now trying to configure it, and have a few questions. I'm using the Marlin_Delta2 firmware that I found in the Folgertech_Kossel_Firmware(V2).zip file posted earlier today, I think. I've been trying to confirm the basic movements of the print head and run it through routines like autoleveling, etc. before trying some prints. So far, I've uploaded the G-Code from the FolgerTech_Kossel_Cura.ini file. After reversing some of the motor connections (I was using the first version of the printed manual for the build), the basic movements seem OK, but I have a couple of questions.

I measured the height of the print head to the print bed at 262 mm, but setting this in the firmware and/or printer settings always resulted in the head crashing into the bed (only once or twice...I've kept my finger on the Stop button on my LCD each time since it first happened and I'm getting good at catching it just in time now). I've since figured out that setting this to 130 mm in the firmware (line 346: #define MANUAL_Z_HOME_POS 130) allows the autolevel routine to work, and it can't be a coincidence that it's about exactly half of the measured value. Am I missing a multiplier somewhere? All the pots on the motor controllers were set to .350mv for the X/Y/Z and .550mv for the extruder per the instructions, but I don't know if there's a "steps per" setting I'm missing somewhere...I didn't see anything like that in the configuration.h file. I also had to set the autolevel grid to 15 (line 348: #define AUTOLEVEL_GRID 15) to avoid having the servo probe miss the edge of the heated plate during the autolevel routine (and I moved the servo to the inside of the lower effector plate so the switch arm is as close as it can get to the print head without melting . My carbon rods are 224mm between the centers of the bolt holes per the original build manual, and I've also set that in Line 86 of the firmware (#define DELTA_DIAGONAL_ROD 224).

It only started the last two times I ran the autolevel function to it's completion with these settings, but now I'm also getting an error in the Repetier Host software right as that routine completes...the servo arm will raise up, the print head will barely drag along the print bed, and then I get the following error in the log window. The error in the log says "Error:Line Number is not Last Line Number+1, Last Line: 60" and then "Resend: 61" on the next line...those line numbers are earlier in the G-Code than the auto-level routine, so that doesn't make sense to me.

I wonder if the dragging has something to do with the offset between the print head and the autolevel probe. It's possible my effector plate is upside-down...the part about the recessed side going down also wasn't in the original build guide, but it went together OK and it looks like the bolts would bottom out on the fins of the hot end if the effector if the lower and upper effector plates were touching (mine are about 4mm apart)

Last question...all the limit switches seem to check out with the M119 command in the G-Code, but I'm wondering if they're working properly. The z-min switch on the autolevel probe is certainly working correctly as the head reverses itself each time it clicks open. For the X, Y, and Z upper limit switches, though, the motors seem to be pushing against the stops even as the switches are open. If I click "Stop Motor", then the motors will "relax" and slide down the guides a little...until I do that or it times out, it seems that the motors are holding the carriages against the stops. That seems OK for holding a more precise Home position as long as the motors can take it, but I'm not sure if that's the normal behavior.

Thanks in advance...I'm anxious to try to actually print something once I'm confident the printer won't tear itself apart due to some bad settings...

Olivier

I measured the height of the print head to the print bed at 262 mm, but setting this in the firmware and/or printer settings always resulted in the head crashing into the bed (only once or twice...I've kept my finger on the Stop button on my LCD each time since it first happened and I'm getting good at catching it just in time now). I've since figured out that setting this to 130 mm in the firmware (line 346: #define MANUAL_Z_HOME_POS 130) allows the autolevel routine to work, and it can't be a coincidence that it's about exactly half of the measured value. Am I missing a multiplier somewhere? All the pots on the motor controllers were set to .350mv for the X/Y/Z and .550mv for the extruder per the instructions, but I don't know if there's a "steps per" setting I'm missing somewhere...I didn't see anything like that in the configuration.h file. I also had to set the autolevel grid to 15 (line 348: #define AUTOLEVEL_GRID 15) to avoid having the servo probe miss the edge of the heated plate during the autolevel routine (and I moved the servo to the inside of the lower effector plate so the switch arm is as close as it can get to the print head without melting . My carbon rods are 224mm between the centers of the bolt holes per the original build manual, and I've also set that in Line 86 of the firmware (#define DELTA_DIAGONAL_ROD 224).

It only started the last two times I ran the autolevel function to it's completion with these settings, but now I'm also getting an error in the Repetier Host software right as that routine completes...the servo arm will raise up, the print head will barely drag along the print bed, and then I get the following error in the log window. The error in the log says "Error:Line Number is not Last Line Number+1, Last Line: 60" and then "Resend: 61" on the next line...those line numbers are earlier in the G-Code than the auto-level routine, so that doesn't make sense to me.

I wonder if the dragging has something to do with the offset between the print head and the autolevel probe. It's possible my effector plate is upside-down...the part about the recessed side going down also wasn't in the original build guide, but it went together OK and it looks like the bolts would bottom out on the fins of the hot end if the effector if the lower and upper effector plates were touching (mine are about 4mm apart)

Last question...all the limit switches seem to check out with the M119 command in the G-Code, but I'm wondering if they're working properly. The z-min switch on the autolevel probe is certainly working correctly as the head reverses itself each time it clicks open. For the X, Y, and Z upper limit switches, though, the motors seem to be pushing against the stops even as the switches are open. If I click "Stop Motor", then the motors will "relax" and slide down the guides a little...until I do that or it times out, it seems that the motors are holding the carriages against the stops. That seems OK for holding a more precise Home position as long as the motors can take it, but I'm not sure if that's the normal behavior.

Thanks in advance...I'm anxious to try to actually print something once I'm confident the printer won't tear itself apart due to some bad settings...

Olivier

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 10:02AM |

Registered: 9 years ago Posts: 76 |

2 Answers here,

mmcginnis9272

1) We are working on an updated config manual, so please hold tight for that. I'm only one guy and the manuals take a lot of time and effort to make, I wanted to get them out as soon as I can to help people build the printers.

ohecht

2) When checking your Z height to 0, don't go all the way to Z0 from the top, that WILL crash the head into the bed if it's not set up properly. Instead, start high and work your way down. Start with an absolute movement like this: G1 Z100 F3000 then decrease the Z value a little at a time to get your true measurement.

Just a note here, the V2 manual and V2 firmware have steps per mm on the XYZ axes set for 20 tooth GT2 pulleys, if you don't change that for the 36 tooth pulleys, your steps per mm will be way off.

mmcginnis9272

1) We are working on an updated config manual, so please hold tight for that. I'm only one guy and the manuals take a lot of time and effort to make, I wanted to get them out as soon as I can to help people build the printers.

ohecht

2) When checking your Z height to 0, don't go all the way to Z0 from the top, that WILL crash the head into the bed if it's not set up properly. Instead, start high and work your way down. Start with an absolute movement like this: G1 Z100 F3000 then decrease the Z value a little at a time to get your true measurement.

Just a note here, the V2 manual and V2 firmware have steps per mm on the XYZ axes set for 20 tooth GT2 pulleys, if you don't change that for the 36 tooth pulleys, your steps per mm will be way off.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 10:06AM |

Registered: 9 years ago Posts: 76 |

The V2 firmware also requires the following put in the start gcode in order for the auto level to work:

after G28 line;

G1 Z15 F4000

M280 P0 S5 (or S120, the angle of your servo deployed, it varies based on how you oriented the servo)

G29

M280 P0 S120 (or S5, the angle of your servo retracted, it varies based on how you oriented the servo)

This will all be in the config manual, hope to have it done this weekend.

after G28 line;

G1 Z15 F4000

M280 P0 S5 (or S120, the angle of your servo deployed, it varies based on how you oriented the servo)

G29

M280 P0 S120 (or S5, the angle of your servo retracted, it varies based on how you oriented the servo)

This will all be in the config manual, hope to have it done this weekend.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 04:43PM |

Registered: 9 years ago Posts: 76 |

Sorry, I skimmed though your post too quick to answer everything, so here's a more complete answer.

FolgerTech is moving to 20-tooth pulleys in the very near future. The V2 firmware is made especially for the build in the V2 manual (no relation to a rev of the kit, just the documents).

For the 36-tooth pulleys, line 359 in configuration.h should read:

#define DEFAULT_AXIS_STEPS_PER_UNIT {100/2.25, 100/2.25, 100/2.25, 100}

As for the rods, you will have to measure and change 2 values. The carriage offset and the delta effector offset are the same:

Here are the lines you have to measure and change:

Lines 85/86 - You already did this, but just letting you know if you want to change it.

// Center-to-center distance of the holes in the diagonal push rods.

#define DELTA_DIAGONAL_ROD 224 // mm (215)

Lines 88/89 - Measure the distance from the rail (front of it facing inwards) to the center of the bolt hole of the rod attached to the effector. Where ??? is the value in mm.

// Horizontal offset from middle of printer to smooth rod center.

#define DELTA_SMOOTH_ROD_OFFSET ??? // mm (137.0)

Just a note on the step above, measure all three towers, if the measurement is off, adjust your endstops, re-home and measure again, this will ensure the effector is correctly homed in the center of the build area.

Having different length rods will change your build height and radius, since your rods are shorter than what's in the firmware, your height will be increased slightly. The best way is to measure this mechanically; here goes:

Set line 346 in configuration.h to a value larger than your build height, for this example, we'll use 300mm because we know that's at least 25mm taller than you can move.

#define MANUAL_Z_HOME_POS 300

Now, in your control program (Pronterface, Repetier etc..) Type the following commands one at a time:

G28 - this will home all the axes

G1 Z50 F4000 - this will bring the effector down to where it thinks 50mm above the print surface is.

Now grab a piece of paper and use the G1 ZXX F4000 command with lower values over and over until you get to the point at which the paper is just pinched between the hot end and the bed, you can use decimals to really dial it in.

Write down the last value you used, let's say it was 16.5 for arguments sake. Subtract that from your starting Z home position and presto! You get your accurate Z height of 283.5mm!

Now, for the auto level switch. You will have to repeat the same method you used to measure the total Z-height with the servo deployed to measure where the probe switch is triggered, bring it down using the same G1 Z command and then slowly creep the effector down until you hear the switch click. Once you know the value for that, re-home the printer and tell it to go .1mm higher than you just measured, the switch should not click, then repeat with the correct value and the switch should click when it contacts the bed, when you dial in the Z value for the auto level switch, slap a - in front of it and throw it in line 355 of Configuration.h like so:

#define Z_PROBE_OFFSET {0, 12.5, -1.4, 0}

All this should get you running and will be in the config manual coming soon!

Edited 4 time(s). Last edit at 02/10/2015 04:50PM by MakerFront.

FolgerTech is moving to 20-tooth pulleys in the very near future. The V2 firmware is made especially for the build in the V2 manual (no relation to a rev of the kit, just the documents).

For the 36-tooth pulleys, line 359 in configuration.h should read:

#define DEFAULT_AXIS_STEPS_PER_UNIT {100/2.25, 100/2.25, 100/2.25, 100}

As for the rods, you will have to measure and change 2 values. The carriage offset and the delta effector offset are the same:

Here are the lines you have to measure and change:

Lines 85/86 - You already did this, but just letting you know if you want to change it.

// Center-to-center distance of the holes in the diagonal push rods.

#define DELTA_DIAGONAL_ROD 224 // mm (215)

Lines 88/89 - Measure the distance from the rail (front of it facing inwards) to the center of the bolt hole of the rod attached to the effector. Where ??? is the value in mm.

// Horizontal offset from middle of printer to smooth rod center.

#define DELTA_SMOOTH_ROD_OFFSET ??? // mm (137.0)

Just a note on the step above, measure all three towers, if the measurement is off, adjust your endstops, re-home and measure again, this will ensure the effector is correctly homed in the center of the build area.

Having different length rods will change your build height and radius, since your rods are shorter than what's in the firmware, your height will be increased slightly. The best way is to measure this mechanically; here goes:

Set line 346 in configuration.h to a value larger than your build height, for this example, we'll use 300mm because we know that's at least 25mm taller than you can move.

#define MANUAL_Z_HOME_POS 300

Now, in your control program (Pronterface, Repetier etc..) Type the following commands one at a time:

G28 - this will home all the axes

G1 Z50 F4000 - this will bring the effector down to where it thinks 50mm above the print surface is.

Now grab a piece of paper and use the G1 ZXX F4000 command with lower values over and over until you get to the point at which the paper is just pinched between the hot end and the bed, you can use decimals to really dial it in.

Write down the last value you used, let's say it was 16.5 for arguments sake. Subtract that from your starting Z home position and presto! You get your accurate Z height of 283.5mm!

Now, for the auto level switch. You will have to repeat the same method you used to measure the total Z-height with the servo deployed to measure where the probe switch is triggered, bring it down using the same G1 Z command and then slowly creep the effector down until you hear the switch click. Once you know the value for that, re-home the printer and tell it to go .1mm higher than you just measured, the switch should not click, then repeat with the correct value and the switch should click when it contacts the bed, when you dial in the Z value for the auto level switch, slap a - in front of it and throw it in line 355 of Configuration.h like so:

#define Z_PROBE_OFFSET {0, 12.5, -1.4, 0}

All this should get you running and will be in the config manual coming soon!

Edited 4 time(s). Last edit at 02/10/2015 04:50PM by MakerFront.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 05:09PM |

Registered: 9 years ago Posts: 76 |

Just uploaded a 36-tooth configured firmware on the drive for those who need it.

Cheers!

[drive.google.com]

Cheers!

[drive.google.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 08:09PM |

Registered: 9 years ago Posts: 23 |

Wow...thanks! This is just what I needed to continue setting this up. Pretty sure I wouldn't have figured all that out by trial and error. What about my effector plates? Is there supposed to be a ~4mm gap between them? Here's what mine looks like from the side and top...

Olivier

Olivier

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 08:25PM |

Registered: 9 years ago Posts: 23 |

Sorry, I'm trying to follow all the instructions and already got stuck. I saw the following note in the Release Notes on the Google drive and I'm not sure where to enter those in Repetier Host for a Mac. The only fields I see that are close under the Printer Settings > Dimension tab are X Min, X Max, Y Min, Y Max, Diameter and Height...I do have it set to a Delta printer, and those settings are currently 0,200,0,200,80,262 based on the current configuration manual. Or do I need to make the changes below in the G-Code? I looked through it but didn't see anything about the center, etc.

Thanks again.

From the Release Notes:

Uploaded CURA profile for Folgertech Kossel that has all the recommended starting settings

and start gCode. Cura is finicky, you still have to set the machine settings for round build area,

center is 0,0 and the dimensions of:

152 for X

152 for Y

215 for Z

Thanks again.

From the Release Notes:

Uploaded CURA profile for Folgertech Kossel that has all the recommended starting settings

and start gCode. Cura is finicky, you still have to set the machine settings for round build area,

center is 0,0 and the dimensions of:

152 for X

152 for Y

215 for Z

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 08:36PM |

Registered: 9 years ago Posts: 23 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 10, 2015 09:13PM |

Registered: 9 years ago Posts: 23 |

OK, assuming I got the smooth rod offsets correct, I think I've got all the heights dialed in. Now the issue is that the .ini file from the Google drive is crashing SlicEr...I keep getting the following error when trying to load the config:

8:55:19 PM: Unreadable configuration file (invalid data at line 3)

8:55:19 PM: Unreadable configuration file (invalid data at line 3)

Sorry, only registered users may post in this forum.