Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 10:58AM |

Registered: 9 years ago Posts: 445 |

Quote

mmcginnis9272

Quote

jculver09

Quote

mmcginnis9272

Haydn only sells rods in 288mm lengths. I asked him for shorter ones and he said he only has one jig that is set for 288mm.

If his lead time is three weeks, this is new, as he shipped mine out the next day.

Emailed him yesterday about this and he said that custom lengths are available up to 490mm, but they're more expensive.

I also found out the lead time is because he is waiting for a new batch of studs from the manufacturer.

That explains it. He must have decided start making custom lengths recently as well. Cool.

Just ordered a set of 250mm rods from him!

And I haven't even received my Kossel from Folger tech yet...

Already have a few mods in mind, these rods, a proximity sensor for the autocalibrating plus 16 tooth pulleys (better accuracy with Haydn's rods).

EDIT:

My plan was to modify this effector to fit with Haydn's rods and a proximity sensor from Folger Tech:

Quote

gowen

Day 6

I have finished off the extruder. getting the pipe fitting to bite took some effort.

[attachment 50286 IMG_20150302_132533.jpg]

The effector and hot end assembly went ok, especially once I found MrOrange26's picture back on Page 16 and Andy's on Page 14. I'm not sure about running the wires up beside the E3D It looks like it is stretching the heater wires at the bend. Should I have routed them under the effector plate and then up?

[attachment 50287 IMG_20150302_133002.jpg] [attachment 50288 IMG_20150302_140156.jpg] [attachment 50289 IMG_20150302_140231.jpg]

I opted to attach the fan with zip ties rather than CA. By putting them in backwards, I was able to use the ratchet block as a stand off to keep the fan near vertical.

[attachment 50290 IMG_20150302_140305.jpg]

I got the hole drilled to pass the extruder wiring from outside to inside. Tomorrow I plan to do the full frame mechanical assembly. Are there any cable runs that I need to do first?

EDIT2: OK, that didn't works as well as I thought, I quoted a post with very nice pictures from the "Cherry Pi III" thread.

Edited 2 time(s). Last edit at 04/08/2015 11:06AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 11:00AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

mmcginnis9272

Quote

jculver09

Quote

mmcginnis9272

Haydn only sells rods in 288mm lengths. I asked him for shorter ones and he said he only has one jig that is set for 288mm.

If his lead time is three weeks, this is new, as he shipped mine out the next day.

Emailed him yesterday about this and he said that custom lengths are available up to 490mm, but they're more expensive.

I also found out the lead time is because he is waiting for a new batch of studs from the manufacturer.

That explains it. He must have decided start making custom lengths recently as well. Cool.

Just ordered a set of 250mm rods from him!

And I haven't even received my Kossel from Folger tech yet...

Already have a few mods in mind, these rods, a proximity sensor for the autocalibrating plus 16 tooth pulleys (better accuracy with Haydn's rods).

I am upgrading to an prox sensor as well I believe, this way I can eliminate the mechanical part. One thing I have noticed is the steppers are blindingly hot, might want to consider adding a fan shroud to your upgrades.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 11:10AM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

Quote

Koenig

Quote

mmcginnis9272

Quote

jculver09

Quote

mmcginnis9272

Haydn only sells rods in 288mm lengths. I asked him for shorter ones and he said he only has one jig that is set for 288mm.

If his lead time is three weeks, this is new, as he shipped mine out the next day.

Emailed him yesterday about this and he said that custom lengths are available up to 490mm, but they're more expensive.

I also found out the lead time is because he is waiting for a new batch of studs from the manufacturer.

That explains it. He must have decided start making custom lengths recently as well. Cool.

Just ordered a set of 250mm rods from him!

And I haven't even received my Kossel from Folger tech yet...

Already have a few mods in mind, these rods, a proximity sensor for the autocalibrating plus 16 tooth pulleys (better accuracy with Haydn's rods).

I am upgrading to an prox sensor as well I believe, this way I can eliminate the mechanical part. One thing I have noticed is the steppers are blindingly hot, might want to consider adding a fan shroud to your upgrades.

You have 16 tooth pulleys?

I was sort of thinking, since you use less torque (I think like 25% less torque) with 16 tooth the temp would stay about the same, losing some speed though.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 11:33AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

You have 16 tooth pulleys?

I was sort of thinking, since you use less torque (I think like 25% less torque) with 16 tooth the temp would stay about the same, losing some speed though.

I currently have 20 tooth pulley, I am considering moving to 16 tooth for the better precision. I am beginning to think I have an issue with the RAMPS, since I powered the board last night and the motors got hot just sitting there holding the effector in place. They are set to the 0.35mv which is stated in the manual to use. I have been reading that's a bit low as these chinese clones are supposed to need +1mv, I guess. It has also burned out two servo motors now, I bought one at a RC store last night, threw it on to replace the old one and after 10 minutes it stopped working. At the 23 minute mark in this video you can see what the servo is doing (http://www.twitch.tv/thevisad/b/647284258) This starts immediately after sending power to the hothead, rattling back and forth. I have double and triple checked all the wiring and plugs. The servo works, it goes up, it goes down, this one is the Hitec h5-55 instead of the TowerPro SG90. Each time it does this "jump" the LCD panel dims, causing a flashing to occur. At some point the powersupply decides it has had enough and powers the entire unit off, terminating the USB connection to the machine as well. Removing the servo eliminates the issue completely, Folger sent me a replacement for the that burned out in the kit, but this has now burned out a second one so I will not that on until I test. I have a second RAMPS spare and will test with that later tonight.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 12:02PM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

Quote

Koenig

You have 16 tooth pulleys?

I was sort of thinking, since you use less torque (I think like 25% less torque) with 16 tooth the temp would stay about the same, losing some speed though.

I currently have 20 tooth pulley, I am considering moving to 16 tooth for the better precision. I am beginning to think I have an issue with the RAMPS, since I powered the board last night and the motors got hot just sitting there holding the effector in place. They are set to the 0.35mv which is stated in the manual to use. I have been reading that's a bit low as these chinese clones are supposed to need +1mv, I guess. It has also burned out two servo motors now, I bought one at a RC store last night, threw it on to replace the old one and after 10 minutes it stopped working. At the 23 minute mark in this video you can see what the servo is doing (http://www.twitch.tv/thevisad/b/647284258) This starts immediately after sending power to the hothead, rattling back and forth. I have double and triple checked all the wiring and plugs. The servo works, it goes up, it goes down, this one is the Hitec h5-55 instead of the TowerPro SG90. Each time it does this "jump" the LCD panel dims, causing a flashing to occur. At some point the powersupply decides it has had enough and powers the entire unit off, terminating the USB connection to the machine as well. Removing the servo eliminates the issue completely, Folger sent me a replacement for the that burned out in the kit, but this has now burned out a second one so I will not that on until I test. I have a second RAMPS spare and will test with that later tonight.

2 things:

The RAMPS board suplies full power to the steppers even when they are not moving. This is required to hold the motor in place. Thus, it will get just as hot when stationary as when it is moving. This is normal. My motors ran so hot at .4v that my motor mounts bagan to melt and I had to print a new set. I also mounted heatsinks and fans from some old computer motherboards I had laying around. Problem solved.

It is a known issue that the 5v line on the ramps cannot run a servo and the LCD at the same time. 3 ways to fix this:

1- Do away with the servo and use the original hex key leveling system or the flex resistor system.

2- remove the jumber from the RAMPS board so the 5v rail is NOT being powered by the board, then get a 5v power supply (or a powered USB hub) and run the 5v from the power supply directly to the RAMPS 5v rail and ground. This will allow the servo and the LCD to function at the same time. (this is probably your best, and easist solution)

3- Keep your servo and don't use the LCD. The RAMPS can power the servo by itself, just not the LCD at the same time.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 03:20PM |

Registered: 9 years ago Posts: 309 |

Hmmm, did I underpower the servo then, burning it out? I will remove that jumper and add a step down power supply to the line and power it that way. Thanks for that tip, that will save me some headaches.

I am adding fan mounts and already have the 3 fans set aside for it. I found a nice fan cap that will slide right over the top of the motors, but I think I might redo the motor mounts to include some directional jets to vent the air out the side of the channels. I am wiring those directly up to the 12v rail so they come on when the power supply does. This way I can eliminate any of the heat associated, plus I can play with a secondary arduino and some led's.

I am adding fan mounts and already have the 3 fans set aside for it. I found a nice fan cap that will slide right over the top of the motors, but I think I might redo the motor mounts to include some directional jets to vent the air out the side of the channels. I am wiring those directly up to the 12v rail so they come on when the power supply does. This way I can eliminate any of the heat associated, plus I can play with a secondary arduino and some led's.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 03:44PM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

Hmmm, did I underpower the servo then, burning it out? I will remove that jumper and add a step down power supply to the line and power it that way. Thanks for that tip, that will save me some headaches.

I am adding fan mounts and already have the 3 fans set aside for it. I found a nice fan cap that will slide right over the top of the motors, but I think I might redo the motor mounts to include some directional jets to vent the air out the side of the channels. I am wiring those directly up to the 12v rail so they come on when the power supply does. This way I can eliminate any of the heat associated, plus I can play with a secondary arduino and some led's.

The concensus in the R/C modeling world (of which I am a part) seems to be the when a servo motor is underpowered it causes a momentary brown out in the servo circuit board. Not enough power on hand causes the voltage to drop in the circuit. This causes the servo circuit to shut down. When the power to the coils in the motor stop all at once, a backwards EMF (voltage spike) of many times the applied voltage occurs. Once the circuit detects the proper voltage again, it starts back up and applies voltage again to the motor, only to shut down all over again. Normally the circuit can handle the normal occuring spikes that occur when voltage is removed from the motor coils under normal shutdown, but during this brown out phenomenon the system switches on and off many times a second. This causes several spikes per second back into the protection circuit causing it to fail. I remember as a teenager in shop/electronic class how we use to wire up coils from the lawn mower engines so that some unsuspecting victim would get the "you know what" shocked out of them when we found creative ways to cause them to absorb the collapsing voltage spike. This is the same priniple that those gimicked shocking cigarette lighters and ball point pens and such work off of. Seems strange that underpower something can actually burn out a board, but the magic of electronics theory proves it can and does happen.

Kinda sounds like you are a typical guy like I am. You should get some of those really loud cooling fans from a rack mount server that sound like a jet taking off. If you can find a way to make it work better and make it louder in the process all the better. Just like our cars.

Edited 1 time(s). Last edit at 04/08/2015 03:49PM by mmcginnis9272.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 03:57PM |

Registered: 9 years ago Posts: 309 |

Quote

mmcginnis9272

The concensus in the R/C modeling world (of which I am a part) seems to be the when a servo motor is underpowered it causes a momentary brown out in the servo circuit board. Not enough power on hand causes the voltage to drop in the circuit. This causes the servo circuit to shut down. When the power to the coils in the motor stop all at once, a backwards EMF (voltage spike) of many times the applied voltage occurs. Once the circuit detects the proper voltage again, it starts back up and applies voltage again to the motor, only to shut down all over again. Normally the circuit can handle the normal occuring spikes that occur when voltage is removed from the motor coils under normal shutdown, but during this brown out phenomenon the system switches on and off many times a second. This causes several spikes per second back into the protection circuit causing it to fail. I remember as a teenager in shop/electronic class how we use to wire up coils from the lawn mower engines so that some unsuspecting victim would get the "you know what" shocked out of them when we found creative ways to cause them to absorb the collapsing voltage spike. This is the same priniple that those gimicked shocking cigarette lighters and ball point pens and such work off of. Seems strange that underpower something can actually burn out a board, but the magic of electronics theory proves it can and does happen.

Kinda sounds like you are a typical guy like I am. You should get some of those really loud cooling fans from a rack mount server that sound like a jet taking off. If you can find a way to make it work better and make it louder in the process all the better. Just like our cars.

Makes perfect sense actually, thanks for that, it was a great read and when thinking about it, sounds exactly like what was occurring.

As for those rack mount server fans? I have a box of them sitting right next to me that I am stripping the casings off of right now! With a temp sensor on the motors, I could could also load up a variable control to them to "quiet" them and turn them up as needed. Not a bad idea at all actually.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 04:24PM |

Registered: 9 years ago Posts: 14 |

In theory you could drop like a 0.1uF capacitor in shunt with the spike and the damage would no longer occur. Deal with this when flipping relays all the time, same thing happens. Power goes off, voltage spike back to whatever was supplying and anything else in its path, drop a cap in across the coil and no more spike since a cap cant change voltages instantly like an inductor (coil) can.

Edited 1 time(s). Last edit at 04/08/2015 04:27PM by ADecker.

Edited 1 time(s). Last edit at 04/08/2015 04:27PM by ADecker.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 04:35PM |

Registered: 9 years ago Posts: 14 |

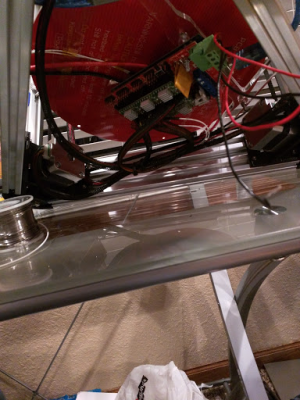

Started taming the wires with 1/4in braided wire loom. Works amazing and keeps everything away from the print. Going to extend all the end stop wires and run them to the back of the printer and down one support so they are out of the way and neat as well. First print was the filament spool holder pictured below. Went alright, lots of strings and things I gotta work on fine tuning once I get all the aesthetics and wires ran. Excuse the picture frame of me and my lovely girlfriend!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 05:47PM |

Registered: 9 years ago Posts: 25 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 06:20PM |

Registered: 9 years ago Posts: 25 |

Quote

mmcginnis9272

Quote

thevisad

Hmmm, did I underpower the servo then, burning it out? I will remove that jumper and add a step down power supply to the line and power it that way. Thanks for that tip, that will save me some headaches.

I am adding fan mounts and already have the 3 fans set aside for it. I found a nice fan cap that will slide right over the top of the motors, but I think I might redo the motor mounts to include some directional jets to vent the air out the side of the channels. I am wiring those directly up to the 12v rail so they come on when the power supply does. This way I can eliminate any of the heat associated, plus I can play with a secondary arduino and some led's.

The concensus in the R/C modeling world (of which I am a part) seems to be the when a servo motor is underpowered it causes a momentary brown out in the servo circuit board. Not enough power on hand causes the voltage to drop in the circuit. This causes the servo circuit to shut down. When the power to the coils in the motor stop all at once, a backwards EMF (voltage spike) of many times the applied voltage occurs. Once the circuit detects the proper voltage again, it starts back up and applies voltage again to the motor, only to shut down all over again. Normally the circuit can handle the normal occuring spikes that occur when voltage is removed from the motor coils under normal shutdown, but during this brown out phenomenon the system switches on and off many times a second. This causes several spikes per second back into the protection circuit causing it to fail. I remember as a teenager in shop/electronic class how we use to wire up coils from the lawn mower engines so that some unsuspecting victim would get the "you know what" shocked out of them when we found creative ways to cause them to absorb the collapsing voltage spike. This is the same priniple that those gimicked shocking cigarette lighters and ball point pens and such work off of. Seems strange that underpower something can actually burn out a board, but the magic of electronics theory proves it can and does happen.

Kinda sounds like you are a typical guy like I am. You should get some of those really loud cooling fans from a rack mount server that sound like a jet taking off. If you can find a way to make it work better and make it louder in the process all the better. Just like our cars.

I'm an RC Guy also, just a thought, since you actually only need a signal wire running from your servo to the controll board, you could power your servo with a UBEC running direct from your 12 volt power supply to the power wires on the servo which will give you a clean constant 5 volts. That's the way I wire my servo's on my Tricopters and no brown outs.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 10:22PM |

Registered: 9 years ago Posts: 309 |

Ok, makes less and less sense. I pulled a 12v to a step down to 5v and put that to the RAMPS 5v rail. The servo powers up and the LCD panel doesn't show that flickering. However, as soon as I turn on the hothead, it immediately starts the twitching again. I tested the voltage coming out of the line and it is 4.94 volts on the 5v at the servo and the signal (?) line is running 0.14 volts regardless of it being on or off.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 08, 2015 11:15PM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

Ok, makes less and less sense. I pulled a 12v to a step down to 5v and put that to the RAMPS 5v rail. The servo powers up and the LCD panel doesn't show that flickering. However, as soon as I turn on the hothead, it immediately starts the twitching again. I tested the voltage coming out of the line and it is 4.94 volts on the 5v at the servo and the signal (?) line is running 0.14 volts regardless of it being on or off.

You do see a small voltage on the signal line when it is disconnected. I never looked to see where is bleeds in from. You shoud test the 5v line when the hot end kicks on as 5V is easy to obtain with no load. What exactly did you use to frop the 12v line to 5v? You might try an external 5v supply, completly separate from the printer power supply. As 3D52 daid, a UBEC is the best, but I doubt you have one of those on hand as they are pretty much am R/C gizmo. Do you have a 5v USB charger that outputs as least 1A? You can butcher an extra USB cable to use for powering this line so you don't have to dedicate the charger to the printer.

You might also, just for grins, temporarily unplug your LCD and see how it works. You might have a weak RAMPS board as it does supply the 5V line that powers the MEGA processor. It is possible the extra load from the servo twitching for an extended time may have done a number on the RAMPS 5v supply. If this is the case, RAMPS boards are like $15.00 or less from a USA supplier on eBay.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 12:04AM |

Registered: 9 years ago Posts: 309 |

Quote

mmcginnis9272

Quote

thevisad

Ok, makes less and less sense. I pulled a 12v to a step down to 5v and put that to the RAMPS 5v rail. The servo powers up and the LCD panel doesn't show that flickering. However, as soon as I turn on the hothead, it immediately starts the twitching again. I tested the voltage coming out of the line and it is 4.94 volts on the 5v at the servo and the signal (?) line is running 0.14 volts regardless of it being on or off.

You do see a small voltage on the signal line when it is disconnected. I never looked to see where is bleeds in from. You shoud test the 5v line when the hot end kicks on as 5V is easy to obtain with no load. What exactly did you use to frop the 12v line to 5v? You might try an external 5v supply, completly separate from the printer power supply. As 3D52 daid, a UBEC is the best, but I doubt you have one of those on hand as they are pretty much am R/C gizmo. Do you have a 5v USB charger that outputs as least 1A? You can butcher an extra USB cable to use for powering this line so you don't have to dedicate the charger to the printer.

You might also, just for grins, temporarily unplug your LCD and see how it works. You might have a weak RAMPS board as it does supply the 5V line that powers the MEGA processor. It is possible the extra load from the servo twitching for an extended time may have done a number on the RAMPS 5v supply. If this is the case, RAMPS boards are like $15.00 or less from a USA supplier on eBay.

I am using a adjustable buck power regulator, LM2596 dialed down to 5.1 volts, I popped it up to 5.35 volts. At that range it can handle 2 amps stable. I popped off the LCD screen for a while and did some testing and it is still doing it with that off. I have extra RAMPS boards, drivers and duinos laying about with a few more coming in. I have decided I want to eliminate the entire servo/button approach and move to a prox sensor of some form. I have several different sensors on hand and it could mount out of the way if it works properly. It's small and unobtrusive so it will work.

I just eliminated the RAMPS 5v rail as the issue, I powered the servo off the buck converter directly. As soon as I triggered the hothead the servo started jumping. It honestly looks like it is jumping in time to the LED blinking on the RAMPS while heating the bed.

Edited 1 time(s). Last edit at 04/09/2015 12:07AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 07:01AM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Ok, makes less and less sense. I pulled a 12v to a step down to 5v and put that to the RAMPS 5v rail. The servo powers up and the LCD panel doesn't show that flickering. However, as soon as I turn on the hothead, it immediately starts the twitching again. I tested the voltage coming out of the line and it is 4.94 volts on the 5v at the servo and the signal (?) line is running 0.14 volts regardless of it being on or off.

You do see a small voltage on the signal line when it is disconnected. I never looked to see where is bleeds in from. You shoud test the 5v line when the hot end kicks on as 5V is easy to obtain with no load. What exactly did you use to frop the 12v line to 5v? You might try an external 5v supply, completly separate from the printer power supply. As 3D52 daid, a UBEC is the best, but I doubt you have one of those on hand as they are pretty much am R/C gizmo. Do you have a 5v USB charger that outputs as least 1A? You can butcher an extra USB cable to use for powering this line so you don't have to dedicate the charger to the printer.

You might also, just for grins, temporarily unplug your LCD and see how it works. You might have a weak RAMPS board as it does supply the 5V line that powers the MEGA processor. It is possible the extra load from the servo twitching for an extended time may have done a number on the RAMPS 5v supply. If this is the case, RAMPS boards are like $15.00 or less from a USA supplier on eBay.

I am using a adjustable buck power regulator, LM2596 dialed down to 5.1 volts, I popped it up to 5.35 volts. At that range it can handle 2 amps stable. I popped off the LCD screen for a while and did some testing and it is still doing it with that off. I have extra RAMPS boards, drivers and duinos laying about with a few more coming in. I have decided I want to eliminate the entire servo/button approach and move to a prox sensor of some form. I have several different sensors on hand and it could mount out of the way if it works properly. It's small and unobtrusive so it will work.

I just eliminated the RAMPS 5v rail as the issue, I powered the servo off the buck converter directly. As soon as I triggered the hothead the servo started jumping. It honestly looks like it is jumping in time to the LED blinking on the RAMPS while heating the bed.

We are dealing with a known good servo right now, correct?

If the servo jitters with good clean 5v supplied to it from externally, then the issue has to be either a bad servo or a signal failure from the arduino/RAMPS combination on servo signal D11. The signal simply passes through the RAMPS board from the Arduino directly to the servo lines D4 D5 D6 and D11. This would indicate the Arduino is loosing power and it gets that power from the RAMPS board.

Does the hotend come on and communication stays open to the arduino with the servo removed? If so, what if you add back in just the LCD?

It might still be a weakened RAMPS or, one of your main power supply 12v legs might be weak, as that ultimatly generates the power for the RAMPS to convert to 5v.

Check your 12v from the power supply when the servo jitters to see if both 12v legs stay level at 12v. I doubt this is the problem.

Or bet yet, do what you said and scrap the servo. I personally use the original bouncing hex key method with good success

As far as the prox sensor.... I've wondered about these as I have no experiance with them: Do they trigger at a precise enough distance to accuratly calibrate bed height? I didn;t know they were that precise.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 09:59AM |

Registered: 9 years ago Posts: 445 |

Quote

mmcginnis9272

As far as the prox sensor.... I've wondered about these as I have no experiance with them: Do they trigger at a precise enough distance to accuratly calibrate bed height? I didn;t know they were that precise.

They might not fit this purpose, it seems that the object that is to be sensed have to be very dense, aluminium might not do it....

[forums.reprap.org]

EDIT: But then again, some have tried and succeded: [groups.google.com]

Small video of it in action: [youtu.be]

Edited 2 time(s). Last edit at 04/09/2015 10:09AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 10:18AM |

Registered: 9 years ago Posts: 309 |

Quote

mmcginnis9272

We are dealing with a known good servo right now, correct?

If the servo jitters with good clean 5v supplied to it from externally, then the issue has to be either a bad servo or a signal failure from the arduino/RAMPS combination on servo signal D11. The signal simply passes through the RAMPS board from the Arduino directly to the servo lines D4 D5 D6 and D11. This would indicate the Arduino is loosing power and it gets that power from the RAMPS board.

Does the hotend come on and communication stays open to the arduino with the servo removed? If so, what if you add back in just the LCD?

It might still be a weakened RAMPS or, one of your main power supply 12v legs might be weak, as that ultimatly generates the power for the RAMPS to convert to 5v.

Check your 12v from the power supply when the servo jitters to see if both 12v legs stay level at 12v. I doubt this is the problem.

Or bet yet, do what you said and scrap the servo. I personally use the original bouncing hex key method with good success

As far as the prox sensor.... I've wondered about these as I have no experiance with them: Do they trigger at a precise enough distance to accuratly calibrate bed height? I didn;t know they were that precise.

I am beginning to suspect the duino myself, I did not have a chance to pull it out and do any testing on it separately last night. I was so geeked about playing with that sensor and the possibilities that I just flashed the printer to test my theories.

Without the servo in place, the printer works perfectly fine, no communication issues of any kind. With the SG90 servo that came with the kit, the system would refuse to power on 9 times out of 10. I tried with a hitec h5-55 and while smaller, exhibits the symptoms you see. I think it's power consumption is less then the sg90 which is why we are seeing it jump.

I will have to check the powersupply I received, its a 360 watt unit. I thought it was a single rail, I only tested one connection on it and it was rock steady at 12.44. I will do more intrusive testing tonight and verify power with various things on what the actual voltage and amp usages are. I do have my deathbox 3000 (https://www.dropbox.com/s/smlp1i9o2mkvoe8/2015-03-25%2000.02.16.jpg?dl=0) I could do some pristine testing with that.

The sensor I have was not responsive enough to do anything other then a proof of concept. I hooked it into the aux 2 on the ramps taking up the first 3 ports, 5v/gnd/a3(d57). The one I have is analog and outputs a voltage difference of 1.65 depending on the voltage input(3.3 or 5v), but only samples from 10 cm - 150 cm. I removed the servo and mounted the sensor to the servo location with a zip tie. The bottom of my sensor was 4.5 cm above the bed and the closest I was able to detect it was 7 cm. When moving the head up to above the detection range (10 cm), I was able to detect a piece of paper being passed through the field. I rush ordered 3 more sensors, a 0.5 cm to 5 cm digital and a 2 cm to 10 cm in both analog and digital. With the analog we have in theory a 0.001 precision ( 1.65v output / 1024 ); although, I doubt we have anywhere near that precision. Hopefully the sensors will be here by Friday/Saturday and I can begin testing with these sensors. Thee nice thing is you can order the super cheap ones from China and when you are ready, the super precise ones are simply plug and play. I have already began modifying the code to support the sensor and writing a replacement for the positioning.

Edited 1 time(s). Last edit at 04/09/2015 10:25AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 10:22AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

mmcginnis9272

As far as the prox sensor.... I've wondered about these as I have no experiance with them: Do they trigger at a precise enough distance to accuratly calibrate bed height? I didn;t know they were that precise.

They might not fit this purpose, it seems that the object that is to be sensed have to be very dense, aluminium might not do it....

[forums.reprap.org]

EDIT: But then again, some have tried and succeded: [groups.google.com]

Small video of it in action: [youtu.be]

Ahh, these are different sensors then the ones I am using (http://www.ediy.com.my/index.php/blog/item/92-sharp-gp2y0a21-ir-distance-sensors). I had looked at those previously and was wondering about them. Might be the same group of guys doing work with the yellow sensor and it's impressive. I think they identified an issue with it detecting glass though?

Edited 1 time(s). Last edit at 04/09/2015 10:24AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 11:07AM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

I think they identified an issue with it detecting glass though?

Seems so, but appears to be fixed by putting aluminium-foil underneath the glass.

Overall there seems to be some issues, but the sensors are not very expensive so I might end up giving it a try anyway. (I have yet to assemble my printer, have not arrived as of now - ordered march 6th, they sent it april 2nd)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 11:18AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

thevisad

I think they identified an issue with it detecting glass though?

Seems so, but appears to be fixed by putting aluminium-foil underneath the glass.

Overall there seems to be some issues, but the sensors are not very expensive so I might end up giving it a try anyway. (I have yet to assemble my printer, have not arrived as of now - ordered march 6th, they sent it april 2nd)

I picked up the following three sensors (IR ones) 2-10 digital : 0.5 - 5 digital : 2 - 15 analog

The one that I have seen (in addition to the one you linked and as an upgrade to that one in particular) is the Fotek PS-15N, I am ordering a couple of those today and hope to have those in early next week. These are just massive compared to everything else.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 11:35AM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

Quote

Koenig

Quote

thevisad

I think they identified an issue with it detecting glass though?

Seems so, but appears to be fixed by putting aluminium-foil underneath the glass.

Overall there seems to be some issues, but the sensors are not very expensive so I might end up giving it a try anyway. (I have yet to assemble my printer, have not arrived as of now - ordered march 6th, they sent it april 2nd)

I picked up the following three sensors (IR ones) 2-10 digital : 0.5 - 5 digital : 2 - 15 analog

The one that I have seen (in addition to the one you linked and as an upgrade to that one in particular) is the Fotek PS-15N, I am ordering a couple of those today and hope to have those in early next week. These are just massive compared to everything else.

Impressive!

Might one ask where you are ordering from?

EDIT: Quite big and sort of real heavy... 126g...

Edited 1 time(s). Last edit at 04/09/2015 11:40AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 02:40PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Impressive!

Might one ask where you are ordering from?

EDIT: Quite big and sort of real heavy... 126g...

I ordered the original sensors from ebay from China. They took a couple of weeks to get here, but I cannot resist the free shipping and bird flu samples I get with every package. Honestly, the quality is the same or better and it's 10X cheaper. The newer more precise versions I just bought from Pololu themselves. The Fotek sensors are on ebay as well, but I am looking at this line now (Mouser) 120$ is a bit pricey for "take one for the team" testing. I bought a 5 MM version of the fotek from here. Here is an 8mm version of the sensor (NO)

FolgerTech Update: I just received my package from Folgertech and it contained a new SG90 servo and a thermister to replace the shorted one on the hotend.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 11:34PM |

Registered: 9 years ago Posts: 14 |

Extruder motor skipps a bunch and doesn't extrude..itll be fine for a few seconds to a minute then skip skip skip skip fine fine fine skip fine. up the voltage to as high as I date (~.9V) and same story, took apart the gear housing and flipped the gear around (maybe its the teeth) still no dice. Thinking its my hotend or something at this point. got an e3d v6 in the mail hopefully here tomorrow and I can see if its the motor or my hot end.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 09, 2015 11:37PM |

Registered: 9 years ago Posts: 309 |

Quote

ADecker

Extruder motor skipps a bunch and doesn't extrude..itll be fine for a few seconds to a minute then skip skip skip skip fine fine fine skip fine. up the voltage to as high as I date (~.9V) and same story, took apart the gear housing and flipped the gear around (maybe its the teeth) still no dice. Thinking its my hotend or something at this point. got an e3d v6 in the mail hopefully here tomorrow and I can see if its the motor or my hot end.

I had this issue and it was possibly the filament I was using. I bumped up the temp and it didn't seem to help, did the gear flip like you did as well. Switched over to a different filament and it took off without an issue. Let me know what you thing of that e3d, I want one of them.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 10, 2015 03:33PM |

Registered: 9 years ago Posts: 14 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 10, 2015 04:56PM |

Registered: 9 years ago Posts: 56 |

I finally got my Folger Kossel printing after a couple of hiccups. The first was the M4 T-nuts, then trying to find the red and black Z-probe wire mentioned in the build manual (kit had 4 lengths of gray cable for both Z-probe and fan - had to mark one of them with a Sharpie), then when it was all together I gave it G28 and watched X and Z move up to the stops while Y went down.

The first troubleshooting step was to swap X and Y (both steppers and endstops). The problem moved to X. Then I swapped Y and Z. The problem moved to Z. Pretty sure that's a RAMPS problem.

I sent a detailed email including all of the troubleshooting steps, and got back "check the endstops". After several rounds of John not reading the email for content, he finally said "Looks like you have a bad RAMPS or Mega. I'll send you a new set."

In the meantime I moved the Y stepper to the E1 position, modified the firmware accordingly, and went about my business.

Yesterday I finally got ABS printing fairly well, but it took quite a while to get the bed hot enough, so I put a couple of layers of cardboard between the bed and the Arduino. Kicked off a new print. Watched the bed heat up (a bit quicker), then it ran autolevel, then started heating the hotend. About that time pronterface lost communication.

After watching it crash every time the hotend started heating, I decided I must have fried either the Arduino or the RAMPS. I had the new set from Folger, so I swapped first the Arduino, then the RAMPS. Same problem every time.

Then I remembered what I tell my students when I teach hardware and software troubleshooting: "Only make ONE change at a time." The last thing I did before it started crashing was to add autolevel to my startup G-code. I realized that the crash was occuring at the end of autolevel (sometimes just before it finished), not the start of hotend heating. Commenting out autolevel got it back in operation.

From reading this thread I realize that running the servo at the same time as the heaters is probably playing havoc with the bus voltages. When this print finishes I'll try running autolevel before the heaters. If that doesn't work I'll put springs under the bed and adjust it manually. The main reason I want autolevel is to compensate for the AquaNet glass I use for ABS.

UPDATE: The servo arm was binding against the end effector when give S120. The servo motion could not complete, so the Arduino dutiful did nothing else while waiting. I changed configuration.h to #define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 5,90} and adjusted my startup g-code accordingly. (don't know how that edit ended up in the middle of the post)

Edited 2 time(s). Last edit at 04/10/2015 06:02PM by Deguello.

The first troubleshooting step was to swap X and Y (both steppers and endstops). The problem moved to X. Then I swapped Y and Z. The problem moved to Z. Pretty sure that's a RAMPS problem.

I sent a detailed email including all of the troubleshooting steps, and got back "check the endstops". After several rounds of John not reading the email for content, he finally said "Looks like you have a bad RAMPS or Mega. I'll send you a new set."

In the meantime I moved the Y stepper to the E1 position, modified the firmware accordingly, and went about my business.

Yesterday I finally got ABS printing fairly well, but it took quite a while to get the bed hot enough, so I put a couple of layers of cardboard between the bed and the Arduino. Kicked off a new print. Watched the bed heat up (a bit quicker), then it ran autolevel, then started heating the hotend. About that time pronterface lost communication.

After watching it crash every time the hotend started heating, I decided I must have fried either the Arduino or the RAMPS. I had the new set from Folger, so I swapped first the Arduino, then the RAMPS. Same problem every time.

Then I remembered what I tell my students when I teach hardware and software troubleshooting: "Only make ONE change at a time." The last thing I did before it started crashing was to add autolevel to my startup G-code. I realized that the crash was occuring at the end of autolevel (sometimes just before it finished), not the start of hotend heating. Commenting out autolevel got it back in operation.

From reading this thread I realize that running the servo at the same time as the heaters is probably playing havoc with the bus voltages. When this print finishes I'll try running autolevel before the heaters. If that doesn't work I'll put springs under the bed and adjust it manually. The main reason I want autolevel is to compensate for the AquaNet glass I use for ABS.

UPDATE: The servo arm was binding against the end effector when give S120. The servo motion could not complete, so the Arduino dutiful did nothing else while waiting. I changed configuration.h to #define SERVO_ENDSTOP_ANGLES {0,0, 0,0, 5,90} and adjusted my startup g-code accordingly. (don't know how that edit ended up in the middle of the post)

Edited 2 time(s). Last edit at 04/10/2015 06:02PM by Deguello.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 10, 2015 05:12PM |

Registered: 9 years ago Posts: 22 |

Well, after a couple times bitching and 30 days later my kit has arrived!...

I'm still building but I think I received all the parts and my box didn't seem too beat up. Everything is packaged and labeled real well but, the mixed bag of hardware (screws nuts washers...) can lead to trouble unless you take the time to sort the fasteners beforehand...

It was mentioned before a few pages back but, if you follow the Googledrive build manual, it tells you to use M3 8mm screws to assemble the corners.This step should all be done with M3 10mm screws not8mm. 8mm will work but it seems they dont supply you enough. Most of the 8mm screws are for mounting the 3 linear slides.

I put all my corners and extrusion together with 8mm -only to remember reading about the slides after the fact.

Working with the corners and screwing from the inside has got to be the most tedious part of this build -you don't want to do this twice ...trust me. I only had the option to swap out the screws because these are hard to find locally. M4 seems the smallest available, at least at my local hardwares.

*A 2.5mm ball end Allen/Hex wrench is a must for these corners.*

I'm still building but I think I received all the parts and my box didn't seem too beat up. Everything is packaged and labeled real well but, the mixed bag of hardware (screws nuts washers...) can lead to trouble unless you take the time to sort the fasteners beforehand...

It was mentioned before a few pages back but, if you follow the Googledrive build manual, it tells you to use M3 8mm screws to assemble the corners.This step should all be done with M3 10mm screws not

I put all my corners and extrusion together with 8mm -only to remember reading about the slides after the fact.

Working with the corners and screwing from the inside has got to be the most tedious part of this build -you don't want to do this twice ...trust me. I only had the option to swap out the screws because these are hard to find locally. M4 seems the smallest available, at least at my local hardwares.

*A 2.5mm ball end Allen/Hex wrench is a must for these corners.*

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 10, 2015 05:39PM |

Registered: 9 years ago Posts: 309 |

Quote

Deguello

I finally got my Folger Kossel printing after a couple of hiccups. The first was the M4 T-nuts, then trying to find the red and black Z-probe wire mentioned in the build manual (kit had 4 lengths of gray cable for both Z-probe and fan - had to mark one of them with a Sharpie), then when it was all together I gave it G28 and watched X and Z move up to the stops while Y went down.

The first troubleshooting step was to swap X and Y (both steppers and endstops). The problem moved to X. Then I swapped Y and Z. The problem moved to Z. Pretty sure that's a RAMPS problem.

I sent a detailed email including all of the troubleshooting steps, and got back "check the endstops". After several rounds of John not reading the email for content, he finally said "Looks like you have a bad RAMPS or Mega. I'll send you a new set."

In the meantime I moved the Y stepper to the E1 position, modified the firmware accordingly, and went about my business.

Yesterday I finally got ABS printing fairly well, but it took quite a while to get the bed hot enough, so I put a couple of layers of cardboard between the bed and the Arduino. Kicked off a new print. Watched the bed heat up (a bit quicker), then it ran autolevel, then started heating the hotend. About that time pronterface lost communication.

After watching it crash every time the hotend started heating, I decided I must have fried either the Arduino or the RAMPS. I had the new set from Folger, so I swapped first the Arduino, then the RAMPS. Same problem every time.

Then I remembered what I tell my students when I teach hardware and software troubleshooting: "Only make ONE change at a time." The last thing I did before it started crashing was to add autolevel to my startup G-code. I realized that the crash was occuring at the end of autolevel (sometimes just before it finished), not the start of hotend heating. Commenting out autolevel got it back in operation.

From reading this thread I realize that running the servo at the same time as the heaters is probably playing havoc with the bus voltages. When this print finishes I'll try running autolevel before the heaters. If that doesn't work I'll put springs under the bed and adjust it manually. The main reason I want autolevel is to compensate for the AquaNet glass I use for ABS.

This is the same exact thing I have an issue with. It is the servo motor causing the issue, drawing too much power and crashing the ramps machine. Adding an external powersupply does not solve the issue, nor does adding a power supply to the 5v rail. The best thing I have been able to do is disable the servo and manually swing the arm up and down. This solves the shutting down problem, but I have no clue what is happening. With a more sensitive servo it starts bouncing. Best theory I have is there is a timing somewhere that is pulsing to the servo pins. I have not had a lot of time to mess with it, but I am replacing it with a fotek sensor. My preliminary work with the IR sensor I have is promising, but I have my doubts that even the more precise one will provide me with what I want. The sensors I ordered will not be here until next week so this weekend I will be making some pressure sensors and adding them to the plate to use the print head tip as the tester. I have; however, seemed to have found a major flaw in the auto leveling system, from what I can tell, it makes the bed look square to the code, instead of sloped. It simply copies the nearest neighbor to the untested locations. What happens when that occurs and the plate warps, is not pretty.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 10, 2015 05:40PM |

Registered: 9 years ago Posts: 309 |

Quote

Flish

Well, after a couple times bitching and 30 days later my kit has arrived!...

I'm still building but I think I received all the parts and my box didn't seem too beat up. Everything is packaged and labeled real well but, the mixed bag of hardware (screws nuts washers...) can lead to trouble unless you take the time to sort the fasteners beforehand...

It was mentioned before a few pages back but, if you follow the Googledrive build manual, it tells you to use M3 8mm screws to assemble the corners.This step should all be done with M3 10mm screws not8mm. 8mm will work but it seems they dont supply you enough. Most of the 8mm screws are for mounting the 3 linear slides.

I put all my corners and extrusion together with 8mm -only to remember reading about the slides after the fact.

Working with the corners and screwing from the inside has got to be the most tedious part of this build -you don't want to do this twice ...trust me. I only had the option to swap out the screws because these are hard to find locally. M4 seems the smallest available, at least at my local hardwares.

*A 2.5mm ball end Allen/Hex wrench is a must for these corners.*

I feel sorry for you if you have big fingers, I rubbed a hole on the top side of my pointer finger trying to screw those stupid things in the motor mounts.

Sorry, only registered users may post in this forum.