Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 01:08PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

Edited 1 time(s). Last edit at 04/21/2015 01:09PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 01:12PM |

Registered: 9 years ago Posts: 309 |

Quote

Wittmason

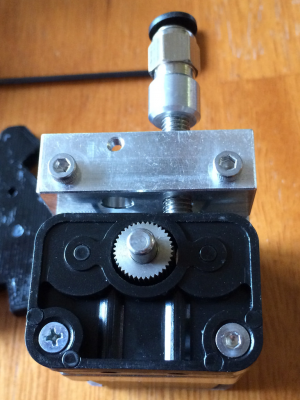

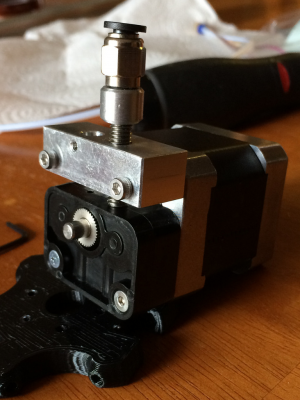

A nice clean way to fix the extrusion system is to get a new hotend throat. The one inside the fake E3D has ptfe tubing in it. You won't be able to get beyond 240c with that hotend in its current state. I got this hotend throat

Hotend throat replacement for E3D knockoffs. 2mm ID for higher temp. usage. by nScaleRail, on Flickr

ebay link to hotend throat I took the old throat out and used it on the extruder.

The extruder included in the kit was built to be attached to a hotend and so to get it to work right you need to mimic that same style layout.

Fix extruder issues on Folger Tech Kossel. by nScaleRail

Fix extruder issues on Folger Tech Kossel. by nScaleRail, on Flickr

P.s. One other note on extruding with this kit. It appears the ptfe tube is the 1.8mm diameter style. So it you have larger filement (say on the 1.77mm size) the tube will be very tight. I replaced the tube with 2mm ID tube, now things are moving better..

I hope this tip helps some.

Tim

Awesome post Tim and explains the issues we are seeing with that block.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 01:16PM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 01:18PM |

Registered: 9 years ago Posts: 309 |

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

I stopped using WD40 20+ years ago and switched to SPO and recently came across Kroil and I absolutely love it in replacement of WD40, but it stinks to high heaven.

Edited 1 time(s). Last edit at 04/21/2015 02:07PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 02:06PM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

Exactly what I did and in between the rounds of WD40 I used white lithium grease (from CRC) to try to get them smooth, still I don't think there should be any missing balls....

Edited 2 time(s). Last edit at 04/21/2015 02:09PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 02:11PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

Exactly what I did and in between the rounds of WD40 I used lithium grease to try to get them smooth, still I don't think there should be any missing balls....

No there should not be, reach out to Folger, they will take care of you for it. I would stay away from lithium grease, that's too thick. You want machinist oil (that little orange oil can your grandpa had), any decent gun oil or motor oil will work. The stuff I use is top notch and overkill, but I bought more then I needed for my guns so why not. The difference is night and day really.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 02:33PM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

Quote

Koenig

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

Exactly what I did and in between the rounds of WD40 I used lithium grease to try to get them smooth, still I don't think there should be any missing balls....

No there should not be, reach out to Folger, they will take care of you for it. I would stay away from lithium grease, that's too thick. You want machinist oil (that little orange oil can your grandpa had), any decent gun oil or motor oil will work. The stuff I use is top notch and overkill, but I bought more then I needed for my guns so why not. The difference is night and day really.

A little hard to see, but you can get the hint of it.

And the lithium fat is what makes the balls not look smooth.

I'll get in touch with Folger and see if they can send me some new ones.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 02:35PM |

Registered: 9 years ago Posts: 309 |

ouch, yup looks like you are missing three should look like this SampleQuote

Koenig

Quote

thevisad

Quote

Koenig

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

Exactly what I did and in between the rounds of WD40 I used lithium grease to try to get them smooth, still I don't think there should be any missing balls....

No there should not be, reach out to Folger, they will take care of you for it. I would stay away from lithium grease, that's too thick. You want machinist oil (that little orange oil can your grandpa had), any decent gun oil or motor oil will work. The stuff I use is top notch and overkill, but I bought more then I needed for my guns so why not. The difference is night and day really.

A little hard to see, but you can get the hint of it.

And the lithium fat is what makes the balls not look smooth.

I'll get in touch with Folger and see if they can send me some new ones.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 03:08PM |

Registered: 9 years ago Posts: 445 |

I sent them a mail.

Still think it's strange, 2 out of 3.....

Just to wait and see then I suppose.

EDIT: From that sample you linked to it sure looked like they used a rather thick grease...

And from what I know from cars motorbikes the ball bearings there use real thick grease as well.

Edited 2 time(s). Last edit at 04/21/2015 03:16PM by Koenig.

Still think it's strange, 2 out of 3.....

Just to wait and see then I suppose.

EDIT: From that sample you linked to it sure looked like they used a rather thick grease...

And from what I know from cars motorbikes the ball bearings there use real thick grease as well.

Edited 2 time(s). Last edit at 04/21/2015 03:16PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 03:11PM |

Registered: 9 years ago Posts: 29 |

ok, I could use a lot of help. I have my kit all put together but i can't get any prints. I have used printrun and cura but i get the same results. the printer will heat up and then probe the bed and then retract the probe. after this the hole thing stops and will not do anything. attached is my configuration.h and i am using the start gcode provided by FolgerTech. How are people mounting the ramps? If i follow the instructions i cant use the usb port.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 03:50PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

I sent them a mail.

Still think it's strange, 2 out of 3.....

Just to wait and see then I suppose.

EDIT: From that sample you linked to it sure looked like they used a rather thick grease...

And from what I know from cars motorbikes the ball bearings there use real thick grease as well.

Yeah, I noticed the grease in that as well, definitely a lot heavier then I would use. I think the one I linked you was for a really heavy machine/load.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 03:59PM |

Registered: 9 years ago Posts: 63 |

Quote

thevisad

ouch, yup looks like you are missing three should look like this SampleQuote

Koenig

Quote

thevisad

Quote

Koenig

Quote

thevisad

Quote

mmcginnis9272

Quote

thevisad

Quote

Koenig

I have serious problem with 2 of my rails, I've spent one and a half big bottle of WD40 to get the to run smooth, I've spent 3 hours just running them back and forth while spraying WD40.

I've bathed them in WD40 running them back and forth and still no luck, looking at the backside of the carriages I can see that one side is missing balls in the bearing (on the two I've got problems with).I

s this common? do you guys have missing balls?

So you used a solvent or water displacement product in your ball bearings on a linear rail and you are complaining that you cannot get them smooth? Most likely you are missing the bearings now due to them failing on the WD40 you squirted in it. Go to the store and buy some gun oil and stop using crap products. WD40 is not a lubricant, never has been and never will, it is a solvent that strips grease and rust. Using it in a bearing will destroy them over time as you are REMOVING the lubrication in the bearings, not adding it. Can WD40 be Used as a Bearing Lubricant?. Anyone telling anyone else to use WD40 as a lubricant does not know what they are talking about. I grabbed the same gun oil I used to lubricate my AR15 and after 10 minutes of cleaning with a qtip, they are perfectly smooth and grit free.

I don't think anyone here has ever recommended using WD-40 as a lubricant. I did and still do recommend using it to clean out the rails, as this is a perfect use for WD-40. Then I, as well as others have recommended lubricating the rails with some kind of oil. I personally use 5w30 synthetic motor oil.

Correct, using it to clean out the rails is fine, for a few moments. Clean them, run a rag down it, lubricate them. Running the bearings across the steel without lubrication will damage them, so it is best to not do this too often. I am having a rough day at work and that came out harsher then I meant.

Exactly what I did and in between the rounds of WD40 I used lithium grease to try to get them smooth, still I don't think there should be any missing balls....

No there should not be, reach out to Folger, they will take care of you for it. I would stay away from lithium grease, that's too thick. You want machinist oil (that little orange oil can your grandpa had), any decent gun oil or motor oil will work. The stuff I use is top notch and overkill, but I bought more then I needed for my guns so why not. The difference is night and day really.

A little hard to see, but you can get the hint of it.

And the lithium fat is what makes the balls not look smooth.

I'll get in touch with Folger and see if they can send me some new ones.

I'm sure Folger will take care of the issue, but it might be worth your time to buy 3 ball bearings at the local hardware store if you can determine the size of them. The True Value store by me has metric and SAE ball bearings in all different sizes. I'm sure they are metric. But then again, I'm an impatient person.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 04:14PM |

Registered: 9 years ago Posts: 63 |

Quote

gaddcasey1

ok, I could use a lot of help. I have my kit all put together but i can't get any prints. I have used printrun and cura but i get the same results. the printer will heat up and then probe the bed and then retract the probe. after this the hole thing stops and will not do anything. attached is my configuration.h and i am using the start gcode provided by FolgerTech. How are people mounting the ramps? If i follow the instructions i cant use the usb port.

I had to add a standoff bushing of about 1/2 inch thick between the mount bracket and the RAMPS to lower it enough for me to feed the USB cable between the 2 horizontal rails and have it plug into the port.

Can you post the real-time log file from Cura or Repetier Host for us to look at? Make sure as much data as possible is written to the file. In Repetier Host, goto Config, Preferences, Basic settings and then turn on logging.

I don't know how to do this in Cura and PrintRun as I don't use this.

Edited 1 time(s). Last edit at 04/21/2015 04:15PM by mmcginnis9272.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 04:21PM |

Registered: 9 years ago Posts: 445 |

Quote

mmcginnis9272

I'm sure Folger will take care of the issue, but it might be worth your time to buy 3 ball bearings at the local hardware store if you can determine the size of them. The True Value store by me has metric and SAE ball bearings in all different sizes. I'm sure they are metric. But then again, I'm an impatient person.

I'm from Sweden so finding a store that has metric items shouldn't be an issue

(The only things not metric here are US cars and Harley's)

(The only things not metric here are US cars and Harley's)But I have never seen anyone who stocks loose ball bearing-balls, and disassembling a ball bearing for measuring wouldn't make me very popular I think.

Edited 1 time(s). Last edit at 04/21/2015 04:22PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 04:44PM |

Registered: 9 years ago Posts: 1 |

I was interested in delivery times to Canada when I placed by order and didn't find much - so here is my information.

Shipping information from Folger Tech to Toronto Ontario.

Order placed: April 1 2015

Shipping notification: April 13 2015

UPS pickup: April 17, 2015

Delivered: April 21, 2015

I don't know the duty cost (if any) at this point. I suspect UPS will bill me.

Shipping information from Folger Tech to Toronto Ontario.

Order placed: April 1 2015

Shipping notification: April 13 2015

UPS pickup: April 17, 2015

Delivered: April 21, 2015

I don't know the duty cost (if any) at this point. I suspect UPS will bill me.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 07:24PM |

Registered: 9 years ago Posts: 24 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 08:08PM |

Registered: 9 years ago Posts: 29 |

Quote

mmcginnis9272

Quote

gaddcasey1

ok, I could use a lot of help. I have my kit all put together but i can't get any prints. I have used printrun and cura but i get the same results. the printer will heat up and then probe the bed and then retract the probe. after this the hole thing stops and will not do anything. attached is my configuration.h and i am using the start gcode provided by FolgerTech. How are people mounting the ramps? If i follow the instructions i cant use the usb port.

I had to add a standoff bushing of about 1/2 inch thick between the mount bracket and the RAMPS to lower it enough for me to feed the USB cable between the 2 horizontal rails and have it plug into the port.

Can you post the real-time log file from Cura or Repetier Host for us to look at? Make sure as much data as possible is written to the file. In Repetier Host, goto Config, Preferences, Basic settings and then turn on logging.

I don't know how to do this in Cura and PrintRun as I don't use this.

Send: N18G1 X-13.200 Y-13.200 E2.68742*118

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N19G1 X13.200 Y-13.200 E3.12645*80

Recv: ok

Send: N20G1 X13.200 Y13.200 E3.56549*120

Recv: ok

Send: N21G1 F2400 E-0.93451*55

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N22G0 F9000 X9.400 Y9.400*87

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N23G1 F2400 E3.56549*26

Recv: Error:No Checksum with line number, Last Line: 13

Recv: Resend: 14

Recv: ok

Send: N14G1 X13.600 Y-13.600 E1.35701*91

Recv: Error:Line Number is not Last Line Number+1, Last Line: 13

Recv: Resend: 14

Recv: ok

Send: N14G1 X13.600 Y-13.600 E1.35701*91

Recv: ok

Send: N15G1 X13.600 Y13.600 E1.80935*112

Communication timeout during printing, forcing a line

Send: M105 T0

Communication timeout during printing, forcing a line

Send: M105 T0

Changing monitoring state from 'Printing' to 'Operational'

Serial timeout while writing to serial port, trying again.

Edited 1 time(s). Last edit at 04/21/2015 08:55PM by gaddcasey1.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 10:43PM |

Registered: 10 years ago Posts: 34 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 21, 2015 11:04PM |

Registered: 9 years ago Posts: 29 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 12:03AM |

Registered: 10 years ago Posts: 34 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 12:12AM |

Registered: 9 years ago Posts: 29 |

Quote

jprochnow

What seems to be the problem with it? It really is cheaper than sourrcing your own parts. Even if you replace the weak motors and add the flange bearings and maybe a real e3d hotend it would be a great unit for the money.

my printed parts where not the best and customer support takes a long time to help you.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 12:14AM |

Registered: 9 years ago Posts: 309 |

Quote

gaddcasey1

Quote

jprochnow

So do people recommend these printers from folgertech? What are some recommended upgrades for it?

At the moment I am not happy with them, I have had this thing for a month and still cant get it to print anything. But this is still cheaper than sourcing your own parts.

Not really, I have gotten the parts list down to about 285$ now for the entire printer. Once you know where to go, you can order all the parts very quickly.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 12:56AM |

Registered: 11 years ago Posts: 69 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 01:26AM |

Registered: 9 years ago Posts: 445 |

Quote

rtideas

Care to share where do you go? Linear rails? Better motors? Extrusions? AliExpress?Quote

thevisad

Not really, I have gotten the parts list down to about 285$ now for the entire printer. Once you know where to go, you can order all the parts very quickly.

I've been thinking about better motors aswell plus these: [folger-technologies-llc.myshopify.com]

They are supposed to a bit better than the ones that comes with the kit, and I'm thinking better (bigger) motors will run cooler.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 01:46AM |

Registered: 9 years ago Posts: 309 |

Quote

rtideas

Care to share where do you go? Linear rails? Better motors? Extrusions? AliExpress?Quote

thevisad

Not really, I have gotten the parts list down to about 285$ now for the entire printer. Once you know where to go, you can order all the parts very quickly.

Ebay, Alibaba, Misumi, igus, McMaster. It took 3 months of digging and buying parts to get the right part numbers, etc. While you may be able to source this cheaper, I cannot applaud Folgertech more for putting it together and supporting it the way they have. I understand a few people have had issues with support, but so far it's been top notch. I think it was money well spent. Any future printers I will source myself, but I was glad to have gotten the kit from Folger and do not regret it.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 01:48AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

rtideas

Care to share where do you go? Linear rails? Better motors? Extrusions? AliExpress?Quote

thevisad

Not really, I have gotten the parts list down to about 285$ now for the entire printer. Once you know where to go, you can order all the parts very quickly.

I've been thinking about better motors aswell plus these: [folger-technologies-llc.myshopify.com]

They are supposed to a bit better than the ones that comes with the kit, and I'm thinking better (bigger) motors will run cooler.

I was thinking the same thing myself and ordered these a couple of days ago to give them a shot.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 02:32AM |

Registered: 9 years ago Posts: 43 |

Quote

rtideas

Care to share where do you go? Linear rails? Better motors? Extrusions? AliExpress?Quote

thevisad

Not really, I have gotten the parts list down to about 285$ now for the entire printer. Once you know where to go, you can order all the parts very quickly.

Dont forget to factor in your TIME for doing all of that. I personally value my time at $40 an hour if its work hours, and at $100 an hour if its family time. I spent 30 minutes and realised the time I would need to invest to beat their price was not worth it for me.

Quote

jprochnow

So do people recommend these printers from folgertech? What are some recommended upgrades for it?

I ordered their kit and I love it. I printed a 20cm tall gnome the other day for a co-worker who has a makerbot, he could not stop commenting how it looks better than what he can make (and now I wished I had taken pictures). I printed it at .1mm layer height and it took FOREVER, but came out really nice.

At the time I had not done any mods, but currently I am in the middle of installing magnetic effector and carriages as well as switching to a 250mm borosilicate build plate with no heater for now.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 06:20AM |

Registered: 9 years ago Posts: 63 |

Quote

gaddcasey1

Quote

mmcginnis9272

Quote

gaddcasey1

ok, I could use a lot of help. I have my kit all put together but i can't get any prints. I have used printrun and cura but i get the same results. the printer will heat up and then probe the bed and then retract the probe. after this the hole thing stops and will not do anything. attached is my configuration.h and i am using the start gcode provided by FolgerTech. How are people mounting the ramps? If i follow the instructions i cant use the usb port.

I had to add a standoff bushing of about 1/2 inch thick between the mount bracket and the RAMPS to lower it enough for me to feed the USB cable between the 2 horizontal rails and have it plug into the port.

Can you post the real-time log file from Cura or Repetier Host for us to look at? Make sure as much data as possible is written to the file. In Repetier Host, goto Config, Preferences, Basic settings and then turn on logging.

I don't know how to do this in Cura and PrintRun as I don't use this.

Send: N18G1 X-13.200 Y-13.200 E2.68742*118

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N19G1 X13.200 Y-13.200 E3.12645*80

Recv: ok

Send: N20G1 X13.200 Y13.200 E3.56549*120

Recv: ok

Send: N21G1 F2400 E-0.93451*55

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N22G0 F9000 X9.400 Y9.400*87

Recv: ok T:218.2 /220.0 B:89.0 /90.0 T0:218.2 /220.0 @:121 B@:127

Send: N23G1 F2400 E3.56549*26

Recv: Error:No Checksum with line number, Last Line: 13

Recv: Resend: 14

Recv: ok

Send: N14G1 X13.600 Y-13.600 E1.35701*91

Recv: Error:Line Number is not Last Line Number+1, Last Line: 13

Recv: Resend: 14

Recv: ok

Send: N14G1 X13.600 Y-13.600 E1.35701*91

Recv: ok

Send: N15G1 X13.600 Y13.600 E1.80935*112

Communication timeout during printing, forcing a line

Send: M105 T0

Communication timeout during printing, forcing a line

Send: M105 T0

Changing monitoring state from 'Printing' to 'Operational'

Serial timeout while writing to serial port, trying again.

I'll openly admit that I know nothing about the inner workings of the Marlin firmware, but it is looks like you are having a communications and/or timeout issue.

If you have an LCD screen, can you try loading your gcode file in that and printing directly from the SD card?

A Google search reveals that your issue is a known issue. You might try another USB cable and/or use another USB port or try adding in a powered USB hub.

Might be a Marlin Firmware bug. You might try the Cura firmware, just to see what happens. Might even be a weak Arduino board. I'm just guessing.

On an Octoprint forum, they mention setting "Swallow the first OK" setting as a possible solution, but I don't know if your host software has an equivalant setting.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 09:03AM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level April 22, 2015 09:25AM |

Registered: 9 years ago Posts: 309 |

Quote

jculver09

Dont forget to factor in your TIME for doing all of that. I personally value my time at $40 an hour if its work hours, and at $100 an hour if its family time. I spent 30 minutes and realised the time I would need to invest to beat their price was not worth it for me.

That's why I specified I spent 3 months doing this, it is seriously a time consuming process. I actually charge 100$ an hour work time for onsite IT work, that is what I value my time at. For my team, it was a requirement, we have designed our own printer and we want a product we can put our name on, not regurgitating the existing lines. We have now gotten to a point where there are no longer non name brand mechanical products in our printer (in other words Chinese parts) and everything is sourced from America/Germany instead. Later this year we will have our own electronics for the printer that we are designing ourselves, so the ramps systems will be replaced.

Sorry, only registered users may post in this forum.