Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 02:54AM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 02:55AM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:17AM |

Registered: 9 years ago Posts: 11 |

Inspired by cman8, I took to configuring my build. It powers on just fine but I'm getting this odd behavior when I ask it to extrude. The X tower pulses like it's trying to home and the Y tower slowly moves down and the extruder motor seems to do nothing ideas? I'm also getting some weird behavior out of my Y tower in general possibly a bad driver? That axis seems to have trouble homing - it stops about 15cm from the endstop and then hangs out.

Edited 1 time(s). Last edit at 05/06/2015 05:19AM by Mylation.

Edited 1 time(s). Last edit at 05/06/2015 05:19AM by Mylation.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 06:14AM |

Registered: 9 years ago Posts: 63 |

Quote

Mylation

Well it's been two days since I got my kit. All the hardware is screwed together and I didn't blow it up when I adjusted the drivers. I am concerned still about adjusting the height because I put it at the maximum possible not knowing the precise place to put the rails with 250mm rods. I ended up having EXACTLY the number of T nuts that I needed which was disappointing because I was hoping to have at least 2 extra for mounting my screen - I guess I'll have to PRINT something!

Yep, print them!! : [www.thingiverse.com] <-- T-nuts

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 06:30AM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 09:01AM |

Registered: 9 years ago Posts: 30 |

Quote

hedgehogsmoker

Can anyone tell me how I find the radius?

Sorry I'm very new to this.

try this page, there is a diagram about 3-4 images down the page: [sites.google.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 09:06AM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 09:18AM |

Registered: 9 years ago Posts: 56 |

hegdehogsmoker, before you try to launch a print job, make sure you can jog the end around with Pronterface. You can use the navigation buttons on the left, or use G code. For example:

G28 ;home everything

G1 F4000 Z10 ;lower to just above the surface

G1 F4000 X50 Y0 ; move it to the right

G1 F4000 X-50 Y0 ;move it to the left

G1 F4000 X0 Y50 ;move it to the back

G1 F4000 X0 Y-50 ;move it to the front

If it won't do those controlled movements you have problems to work out before you turn it loose on its own.

G28 ;home everything

G1 F4000 Z10 ;lower to just above the surface

G1 F4000 X50 Y0 ; move it to the right

G1 F4000 X-50 Y0 ;move it to the left

G1 F4000 X0 Y50 ;move it to the back

G1 F4000 X0 Y-50 ;move it to the front

If it won't do those controlled movements you have problems to work out before you turn it loose on its own.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 01:06PM |

Registered: 9 years ago Posts: 309 |

FYI, remove the PTFE from your throat before you melt it and experience this. One removed I replaced the throat back into service, the opening with the removed PTFE against the nozzle. Since the nozzle hole is concave the filament still proceeds to feed properly without issue.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 01:14PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

thevisad

They are a direct replacement for the a4988 drivers; however, your 16 step will be 32 step with the jumpers in the current place.

Are you really sure?

looking at this: [www.geeetech.com]

I get the sense A and B corresponds to the two phases of the motor, and thus switching 1B and 2A will make the motor not do what it is supposed to...?

BTW, I received my DRV8825 from geetech in the mail yesterday. I was really tired and didn't even think about it, popped out the a4988 drivers and in went the 8825, backwards. Make sure you pay attention, the POT goes on the OPPOSITE side of the RAMPS board, not in the same direction as the 4988. The 8825 handled the reversal without issue and once placed in the right direction and dialed in everything started working fine. You will need to adjust your MM per step as it will now take twice as many to move the same distance.

Correct!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 02:26PM |

Registered: 9 years ago Posts: 445 |

Quote

thevisad

Quote

Koenig

Quote

thevisad

They are a direct replacement for the a4988 drivers; however, your 16 step will be 32 step with the jumpers in the current place.

Are you really sure?

looking at this: [www.geeetech.com]

I get the sense A and B corresponds to the two phases of the motor, and thus switching 1B and 2A will make the motor not do what it is supposed to...?

BTW, I received my DRV8825 from geetech in the mail yesterday. I was really tired and didn't even think about it, popped out the a4988 drivers and in went the 8825, backwards. Make sure you pay attention, the POT goes on the OPPOSITE side of the RAMPS board, not in the same direction as the 4988. The 8825 handled the reversal without issue and once placed in the right direction and dialed in everything started working fine. You will need to adjust your MM per step as it will now take twice as many to move the same distance.

What Vref did you set?

Are the motors more quiet now? (I heard somewhere that this driver makes the motors run more quiet)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:10PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:18PM |

Registered: 9 years ago Posts: 63 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:21PM |

Registered: 9 years ago Posts: 22 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:22PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:22PM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

thevisad

Quote

Koenig

Quote

thevisad

They are a direct replacement for the a4988 drivers; however, your 16 step will be 32 step with the jumpers in the current place.

Are you really sure?

looking at this: [www.geeetech.com]

I get the sense A and B corresponds to the two phases of the motor, and thus switching 1B and 2A will make the motor not do what it is supposed to...?

BTW, I received my DRV8825 from geetech in the mail yesterday. I was really tired and didn't even think about it, popped out the a4988 drivers and in went the 8825, backwards. Make sure you pay attention, the POT goes on the OPPOSITE side of the RAMPS board, not in the same direction as the 4988. The 8825 handled the reversal without issue and once placed in the right direction and dialed in everything started working fine. You will need to adjust your MM per step as it will now take twice as many to move the same distance.

What Vref did you set?

Are the motors more quiet now? (I heard somewhere that this driver makes the motors run more quiet)

I was able to get them to set to .37, .395 and .401 last night with some tinkering, but the adjustment is just so tiny at that point it flips over to the higher voltage pretty easy. I will spend a little more time tweaking them down. What I can say is that the motors did get warm pretty quickly.

The motors are definitely more quiet, but not silent. I will record a bit of video while running the two of them and try to capture the sound later tonight with them.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:26PM |

Registered: 9 years ago Posts: 309 |

Quote

Deguello

The rails are swimming in gun oil, so I'll check the voltages after this print.

Actually, I would place a bet on the fact that your motors are probably smoking hot by the time they are getting to this point and are skipping steps. I don't see any fans on your motors, about 1 hour into a print on a finely tuned machine and my motors are blazing hot. I have this same issue occur when I forget to turn on the fans during the build.

Edited 1 time(s). Last edit at 05/06/2015 05:27PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:29PM |

Registered: 9 years ago Posts: 309 |

Quote

Flish

Quote

Deguello

What causes my taller prints to start "stepping" away from the Z tower like this?

Could be a loose set screw on one of your pulleys - there should be 2 screws per pulley.

A loose screw would be very visible in the print overall rather then a single missed step at some point in the print process. This is more indicative of the motors skipping steps or belts skipping teeth on one axis.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:35PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:48PM |

Registered: 9 years ago Posts: 309 |

Quote

Deguello

You're probably right. I was just thinking about adding fans underneath and maybe heatsink fins on the motors.Quote

thevisad

...motors are probably smoking hot...

There is a nice nema 17 fan shroud on thingaverse, but adding any fans to that area causes other problems (insulation issues) around the bed. Catch 22 situation :/

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 05:51PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 06:27PM |

Registered: 9 years ago Posts: 22 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 07:01PM |

Registered: 9 years ago Posts: 24 |

When I've had this happen on my last 3d printer it was because the nozzle drug through the parts and the steps got offset when the belt slipped. If you set the z lift on layer change to something like 4-6 mm that should help.

Edited 1 time(s). Last edit at 05/06/2015 07:13PM by Wittmason.

Edited 1 time(s). Last edit at 05/06/2015 07:13PM by Wittmason.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 08:31PM |

Registered: 9 years ago Posts: 63 |

Quote

Wittmason

When I've had this happen on my last 3d printer it was because the nozzle drug through the parts and the steps got offset when the belt slipped. If you set the z lift on layer change to something like 4-6 mm that should help.

Did you mean .4 to .6 mm? 4-6 is a huge raise for z change. I use .4 with good results.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 09:05PM |

Registered: 9 years ago Posts: 309 |

Quote

Flish

I said a loose set screw because I had about the same problem... One screw was not tightened and slipped a couple times then 'reseated' itself. It wasnt continually loose. Had the same staggered layers result.

Didn't say you were wrong, just that it seemed more like a missed step then a loose screw. The print appears to be ok otherwise, a little lifting in the corner some rafting/glue/hairspray wouldn't take care of. I see only a single issue in the picture really, what looks to be a missed/skipped step about 10% from finish on a fairly substantial part.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 06, 2015 09:23PM |

Registered: 9 years ago Posts: 24 |

Yes for my part I had to have more clearance since my z index degraded the taller things got. So the taller the z index the further I had to move away. My part on my cartesian printer was 185mm tall.

Quote

mmcginnis9272

Quote

Wittmason

When I've had this happen on my last 3d printer it was because the nozzle drug through the parts and the steps got offset when the belt slipped. If you set the z lift on layer change to something like 4-6 mm that should help.

Did you mean .4 to .6 mm? 4-6 is a huge raise for z change. I use .4 with good results.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 07, 2015 12:04AM |

Registered: 9 years ago Posts: 309 |

Something weird I just noticed and probably would not have until I started investigating why my printer is not exactly precise. All of my prints have been off by a minute amount and when I was tweaking the firmware for the drv8825 I found this line below. When you do the math, 189/2.25 = 84, not 80 which it should be for 1/16 on a 20 tooth pulley gt2 belt or 160 for 1/32. When I corrected this, I found that my build area increased beyond the 253.9 to 254.6, when it was configured in the firmware for 242.4. This is a massive difference and would account for the 1.4+ mm increase on the 15 cm ruler I printed.

At .4 I had issues with the motors jumping, I dialed them up to .5 and they don't jump as much. I have not been able to find the specs on the motors but I assume they are 1.5a so should be safe at .5 They are definitely smoother then they were before and way less of the musical notes while printing. I can actually hear the crunching in the bearings now, I wasn't sure of it before.

Incorrect!?!? Everything I see states 80, not 84 for 20 tooth.

#define DEFAULT_AXIS_STEPS_PER_UNIT {189/2.25, 189/2.25, 189/2.25, 100}

Correct

#define DEFAULT_AXIS_STEPS_PER_UNIT {160, 160, 160, 100}

I am currently streaming it on twitch with all of these updates/changes and I will link the video when I archive it. http://www.twitch.tv/thevisad/b/656835814

Update: Fail... had an issue with the hot end and it refused to feed and jammed up. After running them for a bit at .5 the motors seem to run about 40 c with the fans on (just barely pass the 3 second touch test). Skip to the 20 minute mark to bypass a lot of the screen shuffle and see it printing right at 20:38 or so it makes some weird noise, it sounded like it skipped, but it seemed ok. Shortly after that the hot end jams and I try to get it running again for the rest of the video with no luck. It seems... twitchy tbh, not sure I like it. The noise you hear is the bearings grinding, love me some chinese metal

Edited 2 time(s). Last edit at 05/07/2015 12:56AM by thevisad.

At .4 I had issues with the motors jumping, I dialed them up to .5 and they don't jump as much. I have not been able to find the specs on the motors but I assume they are 1.5a so should be safe at .5 They are definitely smoother then they were before and way less of the musical notes while printing. I can actually hear the crunching in the bearings now, I wasn't sure of it before.

Incorrect!?!? Everything I see states 80, not 84 for 20 tooth.

#define DEFAULT_AXIS_STEPS_PER_UNIT {189/2.25, 189/2.25, 189/2.25, 100}

Correct

#define DEFAULT_AXIS_STEPS_PER_UNIT {160, 160, 160, 100}

I am currently streaming it on twitch with all of these updates/changes and I will link the video when I archive it. http://www.twitch.tv/thevisad/b/656835814

Update: Fail... had an issue with the hot end and it refused to feed and jammed up. After running them for a bit at .5 the motors seem to run about 40 c with the fans on (just barely pass the 3 second touch test). Skip to the 20 minute mark to bypass a lot of the screen shuffle and see it printing right at 20:38 or so it makes some weird noise, it sounded like it skipped, but it seemed ok. Shortly after that the hot end jams and I try to get it running again for the rest of the video with no luck. It seems... twitchy tbh, not sure I like it. The noise you hear is the bearings grinding, love me some chinese metal

Edited 2 time(s). Last edit at 05/07/2015 12:56AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 07, 2015 02:40AM |

Registered: 9 years ago Posts: 43 |

Quote

thevisad

Something weird I just noticed and probably would not have until I started investigating why my printer is not exactly precise. All of my prints have been off by a minute amount and when I was tweaking the firmware for the drv8825 I found this line below. When you do the math, 189/2.25 = 84, not 80 which it should be for 1/16 on a 20 tooth pulley gt2 belt or 160 for 1/32. When I corrected this, I found that my build area increased beyond the 253.9 to 254.6, when it was configured in the firmware for 242.4. This is a massive difference and would account for the 1.4+ mm increase on the 15 cm ruler I printed.

At .4 I had issues with the motors jumping, I dialed them up to .5 and they don't jump as much. I have not been able to find the specs on the motors but I assume they are 1.5a so should be safe at .5 They are definitely smoother then they were before and way less of the musical notes while printing. I can actually hear the crunching in the bearings now, I wasn't sure of it before.

Incorrect!?!? Everything I see states 80, not 84 for 20 tooth.

#define DEFAULT_AXIS_STEPS_PER_UNIT {189/2.25, 189/2.25, 189/2.25, 100}

Correct

#define DEFAULT_AXIS_STEPS_PER_UNIT {160, 160, 160, 100}

I am currently streaming it on twitch with all of these updates/changes and I will link the video when I archive it. http://www.twitch.tv/thevisad/b/656835814

Update: Fail... had an issue with the hot end and it refused to feed and jammed up. After running them for a bit at .5 the motors seem to run about 40 c with the fans on (just barely pass the 3 second touch test). Skip to the 20 minute mark to bypass a lot of the screen shuffle and see it printing right at 20:38 or so it makes some weird noise, it sounded like it skipped, but it seemed ok. Shortly after that the hot end jams and I try to get it running again for the rest of the video with no luck. It seems... twitchy tbh, not sure I like it. The noise you hear is the bearings grinding, love me some chinese metal

I just checked out your video, loving the beard.

I may do the upgrade to the drv8825 soon, but until then I am wondering what the reasoning is behind using "189/2.25" instead of "84"? Since I have not upgraded and have noticed a similar amount of error no matter how well I calibrate or adjust, so it sounds like changing my steps per unit to 80 would help (yours is set to 160 to utilize the 1/32 stepping correct?).

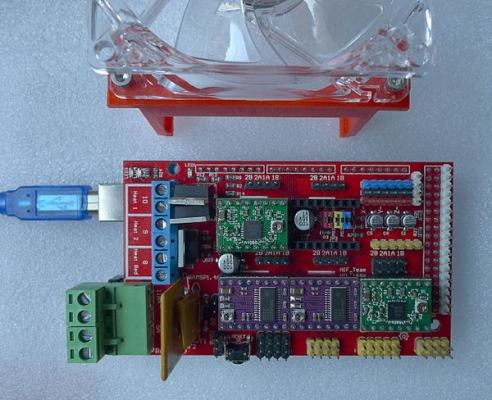

Also, in your pic further up the page, you show only 2 drv8825 in your axis drives, this would make sense to me in a cartesian system but in a delta wouldn't it be better to swap all 3, since they all play an equal role in the print?

Edited 2 time(s). Last edit at 05/07/2015 02:42AM by jculver09.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 07, 2015 09:33AM |

Registered: 9 years ago Posts: 12 |

I just want to give a kudos to Folger Tech this is a great company, They've been very help with any question I had and responsed quickly. I just received my replacement slider rail in 3 days, Thats awesome. Had an issue with one of them getting hung up and they sent me a replacment one. Thank you, and I'm loving this printer.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 07, 2015 10:11AM |

Registered: 9 years ago Posts: 309 |

Quote

jculver09

I just checked out your video, loving the beard.

I may do the upgrade to the drv8825 soon, but until then I am wondering what the reasoning is behind using "189/2.25" instead of "84"? Since I have not upgraded and have noticed a similar amount of error no matter how well I calibrate or adjust, so it sounds like changing my steps per unit to 80 would help (yours is set to 160 to utilize the 1/32 stepping correct?).

Also, in your pic further up the page, you show only 2 drv8825 in your axis drives, this would make sense to me in a cartesian system but in a delta wouldn't it be better to swap all 3, since they all play an equal role in the print?

Lol, thanks

I was wondering the same thing so I tried digging and came across this site and implemented it only to have more problems. I simply went with the 160 values like you said for the 1/32 step. The picture is just a stock photo from reprap, sorry for the confusion, I simply wanted to show the difference in direction. I have 3 and 1 in mine, not sure its worth it for the extruder.

I was wondering the same thing so I tried digging and came across this site and implemented it only to have more problems. I simply went with the 160 values like you said for the 1/32 step. The picture is just a stock photo from reprap, sorry for the confusion, I simply wanted to show the difference in direction. I have 3 and 1 in mine, not sure its worth it for the extruder.

Sorry, only registered users may post in this forum.

well for the most part. All the commands work, and seem to be good following the manual. One question. How do you guys get the filament started into the extruder motor. Mine seems to get caught very easily. DId I do something wrong?

well for the most part. All the commands work, and seem to be good following the manual. One question. How do you guys get the filament started into the extruder motor. Mine seems to get caught very easily. DId I do something wrong?