Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 27, 2015 10:51PM |

Registered: 9 years ago Posts: 11 |

Quote

cislom

Quote

alvinaw11

has anyone else had trouble with their bed temps continually dropping after being on for just a few minutes? I have added a cork board material as a heatshield and the ramps board seem to be shielded from heat now.

im printing ABS so theyre from 100-110, but it will just gradually fall once the z home finishes probing,

also to disable the z probe do i just need to remove the jumper signal?

Also my last attempt ended in my motors "stuttering" in place then freezing, what can be the cause of that?

thanks in advanced for any help guys this things been a headache for 3 days

I had the same problem with the heat. I had to install a heat shield (couple of pieces of cardboard) between the bed and the controller and put in 2 small 40 mm fans that blow across the controller for me to be able to hold the bed temp over 70. I wired up a small switch to be able to turn them off and on since I had no problems printing in PLA with the bed at 50.

I am not sure on the studdering, did that happen in the middle of an ABS print? If so that might be heat related too. I would try a small fan on the controller and see if that helps.

Quote

mmcginnis9272

Quote

cislom

Quote

alvinaw11

Also my last attempt ended in my motors "stuttering" in place then freezing, what can be the cause of that?

Studdering our of nowhere is usually causee by a Polulo driver overheating. The Thermal protection kicks in and it studders. After it cools, it will start up again. I recommend:

1. turn down your Polulo reference voltage. (This can cause other problems if you go too low)

2. install heatsinks in Polulo boards if you havent already.

3. install a cooling fan to blow air accross the Polulo drivers (and all electronics)

4. Insulate your heat bed from the Pululo drivers (and all the electronics)

Thank's for the help both of you, I went out and bought 2 fans today hopefully I can get everything worked out along with readjusting the boards if I need to.

I'm still curious about disabling the auto level tho if anyone can enlighten me on that.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 27, 2015 10:57PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 08:45AM |

Registered: 8 years ago Posts: 24 |

Ok I have a weird issue that Im having a hard time figuring out. Small print jobs print fine but large print jobs the head lifts on one side of the job and stays about an inch above the bed. So lets say that the object is 180x50x20. The print job will start at y90,x-90 and start to move to y-90,x90 after the head passes y0,x0 it steadily lifts until it is about an inch off the bed at y-90,x90. I had removed the autolevel routine from the gcode before hand but have since added it back in. Im stumped!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 09:13AM |

Registered: 8 years ago Posts: 24 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 12:09PM |

Registered: 8 years ago Posts: 19 |

Quote

bluesmike

Nevermind... seems somehow overnight my calibration took a hit. Think I'll try Thevisads firmware and recalibrate.

Yeah - that got me before too. If you do a "Home" - G28 after calibration, you lose your settings - so make sure you do your calibration after you home, or every time before a print.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 12:55PM |

Registered: 9 years ago Posts: 45 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 01:04PM |

Registered: 9 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 01:18PM |

Registered: 10 years ago Posts: 14,672 |

Quote

cislom

Quote

bluesmike

Nevermind... seems somehow overnight my calibration took a hit. Think I'll try Thevisads firmware and recalibrate.

Yeah - that got me before too. If you do a "Home" - G28 after calibration, you lose your settings - so make sure you do your calibration after you home, or every time before a print.

Really??? I haven't used Marlin (assuming that is what you are running) in ages, but that seems perverse to me.

btw if anyone with a Kossel is looking for better electronics and firmware - including segmentation-free delta movement, and full auto delta calibration in 35 seconds, follow the link in my signature to the entry on converting a Mini Kossel to Duet electronics.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 02:01PM |

Registered: 8 years ago Posts: 2 |

Hello, Overall very happy with this kit.

The build manual and configuration manuals were a big help.

But only get you 90% of the way done.

I have uploaded 2 videos to YouTube

The first shows how the extruder head moves back and forth in the x-direction.

Watch the shadow of the extruder tip on the graph paper.

Center is the high spot as I go positive or negative in the x-axis the tip drops slightly

Its not traveling in the same plane.

The same thing happens in the y-axis

It looks like the tip is arching back and forth with the center being the highspot.

I don't think its plate leveling as the center is the high spot.

Any suggestions on how to adjust this???

I was hoping auto leveling would help with the above issue...

But that function is not working

Video 2 shows what happens when I run G29 Autolevel.

It starts and looks like its working but, does not complete...

Suddenly the Z carriage bottoms out.

I have reduced the print area to +50 to -50 for X and Y max/min positions.

Still happens as shown in the video.

Then in Pronterface we Reset and send it to Home position using G28

HELP!!!

Please!!!

Suggestions!!!

Thanks!!!

[youtu.be]

[youtu.be]

Thanks for suggetions.

John

The build manual and configuration manuals were a big help.

But only get you 90% of the way done.

I have uploaded 2 videos to YouTube

The first shows how the extruder head moves back and forth in the x-direction.

Watch the shadow of the extruder tip on the graph paper.

Center is the high spot as I go positive or negative in the x-axis the tip drops slightly

Its not traveling in the same plane.

The same thing happens in the y-axis

It looks like the tip is arching back and forth with the center being the highspot.

I don't think its plate leveling as the center is the high spot.

Any suggestions on how to adjust this???

I was hoping auto leveling would help with the above issue...

But that function is not working

Video 2 shows what happens when I run G29 Autolevel.

It starts and looks like its working but, does not complete...

Suddenly the Z carriage bottoms out.

I have reduced the print area to +50 to -50 for X and Y max/min positions.

Still happens as shown in the video.

Then in Pronterface we Reset and send it to Home position using G28

HELP!!!

Please!!!

Suggestions!!!

Thanks!!!

[youtu.be]

[youtu.be]

Thanks for suggetions.

John

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 02:26PM |

Registered: 9 years ago Posts: 309 |

Quote

dc42

Quote

cislom

Quote

bluesmike

Nevermind... seems somehow overnight my calibration took a hit. Think I'll try Thevisads firmware and recalibrate.

Yeah - that got me before too. If you do a "Home" - G28 after calibration, you lose your settings - so make sure you do your calibration after you home, or every time before a print.

Really??? I haven't used Marlin (assuming that is what you are running) in ages, but that seems perverse to me.

btw if anyone with a Kossel is looking for better electronics and firmware - including segmentation-free delta movement, and full auto delta calibration in 35 seconds, follow the link in my signature to the entry on converting a Mini Kossel to Duet electronics.

I looked at the Duet and dismissed it pretty quick, I cannot remember why though. I cannot find anything on this (segmentation-free delta movement) do you have a tech guide on this?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 03:00PM |

Registered: 10 years ago Posts: 14,672 |

Quote

thevisad

I looked at the Duet and dismissed it pretty quick, I cannot remember why though. I cannot find anything on this (segmentation-free delta movement) do you have a tech guide on this?

I don't have a tech guide. Evidence that segmentation is not the best way to compute the motor movements for a delta printer is towards the end of this thread: [forums.reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 04:18PM |

Registered: 9 years ago Posts: 606 |

Quote

jholst

Hello, Overall very happy with this kit.

The build manual and configuration manuals were a big help.

But only get you 90% of the way done.

I have uploaded 2 videos to YouTube

The first shows how the extruder head moves back and forth in the x-direction.

Watch the shadow of the extruder tip on the graph paper.

Center is the high spot as I go positive or negative in the x-axis the tip drops slightly

Its not traveling in the same plane.

The same thing happens in the y-axis

It looks like the tip is arching back and forth with the center being the highspot.

I don't think its plate leveling as the center is the high spot.

Any suggestions on how to adjust this???

I was hoping auto leveling would help with the above issue...

But that function is not working

Video 2 shows what happens when I run G29 Autolevel.

It starts and looks like its working but, does not complete...

Suddenly the Z carriage bottoms out.

I have reduced the print area to +50 to -50 for X and Y max/min positions.

Still happens as shown in the video.

Then in Pronterface we Reset and send it to Home position using G28

HELP!!!

Please!!!

Suggestions!!!

Thanks!!!

[youtu.be]

[youtu.be]

Thanks for suggetions.

John

You need to adjust the Delta geometry values in your Configuration.h file - I *think* it was SMOOTH_ROD_OFFSET or similar (there is a good Delta calibration guide here somewhere, but I'm mobile, so limited in providing a link) which gives the procedure. After I did that, I am sub .1mm variance across my bed . . . probably could do better, but ran out of patience. You also probably want to bed level by adjusting your endstops at the same time - I'm where my setup and G28 does as well or better than G29 and the probe.

- Tim

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 05:07PM |

Registered: 9 years ago Posts: 309 |

Quote

dc42

Quote

thevisad

I looked at the Duet and dismissed it pretty quick, I cannot remember why though. I cannot find anything on this (segmentation-free delta movement) do you have a tech guide on this?

I don't have a tech guide. Evidence that segmentation is not the best way to compute the motor movements for a delta printer is towards the end of this thread: [forums.reprap.org].

I went ahead and bought one, but I am not sure I see 'evidence' per se in that forum post. I see some great prints, but I have great prints on my Kossel already. Hopefully it will help add to the the pile of ramps/mega/due boards that are collecting dust in the corner now. What I like about it, is the ability to support more then 2 extruders on a reprap board. Although, this picture just makes me cringe...

Edited 1 time(s). Last edit at 05/28/2015 05:08PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 06:39PM |

Registered: 10 years ago Posts: 14,672 |

Quote

thevisad

[I went ahead and bought one, but I am not sure I see 'evidence' per se in that forum post.

The photos in this post [forums.reprap.org] show fringe patterns that change as delta segmentation is adjusted. The following post shows my print of the same part using segmentation-free firmware.

Quote

thevisad

... Although, this picture just makes me cringe...

It makes me cringe too! How about this one, printed on a 2-nozzle Ormerod controlled by Duet + DueX4 (not on a delta, as my delta is still single-extrusion at the moment):

Btw there are now two ways to drive more than one extruder from Duet electronics:

1. Add the DueX4 expansion board, which supports 4 additional extruders and hot ends.

2. Add the Duet Shield, which supports 2 additional extruders and hot ends. It's a daughter board that fits on top of the Duet, so mechanically simpler to install than the DueX4, as long as you don't want to drive more than 3 extuders in total.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 28, 2015 11:56PM |

Registered: 8 years ago Posts: 2 |

Tim, thanks for replying. If you get a chance please send a link for the delta calibration guide that you used.

I have been searching for hours with no success.

I don't understand how the end stops are used to bed level???

In the Folger configuration guide they have you adjust the end stops so that the distance from the extruder tip to the rails is the same to each rail.

I have been searching for hours with no success.

I don't understand how the end stops are used to bed level???

In the Folger configuration guide they have you adjust the end stops so that the distance from the extruder tip to the rails is the same to each rail.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 29, 2015 01:31AM |

Registered: 9 years ago Posts: 606 |

Regarding the end stops, basically you set the distance by moving the head as close to the tower as you can get, and adjusting the end stop such that Z=0 is at the bed surface at all three towers (the end stop on a tower really only effects the height at that tower) after a G28 home and reposition. Once all three towers match, you check the center, and adjust the delta geometry settings such that it matches for Z=0 at the towers. At that point, the head runs an even elevation over the bed.

Here is the guide I found helpful . . . I used paper, not a feeler gauge, but the procedure is sound either way . . .

Steps 8 and 9 correct the concave/convex issue . . .

[forums.reprap.org]

- Tim

Here is the guide I found helpful . . . I used paper, not a feeler gauge, but the procedure is sound either way . . .

Steps 8 and 9 correct the concave/convex issue . . .

[forums.reprap.org]

- Tim

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 29, 2015 01:56AM |

Registered: 9 years ago Posts: 309 |

Quote

dc42

Quote

thevisad

[I went ahead and bought one, but I am not sure I see 'evidence' per se in that forum post.

The photos in this post [forums.reprap.org] show fringe patterns that change as delta segmentation is adjusted. The following post shows my print of the same part using segmentation-free firmware.

Quote

thevisad

... Although, this picture just makes me cringe...

It makes me cringe too! How about this one, printed on a 2-nozzle Ormerod controlled by Duet + DueX4 (not on a delta, as my delta is still single-extrusion at the moment):

Btw there are now two ways to drive more than one extruder from Duet electronics:

1. Add the DueX4 expansion board, which supports 4 additional extruders and hot ends.

2. Add the Duet Shield, which supports 2 additional extruders and hot ends. It's a daughter board that fits on top of the Duet, so mechanically simpler to install than the DueX4, as long as you don't want to drive more than 3 extuders in total.

The frog looks great and thanks for the info on the shield, but at that cost it's cheaper to just go with the DueX4 and have the room to grow into it. Since I am only running a single extruder right now, jumping into the Duet isn't too bad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 29, 2015 03:04PM |

Registered: 9 years ago Posts: 24 |

@jholst Here is the calibration instructions I followed. Calibration of delta printers There is also a minow blog post that's very similar to the link attached.

If you'd prefer to not try to hit a moving target with moving the physical endstops around the aluminum extrusion - then test using the M665 command and the M666 command.

Taken from the smoothieware website:

M665 Set arm solution specific settings: Delta - L R Z M665 L341.0 R350 Z430

M666 On a delta sets trim values for the endstops. (Positive values will crash physical endstops.)

So let's say you are testing your concave or convex build plate issue. In your firmware set to the following (these get reset later)

#define DELTA_TOWER1_CORRECTION 0.0 // front left tower

#define DELTA_TOWER2_CORRECTION 0.0 // front right tower

#define DELTA_TOWER3_CORRECTION 0.0 // back middle tower

Then flash the firmware.

Follow the supplied manual for calibrating.

Instead of physically changing the firmware and reflashing however many times as needed simply run m665 and m666 to update the settings in the memory of the board. When you've got the machine tuned to where you want it. Get the read out from m665 and m666 and place those in your firmware in their appropriate spots.

It makes manual calibration so much easier. I also used this guide when I was still using Marlin Airtripper marlin guide

There is also a great YouTube video here regarding the same procedure.

m665 and m666 delta calibration

Tim (aka wittmason)

Edited 1 time(s). Last edit at 05/29/2015 03:12PM by Wittmason.

If you'd prefer to not try to hit a moving target with moving the physical endstops around the aluminum extrusion - then test using the M665 command and the M666 command.

Taken from the smoothieware website:

M665 Set arm solution specific settings: Delta - L R Z M665 L341.0 R350 Z430

M666 On a delta sets trim values for the endstops. (Positive values will crash physical endstops.)

So let's say you are testing your concave or convex build plate issue. In your firmware set to the following (these get reset later)

#define DELTA_TOWER1_CORRECTION 0.0 // front left tower

#define DELTA_TOWER2_CORRECTION 0.0 // front right tower

#define DELTA_TOWER3_CORRECTION 0.0 // back middle tower

Then flash the firmware.

Follow the supplied manual for calibrating.

Instead of physically changing the firmware and reflashing however many times as needed simply run m665 and m666 to update the settings in the memory of the board. When you've got the machine tuned to where you want it. Get the read out from m665 and m666 and place those in your firmware in their appropriate spots.

It makes manual calibration so much easier. I also used this guide when I was still using Marlin Airtripper marlin guide

There is also a great YouTube video here regarding the same procedure.

m665 and m666 delta calibration

Tim (aka wittmason)

Edited 1 time(s). Last edit at 05/29/2015 03:12PM by Wittmason.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 29, 2015 03:27PM |

Registered: 9 years ago Posts: 56 |

I use this mount to replace the hotend with a dial indicator for calibration. Lets you get as accurate as you care to be. After you get it flat, put the hotend back and use a feeler (or paper) to set Z max.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 31, 2015 03:51AM |

Registered: 9 years ago Posts: 73 |

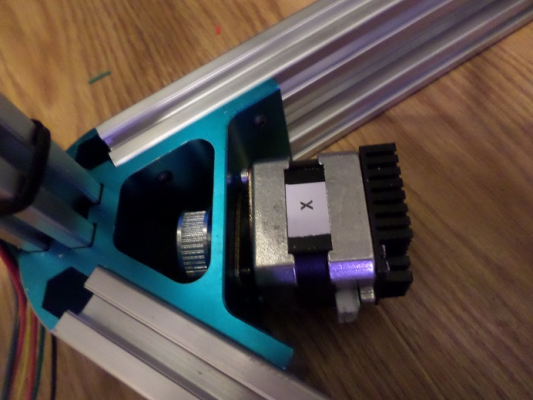

I've reached now page 30 of this interesting thread. What a reading! Too much to remember everything.

But here are my questions:

1

Has anyone here replaced those aluminum parts (as seen in the photo below) and the extruder poles with longer ones, in order to achieve a larger printing area? I am wondering, if it is possible to get a printing area, that way, of 50 cm or even larger on each axis.

2

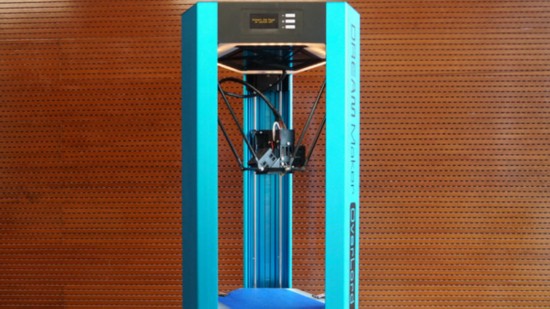

Has anyone ever tried to build a stylish case for the Kossel 2020? I saw a Chinese more-or-less copy, called "Dreammaker Overlord" (much smaller print area than the Kossel 2020), and want to find ways to create a similar encasing for the Kossel 2020, placing the electronics on top, instead of below the printing area. Does anyone have good suggestions, how (where) to get the parts for such a case? Are there companies that can custom-make such metal or plastic parts? Since Kossel cannot get its extruder to print in between and also outside the three vertical beams, I cannot print such parts by myself. Who has ideas?

3

Has anyone here replaced the filament-related parts of the Kossel 2020 with those parts required to print chocolate and other edibles?

Edited 4 time(s). Last edit at 05/31/2015 04:42AM by Sven.L.

But here are my questions:

1

Has anyone here replaced those aluminum parts (as seen in the photo below) and the extruder poles with longer ones, in order to achieve a larger printing area? I am wondering, if it is possible to get a printing area, that way, of 50 cm or even larger on each axis.

2

Has anyone ever tried to build a stylish case for the Kossel 2020? I saw a Chinese more-or-less copy, called "Dreammaker Overlord" (much smaller print area than the Kossel 2020), and want to find ways to create a similar encasing for the Kossel 2020, placing the electronics on top, instead of below the printing area. Does anyone have good suggestions, how (where) to get the parts for such a case? Are there companies that can custom-make such metal or plastic parts? Since Kossel cannot get its extruder to print in between and also outside the three vertical beams, I cannot print such parts by myself. Who has ideas?

3

Has anyone here replaced the filament-related parts of the Kossel 2020 with those parts required to print chocolate and other edibles?

Edited 4 time(s). Last edit at 05/31/2015 04:42AM by Sven.L.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 31, 2015 04:04PM |

Registered: 9 years ago Posts: 43 |

Quote

Sven.L

I've reached now page 30 of this interesting thread. What a reading! Too much to remember everything.

But here are my questions:

1

Has anyone here replaced those aluminum parts (as seen in the photo below) and the extruder poles with longer ones, in order to achieve a larger printing area? I am wondering, if it is possible to get a printing area, that way, of 50 cm or even larger on each axis.

Yes, but upgrade of other components (carriages/linear slides) would be needed to reach maximum benefit, IMO.

I have seen tinkering with cases using materials like cardboard, Foarm board, plywood and even acrylic, a search on the topic "printer enclosure" reveals [www.thingiverse.com]. I would recommend getting your parts at your local home improvement store, they will have most of what you would need, depending on scope of course. There are companies that can custom make anything you can imagine out of whatever you want it made from, question is how much $$$ are you interested in spending [www.protocase.com] might be a good place to start if this is your route.Quote

Sven.L

2

Has anyone ever tried to build a stylish case for the Kossel 2020? I saw a Chinese more-or-less copy, called "Dreammaker Overlord" (much smaller print area than the Kossel 2020), and want to find ways to create a similar encasing for the Kossel 2020, placing the electronics on top, instead of below the printing area. Does anyone have good suggestions, how (where) to get the parts for such a case? Are there companies that can custom-make such metal or plastic parts? Since Kossel cannot get its extruder to print in between and also outside the three vertical beams, I cannot print such parts by myself. Who has ideas?

Quote

Sven.L

3

Has anyone here replaced the filament-related parts of the Kossel 2020 with those parts required to print chocolate and other edibles?

For this printer I have not seen this, but it is not an unheard of conversion creating a delta that can print pastes and such pneumaticly checkout [www.youtube.com] I beleive a system like this could be used for chocolate and the like.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level May 31, 2015 06:26PM |

Registered: 10 years ago Posts: 14,672 |

I converted my Mini Kossel to a 300mm buid diameter successfully by lengthening the horizontal extrusions and diagonal rods, and installing a new bed. The price was a reduction in build height. I have since increased the height too.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 06:27AM |

Registered: 9 years ago Posts: 63 |

Quote

Sven.L

3

Has anyone here replaced the filament-related parts of the Kossel 2020 with those parts required to print chocolate and other edibles?

As a 3D Systems printer repair technician, I can tell you that the CocoJet that will be released on the market soon (although not a delta) uses an enclosed printer so that itcan run 2 small refrigeration units, one on either side of the printer, to reduce the chamber air temps low enough that the hot extruded chocolate solidifies instantly on the model being made. This would not be such an issue with hot jetted sugar. I don't see why a delta could not be made to do the same.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 04:08PM |

Registered: 8 years ago Posts: 37 |

I’ve figured out how to fix the linear rails!

Like everyone else I’ve been fixated on the bearings and hadn’t been looking for other sources of drag. It turns out the bearings where not the issue, it’s the small metal rail on the outside of the bearings! The bar is dragging on the inside of the guide rail. This is why the people using gun oil are seeing such an improvement because gun oil is designed to lubricate metal on metal contact.

I got all 3 of my rails silky smooth by disassembling the slide, cleaning and lubricating everything with white lithium grease, added in replacements for the missing bearings, then reassembling the slide without those little metal rails. It’s a hard to get it back together without those rails but it’s worth it. I used a spacer to keep the bearings in as I slid the guide rail back in. BTW, I initial tried a thicker wheel bearing grease that would hold the bearings in better while I assembled it but the thick grease was too thick to allow the slide to move freely.

I hope this helps. I was able to get even the worst one I had smooth so I think I have the problem figured out.

Like everyone else I’ve been fixated on the bearings and hadn’t been looking for other sources of drag. It turns out the bearings where not the issue, it’s the small metal rail on the outside of the bearings! The bar is dragging on the inside of the guide rail. This is why the people using gun oil are seeing such an improvement because gun oil is designed to lubricate metal on metal contact.

I got all 3 of my rails silky smooth by disassembling the slide, cleaning and lubricating everything with white lithium grease, added in replacements for the missing bearings, then reassembling the slide without those little metal rails. It’s a hard to get it back together without those rails but it’s worth it. I used a spacer to keep the bearings in as I slid the guide rail back in. BTW, I initial tried a thicker wheel bearing grease that would hold the bearings in better while I assembled it but the thick grease was too thick to allow the slide to move freely.

I hope this helps. I was able to get even the worst one I had smooth so I think I have the problem figured out.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 04:22PM |

Registered: 9 years ago Posts: 309 |

Quote

matthew900

I’ve figured out how to fix the linear rails!

Like everyone else I’ve been fixated on the bearings and hadn’t been looking for other sources of drag. It turns out the bearings where not the issue, it’s the small metal rail on the outside of the bearings! The bar is dragging on the inside of the guide rail. This is why the people using gun oil are seeing such an improvement because gun oil is designed to lubricate metal on metal contact.

I got all 3 of my rails silky smooth by disassembling the slide, cleaning and lubricating everything with white lithium grease, added in replacements for the missing bearings, then reassembling the slide without those little metal rails. It’s a hard to get it back together without those rails but it’s worth it. I used a spacer to keep the bearings in as I slid the guide rail back in. BTW, I initial tried a thicker wheel bearing grease that would hold the bearings in better while I assembled it but the thick grease was too thick to allow the slide to move freely.

I hope this helps. I was able to get even the worst one I had smooth so I think I have the problem figured out.

Great post and good on finding that out. How and where did you locate the balls that were the proper size?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 04:40PM |

Registered: 9 years ago Posts: 445 |

What do you guys think of this for solution for the Z-probe?

And where can I buy one of those?

EDIT: Probably will get better answers if I were to provide with a link... [miscsolutions.wordpress.com]

Edited 1 time(s). Last edit at 06/01/2015 05:26PM by Koenig.

And where can I buy one of those?

EDIT: Probably will get better answers if I were to provide with a link... [miscsolutions.wordpress.com]

Edited 1 time(s). Last edit at 06/01/2015 05:26PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 05:05PM |

Registered: 9 years ago Posts: 63 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 05:13PM |

Registered: 9 years ago Posts: 67 |

Quote

matthew900

I’ve figured out how to fix the linear rails!

Like everyone else I’ve been fixated on the bearings and hadn’t been looking for other sources of drag. It turns out the bearings where not the issue, it’s the small metal rail on the outside of the bearings! The bar is dragging on the inside of the guide rail. This is why the people using gun oil are seeing such an improvement because gun oil is designed to lubricate metal on metal contact.

I got all 3 of my rails silky smooth by disassembling the slide, cleaning and lubricating everything with white lithium grease, added in replacements for the missing bearings, then reassembling the slide without those little metal rails. It’s a hard to get it back together without those rails but it’s worth it. I used a spacer to keep the bearings in as I slid the guide rail back in. BTW, I initial tried a thicker wheel bearing grease that would hold the bearings in better while I assembled it but the thick grease was too thick to allow the slide to move freely.

I hope this helps. I was able to get even the worst one I had smooth so I think I have the problem figured out.

Are you talking about the thin 1mm red end caps? Can we just remove them while they are still on the rails? Will the screws still hold the green sections in place?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 05:24PM |

Registered: 9 years ago Posts: 445 |

Quote

mmcginnis9272

Quote

Koenig

What do you guys think of this for solution for the Z-probe?

And where can I buy one of those?

Please post whatever link you would like us to check out.

Sorry about that, totally forgot to paste the link!

This is the one I meant: [miscsolutions.wordpress.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level June 01, 2015 05:38PM |

Registered: 9 years ago Posts: 56 |

I bought this one from Amazon, but IR doesn't work with the mirrors I use for my build surface, so I didn't spend a lot of time on it. I eventually removed the autoprobe altogether and calibrated the endstops and radius.

Sorry, only registered users may post in this forum.