Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 12, 2015 08:03PM |

Registered: 8 years ago Posts: 161 |

What did you guys set your tower buttons to. This is what the tutorial has set:

Next, set up the following buttons/scripts in Pronterface that will move the effector to the following locations:

1.Tower A (front left): G0 F8000 X-77.94 Y-45 Z0

2.Tower B (front right): G0 F8000 X77.94 Y-45 Z0

3.Tower C (rear): G0 F8000 X0 Y90 Z0

4.Centre: G0 F8000 C0 Y0 Z0

Does this work for our printers?

Next, set up the following buttons/scripts in Pronterface that will move the effector to the following locations:

1.Tower A (front left): G0 F8000 X-77.94 Y-45 Z0

2.Tower B (front right): G0 F8000 X77.94 Y-45 Z0

3.Tower C (rear): G0 F8000 X0 Y90 Z0

4.Centre: G0 F8000 C0 Y0 Z0

Does this work for our printers?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 12, 2015 08:38PM |

Registered: 9 years ago Posts: 110 |

What I did to the endstops is hold them down with my thumb and with the other hand loosen the bolt. Then slide ever so slightly up or down to calibrate. as far as positions I used exactly how it stated in the manual. It will work , in fact you might be able to go a bit more depending on your rod length. If your scared of hitting the bed instead of having Z at 0 change it to like 10 or something then slowly come down by 1 or .1 depending where your at. Its a lot to do at first but once you've done it, it is well worth it. Then you can do the fine tuning with all the FW stuff

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 12, 2015 09:35PM |

Registered: 9 years ago Posts: 110 |

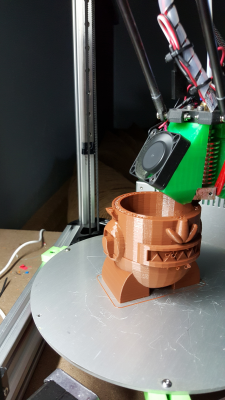

This is what im printing now, without any firmware adjustments just endstops and its coming out pretty darn well. I just re did mybed and took out the electronics from under too.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 12, 2015 11:26PM |

Registered: 8 years ago Posts: 4 |

Hey guys, I've been a lurker and recently signed up so I can post. Got my Folgers Kossel 2020 kit about a week ago. I'm an industrial designer, so the mechanical build of the Kossel took under 3 hours, no sweat. The electrical wiring, on the other hand, has taken the last 6 days and I'm still stumped at these vague instructions. It's like being told to drive to the grocery store in a new car, but without anyone explaining how to start the thing or what the pedals do.

That said, I've loaded the Folger firmware on the board using Arduino and I'm using Repetier to manually plug in gcode. I haven't done anything yet except M119, and all the endstops are functional. However, z-min is always showing as Open, and it is never Triggered regardless of the hotend's position. It only shows triggered when I unplug the black signal wire from the z-min on the RAMPS board.

This leads me to conclude that I made a big mistake with the wiring somewhere. I've spent 14 hours just looking over steps 42-46 of the Rev B manual again and again and again, and I'm still unclear about how it's supposed to be wired.

Pardon my lack of electrical understanding, this is how I wired the induction sensor:

I don't like posting because I don't feel smart enough to ask good questions, but I'm really stumped and out of ideas.

Thanks

That said, I've loaded the Folger firmware on the board using Arduino and I'm using Repetier to manually plug in gcode. I haven't done anything yet except M119, and all the endstops are functional. However, z-min is always showing as Open, and it is never Triggered regardless of the hotend's position. It only shows triggered when I unplug the black signal wire from the z-min on the RAMPS board.

This leads me to conclude that I made a big mistake with the wiring somewhere. I've spent 14 hours just looking over steps 42-46 of the Rev B manual again and again and again, and I'm still unclear about how it's supposed to be wired.

Pardon my lack of electrical understanding, this is how I wired the induction sensor:

- Brown wire went straight to V+ on power supply

- Blue wire has 10K resistor inline before going into V-

- Black wire has 15K resistor soldered, then combined with the black signal wire that went into the z-min position on the RAMPS board.

- Red and white extra wires on the pin connector are just floating free (not touching anything)

I don't like posting because I don't feel smart enough to ask good questions, but I'm really stumped and out of ideas.

Thanks

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 13, 2015 02:11AM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

What did you guys set your tower buttons to. This is what the tutorial has set:

Next, set up the following buttons/scripts in Pronterface that will move the effector to the following locations:

1.Tower A (front left): G0 F8000 X-77.94 Y-45 Z0

2.Tower B (front right): G0 F8000 X77.94 Y-45 Z0

3.Tower C (rear): G0 F8000 X0 Y90 Z0

4.Centre: G0 F8000 C0 Y0 Z0

Does this work for our printers?

It'll work, however, I would change the height to at least 2mm, then use the buttons in pronterface to get down the last bit, to prevent the head crashing into the bed.

I would also change the speed to something lower, at least for my first tries, doubt that the Mega is even capable of 133mm/s, at least not in the X/Y-plane.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 13, 2015 02:21AM |

Registered: 9 years ago Posts: 445 |

Quote

cman8

What I did to the endstops is hold them down with my thumb and with the other hand loosen the bolt. Then slide ever so slightly up or down to calibrate. as far as positions I used exactly how it stated in the manual. It will work , in fact you might be able to go a bit more depending on your rod length. If your scared of hitting the bed instead of having Z at 0 change it to like 10 or something then slowly come down by 1 or .1 depending where your at. Its a lot to do at first but once you've done it, it is well worth it. Then you can do the fine tuning with all the FW stuff

Loosen the endstops manually to calibrate them seems like imprecise and unnecessary physical work, you can do the exact same thing more precisely via software. You can get as low as the resolution of your drivers/steppers allow you.

I have a repeatability well below 2 hundreds of a mm (I would say below one hundred of a mm, but to be on the safe side...), with my 0.9 degree steppers and 1/16 microstep drivers.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 13, 2015 12:42PM |

Registered: 9 years ago Posts: 110 |

Quote

Koenig

Quote

cman8

What I did to the endstops is hold them down with my thumb and with the other hand loosen the bolt. Then slide ever so slightly up or down to calibrate. as far as positions I used exactly how it stated in the manual. It will work , in fact you might be able to go a bit more depending on your rod length. If your scared of hitting the bed instead of having Z at 0 change it to like 10 or something then slowly come down by 1 or .1 depending where your at. Its a lot to do at first but once you've done it, it is well worth it. Then you can do the fine tuning with all the FW stuff

Loosen the endstops manually to calibrate them seems like imprecise and unnecessary physical work, you can do the exact same thing more precisely via software. You can get as low as the resolution of your drivers/steppers allow you.

I have a repeatability well below 2 hundreds of a mm (I would say below one hundred of a mm, but to be on the safe side...), with my 0.9 degree steppers and 1/16 microstep drivers.

I tried with the software and wasnt getting anywhere with it. With the endstops I got it pretty quick. My guess is it was not all level (my endstops) then once I was close (after about a half hour of adjusting endstops) I did the software and was getting where I needed. I think its like everyone has been saying, make it mechanically sound first then do the software which has worked out great for me.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 13, 2015 02:10PM |

Registered: 8 years ago Posts: 47 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 14, 2015 09:56AM |

Registered: 8 years ago Posts: 48 |

|

floating G29, or crashing into bed September 14, 2015 10:27AM |

Registered: 8 years ago Posts: 4 |

A bit of an update from my earlier post.

When I raise the slides all the way to the endstops, the values on M119 show up as:

x_max: triggered

y_max: triggered

z_min: open

z_max: triggered

When I lower the probe all the way to the bed, the values on M119 show up as:

x_max: open

y_max: open

z_min: triggered

z_max: open

That's good, according to the calibration instructions. However....

When I initiate G29 or G28 from a low height, the hot end crashes into the bed.

When I inituate G29 or G28 from all the way up, the probe stops the hot end about 4-5 inches above the bed. G29 makes it do an autolevel while floating.

Is this a configuration.h problem, a max volume problem, or did I wire everything wrong?

Here's the new way that I wired the induction sensor:

Edited 1 time(s). Last edit at 09/14/2015 10:28AM by Sintensity.

When I raise the slides all the way to the endstops, the values on M119 show up as:

x_max: triggered

y_max: triggered

z_min: open

z_max: triggered

When I lower the probe all the way to the bed, the values on M119 show up as:

x_max: open

y_max: open

z_min: triggered

z_max: open

That's good, according to the calibration instructions. However....

When I initiate G29 or G28 from a low height, the hot end crashes into the bed.

When I inituate G29 or G28 from all the way up, the probe stops the hot end about 4-5 inches above the bed. G29 makes it do an autolevel while floating.

Is this a configuration.h problem, a max volume problem, or did I wire everything wrong?

Here's the new way that I wired the induction sensor:

- Brown wire went straight to V+ on power supply

- Blue wire went straight to V- on power supply

- Black wire has 15K resistor soldered, then combined with the black signal wire that went into the z-min position on the RAMPS board.

- Red wire (leading back from the signal from the board) has 10K resistor inline before going into V-

- White extra wire on the pin connector is just floating free (not touching anything)

Edited 1 time(s). Last edit at 09/14/2015 10:28AM by Sintensity.

|

Re: floating G29, or crashing into bed September 14, 2015 06:11PM |

Registered: 8 years ago Posts: 161 |

Quote

Sintensity

A bit of an update from my earlier post.

When I raise the slides all the way to the endstops, the values on M119 show up as:

x_max: triggered

y_max: triggered

z_min: open

z_max: triggered

When I lower the probe all the way to the bed, the values on M119 show up as:

x_max: open

y_max: open

z_min: triggered

z_max: open

That's good, according to the calibration instructions. However....

When I initiate G29 or G28 from a low height, the hot end crashes into the bed.

When I inituate G29 or G28 from all the way up, the probe stops the hot end about 4-5 inches above the bed. G29 makes it do an autolevel while floating.

Is this a configuration.h problem, a max volume problem, or did I wire everything wrong?

Here's the new way that I wired the induction sensor:

- Brown wire went straight to V+ on power supply

- Blue wire went straight to V- on power supply

- Black wire has 15K resistor soldered, then combined with the black signal wire that went into the z-min position on the RAMPS board.

- Red wire (leading back from the signal from the board) has 10K resistor inline before going into V-

- White extra wire on the pin connector is just floating free (not touching anything)

My G29 does the same thing but my blue wire goes to Ground not to V-. If you look at the pictures on the RevB google docs site they have two pictures showing

the blue wire. One going to V- and one going to ground. I have sent an email asking for some help but never heard anything back from folger.

|

Re: floating G29, or crashing into bed September 14, 2015 06:40PM |

Registered: 9 years ago Posts: 445 |

Quote

Sintensity

A bit of an update from my earlier post.

When I raise the slides all the way to the endstops, the values on M119 show up as:

x_max: triggered

y_max: triggered

z_min: open

z_max: triggered

When I lower the probe all the way to the bed, the values on M119 show up as:

x_max: open

y_max: open

z_min: triggered

z_max: open

That's good, according to the calibration instructions. However....

When I initiate G29 or G28 from a low height, the hot end crashes into the bed.

When I inituate G29 or G28 from all the way up, the probe stops the hot end about 4-5 inches above the bed. G29 makes it do an autolevel while floating.

Is this a configuration.h problem, a max volume problem, or did I wire everything wrong?

Here's the new way that I wired the induction sensor:

- Brown wire went straight to V+ on power supply

- Blue wire went straight to V- on power supply

- Black wire has 15K resistor soldered, then combined with the black signal wire that went into the z-min position on the RAMPS board.

- Red wire (leading back from the signal from the board) has 10K resistor inline before going into V-

- White extra wire on the pin connector is just floating free (not touching anything)

You have calibrated your printer?

I might be wrong here, but I think you must calibrate the printer before performing any bed level probing.

When you have your nozzle at the bed what Z-height do you have?

|

Re: floating G29, or crashing into bed September 14, 2015 07:42PM |

Registered: 8 years ago Posts: 4 |

Quote

Koenig

You have calibrated your printer?

I might be wrong here, but I think you must calibrate the printer before performing any bed level probing.

When you have your nozzle at the bed what Z-height do you have?

Sorry, I must have misunderstood the instructions entirely. I was under the impression that this was what I was doing with running the G28 command. In that case, no I haven't calibrated the printer. Is there a resource/link for it? I've been using the Folger calibration guide that is provided via Google Drive. Apart from ensuring that the endstops are functional (and a short discussion on fan power which is probably irrelevant to the calibration procedure), the calibration steps start with G28.

Are you referring to the paper test?

I'm also unsure of what steps to take in order to answer your last question on Z-height. Is it a number that is specified in configuration.h? That would be 315. Or is it calculated by calibrating the hot end to the bed and then letting it go up until it hits the endstops? I hate to say this, but I have a feeling I'm still way off.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 14, 2015 10:03PM |

Registered: 8 years ago Posts: 161 |

Ok I may have something not right. When I home the printer with the G28 command my endstops report triggered. Should the Z_min not be triggered here?

Reporting endstop status

x_max: TRIGGERED

y_max: TRIGGERED

z_min: TRIGGERED

z_max: TRIGGERED

When I bring it down to Z0 it reports

Reporting endstop status

x_max: open

y_max: open

z_min: TRIGGERED

z_max: open

How can my Z_min be triggered both times?

Reporting endstop status

x_max: TRIGGERED

y_max: TRIGGERED

z_min: TRIGGERED

z_max: TRIGGERED

When I bring it down to Z0 it reports

Reporting endstop status

x_max: open

y_max: open

z_min: TRIGGERED

z_max: open

How can my Z_min be triggered both times?

|

Re: floating G29, or crashing into bed September 15, 2015 03:03AM |

Registered: 9 years ago Posts: 445 |

Quote

Sintensity

Quote

Koenig

You have calibrated your printer?

I might be wrong here, but I think you must calibrate the printer before performing any bed level probing.

When you have your nozzle at the bed what Z-height do you have?

Sorry, I must have misunderstood the instructions entirely. I was under the impression that this was what I was doing with running the G28 command. In that case, no I haven't calibrated the printer. Is there a resource/link for it? I've been using the Folger calibration guide that is provided via Google Drive. Apart from ensuring that the endstops are functional (and a short discussion on fan power which is probably irrelevant to the calibration procedure), the calibration steps start with G28.

Are you referring to the paper test?

I'm also unsure of what steps to take in order to answer your last question on Z-height. Is it a number that is specified in configuration.h? That would be 315. Or is it calculated by calibrating the hot end to the bed and then letting it go up until it hits the endstops? I hate to say this, but I have a feeling I'm still way off.

Took a quick look at the instructions, and yes I'm sort of referring to the "papertest" and what comes after.

From my understanding the probe takes care of the fine tuning part of calibration, but you have to be in the "ballpark" from the start for it to function properly.

I have to tell you that I have very limited knowledge about probing, I just recently got one my self, so I might be wrong about this.

It seems reasonable though, that the printer have to have some clue as to where to start.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 03:04AM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

Ok I may have something not right. When I home the printer with the G28 command my endstops report triggered. Should the Z_min not be triggered here?

Reporting endstop status

x_max: TRIGGERED

y_max: TRIGGERED

z_min: TRIGGERED

z_max: TRIGGERED

When I bring it down to Z0 it reports

Reporting endstop status

x_max: open

y_max: open

z_min: TRIGGERED

z_max: open

How can my Z_min be triggered both times?

Wired wrong perhaps.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 03:42PM |

Registered: 8 years ago Posts: 161 |

Ok so I have my towers and center adjusted so that when they pass the paper test and I use the m114 g code I get:

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 03:58PM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

Ok so I have my towers and center adjusted so that when they pass the paper test and I use the m114 g code I get:

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

You are not telling us how you got there, and what way.

You should try to follow this video, it allows for several kinds of firmware:

If not possible, I'll follow you through the steps in what way I can.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 06:03PM |

Registered: 8 years ago Posts: 161 |

Quote

Koenig

Quote

davidf01

Ok so I have my towers and center adjusted so that when they pass the paper test and I use the m114 g code I get:

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

You are not telling us how you got there, and what way.

You should try to follow this video, it allows for several kinds of firmware:

If not possible, I'll follow you through the steps in what way I can.

What I did was send the print head to the proper spot near each tower at Z5. I then dropped it down

Manually till it passed the paper test. I then took the difference and adjusted the endstop by that much. So if

I moved the printhead down 4mm then I moved the endstop up 4mm on that tower.

How do I turn on the EEPROM settings so it will work? Right now the Mxx codes dont work on my firmware. I'm going to do the m665 and m666 commands way to do the fine tuning as much as possible. I wanted to get it as close as I could physically first.

Edited 2 time(s). Last edit at 09/15/2015 09:04PM by davidf01.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 10:34PM |

Registered: 9 years ago Posts: 110 |

Quote

davidf01

Quote

Koenig

Quote

davidf01

Ok so I have my towers and center adjusted so that when they pass the paper test and I use the m114 g code I get:

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

You are not telling us how you got there, and what way.

You should try to follow this video, it allows for several kinds of firmware:

If not possible, I'll follow you through the steps in what way I can.

What I did was send the print head to the proper spot near each tower at Z5. I then dropped it down

Manually till it passed the paper test. I then took the difference and adjusted the endstop by that much. So if

I moved the printhead down 4mm then I moved the endstop up 4mm on that tower.

How do I turn on the EEPROM settings so it will work? Right now the Mxx codes dont work on my firmware. I'm going to do the m665 and m666 commands way to do the fine tuning as much as possible. I wanted to get it as close as I could physically first.

Im not sure but I dont think you move the endstops by how much you come down on the Z. Im probably wrong though. When I adjusted my endstops in seemed like little movements up or down made a big difference.

Edited 1 time(s). Last edit at 09/15/2015 10:35PM by cman8.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 15, 2015 10:56PM |

Registered: 8 years ago Posts: 916 |

Quote

davidf01

Ok so I have my towers and center adjusted so that when they pass the paper test and I use the m114 g code I get:

X tower z position is at 1.0

Y tower z position is at .3

Z tower position is at .3

and center on the build plate is at z .9

This is where I get a little lost. What do I do next? Do I keep adjusting the endstops or do I move ahead and adjust the smooth rod offset? I can still crash into the build plate because

the MANUAL_Z_HOME_POS is still set a little big to let me adjust the towers and center.

Dave

You need to get all your X, Y and Z positions to be exactly the same first. Here's what I did:

1) Adjust the bed so that it is exactly 90 degrees to all towers. This is quite important, and is often missed.

2) Ensure that your steps per unit number is correct for the number of teeth on your pulleys, and the teeth per mm of your belt.

3) Measure the length of your diagonal rods accurately, and plug that into the config.

4) Add a screw to the carriages, so that the screw head triggers the endstops. This means easy adjustment of the trigger points. The screws I used have a pitch of 0.5mm, so you turn it 1/5 of a turn for each 0.1 mm you want to adjust it by.

5) Get your X, Y and Z positions to all be exactly the same, then don't touch the endstop screws again

6) Adjust the MANUAL_Z_HOME_POS so that the nozzle passes the paper test at 0.1 in the centre of the bed

7) Adjust the Delta smooth rod offset so that the nozzle passes the paper test at 0.1 at the edges of the bed (X, Y and Z positions)

Remember to home each time you upload a new config.

You can print once this setup is done.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 11:22AM |

Registered: 8 years ago Posts: 161 |

Well I am to a point where I can start doing some test prints. I seem to be having some major extruder issues. I'm not sure what is going on but I

think I'm not getting enough flow. Here is a picture of a test print ans you can see where there is very little coming out of the hotend. If I put a little

pressure on the filament to help push it through flows better.

I tried calibrating the extruder as per one of the youtube videos where you measure a length and then extrude a length then measure the difference. But I'm not sure then it the problem

and if it is I dont know where to make the change in the firmware to make it put out more filament. What should I do to correct this issue?

think I'm not getting enough flow. Here is a picture of a test print ans you can see where there is very little coming out of the hotend. If I put a little

pressure on the filament to help push it through flows better.

I tried calibrating the extruder as per one of the youtube videos where you measure a length and then extrude a length then measure the difference. But I'm not sure then it the problem

and if it is I dont know where to make the change in the firmware to make it put out more filament. What should I do to correct this issue?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 11:43AM |

Registered: 8 years ago Posts: 90 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 12:45PM |

Registered: 9 years ago Posts: 67 |

Quote

davidf01

Well I am to a point where I can start doing some test prints. I seem to be having some major extruder issues. I'm not sure what is going on but I

think I'm not getting enough flow. Here is a picture of a test print ans you can see where there is very little coming out of the hotend. If I put a little

pressure on the filament to help push it through flows better.

I tried calibrating the extruder as per one of the youtube videos where you measure a length and then extrude a length then measure the difference. But I'm not sure then it the problem

and if it is I dont know where to make the change in the firmware to make it put out more filament. What should I do to correct this issue?

Adjust your E value for the steps per mm temporarily with the M code to get it correct and then adjust the config file/recompile/reflash/reboot. Mine is something like E=0.69 .

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 02:58PM |

Registered: 8 years ago Posts: 161 |

Quote

fattmann

What is your Vref for the extruder stepper motor?

I read a little about the v-Ref and turned mine up to about 90 and it still does not help. I ran an extrusion test and heated the head to 210 (PLA) and extruded 100mm. Im lucky if I got 30mm out of it.

I dont think the extruder is grabbing the filament very hard or it is slipping the whole time. Is there a way to test if the extruder is not grabing the filament.?

Edited 1 time(s). Last edit at 09/16/2015 03:16PM by davidf01.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 03:00PM |

Registered: 8 years ago Posts: 161 |

Quote

llamatrails

Quote

davidf01

Well I am to a point where I can start doing some test prints. I seem to be having some major extruder issues. I'm not sure what is going on but I

think I'm not getting enough flow. Here is a picture of a test print ans you can see where there is very little coming out of the hotend. If I put a little

pressure on the filament to help push it through flows better.

I tried calibrating the extruder as per one of the youtube videos where you measure a length and then extrude a length then measure the difference. But I'm not sure then it the problem

and if it is I dont know where to make the change in the firmware to make it put out more filament. What should I do to correct this issue?

Adjust your E value for the steps per mm temporarily with the M code to get it correct and then adjust the config file/recompile/reflash/reboot. Mine is something like E=0.69 .

Rick

I'm not sure how to do that with eeprom. I don't even know how to turn eeprom on to do that along with everything else. I was going to look into eeprom once

I finished with all the mechanical adjustments.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 16, 2015 09:13PM |

Registered: 9 years ago Posts: 110 |

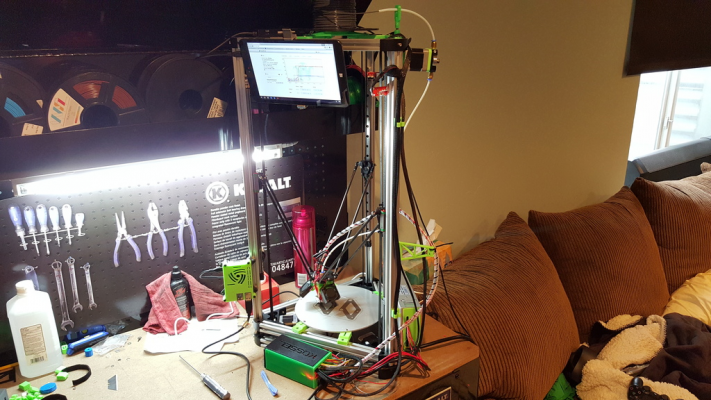

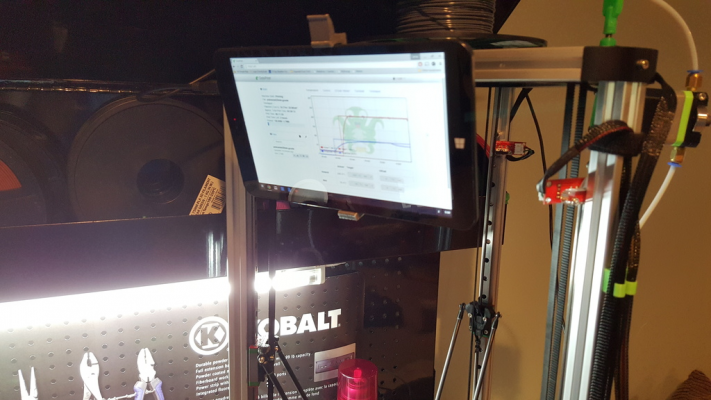

Made the octoprint mod. Works good. Its a little simplistic but overall works awesome. Now gonna install the Azteeg X5 mini. These are the things I have changed from stock

-Motors

-extruder mount

-took off the probe

-added the octoprint

-added the windows tablet. It runs printrun also so I can use either or with the marlin. Planning on running the Azteeg x5 as I have heard great things about it. So far loving the modding and loving the prints its pumping out.

Edited 1 time(s). Last edit at 09/17/2015 12:56AM by cman8.

-Motors

-extruder mount

-took off the probe

-added the octoprint

-added the windows tablet. It runs printrun also so I can use either or with the marlin. Planning on running the Azteeg x5 as I have heard great things about it. So far loving the modding and loving the prints its pumping out.

Edited 1 time(s). Last edit at 09/17/2015 12:56AM by cman8.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 17, 2015 09:56AM |

Registered: 9 years ago Posts: 67 |

Quote

davidf01

I'm not sure how to do that with eeprom. I don't even know how to turn eeprom on to do that along with everything else. I was going to look into eeprom once

I finished with all the mechanical adjustments.

EEPROM is a place where variables are stored in memory that is read from at boot and possibly during runtime. When you change the config file in Marlin and compile the code in the Arduino program, the variables are stored in EEPROM when you flash the Arduino. Boot up, and the values get read. Need to change on the fly? Send an M code like:

M92 E96.25 ; Set extruder steps per mm

Now, if you reboot after sending the above M code, you loose the M setting because the EEPROM still has the old value from the compiling. M500 stores current settings in EEPROM and M501 retreives the data from EEPROM so you can verify them. All this magic is only valid if the EEPROM is enabled in the Marlin config file.

As to the extruder issues, mine was pushing about 110mm when I asked for 100, so I had to use the M92 to adjust it until I got what I asked for. 96.25 worked for me.

In your case, is sounds like your stepper gear is either loose on the shaft or maybe the V bearing is not spinning correctly. Do you hear a grinding noise? Can you push the filament into the stepper to get it to move smoother? I recently had that problem and found the V bearing had popped the shield on one side. Got it working again, but am going to replace the extruder instead of replacing the bearing, the design isn't the greatest but it does work to get you going.

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 17, 2015 10:05AM |

Registered: 8 years ago Posts: 9 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level September 17, 2015 12:50PM |

Registered: 9 years ago Posts: 110 |

Quote

Seriouspete

Thats a really nice clean looking build. I dont suppose you could link the spool holder and printed bed plate mount. I'm always in the market for something better.

I printed this Spool holder with these extension arms. It works great and I think looks cool. The bearing is awesome and glides rather smooth.

Bed plate mounts I printed these in version 2

Sorry, only registered users may post in this forum.