Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 10:37AM |

Registered: 8 years ago Posts: 6 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:05PM |

Registered: 8 years ago Posts: 161 |

Some more calibration questions. I have been calibrating my printer. I made this test print based on a bunch I have

seen online and now I'm not sure what I need to adjust to correct the measurements. See attached picture.

It seems that each tower is off slightly and they are not all off the same amount.

Thevisad I'm guessing this is where your updated firmware can come in and help?

Any help would be great.

Thanks

Dave

seen online and now I'm not sure what I need to adjust to correct the measurements. See attached picture.

It seems that each tower is off slightly and they are not all off the same amount.

Thevisad I'm guessing this is where your updated firmware can come in and help?

Any help would be great.

Thanks

Dave

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:14PM |

Registered: 8 years ago Posts: 432 |

Quote

davidf01

Some more calibration questions. I have been calibrating my printer. I made this test print based on a bunch I have

seen online and now I'm not sure what I need to adjust to correct the measurements. See attached picture.

It seems that each tower is off slightly and they are not all off the same amount.

Thevisad I'm guessing this is where your updated firmware can come in and help?

Any help would be great.

Thanks

Dave

Try this istruction [bootsindustries.com]. And adjust DEFAULT_AXIS_STEPS_PER_UNIT accordingly.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:23PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

davidf01

Some more calibration questions. I have been calibrating my printer. I made this test print based on a bunch I have

seen online and now I'm not sure what I need to adjust to correct the measurements. See attached picture.

It seems that each tower is off slightly and they are not all off the same amount.

Thevisad I'm guessing this is where your updated firmware can come in and help?

Any help would be great.

Thanks

Dave

Try this istruction [bootsindustries.com]. And adjust DEFAULT_AXIS_STEPS_PER_UNIT accordingly.

No need to go through that to adjust your steps/mm, if nothing has changed FT includes 20tooth pulleys which corresponds to 80 steps/mm with 1/16 drivers.

In that guide they use printed pulleys which is why they do travel and measure, since this kit includes metal pulleys that is not needed.

For adjusting the size in XY-plane you alter the length of the rods in the firmware.

Edited 1 time(s). Last edit at 10/31/2015 04:26PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:28PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

No need to go through that to adjust your steps/mm, if nothing has changed FT includes 20tooth pulleys which corresponds to 80 steps/mm with 1/16 drivers.

In that guide they use printed pulleys which is why they do travel and measure, since this kit includes metal pulleys that is not needed.

OK, in Repetier there is a special variable, per tower, to adjust diagonal rod for accurate per axe dimensions. What variables in this case should he adjust in marlin, from your point of view?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:43PM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

Some more calibration questions. I have been calibrating my printer. I made this test print based on a bunch I have

seen online and now I'm not sure what I need to adjust to correct the measurements. See attached picture.

It seems that each tower is off slightly and they are not all off the same amount.

Thevisad I'm guessing this is where your updated firmware can come in and help?

Any help would be great.

Thanks

Dave

Looking at your picture I'd say that your first thing to look for is if the rods on the Y-tower have a different length than the other towers, if you are certain they are the same my next guess would be that your Y-tower have a different offset from the center than the others.

Both errors can be corrected through the firmware.

Don't know if thevisad included code for correcting individual rod length in his repo but I'm sure he has code for correcting the offsets.

Look for something like "delta_tower_correction" in configuration.h, for the rods you can have a look at this page: [www.thingiverse.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:51PM |

Registered: 8 years ago Posts: 432 |

Why people stay with slow Marlin where you need to patch C++ code to adjust diagonal rod per tower, not Configuration.h file or just EEPROM from the nice GUI?

They kill themselves trying to fix issues that Repetier doesn't have from the beginning...

Edited 1 time(s). Last edit at 10/31/2015 04:54PM by paul_delta.

They kill themselves trying to fix issues that Repetier doesn't have from the beginning...

Edited 1 time(s). Last edit at 10/31/2015 04:54PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 04:56PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

Koenig

No need to go through that to adjust your steps/mm, if nothing has changed FT includes 20tooth pulleys which corresponds to 80 steps/mm with 1/16 drivers.

In that guide they use printed pulleys which is why they do travel and measure, since this kit includes metal pulleys that is not needed.

OK, in Repetier there is a special variable, per tower, to adjust diagonal rod for accurate per axe dimensions. What variables in this case should he adjust in marlin, from your point of view?

Marlin as far as I know it doesn't have any options for this "originally", at least during the time I used it (prior RC 1.1), but you can add code for it yourself, se my post above.

From my point of view at the moment Repetier seems to be the best firmware for driving a delta on 8bit electronics.

They seem to have optimized the delta calculations better + offer more options for corrections.

The absolute best options for delta is in 32bit electronics though and I suppose that's where most delta development will happen in the coming future.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 07:18PM |

Registered: 8 years ago Posts: 161 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 08:25PM |

Registered: 8 years ago Posts: 432 |

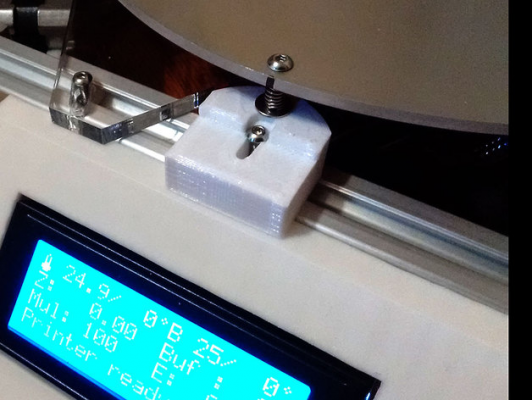

Folger Tech Kossel Mod: DIY adjustable hotbed mount for manual bed leveling

I hate this z-probe. Tried both - Marlin and Repetier. They calibrate, but I don't like the final results.

So, I decided to make my own adjustable hotbed mount using spare screws from printer kit (3 M3x25, 3 M3x15, 3 Nylock M3 nuts, 3 washers and 3 M3 t-nuts for 2020 extruded profile), simple sketchup-made mount (printed using PETG) and 3 springs that I found in $4 Homedepot spring kit.

It's on Thingiverse now: [www.thingiverse.com]

It took only 15 minutes to calibrate the installed bed with very high precision (0.02mm).

Tip: forget about paper test - it is not accurate enough! Use drill bit - roll it under the hotend tip close to the screw and adjust the screw so the drillbit will roll just slightly touching the tip.

Finally, I dismounted the probe and will never use it again... hardware calibration rules.

PS: to avoid mess with slicer and make smooth transition during printing from hex-nut hole to M3 I designed the thin wall, so short bridges over hex-nut hole will do the job pretty well. You need just puncture this thin wall using small screwdriver before inserting M3x25 screw.

Edited 5 time(s). Last edit at 10/31/2015 10:09PM by paul_delta.

I hate this z-probe. Tried both - Marlin and Repetier. They calibrate, but I don't like the final results.

So, I decided to make my own adjustable hotbed mount using spare screws from printer kit (3 M3x25, 3 M3x15, 3 Nylock M3 nuts, 3 washers and 3 M3 t-nuts for 2020 extruded profile), simple sketchup-made mount (printed using PETG) and 3 springs that I found in $4 Homedepot spring kit.

It's on Thingiverse now: [www.thingiverse.com]

It took only 15 minutes to calibrate the installed bed with very high precision (0.02mm).

Tip: forget about paper test - it is not accurate enough! Use drill bit - roll it under the hotend tip close to the screw and adjust the screw so the drillbit will roll just slightly touching the tip.

Finally, I dismounted the probe and will never use it again... hardware calibration rules.

PS: to avoid mess with slicer and make smooth transition during printing from hex-nut hole to M3 I designed the thin wall, so short bridges over hex-nut hole will do the job pretty well. You need just puncture this thin wall using small screwdriver before inserting M3x25 screw.

Edited 5 time(s). Last edit at 10/31/2015 10:09PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level October 31, 2015 08:33PM |

Registered: 8 years ago Posts: 432 |

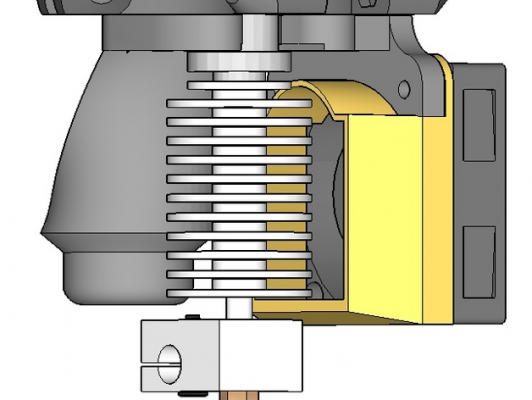

FolgerTech Kossel Mod: Fan upgrade

This fan housing prevents fan from blowing to the extruder's hot end area. This way the extruder heatsink stays cooler and the tip temperature is much stable without unneeded airflow.

Just put this sleeve between the fan and original fan mount.

It's on Thingiverse now: [www.thingiverse.com]

Edited 1 time(s). Last edit at 10/31/2015 08:34PM by paul_delta.

This fan housing prevents fan from blowing to the extruder's hot end area. This way the extruder heatsink stays cooler and the tip temperature is much stable without unneeded airflow.

Just put this sleeve between the fan and original fan mount.

It's on Thingiverse now: [www.thingiverse.com]

Edited 1 time(s). Last edit at 10/31/2015 08:34PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 03:52AM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

I wouldn't mind switching to Repetier but there is no information on how to set Repetier up on this printer. Everytime I try i get results

that are unusable. What firmware do I load to use with Repetier and what settings do I change to match what I have now in marlin?

You flash the repetier firmware, you can use the same settings as you have but some of them are not named exactly the same.

You start here: [www.repetier.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 04:03AM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Tip: forget about paper test - it is not accurate enough! Use drill bit - roll it under the hotend tip close to the screw and adjust the screw so the drillbit will roll just slightly touching the tip.

Don't say that, I just people put to much into it.

The paper test is just a feeler, what you want to do to get it 99.9% right is: finetuning after the paper test.

But then again all calibration counts on a totally flat bed that is absolutely perpendicular to the towers.

Bed leveling is another matter for that you can use screws like the ones you have done, or a probe to correct it in firmware.

Making sure that you have a bed that is perfectly level should be done before any calibration.

Edited 1 time(s). Last edit at 11/01/2015 04:05AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 11:25AM |

Registered: 8 years ago Posts: 161 |

Koenig,

Good information here for setting up the repetier firmare. I'm running through the web setup but I'm not sure what some of these values are

or what they are used for. Like is "Floor safety margin" used to tell it how far down the sliders can move? I'm also not sure

what the heck Z-correction (distortion correction) is used for. I dont want to enter something that will crash my printer. I there some

basic settings I can use for the folger printer to start with?

Good information here for setting up the repetier firmare. I'm running through the web setup but I'm not sure what some of these values are

or what they are used for. Like is "Floor safety margin" used to tell it how far down the sliders can move? I'm also not sure

what the heck Z-correction (distortion correction) is used for. I dont want to enter something that will crash my printer. I there some

basic settings I can use for the folger printer to start with?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 11:32AM |

Registered: 9 years ago Posts: 309 |

Quote

Koenig

Quote

paul_delta

Tip: forget about paper test - it is not accurate enough! Use drill bit - roll it under the hotend tip close to the screw and adjust the screw so the drillbit will roll just slightly touching the tip.

Don't say that, I just people put to much into it.

The paper test is just a feeler, what you want to do to get it 99.9% right is: finetuning after the paper test.

But then again all calibration counts on a totally flat bed that is absolutely perpendicular to the towers.

Bed leveling is another matter for that you can use screws like the ones you have done, or a probe to correct it in firmware.

Making sure that you have a bed that is perfectly level should be done before any calibration.

Paper has long been the defacto tool in almost all industries for measuring the gap between two objects. As a mechanic who worked with points and condenser systems, I used a dollar bill as the proper gauge distance to create the right air gap for optimum power. Standard 80 lb paper is .0055 thick, out of the package, every package. So when paper is used and the nozzle is pinching the paper, the tip should be .0055ish to the bed. You cannot much more accurate then that, 10 sheets for a penny. I dare you, absolutely double dog dare you to go to Harbor Freight and buy me a box of straight drill bits. Drill bits are not precise enough to be used as a measuring device regardless of the quality of the bit simply due to the manufacturing process. If you truly wanted to measure this in the correct manner, then you would use feeler gauges; however, tight quarters, heated beds and ease of use makes paper the way to test.

Also, unless you are removing the bed after a print, swapping beds out for one another or using FSR's for adjusting the tip to the minute variations that exist on a heated surface after they have been vigorously heated from room temperature, then the bed should be set it and forget it and your focus should be on the hotend.

Edited 3 time(s). Last edit at 11/01/2015 11:46AM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 12:20PM |

Registered: 8 years ago Posts: 432 |

Quote

thevisad

Paper has long been the defacto tool in almost all industries for measuring the gap between two objects. As a mechanic who worked with points and condenser systems, I used a dollar bill as the proper gauge distance to create the right air gap for optimum power. Standard 80 lb paper is .0055 thick, out of the package, every package. So when paper is used and the nozzle is pinching the paper, the tip should be .0055ish to the bed. You cannot much more accurate then that, 10 sheets for a penny. I dare you, absolutely double dog dare you to go to Harbor Freight and buy me a box of straight drill bits. Drill bits are not precise enough to be used as a measuring device regardless of the quality of the bit simply due to the manufacturing process. If you truly wanted to measure this in the correct manner, then you would use feeler gauges; however, tight quarters, heated beds and ease of use makes paper the way to test.

Also, unless you are removing the bed after a print, swapping beds out for one another or using FSR's for adjusting the tip to the minute variations that exist on a heated surface after they have been vigorously heated from room temperature, then the bed should be set it and forget it and your focus should be on the hotend.

]

So many men so many minds. With paper test It's very hard to get accurate calibration. Even more - for delta this is completely wrong way, because the chances to crash the head are very high - there is no safety room. Now you have an airgap, second later you have unneeded deformation of whole system. The drillbits give you a room to work, they have zero deformation under tip pressure and precise enough - I measured couple of them with calipers - the opposite end of drill bits were always pretty accurate and round even cheap drill bits from HarborTools. I use round end of drill bit, the straighteness of rod in this case doesn't play a role because of simple geometry. So, I highly recommend to try this way. But I understand that "paper as a tool" traditions is a kind of religion and I respect religious people

Edited 1 time(s). Last edit at 11/01/2015 12:20PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 12:47PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

thevisad

So many men so many minds. With paper test It's very hard to get accurate calibration. Even more - for delta this is completely wrong way, because the chances to crash the head are very high - there is no safety room. Now you have an airgap, second later you have unneeded deformation of whole system. The drillbits give you a room to work, they have zero deformation under tip pressure and precise enough - I measured couple of them with calipers - the opposite end of drill bits were always pretty accurate and round even cheap drill bits from HarborTools. I use round end of drill bit, the straighteness of rod in this case doesn't play a role because of simple geometry. So, I highly recommend to try this way. But I understand that "paper as a tool" traditions is a kind of religion and I respect religious people

The deformation of the paper is what makes it a good way of doing this, because you want it to pinch the paper but not clamp it down, it should move both backwards and forward with some resistance but not shred or fold, how do you distinguish that difference with a drill bit?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 12:55PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

Quote

paul_delta

Quote

thevisad

So many men so many minds. With paper test It's very hard to get accurate calibration. Even more - for delta this is completely wrong way, because the chances to crash the head are very high - there is no safety room. Now you have an airgap, second later you have unneeded deformation of whole system. The drillbits give you a room to work, they have zero deformation under tip pressure and precise enough - I measured couple of them with calipers - the opposite end of drill bits were always pretty accurate and round even cheap drill bits from HarborTools. I use round end of drill bit, the straighteness of rod in this case doesn't play a role because of simple geometry. So, I highly recommend to try this way. But I understand that "paper as a tool" traditions is a kind of religion and I respect religious people

The deformation of the paper is what makes it a good way of doing this, because you want it to pinch the paper but not clamp it down, it should move both backwards and forward with some resistance but not shred or fold, how do you distinguish that difference with a drill bit?

Just try, OK? You will see the difference in gradations/feeling.

PS: of course the drill bit must be small enough - 1.5mm-3mm max. With 10mm drill bit there is a chance to get non-symmetrical (oval) end.

Edited 2 time(s). Last edit at 11/01/2015 12:59PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:00PM |

Registered: 9 years ago Posts: 309 |

Quote

paul_delta

Quote

thevisad

Paper has long been the defacto tool in almost all industries for measuring the gap between two objects. As a mechanic who worked with points and condenser systems, I used a dollar bill as the proper gauge distance to create the right air gap for optimum power. Standard 80 lb paper is .0055 thick, out of the package, every package. So when paper is used and the nozzle is pinching the paper, the tip should be .0055ish to the bed. You cannot much more accurate then that, 10 sheets for a penny. I dare you, absolutely double dog dare you to go to Harbor Freight and buy me a box of straight drill bits. Drill bits are not precise enough to be used as a measuring device regardless of the quality of the bit simply due to the manufacturing process. If you truly wanted to measure this in the correct manner, then you would use feeler gauges; however, tight quarters, heated beds and ease of use makes paper the way to test.

Also, unless you are removing the bed after a print, swapping beds out for one another or using FSR's for adjusting the tip to the minute variations that exist on a heated surface after they have been vigorously heated from room temperature, then the bed should be set it and forget it and your focus should be on the hotend.

]

So many men so many minds. With paper test It's very hard to get accurate calibration. Even more - for delta this is completely wrong way, because the chances to crash the head are very high - there is no safety room. Now you have an airgap, second later you have unneeded deformation of whole system. The drillbits give you a room to work, they have zero deformation under tip pressure and precise enough - I measured couple of them with calipers - the opposite end of drill bits were always pretty accurate and round even cheap drill bits from HarborTools. I use round end of drill bit, the straighteness of rod in this case doesn't play a role because of simple geometry. So, I highly recommend to try this way. But I understand that "paper as a tool" traditions is a kind of religion and I respect religious people

The manufacturing process of a drill bit is such that it will destroy any and all potential mechanical accuracy. A drill bit has never been and will never be used to gauge measurement accuracy. There are many variations in the creation of a drill bit and even from the same company, one bit will be different then another. Straightness of the rod does count as it varies based upon how its placed on the surface of the object to be measured. Again, if you want true and proper measurement of the mecahnical gap, then you need to use feeler gauges or some other tool specifically designed for this purpose. [en.wikipedia.org]

With paper, you can feel the pressure that is there indicating the distance based on drag. Feeler gauges can give this same sense of drag while maintaining an exact measurement. Even better would be a mount for a dial indicator, with that I could measure the exact distance down to 0.001 mm

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:02PM |

Registered: 10 years ago Posts: 14,672 |

The problem I have found with the paper test is that the result you get depends on the friction of the bed surface. Higher friction surface (e.g. PVA glue) -> greater height at which the nozzle grips the paper as hard as you are looking for. But I still use the paper test for checking the Z=0 height because it's quicker than using feeler gauges.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:05PM |

Registered: 8 years ago Posts: 432 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:07PM |

Registered: 8 years ago Posts: 432 |

Quote

dc42

The problem I have found with the paper test is that the result you get depends on the friction of the bed surface. Higher friction surface (e.g. PVA glue) -> greater height at which the nozzle grips the paper as hard as you are looking for. But I still use the paper test for checking the Z=0 height because it's quicker than using feeler gauges.

Please let me remind that I'm talking about bed leveling - the way to get the tip equidistant from the bed on at least 4 points. Of course paper test is better (faster) way to get Z0 when everything is flat.

Edited 1 time(s). Last edit at 11/01/2015 01:11PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:10PM |

Registered: 9 years ago Posts: 309 |

Quote

paul_delta

Just try, OK? You will see the difference in gradations/feeling.

PS: of course the drill bit must be small enough - 1.5mm-3mm max. With 10mm drill bit there is a chance to get non-symmetrical (oval) end.

Lol, I do not need to "try and see" I know from a lifetime of working with mechanical objects, measurement tools, manufacturing processes and designing my own objects based upon the measurements I have taken. I also have all of the proper measurement tools in my toolbox, something instilled into me at an early age by my grandfather.Buy the right tool for the right job. A drill bit is not a measurement device nor is it the right tool for the job, you absolutely cannot take a 5/16 drill bit, a number 45 drill bit or a 2.5 mm drill bit and tell someone use that as your measurement. Drill bits have variations based upon how they are made, cut, ground, shaped and sharpened. Paper; however, is like I stated before an industry standard thickness and beyond that the first measurement tool that should be used is the feeler gauge. Harbor Freight sells them for 3-5$ a pop, depending on your size requirements.

This used to be a Folgertech printer and has been rebuilt from the ground up. This was created with proper tools to measure spaces, why on earth would I use some ramshackle process to gauge a distance or tell someone else to do so?

Edited 3 time(s). Last edit at 11/01/2015 01:31PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:23PM |

Registered: 9 years ago Posts: 309 |

Quote

paul_delta

Please let me remind that I'm talking about bed leveling - the way to get the tip equidistant from the bed on at least 4 points. Of course paper test is better (faster) way to get Z0 when everything is flat.

As I posted a few posts ago. The bed should be made as mechanically flat and level to the object itself. Using the metal corners the mechanical flatness/leveling will be as accurate as possible. Second would be the printed corners, if printed all in the same time, plastic, printer and position. Mounting the bed to the printer at this point becomes the most critical aspect. With mine, I mounted it directly to the 6mm aluminum plate, with a 5.5 thick piece of wood, a layer of heat tape and then a 6mm thick piece of corkboard. This was all bolted through the standard holes to the plate and then snugged down to the same height on all corners. The bed is and will always remain 100% perfectly flat and level to the printer.

Quote

thevisad

Also, unless you are removing the bed after a print, swapping beds out for one another or using FSR's for adjusting the tip to the minute variations that exist on a heated surface after they have been vigorously heated from room temperature, then the bed should be set it and forget it and your focus should be on the hotend.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:27PM |

Registered: 9 years ago Posts: 309 |

Quote

dc42

The problem I have found with the paper test is that the result you get depends on the friction of the bed surface. Higher friction surface (e.g. PVA glue) -> greater height at which the nozzle grips the paper as hard as you are looking for. But I still use the paper test for checking the Z=0 height because it's quicker than using feeler gauges.

It should always be said to clean off the surface you are testing on first so that there is nothing between the actual surface and the tip.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:28PM |

Registered: 8 years ago Posts: 432 |

Quote

thevisad

Quote

paul_delta

Just try, OK? You will see the difference in gradations/feeling.

PS: of course the drill bit must be small enough - 1.5mm-3mm max. With 10mm drill bit there is a chance to get non-symmetrical (oval) end.

Lol, I do not need to "try and see" I know from a lifetime of working with mechanical objects, measurement tools, manufacturing processes and designing my own objects based upon the measurements I have taken. A drill bit is not a measurement device, you absolutely cannot take a 5/16 drill bit, a number 45 drill bit or a 2.5 mm drill bit and tell someone use that as your measurement. Drill bits have variations based upon how they are made, cut, ground, shaped and sharpened. Paper; however, is like I stated before an industry standard thickness.

This used to be a Folgertech printer and has been rebuilt from the ground up. This was created with proper tools to measure spaces, why on earth would I use some ramshackle process to gauge a distance or tell someone else to do so?

I know, you are cool

But the problem is that you don't listen me carefully. Again, I'm talking about round (non-working) end of drill bit as a hard, cylindrical object where diameter doesn't play any role. It's just a round object that we can roll under tip to make sure that the tip is equidistant from the bed near screws and in the center. I don't care that it's 2.98mm and not 3mm as it should. I measure it, and I know it's 2.98mm. And when everything is on level, I know that I should change ZMAX to 2.98 to get perfect zero.

But the problem is that you don't listen me carefully. Again, I'm talking about round (non-working) end of drill bit as a hard, cylindrical object where diameter doesn't play any role. It's just a round object that we can roll under tip to make sure that the tip is equidistant from the bed near screws and in the center. I don't care that it's 2.98mm and not 3mm as it should. I measure it, and I know it's 2.98mm. And when everything is on level, I know that I should change ZMAX to 2.98 to get perfect zero.PS: I don't want even discuss that hardware bed leveling is much, much better that a set of software compensations with their errors and floating point math problems.

Edited 3 time(s). Last edit at 11/01/2015 01:38PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:41PM |

Registered: 9 years ago Posts: 309 |

Quote

paul_delta

I know, you are coolBut the problem is that you don't listen me carefully. Again, I'm talking about round (non-working) end of drill bit as a hard, cylindrical object where diameter doesn't play any role. It's just a round object that we can roll under tip to make sure that the tip is equidistant from the bed near screws and in the center. I don't care that it's 2.98mm and not 3mm as it should. I measure it, and I know it's 2.98mm. And when everything is on level, I know that I should change ZMAX to 2.98 to get perfect zero.

PS: I don't want even discuss that hardware bed leveling is much, much better that a set of software compensations with their errors and floating point math problems.

Keep your patronizing comments to yourself. I did listen to you, I do understand exactly what you are referring to, I am not an idiot. A drill bits manufacturing process is enough to cause the bit to become bent. It could be bent during packaging and bent in such a small amount that your eye is unable to see this. Rolling this then bent object, which could be off by as little a few microns in size across the surface of your bed will then lead to inaccuracies. In the 3 boxes of 60+ drill bits I JUST bought are at least 15 or so that are bent visibly, others are bent only slight so that you can tell when its in the drill. I am sure others are just ever so slightly off, that means almost 1/3rd of the bits are bent, well above the 6 Sigma failure acceptable ratings. I have zero problems with you doing this for yourself, feel free to measure and create your printer any way you see fit. My issue is when you tell others to try a mechanically inaccurate process to create mechanical accuracy. So to quote your own comment, you didn't listen very carefully, this tool [www.harborfreight.com] sold for 4.49 + tax is designed for the exact purpose of what you are "trying" to do and is the proper tool to use in replacement of paper.

Again, bed leveling is a MUTE point on a printer the bed will never be removed from and does not physically move in the x,y or z axis's.

Edited 3 time(s). Last edit at 11/01/2015 01:50PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:49PM |

Registered: 8 years ago Posts: 432 |

Quote

thevisad

My issue is when you tell others to try a mechanically inaccurate process to create mechanical accuracy. So to quote your own comment, you didn't listen very carefully, this tool [www.harborfreight.com] sold for 4.49 + tax is designed for the exact purpose of what you are "trying" to do and is the proper tool to use in replacement of paper.

Again, bed leveling is a MUTE point on a printer then bed will never be removed from.

OK, we speak about issues... My issue that you make a fork of Marlin that has z-probe problems and confuse people that think that this fork is the best they can get. So, please stop spaming this tread.

PS: keep shopping in Harbor Tools - the US #1 collection of chinese garbage with bent drillbits...

Edited 4 time(s). Last edit at 11/01/2015 02:05PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 01:57PM |

Registered: 9 years ago Posts: 309 |

Quote

paul_delta

Quote

thevisad

My issue is when you tell others to try a mechanically inaccurate process to create mechanical accuracy. So to quote your own comment, you didn't listen very carefully, this tool [www.harborfreight.com] sold for 4.49 + tax is designed for the exact purpose of what you are "trying" to do and is the proper tool to use in replacement of paper.

Again, bed leveling is a MUTE point on a printer then bed will never be removed from.

OK, we speak about issues... My issue that you make a fork of Marlin that has z-probe problems and confuse people that think that this fork is the best they can get. So, please stop spaming this tread.

Lol, ok have fun with that there

my "fork" is simply a copy of the Marlin firmware, with the tower corrections added and the configuration.h file adjusted to the settings from the original firmware provided by Folgertech. So if you have an issue with it, feel free to take it up with the original authors. It works, I used it exclusively until I upgraded to the Duet, I didn't write it. I used github for exactly the purpose it was meant for, forking code and releasing a branched version.

my "fork" is simply a copy of the Marlin firmware, with the tower corrections added and the configuration.h file adjusted to the settings from the original firmware provided by Folgertech. So if you have an issue with it, feel free to take it up with the original authors. It works, I used it exclusively until I upgraded to the Duet, I didn't write it. I used github for exactly the purpose it was meant for, forking code and releasing a branched version. As for spamming, feel free to report me for pointing out your using inaccurate measurements and telling others to do so as well if you wish, but you will see from my profile page that prior to replying to your inaccurate processes,I have not posted in these forums for 8 days, then 23, then 4+ weeks. Gotta love a troll like you.

[forums.reprap.org]

Edited 1 time(s). Last edit at 11/01/2015 01:59PM by thevisad.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 07:30PM |

Registered: 8 years ago Posts: 161 |

Sorry, only registered users may post in this forum.