Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 07:36PM |

Registered: 8 years ago Posts: 6 |

I have been having the issue that when my bed reaches temperature, and the print starts, the bed will the drop around 10 degrees. I have been printing at 115 and the bed will drop down to around 105. I am using slic3r to create the G-Code, and I have the temperature the same for the first layer and other layers. Any input would be appreciated

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 01, 2015 11:06PM |

Registered: 10 years ago Posts: 14,672 |

Does the power supply output voltage drop when the print starts?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 03:21AM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

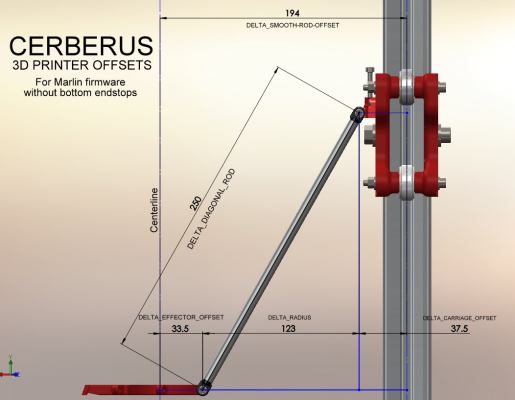

Can anyone tell me where the measurements are taken for:

DELTA_CARRIAGE_OFFSET

DELTA_EFFECTOR_OFFSET

I measure from what point to what point for these two settings?

Thanks

Do keep in mind that the "DELTA_EFFECTOR_OFFSET" is an imaginary point between the rods in a pair.

However, both these measurements don't really serve a purpose, the only interesting measurements in that picture is the "delta_radius" and "delta_diagonal_rod"

but both repetier and marlin have chosen to complicate the "delta_radius" by having to input "delta_smooth_rod_offset", "delta_carriage_offset" and "delta_effector_offset"

and then calculate the "delta_radius" from those three values, something like: "delta_radius" = "delta_smooth_rod_offset" - ("delta_carriage_offset" + "delta_effector_offset")

Edited 2 time(s). Last edit at 11/02/2015 03:26AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 08:54AM |

Registered: 8 years ago Posts: 107 |

Hello everyone!

I'm new to the 3D printing universe and have purchased a Folgertech Kossel 2020 that I'm trying to fire up.The build went relatively smoothly (although they sent me the wrong heat bed and it's a good thing I have access to a machine shop to fix some parts) but my problem seems to be that the end stops just aren't doing anything. I try to "home" the machine and the three axis (after I inverted them in the code) fly to the top of the printer but when they hit the stops (which do light up), the motors just keep trying to drive the axis further. If I take smaller steps using Pronterface while holding any of the endstops closed (tripped, lit up) then I can still move any and all axis. Any ideas what the issue might be? Did I just get a bad RAMPS board?

Thanks for any ideas and assistance.

Legrand

I'm new to the 3D printing universe and have purchased a Folgertech Kossel 2020 that I'm trying to fire up.The build went relatively smoothly (although they sent me the wrong heat bed and it's a good thing I have access to a machine shop to fix some parts) but my problem seems to be that the end stops just aren't doing anything. I try to "home" the machine and the three axis (after I inverted them in the code) fly to the top of the printer but when they hit the stops (which do light up), the motors just keep trying to drive the axis further. If I take smaller steps using Pronterface while holding any of the endstops closed (tripped, lit up) then I can still move any and all axis. Any ideas what the issue might be? Did I just get a bad RAMPS board?

Thanks for any ideas and assistance.

Legrand

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 10:32AM |

Registered: 9 years ago Posts: 309 |

Quote

Legrand

Hello everyone!

I'm new to the 3D printing universe and have purchased a Folgertech Kossel 2020 that I'm trying to fire up.The build went relatively smoothly (although they sent me the wrong heat bed and it's a good thing I have access to a machine shop to fix some parts) but my problem seems to be that the end stops just aren't doing anything. I try to "home" the machine and the three axis (after I inverted them in the code) fly to the top of the printer but when they hit the stops (which do light up), the motors just keep trying to drive the axis further. If I take smaller steps using Pronterface while holding any of the endstops closed (tripped, lit up) then I can still move any and all axis. Any ideas what the issue might be? Did I just get a bad RAMPS board?

Thanks for any ideas and assistance.

Legrand

Sounds like your endstops are either not actuating or are backwards. The fact that they light up is an indication that this is occurring, but RAMPS is not obtaining the signal. Check the wiring on the end of the harness and that you have them plugged in correctly.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:06PM |

Registered: 8 years ago Posts: 107 |

Quote

thevisad

Sounds like your endstops are either not actuating or are backwards. The fact that they light up is an indication that this is occurring, but RAMPS is not obtaining the signal. Check the wiring on the end of the harness and that you have them plugged in correctly.

There is only one way to plug them into the small boards where the switches are, and that's keyed so you can't screw it up. I plugged the other three in per the instructions as seen in this pic:

I have passed some m119 codes to the board via Pronterface and if I activate a switch it will report "TRIGGERED" however the motors do not stop.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:18PM |

Registered: 9 years ago Posts: 445 |

Quote

Legrand

Quote

thevisad

Sounds like your endstops are either not actuating or are backwards. The fact that they light up is an indication that this is occurring, but RAMPS is not obtaining the signal. Check the wiring on the end of the harness and that you have them plugged in correctly.

There is only one way to plug them into the small boards where the switches are, and that's keyed so you can't screw it up. I plugged the other three in per the instructions as seen in this pic:

I have passed some m119 codes to the board via Pronterface and if I activate a switch it will report "TRIGGERED" however the motors do not stop.

That means the hardware is okay.

What firmware did you flash?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:21PM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

I have passed some m119 codes to the board via Pronterface and if I activate a switch it will report "TRIGGERED" however the motors do not stop.

OK, look at your endstop from the conector side. The wires order from the bottom Green, empty pin, Black, Red. Correct?

Attach your Configuration.h file, I think something wrong with firmware logic.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:36PM |

Registered: 8 years ago Posts: 107 |

Quote

paul_delta

Quote

Legrand

I have passed some m119 codes to the board via Pronterface and if I activate a switch it will report "TRIGGERED" however the motors do not stop.

OK, look at your endstop from the conector side. The wires order from the bottom Green, empty pin, Black, Red. Correct?

Attach your Configuration.h file, I think something wrong with firmware logic.

Correct that the wires are as you state: Green, Empty, Black, Red (starting from the switch side).

I downloaded the firmware right from Kossel and have flashed both the REVB and REVBPE versions (I have no idea what the difference is). I'm currently using BPE with a couple minor tweaks for axis inverting and offset lengths.

Edited 1 time(s). Last edit at 11/02/2015 01:39PM by Legrand.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:45PM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

I downloaded the firmware right from Kossel and have flashed both the REVB and REVBPE versions (I have no idea what the difference is). I'm currently using BPE with a couple minor tweaks for axis inverting and offset lengths.

Check your MANUAL_Z_HOME_POS and set to something real like 250-300mm first. And put space between your value and "//".

Edited 2 time(s). Last edit at 11/02/2015 01:46PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 01:54PM |

Registered: 8 years ago Posts: 432 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 02:52PM |

Registered: 8 years ago Posts: 107 |

Updated both. Got it fixed.

If you were here, you'd slap me. I fixed it by watching what was triggering when and I switched the X and Y endstop connectors. Shazam. It's homing now. I just have to get some better values the offests so it moves more smoothly.

Onto the next problem. Thanks for everyone's help!

If you were here, you'd slap me. I fixed it by watching what was triggering when and I switched the X and Y endstop connectors. Shazam. It's homing now. I just have to get some better values the offests so it moves more smoothly.

Onto the next problem. Thanks for everyone's help!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:22PM |

Registered: 8 years ago Posts: 161 |

Quote

Koenig

Quote

davidf01

Can anyone tell me where the measurements are taken for:

DELTA_CARRIAGE_OFFSET

DELTA_EFFECTOR_OFFSET

I measure from what point to what point for these two settings?

Thanks

[attachment 65128 Delta_geometry.jpg]

Do keep in mind that the "DELTA_EFFECTOR_OFFSET" is an imaginary point between the rods in a pair.

However, both these measurements don't really serve a purpose, the only interesting measurements in that picture is the "delta_radius" and "delta_diagonal_rod"

but both repetier and marlin have chosen to complicate the "delta_radius" by having to input "delta_smooth_rod_offset", "delta_carriage_offset" and "delta_effector_offset"

and then calculate the "delta_radius" from those three values, something like: "delta_radius" = "delta_smooth_rod_offset" - ("delta_carriage_offset" + "delta_effector_offset")

Well According to this picture my Delta carriage offset is way off due to the fact that Folgers carriages did not fit my kit properly. My

DELTA_SMOOTH_ROD_OFFSET is also off by about 10mm if I measure from this picture.

Would these two settings mess up my prints by 0.8mm or less?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:34PM |

Registered: 8 years ago Posts: 432 |

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

Quote

davidf01

Quote

Koenig

Quote

davidf01

Can anyone tell me where the measurements are taken for:

DELTA_CARRIAGE_OFFSET

DELTA_EFFECTOR_OFFSET

I measure from what point to what point for these two settings?

Thanks

[attachment 65128 Delta_geometry.jpg]

Do keep in mind that the "DELTA_EFFECTOR_OFFSET" is an imaginary point between the rods in a pair.

However, both these measurements don't really serve a purpose, the only interesting measurements in that picture is the "delta_radius" and "delta_diagonal_rod"

but both repetier and marlin have chosen to complicate the "delta_radius" by having to input "delta_smooth_rod_offset", "delta_carriage_offset" and "delta_effector_offset"

and then calculate the "delta_radius" from those three values, something like: "delta_radius" = "delta_smooth_rod_offset" - ("delta_carriage_offset" + "delta_effector_offset")

Well According to this picture my Delta carriage offset is way off due to the fact that Folgers carriages did not fit my kit properly. My

DELTA_SMOOTH_ROD_OFFSET is also off by about 10mm if I measure from this picture.

Would these two settings mess up my prints by 0.8mm or less?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:44PM |

Registered: 9 years ago Posts: 445 |

Quote

davidf01

Quote

Koenig

Quote

davidf01

Can anyone tell me where the measurements are taken for:

DELTA_CARRIAGE_OFFSET

DELTA_EFFECTOR_OFFSET

I measure from what point to what point for these two settings?

Thanks

[attachment 65128 Delta_geometry.jpg]

Do keep in mind that the "DELTA_EFFECTOR_OFFSET" is an imaginary point between the rods in a pair.

However, both these measurements don't really serve a purpose, the only interesting measurements in that picture is the "delta_radius" and "delta_diagonal_rod"

but both repetier and marlin have chosen to complicate the "delta_radius" by having to input "delta_smooth_rod_offset", "delta_carriage_offset" and "delta_effector_offset"

and then calculate the "delta_radius" from those three values, something like: "delta_radius" = "delta_smooth_rod_offset" - ("delta_carriage_offset" + "delta_effector_offset")

Well According to this picture my Delta carriage offset is way off due to the fact that Folgers carriages did not fit my kit properly. My

DELTA_SMOOTH_ROD_OFFSET is also off by about 10mm if I measure from this picture.

Would these two settings mess up my prints by 0.8mm or less?

No, if you have gotten the effector to move flat across the printable surface you are good.

As you can see from the picture they are only used to get the only value that is actually used in the firmwares calculations, "delta_radius".

Personally I think they are mainly confusing and serve no real purpose, in "newer" firmwares you just put in your "delta_radius" directly and don't complicate things with these other measurements.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:45PM |

Registered: 8 years ago Posts: 161 |

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

I have printed a asterisk that I made myself and know the different sizes per tower. I just need to find out where to correct it in Marlin. I'm just not sure what setting Im looking

for to make the adjustment. I have downloaded repetier and the firmware for it but it is a bit more involved getting setup then marlin right now and I need to get some prints

from this before I mess around with a completely new firmware setup. I have only worked with Marlin so going through the repetier firmware is going to require more time from me.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:50PM |

Registered: 8 years ago Posts: 432 |

[www.thingiverse.com]

Only reading of this BS with Marlin should push you to Repetier Actually, there is no big difference between them from transition point of view. Now you know almost all variables to configure Repetier from scratch. Then, using Repetier Host, go to eeprom menu and change everything you need to make perfect sizing and level.

Actually, there is no big difference between them from transition point of view. Now you know almost all variables to configure Repetier from scratch. Then, using Repetier Host, go to eeprom menu and change everything you need to make perfect sizing and level.

PS: Repetier 092.5 has advanced z-probe calibration options, but broken G131/G132. I'd recommend to setup repetier 091 and do manual calibration, using easy and simple Eeprom tool GUI.

Edited 1 time(s). Last edit at 11/02/2015 06:53PM by paul_delta.

Only reading of this BS with Marlin should push you to Repetier

Actually, there is no big difference between them from transition point of view. Now you know almost all variables to configure Repetier from scratch. Then, using Repetier Host, go to eeprom menu and change everything you need to make perfect sizing and level.

Actually, there is no big difference between them from transition point of view. Now you know almost all variables to configure Repetier from scratch. Then, using Repetier Host, go to eeprom menu and change everything you need to make perfect sizing and level.PS: Repetier 092.5 has advanced z-probe calibration options, but broken G131/G132. I'd recommend to setup repetier 091 and do manual calibration, using easy and simple Eeprom tool GUI.

Edited 1 time(s). Last edit at 11/02/2015 06:53PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:52PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

IF that is his problem, might as well be the tower offsets (tower radii) that might be off.

Or a combination of the two, hard to tell.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 06:54PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

IF that is his problem, might as well be the tower offsets (tower radii) that might be off.

Or a combination of the two, hard to tell.

Actually, yes. But finally we can tweak only rod lenght per tower to compensate such kind of dimension errors.

PS: I assembled my Folgertech Kossel pretty accurate, all parts were attached almost with zero gap.All rods were assembled using special tool that I build especially for this purposes, so all rods were absolutely identical. But after measurement one axe was OK, but two another had around 0.5-0.7mm off with asterisk calibration model. Finally I printet DIY asterisk with maximum radius that bed allowed, changed rod correction per tower and now I'm pretty happy with measurements.

Edited 3 time(s). Last edit at 11/02/2015 07:05PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 07:05PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

Koenig

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

IF that is his problem, might as well be the tower offsets (tower radii) that might be off.

Or a combination of the two, hard to tell.

Actually, yes. But finally we can tweak only rod lenght per tower to compensate such kind of dimension errors.

As I said, might not be the rods that need correcting but the tower radii.

Both errors give dimensional inaccuracies.

If has done his rods in a jig it's unlikely there the problem is...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 07:08PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

Koenig

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

IF that is his problem, might as well be the tower offsets (tower radii) that might be off.

Or a combination of the two, hard to tell.

Actually, yes. But finally we can tweak only rod lenght per tower to compensate such kind of dimension errors.

PS: I assembled my Folgertech Kossel pretty accurate, all parts were attached almost with zero gap.All rods were assembled using special tool that I build especially for this purposes, so all rods were absolutely identical. But after measurement one axe was OK, but two another had around 0.5-0.7mm off with asterisk calibration model. Finally I printet DIY asterisk with maximum radius that bed allowed, changed rod correction per tower and now I'm pretty happy with measurements.

Were you actually sure you made the rods so inaccurate?

The other error, tower radii, is much harder to take any physical measure to confirm.

Correcting to wrong thing will likely give you other issues, like inconsistent Z=0, meaning the thickness of the first layer will vary over the build pate perhaps even so much it will get hard to get it to stick over the entire build plate

Edited 1 time(s). Last edit at 11/02/2015 07:14PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 07:12PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

PS: I assembled my Folgertech Kossel pretty accurate, all parts were attached almost with zero gap.All rods were assembled using special tool that I build especially for this purposes, so all rods were absolutely identical. But after measurement one axe was OK, but two another had around 0.5-0.7mm off with asterisk calibration model. Finally I printet DIY asterisk with maximum radius that bed allowed, changed rod correction per tower and now I'm pretty happy with measurements.

Were you actually sure you made the rods so inaccurate?

The other error, tower radii, is much harder to take any physical measure to confirm.[/quote]

Of course it was not rod. Something in the frame size. Some people complained about aluminum corners that sometimes are slightly off of right angle. But rod compensation solved dimensional errors completely.

Edited 1 time(s). Last edit at 11/02/2015 07:13PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 07:16PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

PS: I assembled my Folgertech Kossel pretty accurate, all parts were attached almost with zero gap.All rods were assembled using special tool that I build especially for this purposes, so all rods were absolutely identical. But after measurement one axe was OK, but two another had around 0.5-0.7mm off with asterisk calibration model. Finally I printet DIY asterisk with maximum radius that bed allowed, changed rod correction per tower and now I'm pretty happy with measurements.

Quote

Koenig

Were you actually sure you made the rods so inaccurate?

The other error, tower radii, is much harder to take any physical measure to confirm.

Quote

paul_delta

Of course it was not rod. Something in the frame size. Some people complained about aluminum corners that sometimes are slightly off of right angle. But rod compensation solved dimensional errors completely.

Correcting to wrong thing will likely give you other issues, like inconsistent Z=0, meaning the thickness of the first layer will vary over the build pate perhaps even so much it will get hard to get it to stick over the entire build plate

You can correct the angles as well.

Edited 1 time(s). Last edit at 11/02/2015 07:18PM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 07:26PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

Quote

paul_delta

PS: I assembled my Folgertech Kossel pretty accurate, all parts were attached almost with zero gap.All rods were assembled using special tool that I build especially for this purposes, so all rods were absolutely identical. But after measurement one axe was OK, but two another had around 0.5-0.7mm off with asterisk calibration model. Finally I printet DIY asterisk with maximum radius that bed allowed, changed rod correction per tower and now I'm pretty happy with measurements.

Quote

Koenig

Were you actually sure you made the rods so inaccurate?

The other error, tower radii, is much harder to take any physical measure to confirm.

Quote

paul_delta

Of course it was not rod. Something in the frame size. Some people complained about aluminum corners that sometimes are slightly off of right angle. But rod compensation solved dimensional errors completely.

Correcting to wrong thing will likely give you other issues, like inconsistent Z=0, meaning the thickness of the first layer will vary over the build pate perhaps even so much it will get hard to get it to stick over the entire build plate

You can correct the angles as well.

You know, looking at these shitty V-slot carriages, I am pretty happy with results I finally got after installing adjustable bed mounts and disabling all software corrections like distortion, etc.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 08:01PM |

Registered: 8 years ago Posts: 161 |

Quote

Koenig

Quote

paul_delta

Quote

Koenig

Quote

paul_delta

Repetier configuration tool sets these values to zero. I guess your diagonal rod lenght is the reason. If you will print asterisk from thingiverse, you will see which tower has longer or shorter diagonal rod. Both marlin and Repetier allow to correct the lenght of rod per tower - repetier via GUI and Eeprom, Marlin via changes in calculation in .cpp file.

IF that is his problem, might as well be the tower offsets (tower radii) that might be off.

Or a combination of the two, hard to tell.

Actually, yes. But finally we can tweak only rod lenght per tower to compensate such kind of dimension errors.

As I said, might not be the rods that need correcting but the tower radii.

Both errors give dimensional inaccuracies.

If has done his rods in a jig it's unlikely there the problem is...

My rods are damn close. I made a jig to make them and they are measured and all of them are the same size or at lease within 0.1mm. I'm guessing my tower offsets are the problem.

I just need to know what to adjust to test if it is the tower offsets or not. I think it has something to do with the build. My aluminum corners were not perfect and I had to use a belt strap

to get the frame together.

Edited 1 time(s). Last edit at 11/02/2015 08:02PM by davidf01.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 08:23PM |

Registered: 8 years ago Posts: 432 |

Quote

davidf01

My rods are damn close. I made a jig to make them and they are measured and all of them are the same size or at lease within 0.1mm. I'm guessing my tower offsets are the problem.

I just need to know what to adjust to test if it is the tower offsets or not. I think it has something to do with the build. My aluminum corners were not perfect and I had to use a belt strap

to get the frame together.

I guess there are only two things you can adjust in software - the tower's angle and diagonal rod lenght per tower (if angle in printed asterisk is wrong or lenght of asterisk for corresponding axe is off).

Adjustment of diagonal rod lenght per tower, actually, compensates frame problems. As I said, In my case I'm pretty happy with results. My software (Repetier) diagonal rod adjustment, per tower, is:

A : 0.920mm

B : -1.341mm

C: -1.054

As I said, my rods almost ideal and these corrections compensate frame misalignments or something else.

PS: the quality of deflector from FolgerTech is far from good. I suspect that all compensations I have to add are because of dimensional disproportions of deflector (uncalibrated printer in Folgertech per axe, for example.). Probably I'll print one myself with all my calibrations and will see the difference.

Edited 5 time(s). Last edit at 11/02/2015 08:34PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 08:49PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

davidf01

My rods are damn close. I made a jig to make them and they are measured and all of them are the same size or at lease within 0.1mm. I'm guessing my tower offsets are the problem.

I just need to know what to adjust to test if it is the tower offsets or not. I think it has something to do with the build. My aluminum corners were not perfect and I had to use a belt strap

to get the frame together.

I guess there are only two things you can adjust in software - the tower's angle and diagonal rod lenght per tower (if angle in printed asterisk is wrong or lenght of asterisk for corresponding axe is off).

Adjustment of diagonal rod lenght per tower, actually, compensates frame problems. As I said, In my case I'm pretty happy with results. My software (Repetier) diagonal rod adjustment, per tower, is:

A : 0.920mm

B : -1.341mm

C: -1.054

As I said, my rods almost ideal and these corrections compensate frame misalignments or something else.

PS: the quality of deflector from FolgerTech is far from good. I suspect that all compensations I have to add are because of dimensional disproportions of deflector (uncalibrated printer in Folgertech per axe, for example.). Probably I'll print one myself with all my calibrations and will see the difference.

I don't know how many times I have to mention this for you but the the tower radii (offset) is correctable both with Marlin and repetier.

I've mentioned in at least my three latest posts.

Not in the version provided by FT but in later "official" versions, thevisads repo have it together with other settings suitable for this printer.

If you go for thevisads version look for something like "tower_correction" in configuration.h

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 10:00PM |

Registered: 8 years ago Posts: 432 |

Koenig, I respect your patience but I'm really tired of your RADII  Probably it's just terms misuse...

Probably it's just terms misuse...

Again, I'm talking about per axe size disproportion of printed item. This is what DIAGONAL correction does (Corr. diagonal A/B/C in Repetier). I don't care what is the reason of such disproportion - I just know that diagonal rod corection per tower is the way to handle it, with minimum AVR computation power. I don't need ABC/XYZ delta radius compensation because I have no gaps with Z0 across A/B/C towers - everything is flat enough to forget about delta radius correction PER TOWER.

PS: and it's not correct to use "tower offset" in this matter, because it's linked to endstop adjustment - both in Marlin and Repetier.

Edited 2 time(s). Last edit at 11/02/2015 10:20PM by paul_delta.

Probably it's just terms misuse...

Probably it's just terms misuse...Again, I'm talking about per axe size disproportion of printed item. This is what DIAGONAL correction does (Corr. diagonal A/B/C in Repetier). I don't care what is the reason of such disproportion - I just know that diagonal rod corection per tower is the way to handle it, with minimum AVR computation power. I don't need ABC/XYZ delta radius compensation because I have no gaps with Z0 across A/B/C towers - everything is flat enough to forget about delta radius correction PER TOWER.

PS: and it's not correct to use "tower offset" in this matter, because it's linked to endstop adjustment - both in Marlin and Repetier.

Quote

Koenig

Quote

paul_delta

Quote

davidf01

My rods are damn close. I made a jig to make them and they are measured and all of them are the same size or at lease within 0.1mm. I'm guessing my tower offsets are the problem.

I just need to know what to adjust to test if it is the tower offsets or not. I think it has something to do with the build. My aluminum corners were not perfect and I had to use a belt strap

to get the frame together.

I guess there are only two things you can adjust in software - the tower's angle and diagonal rod lenght per tower (if angle in printed asterisk is wrong or lenght of asterisk for corresponding axe is off).

Adjustment of diagonal rod lenght per tower, actually, compensates frame problems. As I said, In my case I'm pretty happy with results. My software (Repetier) diagonal rod adjustment, per tower, is:

A : 0.920mm

B : -1.341mm

C: -1.054

As I said, my rods almost ideal and these corrections compensate frame misalignments or something else.

PS: the quality of deflector from FolgerTech is far from good. I suspect that all compensations I have to add are because of dimensional disproportions of deflector (uncalibrated printer in Folgertech per axe, for example.). Probably I'll print one myself with all my calibrations and will see the difference.

I don't know how many times I have to mention this for you but the the tower radii (offset) is correctable both with Marlin and repetier.

I've mentioned in at least my three latest posts.

Not in the version provided by FT but in later "official" versions, thevisads repo have it together with other settings suitable for this printer.

If you go for thevisads version look for something like "tower_correction" in configuration.h

Edited 2 time(s). Last edit at 11/02/2015 10:20PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 10:12PM |

Registered: 8 years ago Posts: 90 |

After a few weeks of hiatus from trying to get this thing setup, I am back with more (of the same ) questions.

I was having trouble getting my Z axis to move 10mm when told to have it move 10mm. As of right now it is only moving 5mm. I had upgraded to the Drv8825 stepper drivers after finding all mine from Folger were bad. I was enlightened earlier in this thread that you have to have the jumpers in a different configuration to get 1/16 steps out of the 8825s. Using the advice of others, and this guide, I attempted to just have the M3 jumper, and leave the FW Steps Per Unit at 80 (20 tooth pulley)

That did not help. In fact, any configuration of jumpers, and Steps Per Unit all result in moving 5mm instead of 10mm. Nothing seems to change that at all. I'm also still running into the issue that I have to have my MANUAL_Z_HOME_POS over 500 (534.4 to be exact) to get it to pass the paper test. I was hoping that that was tied to the steps problem, but so far I can't fix one to fix the other.

Every time I adjust the FW, or jumpers- I completely power down, disconnect power/usb, then recompile and upload FW. Every time.

What else can I look at?

EDIT: When I use the M114 command, it indicates that it is moving 10mm digitally, but only moves 5mm when placed against a ruler.

Edited 1 time(s). Last edit at 11/02/2015 10:30PM by fattmann.

I was having trouble getting my Z axis to move 10mm when told to have it move 10mm. As of right now it is only moving 5mm. I had upgraded to the Drv8825 stepper drivers after finding all mine from Folger were bad. I was enlightened earlier in this thread that you have to have the jumpers in a different configuration to get 1/16 steps out of the 8825s. Using the advice of others, and this guide, I attempted to just have the M3 jumper, and leave the FW Steps Per Unit at 80 (20 tooth pulley)

That did not help. In fact, any configuration of jumpers, and Steps Per Unit all result in moving 5mm instead of 10mm. Nothing seems to change that at all. I'm also still running into the issue that I have to have my MANUAL_Z_HOME_POS over 500 (534.4 to be exact) to get it to pass the paper test. I was hoping that that was tied to the steps problem, but so far I can't fix one to fix the other.

Every time I adjust the FW, or jumpers- I completely power down, disconnect power/usb, then recompile and upload FW. Every time.

What else can I look at?

EDIT: When I use the M114 command, it indicates that it is moving 10mm digitally, but only moves 5mm when placed against a ruler.

Edited 1 time(s). Last edit at 11/02/2015 10:30PM by fattmann.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 02, 2015 10:40PM |

Registered: 8 years ago Posts: 432 |

AFAIK RAMPS doesn't support 1/32. You have to double your steps in firmware.

Quote

fattmann

After a few weeks of hiatus from trying to get this thing setup, I am back with more (of the same ) questions.

I was having trouble getting my Z axis to move 10mm when told to have it move 10mm. As of right now it is only moving 5mm. I had upgraded to the Drv8825 stepper drivers after finding all mine from Folger were bad. I was enlightened earlier in this thread that you have to have the jumpers in a different configuration to get 1/16 steps out of the 8825s. Using the advice of others, and this guide, I attempted to just have the M3 jumper, and leave the FW Steps Per Unit at 80 (20 tooth pulley)

That did not help. In fact, any configuration of jumpers, and Steps Per Unit all result in moving 5mm instead of 10mm. Nothing seems to change that at all. I'm also still running into the issue that I have to have my MANUAL_Z_HOME_POS over 500 (534.4 to be exact) to get it to pass the paper test. I was hoping that that was tied to the steps problem, but so far I can't fix one to fix the other.

Every time I adjust the FW, or jumpers- I completely power down, disconnect power/usb, then recompile and upload FW. Every time.

What else can I look at?

EDIT: When I use the M114 command, it indicates that it is moving 10mm digitally, but only moves 5mm when placed against a ruler.

Sorry, only registered users may post in this forum.