Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 12:53PM |

Registered: 8 years ago Posts: 432 |

Quote

fattmann

Mine does this too. If I hit the general Home button in the bottom left, it homes just fine. If I use G28, it homes just fine.

But if I hit that red X/Y home button in the middle- all hell breaks loose as it rams to one side and I have to power it off.

Check your setting in pronterface. Set width/depth/height to 160x160x250 and build offset to -80,-80,0.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 01:16PM |

Registered: 8 years ago Posts: 107 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 01:21PM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

It moves just fine. Straight down. The G28 works fine also. It's just as fattman describes. Hit the red Y/X button in the center bullseye and all hell breaks loose. Power down, Hit reset button on the board, Re-ho

So, your printer works fine, it's just Pronterface wrong settings. When you press this red button, what do you see in communication window? What command does it send? It will explain you everything.

Edited 1 time(s). Last edit at 11/04/2015 01:23PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 01:52PM |

Registered: 8 years ago Posts: 90 |

Quote

paul_delta

Quote

Legrand

It moves just fine. Straight down. The G28 works fine also. It's just as fattman describes. Hit the red Y/X button in the center bullseye and all hell breaks loose. Power down, Hit reset button on the board, Re-ho

So, your printer works fine, it's just Pronterface wrong settings. When you press this red button, what do you see in communication window? What command does it send? It will explain you everything.

When I press the software buttons, nothing populates in the console, never has for me.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 01:58PM |

Registered: 8 years ago Posts: 432 |

Quote

fattmann

Quote

paul_delta

Quote

Legrand

It moves just fine. Straight down. The G28 works fine also. It's just as fattman describes. Hit the red Y/X button in the center bullseye and all hell breaks loose. Power down, Hit reset button on the board, Re-ho

So, your printer works fine, it's just Pronterface wrong settings. When you press this red button, what do you see in communication window? What command does it send? It will explain you everything.

When I press the software buttons, nothing populates in the console, never has for me.

Settings->Debug Communication.

Actually, this center red button just does G0 X0 Y0 - centers the head at any hight.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 02:00PM |

Registered: 8 years ago Posts: 90 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 06:45PM |

Registered: 8 years ago Posts: 6 |

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

Edited 1 time(s). Last edit at 11/04/2015 06:49PM by jonh5498.

Edited 1 time(s). Last edit at 11/04/2015 06:49PM by jonh5498.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 04, 2015 06:49PM |

Registered: 8 years ago Posts: 432 |

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

Attach your Configuration.h file.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 01:31AM |

Registered: 9 years ago Posts: 445 |

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

Dude, just try rotating them, they will go the other direction then, if they stop at the endstops all is well, if they do not stop at the endstops, then you should invert the motors or the endstops in the firmware (assuming you have connected the endstops to the "MAX" position of the RAMPS.

Just have your finger ready at the power-switch if they should not stop at the endstops.

I took a peek at your configuration.h at your other post to me the motors/endstops seems to be correctly configured, but then again I not really a wizard on Marlin, I have only used it for a couple of months before I changed my electronics for another board.

Edited 2 time(s). Last edit at 11/05/2015 01:39AM by Koenig.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 03:41PM |

Registered: 8 years ago Posts: 29 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 03:44PM |

Registered: 9 years ago Posts: 309 |

Quote

gaddcasey1

Anyone have plans for the psu mount? I broke mine and need new ones.

I can laser cut new ones for you if needed, I have some 6MM clear acrylic on hand right now or you can peruse the thingiverse site to see if they have one that will work for you.

[www.thingiverse.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:28PM |

Registered: 8 years ago Posts: 432 |

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

OK, I found your old post with attached firmware. Here is what is different between your config and mine :

const bool X_MIN_ENDSTOP_INVERTING = false;

const bool Y_MIN_ENDSTOP_INVERTING = false;

All of them must be true.

Update: sorry, I didn't pay attention that they are "MIN". Min endstops don't play any role, just disable them:

// Deltas never have min endstops

#define DISABLE_MIN_ENDSTOPS

The problem is your inverted XYZ direction. Should be:

#define INVERT_X_DIR false // DELTA does not invert

#define INVERT_Y_DIR false

#define INVERT_Z_DIR false

Edited 4 time(s). Last edit at 11/05/2015 04:40PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:30PM |

Registered: 8 years ago Posts: 432 |

Quote

gaddcasey1

Anyone have plans for the psu mount? I broke mine and need new ones.

It looks, like there is more economical, from the filament point of view, mount on Thingiverse:

[www.thingiverse.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:32PM |

Registered: 9 years ago Posts: 445 |

Quote

paul_delta

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

OK, I found your old post with attached firmware. Here is what is different between your config and mine :

const bool X_MIN_ENDSTOP_INVERTING = false;

const bool Y_MIN_ENDSTOP_INVERTING = false;

All of them must be true.

Not a wizard of Marlin, but those read MIN endstops and is not in use in a delta (except for the probe).

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:36PM |

Registered: 8 years ago Posts: 432 |

Quote

Koenig

Quote

paul_delta

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

OK, I found your old post with attached firmware. Here is what is different between your config and mine :

const bool X_MIN_ENDSTOP_INVERTING = false;

const bool Y_MIN_ENDSTOP_INVERTING = false;

All of them must be true.

Not a wizard of Marlin, but those read MIN endstops and is not in use in a delta (except for the probe).

Yes, I updated my post, the problem solved.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:42PM |

Registered: 8 years ago Posts: 6 |

Quote

Koenig

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

Dude, just try rotating them, they will go the other direction then, if they stop at the endstops all is well, if they do not stop at the endstops, then you should invert the motors or the endstops in the firmware (assuming you have connected the endstops to the "MAX" position of the RAMPS.

Just have your finger ready at the power-switch if they should not stop at the endstops.

I took a peek at your configuration.h at your other post to me the motors/endstops seems to be correctly configured, but then again I not really a wizard on Marlin, I have only used it for a couple of months before I changed my electronics for another board.

I am more convinced that this will work after a discovery I made today. In looking through pictures of my build on my phone(at work) and comparing them to the pictures in the guide on Folger's Google drive for the Kossel, I found that the belt blocks that bolt to the carriages are a mirror image of what I have. This would mechanically reverse the movement. I thought that maybe these were printed for another version of the printer, but all the pictures of them on any of the guides are opposite of mine. Perhaps they were printed with axis inversion turned on for X & Y in the host software or something like that(by accident). The part that was confusing me more, was that the printer actually seemed to be moving correctly when I ran a G29 except for the fact that it was several inches off the bed. That's not surprising, though since it has never been properly homed. I will reverse the connections at the RAMPS tonight and see how it goes. Thanks to all for checking my config and helping with this.

On another note, what replacement board did you go with?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 04:43PM |

Registered: 8 years ago Posts: 432 |

Quote

jonh5498

Quote

Koenig

Quote

jonh5498

So I have the Rev B kit built and in operation, well sorta. It homes in the wrong direction. Someone suggested that I rotate the motor lead connectors 180 degrees at the RAMPS board. I don't think that will solve the problem without creating other problems. Anyone else seen this? My build uses 240 mm rods hole to hole. I also have the 2004 LCD/SD card reader that I haven't installed yet. Anyone got an example firmware that is close for this rig? I can change the rod lengths and basic measurements, but I have been reading through these config files for hours and I'm not getting anywhere. Also, I am using Repitier as the host.

Dude, just try rotating them, they will go the other direction then, if they stop at the endstops all is well, if they do not stop at the endstops, then you should invert the motors or the endstops in the firmware (assuming you have connected the endstops to the "MAX" position of the RAMPS.

Just have your finger ready at the power-switch if they should not stop at the endstops.

I took a peek at your configuration.h at your other post to me the motors/endstops seems to be correctly configured, but then again I not really a wizard on Marlin, I have only used it for a couple of months before I changed my electronics for another board.

I am more convinced that this will work after a discovery I made today. In looking through pictures of my build on my phone(at work) and comparing them to the pictures in the guide on Folger's Google drive for the Kossel, I found that the belt blocks that bolt to the carriages are a mirror image of what I have. This would mechanically reverse the movement. I thought that maybe these were printed for another version of the printer, but all the pictures of them on any of the guides are opposite of mine. Perhaps they were printed with axis inversion turned on for X & Y in the host software or something like that(by accident). The part that was confusing me more, was that the printer actually seemed to be moving correctly when I ran a G29 except for the fact that it was several inches off the bed. That's not surprising, though since it has never been properly homed. I will reverse the connections at the RAMPS tonight and see how it goes. Thanks to all for checking my config and helping with this.

On another note, what replacement board did you go with?

No difference for movement. My kit had inverted version as well.

Just fix your config:

#define INVERT_X_DIR false // DELTA does not invert

#define INVERT_Y_DIR false

#define INVERT_Z_DIR false

Edited 1 time(s). Last edit at 11/05/2015 04:44PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 05:20PM |

Registered: 9 years ago Posts: 445 |

Quote

jonh5498

On another note, what replacement board did you go with?

I went with a duet.

Was mainly interested to see if the segment free printing would be an improvement.

If I had known what I know now when I bought this kit I wouldn't have bought it, not that it is all bad, it just didn't do for me what I wanted.

I have changed everything except for horizontal extrusions, heatbed, endstop switches, some of the acrylic parts and the PSU

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 07:40PM |

Registered: 9 years ago Posts: 67 |

Quote

Koenig

Quote

jonh5498

On another note, what replacement board did you go with?

I went with a duet.

Was mainly interested to see if the segment free printing would be an improvement.

If I had known what I know now when I bought this kit I wouldn't have bought it, not that it is all bad, it just didn't do for me what I wanted.

I have changed everything except for horizontal extrusions, heatbed, endstop switches, some of the acrylic parts and the PSU

Mine is a model B, before the metal corners. I got a set of the metal corners from Folger when they had the prototypes.

Also went with the duet and the IR sensor. Best move I made, it is a breeze to configure and maintain.

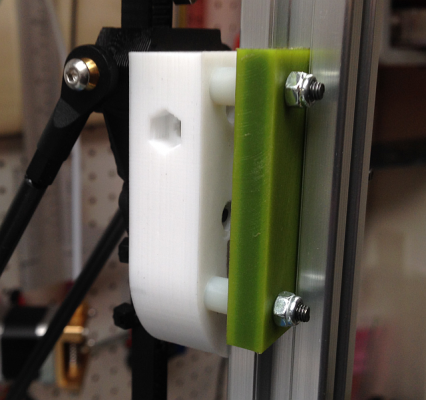

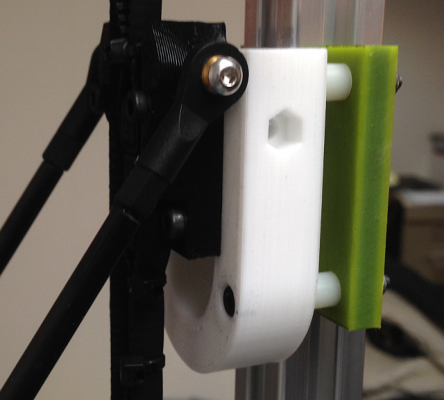

Aside from the above, I have also dumped the linear slides for oil impregnated nylon ones I made.

The carriage blocks are from thingiverse and dc42.

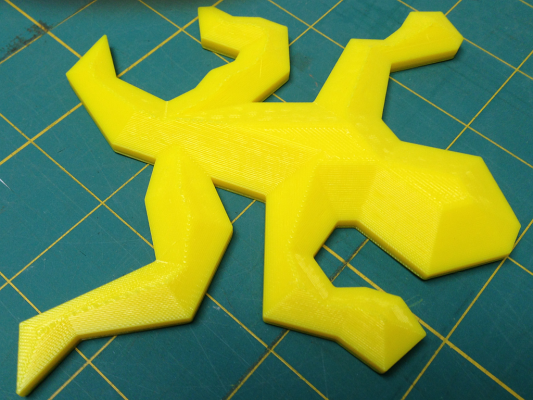

Here is a piece printed with the new slides:

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 08:10PM |

Registered: 8 years ago Posts: 432 |

Quote

llamatrails

Aside from the above, I have also dumped the linear slides for oil impregnated nylon ones I made.

Interesting... I was thinking about replacing v-slot to linear but now I'm not sure, looking at these sliders. Are they really so good? How about the amount of play? Wear-resistance?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 09:13PM |

Registered: 9 years ago Posts: 67 |

Quote

paul_delta

Quote

llamatrails

Aside from the above, I have also dumped the linear slides for oil impregnated nylon ones I made.

Interesting... I was thinking about replacing v-slot to linear but now I'm not sure, looking at these sliders. Are they really so good? How about the amount of play? Wear-resistance?

The above pics don't show the cross bolt, I added it a few days after the pics were taken.

No play at all, and I don't expect to see any wear. Been using HDPE on round rails for a few years on my cnc with no slop at all. With no rough surfaces, the plastic doesn't wear, it glides.

I couldn't run the Folger provided linear rails without constant lube during prints, even after taking them apart and adding the missing ball bearings. These slides don't need any lube at all.

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 09:22PM |

Registered: 8 years ago Posts: 432 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 05, 2015 09:46PM |

Registered: 8 years ago Posts: 6 |

Quote

Koenig

Quote

jonh5498

On another note, what replacement board did you go with?

I went with a duet.

Was mainly interested to see if the segment free printing would be an improvement.

If I had known what I know now when I bought this kit I wouldn't have bought it, not that it is all bad, it just didn't do for me what I wanted.

I have changed everything except for horizontal extrusions, heatbed, endstop switches, some of the acrylic parts and the PSU

The printer is homing correctly now. It also appears to be executing a G29 correctly(which I am minimally concerned with). Switching the connections at the board worked. I have been moving the effector all over the place tonight as a test and it seems very accurate. I also tested bed and hotend heaters and thermistors. They are spot on. I should get on with calibration. Thanks for being persistent and looking at my config(all of you). It's time to move this project into my office where I have a better machine that can do OpenGL. LOL. Crappy old laptop needs the dumpster.....or linux.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 08:47AM |

Registered: 9 years ago Posts: 67 |

Quote

paul_delta

Quote

llamatrails

These slides don't need any lube at all.

Rick

What do you think - will PETG work for these sliders as well as nylon?

Thanks.

Probably not, no Slippery properties compared to others. See the page [www.mcmaster.com] and click on "About Plastics" .

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 09:34AM |

Registered: 9 years ago Posts: 309 |

Quote

llamatrails

Quote

paul_delta

Quote

llamatrails

These slides don't need any lube at all.

Rick

What do you think - will PETG work for these sliders as well as nylon?

Thanks.

Probably not, no Slippery properties compared to others. See the page [www.mcmaster.com] and click on "About Plastics" .

Rick

How does this compare to Delrin/Acetal for longevity?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 03:52PM |

Registered: 9 years ago Posts: 67 |

Quote

thevisad

Quote

llamatrails

Quote

paul_delta

Quote

llamatrails

These slides don't need any lube at all.

Rick

What do you think - will PETG work for these sliders as well as nylon?

Thanks.

Probably not, no Slippery properties compared to others. See the page [www.mcmaster.com] and click on "About Plastics" .

Rick

How does this compare to Delrin/Acetal for longevity?

See:

[info.craftechind.com]

[www.usplastic.com]

ACETAL (Delrin®) White Acetal-150 has excellent load-bearing qualities in both tension and compression. Acetal does not absorb a large amount of moisture and are resistant to a wide range of solvents. Acetals are attacked by both strong acids and oxidizing agents. The service temp range is -20 to 185 deg F, intermittent 200 deg F. High yield strength at elevated temperatures. It is an excellent material for bearings, gears, cams, and other small parts. Properties include low friction, high wear resistance, and ease of fabrication. Meets FDA standards and is USDA approved. It is not UV stabilized.

NYLON With ease of fabrication and many superior properties, Nylon has found wide application for bearings, bushings, washers, seals, gears, guides, rollers, wear plates, fasteners, insulators, forming dies, sleeves, liners, cooling fans, and many other parts. Properties include high wear and abrasion resistance, with low coefficient of friction, high strength to weight ratio. It has corrosion resistant to alkalis and organic chemicals. It is non-abrasive to other material, with noise dampening characteristics, also good electrical insulator. It is not UV stabilized, but it is USDA and FDA compliant. The temp range is -40 deg F to 225 deg F.

McMaster has the nylon in 1"x 1/4" and priced per foot. Darn shipping was almost as much, sigh. A little milling to fit, some drilling, and I am way happy with the results. Doubt I'll wear them out, probably cannibalize the printer to build another before that as this is my first 3d printer.

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 04:51PM |

Registered: 9 years ago Posts: 25 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 06:03PM |

Registered: 9 years ago Posts: 67 |

Quote

3D52

Quote

llamatrails

These slides don't need any lube at all.

Rick

Rick those slides are really nice, I have a cnc machine as well. What would it take to get you to share your files?

Steve

It was so simple that I didn't use the cnc, just manually milled them. Printing the carriages was the difficult part, I had to baby sit the printer to keep the linear slides sliding. Uggghhh.

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 06, 2015 07:21PM |

Registered: 9 years ago Posts: 25 |

Quote

llamatrails

Quote

3D52

Quote

llamatrails

These slides don't need any lube at all.

Rick

Rick those slides are really nice, I have a cnc machine as well. What would it take to get you to share your files?

Steve

It was so simple that I didn't use the cnc, just manually milled them. Printing the carriages was the difficult part, I had to baby sit the printer to keep the linear slides sliding. Uggghhh.

Rick

When I looked at the photos the white carriages looked like HDPE but it's not it's printed, I found it on thingiverse, cool beans. Those linear slides are a pain in the butt...

Steve

Edited 1 time(s). Last edit at 11/06/2015 07:22PM by 3D52.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 07, 2015 12:51AM |

Registered: 8 years ago Posts: 4 |

Had my Rev A for a while and everything calibrated nicely ... but always noticed these weird jolts on my extruder - thought in the beginning these were actually retracts but checked the code - no retract commands ...

Finally came across somebody with a Rostock Max mentioning something similar - linked to #define AXIS_RELATIVE_MODES {false, false, false, false} in Configuration_adv.h

Experimentally changed mine to #define AXIS_RELATIVE_MODES {false, false, false, true} and oh what a difference! While my prints were very precise I apparently did not get consistent feed rates which was definitely noticeable

on my translucent PLA prints. My red translucent prints now look like top grade ahi sashimi, while before they looked like, well, cheap plastic

It makes sense to me that extruder mode should be relative feeds instead of absolute - so if for some reason feed gets back logged the error is dropped and it is not constantly fighting to catch up (my interpretation)...

Any comments or observations welcome. And if you are running with folgertech firmware defaults you might want to try the new settings. Really surprised I did not find more hits when googling the topic.

Jens

PS: so much prefer to manually level with some simple leveling screws vs auto. Still looking for a good more advanced leveling mechanisms - any leads?

Finally came across somebody with a Rostock Max mentioning something similar - linked to #define AXIS_RELATIVE_MODES {false, false, false, false} in Configuration_adv.h

Experimentally changed mine to #define AXIS_RELATIVE_MODES {false, false, false, true} and oh what a difference! While my prints were very precise I apparently did not get consistent feed rates which was definitely noticeable

on my translucent PLA prints. My red translucent prints now look like top grade ahi sashimi, while before they looked like, well, cheap plastic

It makes sense to me that extruder mode should be relative feeds instead of absolute - so if for some reason feed gets back logged the error is dropped and it is not constantly fighting to catch up (my interpretation)...

Any comments or observations welcome. And if you are running with folgertech firmware defaults you might want to try the new settings. Really surprised I did not find more hits when googling the topic.

Jens

PS: so much prefer to manually level with some simple leveling screws vs auto. Still looking for a good more advanced leveling mechanisms - any leads?

Sorry, only registered users may post in this forum.