Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 25, 2015 03:04PM |

Registered: 8 years ago Posts: 28 |

Quote

fattmann

Whoa. Good to know. My buddy swears by Hatchbox, so that's what I've stared off with. Will keep that in mind when performing further tests.

It is more of an issue regarding your particular bowden setup, speed, temp, retraction, etc, as stated before. I can personally vouch for Hatchbox (as many others can, I am sure). For straight PLA/ABS I buy theirs exclusively and have only ever had one bad roll (inconsistent diameter halfway through a .5kg roll of translucent red PLA) out of 30 or so. Have not tried any of their specialty filaments. I tend to go towards higher end sources for those. In my experience with direct drive, speed and temp are the most important, with retraction being farther down the checklist. With bowden, retraction is #1 with temp and speed close on its heels. On my Folger Kossel I never even installed the stock extruder. I had printed a nice bowden wade style geared extruder for my cartesian printer, but never could get it dialed in. String city and oozy plastic everywhere. Nothing seemed to make a difference. That same extruder on the kossel works like a champ with almost no work to dial it in. Odd.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 25, 2015 03:41PM |

Registered: 8 years ago Posts: 432 |

Quote

Vlerherg

It is more of an issue regarding your particular bowden setup, speed, temp, retraction, etc, as stated before. I can personally vouch for Hatchbox (as many others can, I am sure). For straight PLA/ABS I buy theirs exclusively and have only ever had one bad roll (inconsistent diameter halfway through a .5kg roll of translucent red PLA) out of 30 or so. Have not tried any of their specialty filaments. I tend to go towards higher end sources for those. In my experience with direct drive, speed and temp are the most important, with retraction being farther down the checklist. With bowden, retraction is #1 with temp and speed close on its heels. On my Folger Kossel I never even installed the stock extruder. I had printed a nice bowden wade style geared extruder for my cartesian printer, but never could get it dialed in. String city and oozy plastic everywhere. Nothing seemed to make a difference. That same extruder on the kossel works like a champ with almost no work to dial it in. Odd.

When you get a chance, can you please print this model with hatchbox PLA. On your photos I see that your extruder printed with the same Silver hatchbox PLA. Geared extruders usually slower that direct, probably slower retraction speed will work for me, I'll check it.

Edited 1 time(s). Last edit at 11/25/2015 03:41PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 25, 2015 08:57PM |

Registered: 8 years ago Posts: 432 |

Quote

Vlerherg

Quote

fattmann

Whoa. Good to know. My buddy swears by Hatchbox, so that's what I've stared off with. Will keep that in mind when performing further tests.

It is more of an issue regarding your particular bowden setup, speed, temp, retraction, etc, as stated before. I can personally vouch for Hatchbox (as many others can, I am sure). For straight PLA/ABS I buy theirs exclusively and have only ever had one bad roll (inconsistent diameter halfway through a .5kg roll of translucent red PLA) out of 30 or so. Have not tried any of their specialty filaments. I tend to go towards higher end sources for those. In my experience with direct drive, speed and temp are the most important, with retraction being farther down the checklist. With bowden, retraction is #1 with temp and speed close on its heels. On my Folger Kossel I never even installed the stock extruder. I had printed a nice bowden wade style geared extruder for my cartesian printer, but never could get it dialed in. String city and oozy plastic everywhere. Nothing seemed to make a difference. That same extruder on the kossel works like a champ with almost no work to dial it in. Odd.

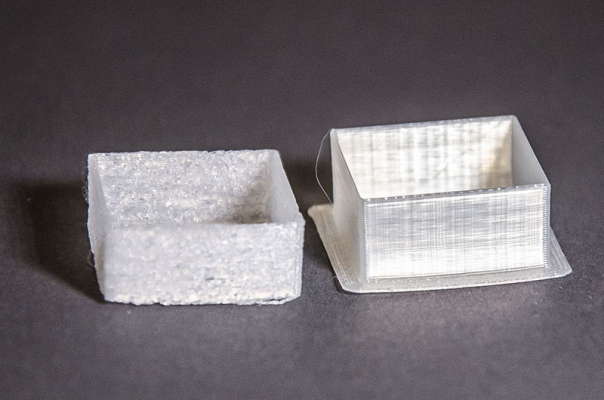

No, I don't like how this Hatchbox Silver PLA prints small objects. My Moon Wihte FolgerTech PLA prints are much cleaner and the roll is two times (!) cheaper. I reduced retraction speed twice - to 30mm/s and temperature to 175C - still visible blobs and strings:

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 29, 2015 08:50PM |

Registered: 8 years ago Posts: 90 |

Quote

paul_delta

No, I don't like how this Hatchbox Silver PLA prints small objects. My Moon Wihte FolgerTech PLA prints are much cleaner and the roll is two times (!) cheaper. I reduced retraction speed twice - to 30mm/s and temperature to 175C - still visible blobs and strings:

[attachment 66587 IMG_20151125_204705643.jpg]

Interesting. I don't get any of the blobbing, but I definitely get the stringing. Next color I buy I will have to try Folger Tech's. Thanks again.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 29, 2015 09:11PM |

Registered: 8 years ago Posts: 432 |

Quote

fattmann

Quote

paul_delta

No, I don't like how this Hatchbox Silver PLA prints small objects. My Moon Wihte FolgerTech PLA prints are much cleaner and the roll is two times (!) cheaper. I reduced retraction speed twice - to 30mm/s and temperature to 175C - still visible blobs and strings:

[attachment 66587 IMG_20151125_204705643.jpg]

Interesting. I don't get any of the blobbing, but I definitely get the stringing. Next color I buy I will have to try Folger Tech's. Thanks again.

I'm building filament dehumidifier and will try to dry Hatchbox roll before printing. Probably it was not so dry out of the box, from the factory.

PS: I tried Folgertech Nylon yesterday - it's unusable out of the box, not dry - even vacuum-packed with silicagel. Actually, this is the reason why I started to build filament dehumidifier box.

Edited 1 time(s). Last edit at 11/29/2015 09:12PM by paul_delta.

|

Anonymous User

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 30, 2015 03:27AM |

Quote

fattmann

Quote

paul_delta

No, I don't like how this Hatchbox Silver PLA prints small objects. My Moon Wihte FolgerTech PLA prints are much cleaner and the roll is two times (!) cheaper. I reduced retraction speed twice - to 30mm/s and temperature to 175C - still visible blobs and strings:

[attachment 66587 IMG_20151125_204705643.jpg]

Interesting. I don't get any of the blobbing, but I definitely get the stringing. Next color I buy I will have to try Folger Tech's. Thanks again.

Reducing temperature might have been the wrong way :-)

I had to fight nearly two complete rolls of PLA, until I managed to get rid of the strings...

In earlier days, PLA was usually printed about 185°C - nowadys many manufacturer advise to print their PLA at about 210-230°C, because it is made in another way / with some special additives...

I went up till 225°C - strings like a big spider web... 230°C - and the strings are gone.... no other changed parameters....

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 30, 2015 02:24PM |

Registered: 8 years ago Posts: 107 |

I can't seem to get ABS parts to print out without curling up on me.

I tried:

Glass with purple Elmers glue

Glass with an ABS slurry

ABS slurry directly on the aluminum heat bed

7mm wide brims

2 layer thick rafts

Nothing seems to help. Will the temperature of the bed directly effect this? I can set my bed to 110°C and eventually it will get there, but as soon as I start printing (no matter what temperature I set the bed at) the temp f the bed drops to the mid 90°'s C. During printing it never really gets above 96°C.

Is this drop in temperature because the motors are pulling too much juice from the power supply and it can't keep up? Is this why the ABS prints keep pulling up? I'm getting fairly frustrated because I can't print anything larger than about 1" long before I start having issues. Any help would be greatly appreciated. Thanks.

I tried:

Glass with purple Elmers glue

Glass with an ABS slurry

ABS slurry directly on the aluminum heat bed

7mm wide brims

2 layer thick rafts

Nothing seems to help. Will the temperature of the bed directly effect this? I can set my bed to 110°C and eventually it will get there, but as soon as I start printing (no matter what temperature I set the bed at) the temp f the bed drops to the mid 90°'s C. During printing it never really gets above 96°C.

Is this drop in temperature because the motors are pulling too much juice from the power supply and it can't keep up? Is this why the ABS prints keep pulling up? I'm getting fairly frustrated because I can't print anything larger than about 1" long before I start having issues. Any help would be greatly appreciated. Thanks.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level November 30, 2015 03:10PM |

Registered: 8 years ago Posts: 1 |

Hi everyone I'm new to the forum and I have some questions about the fg 2020 delta kit. O built the kit and it's all together but I burnt out my first mega by having the endstops in the wrong way so I got a new board. Now I'm trying to set it up and my z tower will not move I've tried everything from swapping drivers, firmwares, wires and motors. I used my multi meter on the motor leads and there is nothing being sent to the motor could I have burnt out the ramps board as Well? Any help is greatly appreciated I've had this for over 2 and half weeks and would love to start printing. Also the LCD goes dim when the x and y towers move.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 01, 2015 12:03PM |

Registered: 8 years ago Posts: 432 |

Test drive review of Folger Tech Nylon

Recently I bought a roll of Nylon from Folger Tech. Right out of the box the print quality was absolutely unacceptable, a lot of moist, steam and popping sound. Looks like it was packed in this condition because the bag was vacuumed with silicagel. I dried couple of meters in convection oven for 2 hours at 310F (154C) and printed calibration cube again. Here is the photo before and after drying:

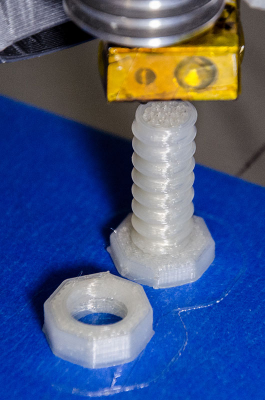

I had to reduce extrusion to 0.83 to get the right width. The temperature was set to 245C and 70C for the bed. Nylon sticks to blue tape very well, but it warps so strong that for some parts may need additional measures like glue stick on the glass, etc.

After 20 hours at 45% humidity I printed this dual bolt and nut and the Nylon was still dry, I heard only two pops during printing.

Out of the printer the parts are brittle and need some time to restore water balance.

Update: I printed calibration cube again with layer height 0.25 and nylon started popping, so it looks like 20 hours is max usable time after drying when humidity is around 40%-50%. The higher the layer, the more visible imperfections because of steam bubbles.

Edited 1 time(s). Last edit at 12/01/2015 12:51PM by paul_delta.

Recently I bought a roll of Nylon from Folger Tech. Right out of the box the print quality was absolutely unacceptable, a lot of moist, steam and popping sound. Looks like it was packed in this condition because the bag was vacuumed with silicagel. I dried couple of meters in convection oven for 2 hours at 310F (154C) and printed calibration cube again. Here is the photo before and after drying:

I had to reduce extrusion to 0.83 to get the right width. The temperature was set to 245C and 70C for the bed. Nylon sticks to blue tape very well, but it warps so strong that for some parts may need additional measures like glue stick on the glass, etc.

After 20 hours at 45% humidity I printed this dual bolt and nut and the Nylon was still dry, I heard only two pops during printing.

Out of the printer the parts are brittle and need some time to restore water balance.

Update: I printed calibration cube again with layer height 0.25 and nylon started popping, so it looks like 20 hours is max usable time after drying when humidity is around 40%-50%. The higher the layer, the more visible imperfections because of steam bubbles.

Edited 1 time(s). Last edit at 12/01/2015 12:51PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 01, 2015 08:16PM |

Registered: 8 years ago Posts: 432 |

Try this solution: [www.thingiverse.com]

Quote

Legrand

I can't seem to get ABS parts to print out without curling up on me.

I tried:

Glass with purple Elmers glue

Glass with an ABS slurry

ABS slurry directly on the aluminum heat bed

7mm wide brims

2 layer thick rafts

Nothing seems to help. Will the temperature of the bed directly effect this? I can set my bed to 110°C and eventually it will get there, but as soon as I start printing (no matter what temperature I set the bed at) the temp f the bed drops to the mid 90°'s C. During printing it never really gets above 96°C.

Is this drop in temperature because the motors are pulling too much juice from the power supply and it can't keep up? Is this why the ABS prints keep pulling up? I'm getting fairly frustrated because I can't print anything larger than about 1" long before I start having issues. Any help would be greatly appreciated. Thanks.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 01, 2015 08:20PM |

Registered: 8 years ago Posts: 432 |

PS: you may start from Elmers stick on blue tape. And let it dry heating the bed 50C.

Edited 1 time(s). Last edit at 12/01/2015 08:21PM by paul_delta.

Quote

paul_delta

Try this solution: [www.thingiverse.com]

Quote

Legrand

I can't seem to get ABS parts to print out without curling up on me.

I tried:

Glass with purple Elmers glue

Glass with an ABS slurry

ABS slurry directly on the aluminum heat bed

7mm wide brims

2 layer thick rafts

Nothing seems to help. Will the temperature of the bed directly effect this? I can set my bed to 110°C and eventually it will get there, but as soon as I start printing (no matter what temperature I set the bed at) the temp f the bed drops to the mid 90°'s C. During printing it never really gets above 96°C.

Is this drop in temperature because the motors are pulling too much juice from the power supply and it can't keep up? Is this why the ABS prints keep pulling up? I'm getting fairly frustrated because I can't print anything larger than about 1" long before I start having issues. Any help would be greatly appreciated. Thanks.

Edited 1 time(s). Last edit at 12/01/2015 08:21PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 02, 2015 06:23AM |

Registered: 8 years ago Posts: 107 |

Thanks Paul. You don't think that the curling has anything to do with the heated bed not being able to stay at temperature? It's a simple matter of adhesion?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 02, 2015 07:41AM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

Thanks Paul. You don't think that the curling has anything to do with the heated bed not being able to stay at temperature? It's a simple matter of adhesion?

I think that adhesion is the reason. Try to clean your glass with alcohol and then with white vinegar. But you may also try to stabilize the bed temperature, to prevent temperature contractions - insulating bottom of aluminum plate. Some people use cork and foil sandwich. BTW it's normal to reduce the bed temperature after first layers. Does it wrap on just one side? If so - this is the bed leveling and first layer problem.

Edited 1 time(s). Last edit at 12/02/2015 07:43AM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 02, 2015 10:47AM |

Registered: 8 years ago Posts: 107 |

OK so I switched over to 3mm PLA filament and the blue tape. Blue tape works great.

New problem: After switching to the thicker material, my prints seem to be starved for material now. The extruder is skipping.

I switched the settings in slicer to 3mm and am running at a 210°C head temp to try to liquefy enough material so that it will extrude properly. I believe that the tip that folger supplied with the 3mm hot end is 0.3mm.

Should I drill the tip larger? I can't think why else the extruder would be skipping on the material so much now. It works fine when the tube is separated from the head.

New problem: After switching to the thicker material, my prints seem to be starved for material now. The extruder is skipping.

I switched the settings in slicer to 3mm and am running at a 210°C head temp to try to liquefy enough material so that it will extrude properly. I believe that the tip that folger supplied with the 3mm hot end is 0.3mm.

Should I drill the tip larger? I can't think why else the extruder would be skipping on the material so much now. It works fine when the tube is separated from the head.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 02, 2015 11:00AM |

Registered: 8 years ago Posts: 90 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 02, 2015 04:57PM |

Registered: 9 years ago Posts: 67 |

Quote

fattmann

Quote

Legrand

I believe that the tip that folger supplied with the 3mm hot end is 0.3mm.

I've wondered this too, what is the size of the Folger tip? Have they changed it from Rev A to Rev B?

Caliper, caliper, caliper.

Extrude some with the hotend way above the heatbed to let it dangle when extruded. Turn off the heat to the hotend, and measure the diameter of the cooled, extruded filament with the caliper. Now you know for sure what the nozzle diameter is.

As for the setting to put into slic3r, measure the filament off the roll at a few spots to get an average diameter. Just because you bought a 3mm spool doesn't mean that the filament really is 3mm. For example, my 1.75mm PLA is 1.72mm on one roll and 1.71mm on another.

Rick

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 07:59AM |

Registered: 8 years ago Posts: 107 |

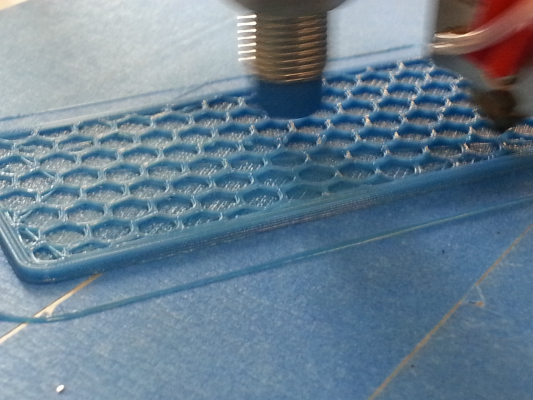

So, here's what I'm getting with the 3mm PLA filament running at 210°C. I slowed the print speed down to 75, which would have been equivelant to an infill rate of 60mm/sec. Looks like garbage.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 08:48AM |

Registered: 8 years ago Posts: 432 |

Print will look like this when the speed is too high, temperature is too low or extrusion rate is too low. You say the speed is 60mm/s, so it should be OK, the temperature looks OK too (I print PLA at 180C, actually), so you have underextrusion. The nozzle size in slicer is wrong, filament diameter in slicer is wrong or you have to calibrate your extruder steps.

Quote

Legrand

So, here's what I'm getting with the 3mm PLA filament running at 210°C. I slowed the print speed down to 75, which would have been equivelant to an infill rate of 60mm/sec. Looks like garbage.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 09:16AM |

Registered: 8 years ago Posts: 107 |

Filament diameter was set to actual diameter of 2.85mm. Extruder has been calibrated, I even double checked it after moving to the 3mm filament.

Regarding the nozzle diameter: I tried to read up on "3mm pla print speed" via google and came across an old thread (3mm vs. 1.75mm filament) that stated that (in a nutshell) there could be an issue with the motor/gearing not being up to the task. I think that either this is the problem, or the hot end can't melt the plastic fast enough.

I drilled out the tip to .45mm but the extruder is still "skipping" on the filament. It's trying to push the material in, but the extruder gear ends up slipping. If I push the filament in, it helps some, but it takes a lot of force to push it and it still slips now and then.I will also say that the very beginning of the print is fine so it seems to me that while the printer is sitting at 210°C waiting to start the print, it has time to melt enough of the plastic but then once it gets going, it either can't melt it fast enough, or the extruder setup isn't capable of creating the force required to push in the filament.

I'm going to set the print speed back to 25% and see what happens.- UPDATE: Still slipping even printing at 25%

Is anyone else successfully running 3mm filament on this printer?

Regarding the nozzle diameter: I tried to read up on "3mm pla print speed" via google and came across an old thread (3mm vs. 1.75mm filament) that stated that (in a nutshell) there could be an issue with the motor/gearing not being up to the task. I think that either this is the problem, or the hot end can't melt the plastic fast enough.

I drilled out the tip to .45mm but the extruder is still "skipping" on the filament. It's trying to push the material in, but the extruder gear ends up slipping. If I push the filament in, it helps some, but it takes a lot of force to push it and it still slips now and then.I will also say that the very beginning of the print is fine so it seems to me that while the printer is sitting at 210°C waiting to start the print, it has time to melt enough of the plastic but then once it gets going, it either can't melt it fast enough, or the extruder setup isn't capable of creating the force required to push in the filament.

I'm going to set the print speed back to 25% and see what happens.- UPDATE: Still slipping even printing at 25%

Is anyone else successfully running 3mm filament on this printer?

Quote

paul_delta

Print will look like this when the speed is too high, temperature is too low or extrusion rate is too low. You say the speed is 60mm/s, so it should be OK, the temperature looks OK too (I print PLA at 180C, actually), so you have underextrusion. The nozzle size in slicer is wrong, filament diameter in slicer is wrong or you have to calibrate your extruder steps.

Quote

Legrand

So, here's what I'm getting with the 3mm PLA filament running at 210°C. I slowed the print speed down to 75, which would have been equivelant to an infill rate of 60mm/sec. Looks like garbage.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 09:23AM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

it either can't melt it fast enough, or the extruder setup isn't capable of creating the force required to push in the filament.

In this case you should hear extruder gear skipping the filament. I experience this problem with 1.75 0.4 nozzle after 120mm/s.

If you still use original direct extruder - think about geared one. You need much more power to push 3mm filament.

Edited 1 time(s). Last edit at 12/03/2015 09:23AM by paul_delta.

|

Anonymous User

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 11:28AM |

Quote

paul_delta

.... You say the speed is 60mm/s, so it should be OK, the temperature looks OK too (I print PLA at 180C, actually), so you have underextrusion. The nozzle size in slicer is wrong, filament diameter in slicer is wrong or you have to calibrate your extruder steps.

Not neccesarrily correct.

In earlier days PLA was always printed around 185°C; Nowadays - especially in Europe - you only get PLA to print at 210-230°C!

I print PLA at 230°C, 25mm/sec - not more possible with my chineese hotend...

EDIT Nozzle 0,4mm, Layer 0,2mm

Edited 2 time(s). Last edit at 12/03/2015 11:30AM by Sir_Death.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 01:00PM |

Registered: 8 years ago Posts: 107 |

I had some problems getting above 210°C due to the hot end being too close to the circular radiator and fan (after I switched over to the 3mm head) so I created a small aluminum "foil" shield to keep the "wind" away form the hot end and am now printing at 230°C.

Settings:

230°C Head

70°C Bed

3 mm PLA filament (from RS, good material but was purchased thru Allied electronics, don't buy from them, their deliveries take forever)

0.45 mm nozzle

0.3 mm layer

80 mm/sec infill

60 mm/sec perimeter

I may try a smaller nozzle now with the higher temperature for greater accuracy after I print out a few things that I need really badly.

QUESTION: Since I've never printed anything sucessfully in PLA, how do I get this thing off the bed without warping the hell out of it? Do I just let the bed completely cool down and then lift up the tape?

Settings:

230°C Head

70°C Bed

3 mm PLA filament (from RS, good material but was purchased thru Allied electronics, don't buy from them, their deliveries take forever)

0.45 mm nozzle

0.3 mm layer

80 mm/sec infill

60 mm/sec perimeter

I may try a smaller nozzle now with the higher temperature for greater accuracy after I print out a few things that I need really badly.

QUESTION: Since I've never printed anything sucessfully in PLA, how do I get this thing off the bed without warping the hell out of it? Do I just let the bed completely cool down and then lift up the tape?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 02:07PM |

Registered: 8 years ago Posts: 188 |

Quote

Legrand

QUESTION: Since I've never printed anything sucessfully in PLA, how do I get this thing off the bed without warping the hell out of it? Do I just let the bed completely cool down and then lift up the tape?

You can use like a scraper to help peel it off when the bed is cooler. I have this: Magical Useful Item

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 02:47PM |

Registered: 8 years ago Posts: 432 |

Here is my video. I've just printed 20x20 model using stock FolgerTech rev.B Kossel, 04mm nozzle, Black FolgerTech PLA at 180C, bed 50C, speed 120mm/s infill, outline 80mm/s, 0.3mm layer.

I interrupted it in the middle. With DYI active cooling I posted recently.

120mm/s Kossel video

Update: the measured actual speed was around 60mm/s, going to investigate this issue.

Edited 5 time(s). Last edit at 12/03/2015 05:04PM by paul_delta.

I interrupted it in the middle. With DYI active cooling I posted recently.

120mm/s Kossel video

Update: the measured actual speed was around 60mm/s, going to investigate this issue.

Quote

Sir_Death

Quote

paul_delta

.... You say the speed is 60mm/s, so it should be OK, the temperature looks OK too (I print PLA at 180C, actually), so you have underextrusion. The nozzle size in slicer is wrong, filament diameter in slicer is wrong or you have to calibrate your extruder steps.

Not neccesarrily correct.

In earlier days PLA was always printed around 185°C; Nowadays - especially in Europe - you only get PLA to print at 210-230°C!

I print PLA at 230°C, 25mm/sec - not more possible with my chineese hotend...

EDIT Nozzle 0,4mm, Layer 0,2mm

Edited 5 time(s). Last edit at 12/03/2015 05:04PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 03:49PM |

Registered: 8 years ago Posts: 432 |

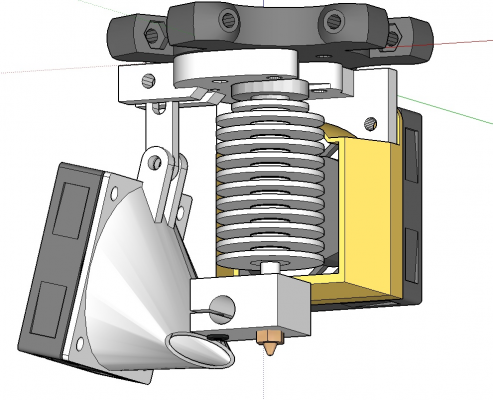

I had the same problem. With original fan mount it's hard to get stable temperature above 200C. I designed this sleeve (on the picture - the yellow one), just print it and put between the fan and fan mount: [www.thingiverse.com]

Edited 2 time(s). Last edit at 12/03/2015 03:51PM by paul_delta.

Quote

Legrand

I had some problems getting above 210°C due to the hot end being too close to the circular radiator and fan (after I switched over to the 3mm head) so I created a small aluminum "foil" shield to keep the "wind" away form the hot end and am now printing at 230°C.

Edited 2 time(s). Last edit at 12/03/2015 03:51PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 03:52PM |

Registered: 10 years ago Posts: 14,672 |

Quote

paul_delta

Here is my video. I've just printed 20x20 model using stock FolgerTech rev.B Kossel, 04mm nozzle, Black FolgerTech PLA at 180C, bed 50C, speed 120mm/s infill, outline 80mm/s, 0.3mm layer.

I interrupted it in the middle. With DYI active cooling I posted recently.

120mm/s Kossel video

Assuming the video is running at normal speed, I think it's printing at more like 60mm/sec. You can tell by the time it takes to print the long diagonal. It may be that the print speed is acceleration-limited, and you need to print a much larger piece to reach 120mm/sec.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 04:01PM |

Registered: 8 years ago Posts: 432 |

You are right, I'll try to create and print 120mmx10mm long piece.

Quote

dc42

Quote

paul_delta

Here is my video. I've just printed 20x20 model using stock FolgerTech rev.B Kossel, 04mm nozzle, Black FolgerTech PLA at 180C, bed 50C, speed 120mm/s infill, outline 80mm/s, 0.3mm layer.

I interrupted it in the middle. With DYI active cooling I posted recently.

120mm/s Kossel video

Assuming the video is running at normal speed, I think it's printing at more like 60mm/sec. You can tell by the time it takes to print the long diagonal. It may be that the print speed is acceleration-limited, and you need to print a much larger piece to reach 120mm/sec.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 04:41PM |

Registered: 8 years ago Posts: 432 |

Interesting, 120mm long print speed is the same... the long side takes 2 sec, which is 60mm/s. The slicer says 120mm/s:

but real speed is 2 times slower. Where is the bottleneck?

but real speed is 2 times slower. Where is the bottleneck?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 03, 2015 05:02PM |

Registered: 8 years ago Posts: 432 |

OK, I used the LCD menu and increased the speed multiplier to 180%, so the long side print speed was around 108-110mm/s. Looks like it's hardware limit for this printer, after this limit it starts loosing steps and head goes in random direction.

Edited 1 time(s). Last edit at 12/03/2015 05:07PM by paul_delta.

Edited 1 time(s). Last edit at 12/03/2015 05:07PM by paul_delta.

|

Anonymous User

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 04, 2015 03:04AM |

Quote

Legrand

Settings:

230°C Head

70°C Bed

3 mm PLA filament (from RS, good material but was purchased thru Allied electronics, don't buy from them, their deliveries take forever)

0.45 mm nozzle

0.3 mm layer

80 mm/sec infill

60 mm/sec perimeter

QUESTION: Since I've never printed anything sucessfully in PLA, how do I get this thing off the bed without warping the hell out of it? Do I just let the bed completely cool down and then lift up the tape?

As you are printing PLA with Heatbed on:

I print PLA directly on the Aluminium Heatbed at 60°C - no tape, no glue, no nothing.... only clean the heatbed once a week with glass-cleaner...

After print finished let cool down the heatbed to 30° - the printed object does a crackling Sound and self-deploys...

Edited 3 time(s). Last edit at 12/04/2015 03:06AM by Sir_Death.

Sorry, only registered users may post in this forum.