Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 08, 2015 02:14PM |

Registered: 8 years ago Posts: 90 |

Quote

paul_delta

I'd suggest to run PID calibration procedure after fan modification. The PID coefficient changes significantly after installation and re-calibration helps to make the temperature as stable as possible.

Interesting, haven't heard of the PID calibration before, will look into it.

Quote

paul_delta

I tried this fan duct before I decided to make my own. It doesn't work - the draft from open door works better smiling smiley

Lol, if anything I as having trouble with it working too good. The PLA would solidify before even adhering to the bed. Either way, I shall be trying another route.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 08, 2015 02:19PM |

Registered: 8 years ago Posts: 432 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 08, 2015 02:28PM |

Registered: 8 years ago Posts: 90 |

Quote

paul_delta

Quote

fattmann

The PLA would solidify before even adhering to the bed. Either way, I shall be trying another route.

Use your slicer to turn fan On only after N layers.

On my ever growing list. I have it hardwired as per the build manual, and haven't gotten it routed through the RAMPS board yet.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 08, 2015 02:36PM |

Registered: 8 years ago Posts: 432 |

I mean the filament cooler, not the extruder fan. Extruder fan must be on all the time (or connect it to pin 9 and set firmware to turn it on if temperature is higher than 50C).

Slicer usually manages Filament cooler speed using M106 command.

Actually, RAPMS can control only one fan via pin 9 (8 and 10 we use for heat bed and extruder). You can add your own additional fan control using MOSFET and resistor or just buy the fan extender for RAMPS. It's around $6 and able to control two fans.

Edited 3 time(s). Last edit at 12/08/2015 02:42PM by paul_delta.

Slicer usually manages Filament cooler speed using M106 command.

Actually, RAPMS can control only one fan via pin 9 (8 and 10 we use for heat bed and extruder). You can add your own additional fan control using MOSFET and resistor or just buy the fan extender for RAMPS. It's around $6 and able to control two fans.

Quote

fattmann

Quote

paul_delta

Quote

fattmann

The PLA would solidify before even adhering to the bed. Either way, I shall be trying another route.

Use your slicer to turn fan On only after N layers.

On my ever growing list. I have it hardwired as per the build manual, and haven't gotten it routed through the RAMPS board yet.

Edited 3 time(s). Last edit at 12/08/2015 02:42PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 12, 2015 06:28PM |

Registered: 8 years ago Posts: 432 |

Some of us cover the aluminum bed with glass or mirrors. Here is the adapter I made to convert inductive probe to non-inductive.

It works pretty well, no precision degradation at all. Here is the Thingiverse with files : [www.thingiverse.com]

Don't forget to adjust the z-probe height in firmware. I had to make another one

Edited 1 time(s). Last edit at 12/12/2015 06:39PM by paul_delta.

It works pretty well, no precision degradation at all. Here is the Thingiverse with files : [www.thingiverse.com]

Don't forget to adjust the z-probe height in firmware. I had to make another one

Edited 1 time(s). Last edit at 12/12/2015 06:39PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 12, 2015 10:35PM |

Registered: 8 years ago Posts: 90 |

How often are people having to recalibrate their Deltas?

I had it dialed in, and printed a few beautiful pieces last night, was really happy with it. Tonight I fire it up (haven't moved the machine at all, or changed any settings) and went to print the exact same file I printed last night- and it nosedives into the bed on the X+ side.... It seems like I go through this every week. I'll get a day, maybe two if I'm lucky, of good printing, then I have to relevel the bed/calibrate it with all new Z home and smooth rod offset values, which takes for ever to get dialed in.

Seems really odd, and not something that should happen. For the record I'm not using EEPROM, I can't get it calibrated with that enabled even remotely.

I had it dialed in, and printed a few beautiful pieces last night, was really happy with it. Tonight I fire it up (haven't moved the machine at all, or changed any settings) and went to print the exact same file I printed last night- and it nosedives into the bed on the X+ side.... It seems like I go through this every week. I'll get a day, maybe two if I'm lucky, of good printing, then I have to relevel the bed/calibrate it with all new Z home and smooth rod offset values, which takes for ever to get dialed in.

Seems really odd, and not something that should happen. For the record I'm not using EEPROM, I can't get it calibrated with that enabled even remotely.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 13, 2015 03:51AM |

Registered: 10 years ago Posts: 14,672 |

It sounds to me that either something in your build is loose, or your homing switches are drifting seriously. I don't know the homing switch arrangement on the Folger. Is it the traditional arrangement whereby the carriages drive into the switches, or something else?

I recalibrate each time I turn the printer on, and when swapping bed plates - not because I have to, but because it takes only 20 seconds. It is not much slower than using G30 to get an accurate Z=0 height, which is what I would do otherwise.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I recalibrate each time I turn the printer on, and when swapping bed plates - not because I have to, but because it takes only 20 seconds. It is not much slower than using G30 to get an accurate Z=0 height, which is what I would do otherwise.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 13, 2015 08:24AM |

Registered: 8 years ago Posts: 188 |

So I just got around to attempting to calibrate it for the first time. I haven't had much free time, so I'm making use of it now. Going through the calibration as per what the instructions say, using the marlin firmware, and when I home my printer, it goes down instead of up. Which variable do I change to fix this problem?

Pual_delta, That's a nice looking probe

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

Pual_delta, That's a nice looking probe

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 13, 2015 07:35PM |

Registered: 8 years ago Posts: 432 |

The mounts provided in my rev.B are crappy. The standard makerbot red endstop just doesn't want to attach tight to the mount because of solder bumps. It needs a hole that will adapt these bumps. Going to create one soon.

Quote

dc42

It sounds to me that either something in your build is loose, or your homing switches are drifting seriously. I don't know the homing switch arrangement on the Folger. Is it the traditional arrangement whereby the carriages drive into the switches, or something else?

I recalibrate each time I turn the printer on, and when swapping bed plates - not because I have to, but because it takes only 20 seconds. It is not much slower than using G30 to get an accurate Z=0 height, which is what I would do otherwise.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 13, 2015 07:44PM |

Registered: 8 years ago Posts: 432 |

I suggest to use nice online calibrator by dc42, you see the URL in dc42 signature. This is online JS implementation of algorithm that David uses in his ReprapFirmware fork. I was able to improve my bed leveling in just one shot. But to get great results you have to mount your probe under the nozzle, to get X0 Y0, without offset. I'm going to publish the magnetic mount that I designed recently to check how the probe offset affects the precision. It does affect! The X/Y offset of original mount screws the idea of calibration and just pain in the ass. I was not able to calibrate my Kossel with this original mount for good results. With zero offset mount I did it pretty fast. And David's calibrator does it like 1-2-3.

Quote

Captain_Tim

So I just got around to attempting to calibrate it for the first time. I haven't had much free time, so I'm making use of it now. Going through the calibration as per what the instructions say, using the marlin firmware, and when I home my printer, it goes down instead of up. Which variable do I change to fix this problem?

Pual_delta, That's a nice looking probe

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 13, 2015 11:52PM |

Registered: 8 years ago Posts: 432 |

Here is the magnetic mount for inductive probe that holds the probe right under the extruder tip with zero X-Y offset. Now all my z-probe readings make sense and bed leveling works as expected.

[www.thingiverse.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 12/14/2015 01:48PM by paul_delta.

[www.thingiverse.com]

[www.youtube.com]

Edited 1 time(s). Last edit at 12/14/2015 01:48PM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 14, 2015 09:39AM |

Registered: 8 years ago Posts: 107 |

Fattman (and Tim):

I decided to manually calibrated my Folger Delta using springs since I had the same problem Tim is having, namely that I ended up with one of two scenarios depending on how I set the "inverting axis" flags. Either the head goes up when calibrating instead of down and it would home correctly, or vice versa: the printer would calibrate correctly but the head would crash into the plate when homing. I never was able to figure out why Tim, sorry.

I will say that since I completed the build and added springs under each of the three bed screws a few weeks ago, I've never had to touch it again except when I rebuilt the center portion using an aluminum extruder mount instead of the printed one. I used fairly rigid springs and even when I have to crank on the bed to remove a part, it is still level and my prints turn out fine.

I decided to manually calibrated my Folger Delta using springs since I had the same problem Tim is having, namely that I ended up with one of two scenarios depending on how I set the "inverting axis" flags. Either the head goes up when calibrating instead of down and it would home correctly, or vice versa: the printer would calibrate correctly but the head would crash into the plate when homing. I never was able to figure out why Tim, sorry.

I will say that since I completed the build and added springs under each of the three bed screws a few weeks ago, I've never had to touch it again except when I rebuilt the center portion using an aluminum extruder mount instead of the printed one. I used fairly rigid springs and even when I have to crank on the bed to remove a part, it is still level and my prints turn out fine.

Quote

Captain Tim

So I just got around to attempting to calibrate it for the first time. I haven't had much free time, so I'm making use of it now. Going through the calibration as per what the instructions say, using the marlin firmware, and when I home my printer, it goes down instead of up. Which variable do I change to fix this problem?

Quote

fattmann

How often are people having to recalibrate their Deltas?

I had it dialed in, and printed a few beautiful pieces last night, was really happy with it. Tonight I fire it up (haven't moved the machine at all, or changed any settings) and went to print the exact same file I printed last night- and it nosedives into the bed on the X+ side.... It seems like I go through this every week. I'll get a day, maybe two if I'm lucky, of good printing, then I have to relevel the bed/calibrate it with all new Z home and smooth rod offset values, which takes for ever to get dialed in.

Seems really odd, and not something that should happen. For the record I'm not using EEPROM, I can't get it calibrated with that enabled even remotely.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 14, 2015 10:21AM |

Registered: 8 years ago Posts: 90 |

Quote

Legrand

Fattman (and Tim):

I decided to manually calibrated my Folger Delta using springs since I had the same problem Tim is having, namely that I ended up with one of two scenarios depending on how I set the "inverting axis" flags. Either the head goes up when calibrating instead of down and it would home correctly, or vice versa: the printer would calibrate correctly but the head would crash into the plate when homing. I never was able to figure out why Tim, sorry.

I will say that since I completed the build and added springs under each of the three bed screws a few weeks ago, I've never had to touch it again except when I rebuilt the center portion using an aluminum extruder mount instead of the printed one. I used fairly rigid springs and even when I have to crank on the bed to remove a part, it is still level and my prints turn out fine.

I have already placed the springs under the three mounting points. That did help, and I have a damn near perfectly level bed to global. The print head isn't traveling perfectly flat in the X-axis though, it is traveling on an angled plane.I think my issue is mechanical/firmware. My suspects are the end stops being sloppy (just using the mechanical arm ones that came with the kit), or sloppy joints on the arms. I was thinking of purchasing some pre-cut lengths to rule out any issues with us having cut them wrong.

As of last night I've been compensating by printing a 3 layer raft with the first layer at 150% (printing at 0.1mm). Once the actual print gets laid on the raft, it turns out pretty good- just getting past those first layers is the issue. Other wise I'm getting pretty good detail. (still can't get rid of that damn stringing problem...)

I'm also going to look at getting a glass plate that I can shim, or doing a 4-point mount on the aluminum bed. All my leveling issues are in the X-axis and I can't simply tilt the bed in that axis with the 3-point mounting. Everytime I plug in the servo to attempt to work out the auto-level, it fries stepper drivers. Has happened twice, so I said screw that thing.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 14, 2015 10:28AM |

Registered: 8 years ago Posts: 432 |

Quote

fattmann

The print head isn't traveling perfectly flat in the X-axis though, it is traveling on an angled plane.I think my issue is mechanical/firmware. My suspects are the end stops being sloppy (just using the mechanical arm ones that came with the kit), or sloppy joints on the arms. I was thinking of purchasing some pre-cut lengths to rule out any issues with us having cut them wrong.

It's easy to fix - just adjust diagonal radius for X axis. If the point near X tower is lower than the point on opposite side of the bed - increase the delta radius for X, or decrease if it's higher. For beginning - add/subtract the height difference to diagonal radius for X, rehome and check everything (all XYZ) again. Adjust, if needed. So, doing this procedure for all axis it's easy to make the bed really flat.

But I suggest to use David's calculator and make it in one shot: [escher3d.com]

Edited 3 time(s). Last edit at 12/14/2015 10:33AM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 14, 2015 11:23AM |

Registered: 8 years ago Posts: 432 |

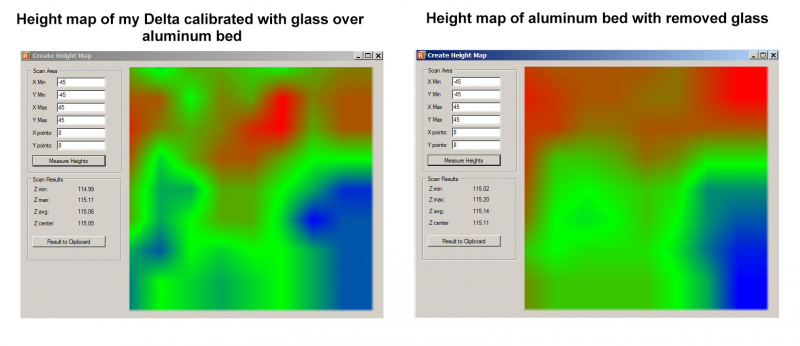

Just to show the imperfection of our world  Here is my recent height map of aluminum bed covered with 2.2mm glass. The bed was calibrated with the glass. Then I measured the height map with and without the glass. The top side of aluminum bed is slightly bent down but it looks that my 3 paper clips holding the glass are so strong that bent the glass over the aluminum plate.

Here is my recent height map of aluminum bed covered with 2.2mm glass. The bed was calibrated with the glass. Then I measured the height map with and without the glass. The top side of aluminum bed is slightly bent down but it looks that my 3 paper clips holding the glass are so strong that bent the glass over the aluminum plate.

Edited 2 time(s). Last edit at 12/14/2015 11:43AM by paul_delta.

Here is my recent height map of aluminum bed covered with 2.2mm glass. The bed was calibrated with the glass. Then I measured the height map with and without the glass. The top side of aluminum bed is slightly bent down but it looks that my 3 paper clips holding the glass are so strong that bent the glass over the aluminum plate.

Here is my recent height map of aluminum bed covered with 2.2mm glass. The bed was calibrated with the glass. Then I measured the height map with and without the glass. The top side of aluminum bed is slightly bent down but it looks that my 3 paper clips holding the glass are so strong that bent the glass over the aluminum plate.Edited 2 time(s). Last edit at 12/14/2015 11:43AM by paul_delta.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 15, 2015 03:00PM |

Registered: 8 years ago Posts: 62 |

Hey all. I'm a noob in every sense of the word. Let me know if there's a better place for me to be asking this, but I just discovered this thread, and it seemed appropriate. It may have been answered already, but I can't find it in these 77 pages.

I just assembled my first 3d printer kit. It's a Folgertech Kossel 2020 Rev B. Got everything together, all the wiring correct and connected it to my laptop. I downloaded Arduino, RepetierHost and Marlin firmware(Kossel Firmare(V2) 20tooth GT2 pulley firmware [shows up in Arduino as Marline_Delta2).

G code is a pain so far. I successfully set the Z min, so it passes the paper test at G X0 Y0 Z0. Now the instructions for how to calibrate min. x and y position are a little shoddy. My main problem (as far as I can tell) is that Repetier can't process negative values, so I can seemingly only effectively use 1/4 of my print bed space. (When I enter negative X or Y value to find X or Y min., It goes to 0. I fixed this problem when establishing Z0 by making the home/max. Z value larger to compensate for higher endstops, but I can't see how that would work for X and Y. Entering G28 homes my printer, so the endstops are engaged. That much is fine, but G29, which is supposed to activate the Z probe(?) (An inductive sensor), causes the hot end to move towards the z tower and begin climbing the towers, probing as it goes, so the z probe moves across the x/y axes as it should, but the z axis is engaged as well. The only reason I can come up with is that the command to tell the Z probe to come back down to detect the metal print bed isn't there, or something is wrong with it. So, the hot end comes down, senses the print bed, comes up, moves to the next spot and comes down to sense the print bed again, and so on-but it never comes down. Only up.

I appreciate any guidance. I'm really lost here.

Also, I installed a 3 Amp circuit breaker on the live wire, as recommended in the instructions. Is there any harm in doing that? It was working fine before, but I wanted to play it safe. Hoping it doesn't do more harm than good.

Edited 3 time(s). Last edit at 12/15/2015 03:13PM by FirmwareFool.

I just assembled my first 3d printer kit. It's a Folgertech Kossel 2020 Rev B. Got everything together, all the wiring correct and connected it to my laptop. I downloaded Arduino, RepetierHost and Marlin firmware(Kossel Firmare(V2) 20tooth GT2 pulley firmware [shows up in Arduino as Marline_Delta2).

G code is a pain so far. I successfully set the Z min, so it passes the paper test at G X0 Y0 Z0. Now the instructions for how to calibrate min. x and y position are a little shoddy. My main problem (as far as I can tell) is that Repetier can't process negative values, so I can seemingly only effectively use 1/4 of my print bed space. (When I enter negative X or Y value to find X or Y min., It goes to 0. I fixed this problem when establishing Z0 by making the home/max. Z value larger to compensate for higher endstops, but I can't see how that would work for X and Y. Entering G28 homes my printer, so the endstops are engaged. That much is fine, but G29, which is supposed to activate the Z probe(?) (An inductive sensor), causes the hot end to move towards the z tower and begin climbing the towers, probing as it goes, so the z probe moves across the x/y axes as it should, but the z axis is engaged as well. The only reason I can come up with is that the command to tell the Z probe to come back down to detect the metal print bed isn't there, or something is wrong with it. So, the hot end comes down, senses the print bed, comes up, moves to the next spot and comes down to sense the print bed again, and so on-but it never comes down. Only up.

I appreciate any guidance. I'm really lost here.

Also, I installed a 3 Amp circuit breaker on the live wire, as recommended in the instructions. Is there any harm in doing that? It was working fine before, but I wanted to play it safe. Hoping it doesn't do more harm than good.

Edited 3 time(s). Last edit at 12/15/2015 03:13PM by FirmwareFool.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 06:56AM |

Registered: 8 years ago Posts: 107 |

Does anyone know how to fix this material issue?

This is PLA on a 60° bed printing at 220°

PS to FirmwareFool: I have the same issue with the inductive sensor climbing the tower and I haven't figured it out either. I went to springs under the three screws to level the plate and I've been fine with that. The aluminum disk they supply is plenty flat for the accuracy of this machine, in my opinion.

Edited 1 time(s). Last edit at 12/17/2015 06:59AM by Legrand.

This is PLA on a 60° bed printing at 220°

PS to FirmwareFool: I have the same issue with the inductive sensor climbing the tower and I haven't figured it out either. I went to springs under the three screws to level the plate and I've been fine with that. The aluminum disk they supply is plenty flat for the accuracy of this machine, in my opinion.

Edited 1 time(s). Last edit at 12/17/2015 06:59AM by Legrand.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 08:41AM |

Registered: 8 years ago Posts: 90 |

Quote

Legrand

I went to springs under the three screws to level the plate and I've been fine with that. The aluminum disk they supply is plenty flat for the accuracy of this machine, in my opinion.

Just as a heads up, it doesn't stay flat. Mine was flat as cut stone when I started. I've printed quite a bit so far, with my heatbed ranging from 40-70*C. It is starting to curl up the edges, ever so slightly. So it is thin enough to warp over time. I think I'm going to look into the glass sheet thing after the holidays.

Side note/question- does anyone have provisions to keep the bed from sliding with the screw/springs? When I'm wrenching a print off the bed, sometimes it will slide a little bit, looks like slop in the holes vs the bolts that were in the kit. I was thinking about drilling slightly bigger holes and putting a thicker bolt to prevent. Didn't know if anyone else had this problem.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 04:34PM |

Registered: 8 years ago Posts: 62 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 05:01PM |

Registered: 8 years ago Posts: 90 |

Quote

FirmwareFool

So you were able to print though? Do you just not do a G29? How do you calibrate your bed if you can't G29 properly?

Not sure if you were directing towards me, but I'll throw in my experiences.

I tried twice to get the autolevel to work- both times it fried some of my stepper drivers, so I promptly removed the servo and tossed it in a box. So no, I do not use G29 at all, never have.

I use a combination of the paper test, and using the same principal (as suggested by paul_delta) I will often use a 2.5mm allen key to set the Z Home position. For the bed itself I went out and got three small levels (about 3" long, think they were "line levels") and leveled the bed to the world using springs under the mounting screws. I then use the G1 Z## F4000 command while at the edges of the bed to find discrepancies to adjust Delta Smooth Rod Offset.

That's pretty vague, sorry. My print plane is near perfect in the Y axis, but the X is all jacked up. I still need to try paul_delta's suggestion to adjust the diagonal radius for X axis to try and fix it.

Right now I'm ghetto band-aiding it just to get some trinkets printed for small x-mas gifts. I've been using 150% first layer, with a 3 layer raft. Once it gets past the raft, my prints are pretty damn good, considering.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 05:16PM |

Registered: 8 years ago Posts: 62 |

Quote

fattmann

Quote

FirmwareFool

So you were able to print though? Do you just not do a G29? How do you calibrate your bed if you can't G29 properly?

Not sure if you were directing towards me, but I'll throw in my experiences.

I tried twice to get the autolevel to work- both times it fried some of my stepper drivers, so I promptly removed the servo and tossed it in a box. So no, I do not use G29 at all, never have.

I use a combination of the paper test, and using the same principal (as suggested by paul_delta) I will often use a 2.5mm allen key to set the Z Home position. For the bed itself I went out and got three small levels (about 3" long, think they were "line levels") and leveled the bed to the world using springs under the mounting screws. I then use the G1 Z## F4000 command while at the edges of the bed to find discrepancies to adjust Delta Smooth Rod Offset.

That's pretty vague, sorry. My print plane is near perfect in the Y axis, but the X is all jacked up. I still need to try paul_delta's suggestion to adjust the diagonal radius for X axis to try and fix it.

Right now I'm ghetto band-aiding it just to get some trinkets printed for small x-mas gifts. I've been using 150% first layer, with a 3 layer raft. Once it gets past the raft, my prints are pretty damn good, considering.

Okay, that makes sense. So then I guess I'll just try printing some stuff, or maybe just dry run without G29. I hope that works well enough.

Another problem I had was with the fan, I wasn't sure if it was coming on automatically. Ideally I would like to have it adjust speed according to the hot end temp, but just having it come on automatically without me turning it on in RepetierHost would be nice. Maybe it will come on automatically with the changes I made. I've been really hesitant about giving it another try after the belt came loose along with the first set of errors I encountered.

Using the springs is a really good idea, you can probably really reduce the chances of strong collision that way.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 05:22PM |

Registered: 8 years ago Posts: 432 |

My firmware/config [forums.reprap.org]

Just connect your fan to PIN9 between bed and axtruder pin and firmware will turn fan when extruder is 50C or higher.

Edited 2 time(s). Last edit at 12/18/2015 10:42AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Just connect your fan to PIN9 between bed and axtruder pin and firmware will turn fan when extruder is 50C or higher.

Quote

FirmwareFool

Another problem I had was with the fan, I wasn't sure if it was coming on automatically. Ideally I would like to have it adjust speed according to the hot end temp, but just having it come on automatically without me turning it on in RepetierHost would be nice. Maybe it will come on automatically with the changes I made. I've been really hesitant about giving it another try after the belt came loose along with the first set of errors I encountered.

Using the springs is a really good idea, you can probably really reduce the chances of strong collision that way.

Edited 2 time(s). Last edit at 12/18/2015 10:42AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 06:13PM |

Registered: 8 years ago Posts: 62 |

Quote

paul_delta

My firmware/config [forums.reprap.org]

Just connect your fan to PIN9 between bed and axtruder pin and firmware will turn fan when extruder is 50C or higher.

Quote

FirmwareFool

Another problem I had was with the fan, I wasn't sure if it was coming on automatically. Ideally I would like to have it adjust speed according to the hot end temp, but just having it come on automatically without me turning it on in RepetierHost would be nice. Maybe it will come on automatically with the changes I made. I've been really hesitant about giving it another try after the belt came loose along with the first set of errors I encountered.

Using the springs is a really good idea, you can probably really reduce the chances of strong collision that way.

Hey man. Yeah, that didn't work. I tried G28, and it sounded like my motors were trying to push against something that wasn't there. Sounded like they were struggling, so I don't know what that means. It did ay in arduino when it was compiling that the memory would be low, (although I don't think it took up THAT much space).

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 06:21PM |

Registered: 8 years ago Posts: 432 |

If you assembled your folgertech rev.B using manual they provide - my foirmware/config should work out of the box (with some corrections like diagonal, z-height, etc). But without any motor/direction issues.

I think your eeprom is screwed previous Marlin (?) experiments. You have to load defaults and write them back to eeprom.

M502

M500

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

I think your eeprom is screwed previous Marlin (?) experiments. You have to load defaults and write them back to eeprom.

M502

M500

Quote

FirmwareFool

Quote

paul_delta

My firmware/config [forums.reprap.org]

Just connect your fan to PIN9 between bed and axtruder pin and firmware will turn fan when extruder is 50C or higher.

Quote

FirmwareFool

Another problem I had was with the fan, I wasn't sure if it was coming on automatically. Ideally I would like to have it adjust speed according to the hot end temp, but just having it come on automatically without me turning it on in RepetierHost would be nice. Maybe it will come on automatically with the changes I made. I've been really hesitant about giving it another try after the belt came loose along with the first set of errors I encountered.

Using the springs is a really good idea, you can probably really reduce the chances of strong collision that way.

Hey man. Yeah, that didn't work. I tried G28, and it sounded like my motors were trying to push against something that wasn't there. Sounded like they were struggling, so I don't know what that means. It did ay in arduino when it was compiling that the memory would be low, (although I don't think it took up THAT much space).

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 08:23PM |

Registered: 8 years ago Posts: 62 |

Okay, I'll give that a shot. I'm waffling between 'this is super complex, and this is easy and I'm just over complicating things'. I think it's the latter.

I studied java a bit, so i get an idea of what the g code is saying, but I have no familiarity the EEPROM.

Anyway, I really appreciate the help here.

I studied java a bit, so i get an idea of what the g code is saying, but I have no familiarity the EEPROM.

Anyway, I really appreciate the help here.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 08:57PM |

Registered: 8 years ago Posts: 62 |

Quote

paul_delta

If you assembled your folgertech rev.B using manual they provide - my foirmware/config should work out of the box (with some corrections like diagonal, z-height, etc). But without any motor/direction issues.

I think your eeprom is screwed previous Marlin (?) experiments. You have to load defaults and write them back to eeprom.

M502

M500

Quote

FirmwareFool

Quote

paul_delta

My firmware/config [forums.reprap.org]

Just connect your fan to PIN9 between bed and axtruder pin and firmware will turn fan when extruder is 50C or higher.

Quote

FirmwareFool

Another problem I had was with the fan, I wasn't sure if it was coming on automatically. Ideally I would like to have it adjust speed according to the hot end temp, but just having it come on automatically without me turning it on in RepetierHost would be nice. Maybe it will come on automatically with the changes I made. I've been really hesitant about giving it another try after the belt came loose along with the first set of errors I encountered.

Using the springs is a really good idea, you can probably really reduce the chances of strong collision that way.

Hey man. Yeah, that didn't work. I tried G28, and it sounded like my motors were trying to push against something that wasn't there. Sounded like they were struggling, so I don't know what that means. It did ay in arduino when it was compiling that the memory would be low, (although I don't think it took up THAT much space).

So, it looks like it's working, but it's moving VERY slowly. I don't know what that means. I entered m502 to reset to factory defaults, and then m500 and stored configuration to EEPROM, so I don't know what's goin on.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 09:19PM |

Registered: 8 years ago Posts: 432 |

Quote

FirmwareFool

So, it looks like it's working, but it's moving VERY slowly. I don't know what that means. I entered m502 to reset to factory defaults, and then m500 and stored configuration to EEPROM, so I don't know what's goin on.

In RepetierHost check your printer settings and travel rate (should be around to 9000 mm/min).

And in eeprom menu check the travel speed, like 100mm/s. If it's still VERY slow - check your RAMPS driver jumpers. All 3 should be On.

PS: try to home and then enter G1 X0 Y0 Z100 F9000 - still slow?

Edited 2 time(s). Last edit at 12/17/2015 09:23PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 10:32PM |

Registered: 8 years ago Posts: 62 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 10:55PM |

Registered: 8 years ago Posts: 432 |

In eeprom check Max. feedrate. Set it to 150.

When you enter G28 (home) - the homing speed is OK?

Did you try manually enter G28 for home and then enter G1 X0 Y0 Z100 F9000?

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

When you enter G28 (home) - the homing speed is OK?

Did you try manually enter G28 for home and then enter G1 X0 Y0 Z100 F9000?

Quote

FirmwareFool

In EEPROM settings, Travel Acceleration is 100 mm/s^2.

In printer settings, Travel Feed Rate is 4800 mm/min and Z-Axis Feed Rate is 100 mm/min.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 17, 2015 11:01PM |

Registered: 8 years ago Posts: 62 |

Yes, Max Feedrate was set to 2.000 and I changed it to 150.000, but it was still slow. I entered G28 into the RepetierHost Manual Control tab G code bar.

The F speed value I enter doesn't seem to have an effect on how fast it goes. I really am stumped about how two delta printers could be so different using the same firmware.

Edited 1 time(s). Last edit at 12/17/2015 11:03PM by FirmwareFool.

The F speed value I enter doesn't seem to have an effect on how fast it goes. I really am stumped about how two delta printers could be so different using the same firmware.

Edited 1 time(s). Last edit at 12/17/2015 11:03PM by FirmwareFool.

Sorry, only registered users may post in this forum.