Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 15, 2016 09:22PM |

Registered: 8 years ago Posts: 188 |

Quote

chaster

Minor question - did other people receive four pieces of plastic U-channel with their kits? They are about 7mm wide and 1.5' long (sorry for mixing units.. I don't have a long metric ruler). I just noticed them sitting in the box and the instructions don't make any mention of them. I am guessing they are for aesthetics (covering up wires that run in the slots of the aluminum extrusion) but just wanted to make sure they aren't for something else...?

Eric

If they're what I think you're describing, then yes they are. They are used to make the whole thing look cleaner by covering the wires in the aluminum extrusions.

Owner of a QUBD Two Up

And

Folger Kossel 2020

And

Tevo Tarantula

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 15, 2016 09:27PM |

Registered: 8 years ago Posts: 432 |

Quote

Dav3xor

My heater plate had a little bow in it; I figured out it's geometry, and with a careful and studious use of my foot, and a copy of Bill Shatner's autobiography (hardcover), I was able to make it as flat as my cheap metal ruler and a bright light source could measure.

That's what we call Nanotechnology!

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 15, 2016 11:49PM |

Registered: 9 years ago Posts: 93 |

Quote

09zx-6r

ok so i have my FT kossel Rev B calibrated on XYZ... PID auto tuned the Bed... BUT when i try to PID atuo tune the nozzle, it wont go over 78C !!! i have a full 12.10VDC at the cartridge connector...

SUGGESTIONS ????

Anyone?????

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 16, 2016 12:11AM |

Registered: 8 years ago Posts: 16 |

Quote

09zx-6r

Quote

09zx-6r

ok so i have my FT kossel Rev B calibrated on XYZ... PID auto tuned the Bed... BUT when i try to PID atuo tune the nozzle, it wont go over 78C !!! i have a full 12.10VDC at the cartridge connector...

SUGGESTIONS ????

Anyone?????

I haven't done any PID auto tunign myself yet, so this will all be guesswork. It sounds like there is an artificial limit being imposed by the PID code. Pour over that section of the firmware and see what you find. Knowing the temp it stops at gives you a figure to search for, and hopefully change. You might also see if the code is notarized in the firmware. That could lead you to a help file or other documentation for the PID tuning.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 16, 2016 02:10AM |

Registered: 9 years ago Posts: 93 |

Any one know how to relocate the heat bed symbol on the LCD full graphics display... i can move the position of the temps but not the symbol itself... how do i do that... i dont like that its all the way to the right...

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 16, 2016 09:03PM |

Registered: 8 years ago Posts: 197 |

Quote

09zx-6r

Any one know how to relocate the heat bed symbol on the LCD full graphics display... i can move the position of the temps but not the symbol itself... how do i do that... i dont like that its all the way to the right...

Something to do with the firmware.

I have one that i use and when running an older verison of marlin it shows 3, but when running a newer ver. Marlin 1.1 (i think rc3) it only show the icon for the amount i have set.

I heard its somewhere in the LCD file in the marlin firmware. but unsure where

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2016 01:11AM |

Registered: 9 years ago Posts: 93 |

@Xile6...ok thanks... hopefully someone will know something eventually...

UPDATE: so my previous heater cartridge issue has been somewhat resolved...found out i had a 24v 40w and NOT the 12v40w i needed.. swapped it with a known working cartridge, and BINGO it heats up..however if the fan is running i cant get it above 215C... thoughts?

Also, when doing a G28 to home the xyz pillars it works fine, then do a G29 for auto probing, which it comes down to the bed and does a bunch of probing. The issue is the probing points arent center of the bed, they are too far to one side of the bed, how do i correct this ?

on another note, AFTER G29 is done, it starts to home itself but when 1 of the 3 pillars reaches a endstop the other 2 axis's vibrate..then they all vibrate at the endstops like they are trying to go past it and cant... how do i fix this ?

added config.h file for your viewing pleasure

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

UPDATE: so my previous heater cartridge issue has been somewhat resolved...found out i had a 24v 40w and NOT the 12v40w i needed.. swapped it with a known working cartridge, and BINGO it heats up..however if the fan is running i cant get it above 215C... thoughts?

Also, when doing a G28 to home the xyz pillars it works fine, then do a G29 for auto probing, which it comes down to the bed and does a bunch of probing. The issue is the probing points arent center of the bed, they are too far to one side of the bed, how do i correct this ?

on another note, AFTER G29 is done, it starts to home itself but when 1 of the 3 pillars reaches a endstop the other 2 axis's vibrate..then they all vibrate at the endstops like they are trying to go past it and cant... how do i fix this ?

added config.h file for your viewing pleasure

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 17, 2016 01:26PM |

Registered: 8 years ago Posts: 12 |

I've got all my mechanical and wiring issues sorted out and now I'm on to calibration. I can't get it to print level even after the bed leveling. I still have EEPROM off and I'm wondering if that's the issue? I've also had a few times where it stops its correct motion and starts jittering around all over. Any ideas?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 06:13AM |

Registered: 8 years ago Posts: 107 |

Faithblinded: I use this one on my two FT machines: Universal Spool holder

When the tripod base is printed out, you'll notice two blind holes at the ends of these feet. I drilled them thru with a 3mm bit and then mounted the base to the top of the machine with some of the extra t-slot nuts and bolts. Works like a charm.

When the tripod base is printed out, you'll notice two blind holes at the ends of these feet. I drilled them thru with a 3mm bit and then mounted the base to the top of the machine with some of the extra t-slot nuts and bolts. Works like a charm.

Quote

faithblinded

I lowered my temp and adjusted my retraction settings, and now I'm getting really good prints, with no stringing at all. Thanks Paul Delta for all your help and suggestions!

I printed a fan shroud that splits the output between the heat sink and the part, and my hotend seems to be holding a much steadier temp. It was falling off due to the quick infill motions of my printer, so I drilled a couple holes in it, and wrapped a zip tie around the top of the heat sink to secure it. Good to go!

I'm still looking for a printable spool holder that works well with the revB extruder setup, as stock. Any suggestions would be appreciated.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 09:20AM |

Registered: 8 years ago Posts: 16 |

Quote

Legrand

Faithblinded: I use this one on my two FT machines: Universal Spool holder

When the tripod base is printed out, you'll notice two blind holes at the ends of these feet. I drilled them thru with a 3mm bit and then mounted the base to the top of the machine with some of the extra t-slot nuts and bolts. Works like a charm.

It's funny you posted this. I was getting ready to make a post later today with pictures, about how I found my perfect fully printed spool holder. It's that one! You should grab the current files for it. There are a bunch of alternative bases, including a couple made for 2020 extrusion. I printed one, and it mounted on top of my printer. It spins effortlessly even with the heaviest roll I have. Now I can feel comfortable that a 10 hour print won't fail due to filament feeding issues(happened to me a couple times before I printed this). I like this spool holder so much, I'm printing parts for a second one, with the standard tripod base. I know more printers are in my future, so why not.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 09:24AM |

Registered: 8 years ago Posts: 107 |

Small world...

I forget to mention that I had issues with the cone part printing due to the text on it acting like the first layer and printing it the other way made for a sloppy print (large overhang angle wasn't printing nicely), so I remodeled it without the text and if anyone needs it, just let me know.

I forget to mention that I had issues with the cone part printing due to the text on it acting like the first layer and printing it the other way made for a sloppy print (large overhang angle wasn't printing nicely), so I remodeled it without the text and if anyone needs it, just let me know.

Quote

faithblinded

Quote

Legrand

Faithblinded: I use this one on my two FT machines: Universal Spool holder

When the tripod base is printed out, you'll notice two blind holes at the ends of these feet. I drilled them thru with a 3mm bit and then mounted the base to the top of the machine with some of the extra t-slot nuts and bolts. Works like a charm.

It's funny you posted this. I was getting ready to make a post later today with pictures, about how I found my perfect fully printed spool holder. It's that one! You should grab the current files for it. There are a bunch of alternative bases, including a couple made for 2020 extrusion. I printed one, and it mounted on top of my printer. It spins effortlessly even with the heaviest roll I have. Now I can feel comfortable that a 10 hour print won't fail due to filament feeding issues(happened to me a couple times before I printed this). I like this spool holder so much, I'm printing parts for a second one, with the standard tripod base. I know more printers are in my future, so why not.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 09:31AM |

Registered: 8 years ago Posts: 432 |

This holder has an additional part - the base for 2020 extrusion. Just print this base instead of tripod.

I plan to design another base for this holder, that will push-and-click to the extrusion without screws.

Edited 1 time(s). Last edit at 01/18/2016 09:33AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

I plan to design another base for this holder, that will push-and-click to the extrusion without screws.

Edited 1 time(s). Last edit at 01/18/2016 09:33AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 09:33AM |

Registered: 8 years ago Posts: 16 |

Quote

Legrand

Small world...

I forget to mention that I had issues with the cone part printing due to the text on it acting like the first layer and printing it the other way made for a sloppy print (large overhang angle wasn't printing nicely), so I remodeled it without the text and if anyone needs it, just let me know.

I aborted my first attempt with the cone for the same reason. However, I had no problem printing it upside down. I'm presently printing the long split cone. It had a recessed bit of text on the first layer, but I think it will not cause problems, as on the other one. I like how the round parts resist warping/lifting so much better. And, bonus, deltas excel at circles.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 09:53AM |

Registered: 8 years ago Posts: 16 |

Here's what that Universal Spool Holder looks like on my FT Kossel. This is the one piece version for 2020 extrusion. I initially printed the 4 inch spool holder, only to realize it was too short for my roll of black PLA. So I printed the long one in chartreuse. It's working great for me.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 02:54PM |

Registered: 8 years ago Posts: 107 |

OK, I'm coming back at the auto leveling problem since my plate keeps getting skewed when I remove parts from it (with the springs under it).

Can anyone who had the "climbing problem" tell me how they fixed it, and Paul, do you have to have some sort of compensation factor, or offset, since you're probing so far from the nozzle?

Can anyone who had the "climbing problem" tell me how they fixed it, and Paul, do you have to have some sort of compensation factor, or offset, since you're probing so far from the nozzle?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 05:12PM |

Registered: 9 years ago Posts: 93 |

Quote

Legrand

OK, I'm coming back at the auto leveling problem since my plate keeps getting skewed when I remove parts from it (with the springs under it).

Can anyone who had the "climbing problem" tell me how they fixed it, and Paul, do you have to have some sort of compensation factor, or offset, since you're probing so far from the nozzle?

if ur refering to the nozzle climbing as it reaches the outside of the plate then you need to ADD (+) a dimension to the DELTA RADIUS...(note the BOLD print at the end of the equation)

// Horizontal distance bridged by diagonal push rods when effector is centered.

#define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+.30)

your number may differ... but if the plate is cupped then you add if its humped then you subtract a number

if the plate to nozzle distance is flat but the plate is tilted, then adjust your endstops

Edited 1 time(s). Last edit at 01/18/2016 05:20PM by 09zx-6r.

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 05:27PM |

Registered: 8 years ago Posts: 432 |

Quote

Legrand

Can anyone who had the "climbing problem" tell me how they fixed it, and Paul, do you have to have some sort of compensation factor, or offset, since you're probing so far from the nozzle?

Do you mean my zero offset probe mount? No, I don't have any compensation, just measured probe height (distance from the nozzle to the height where probe triggers).

Make sure your nozzle touches the bed at Z0 (paper test), home your printer, attach the mount and move effector/probe down until LED turns On (the probe triggers). Move up 1mm and repeat using 0.01 increment to get more precise reading. Read Z height and put the value in "probe height" field of eeprom window.

Edited 1 time(s). Last edit at 01/18/2016 05:35PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 18, 2016 10:38PM |

Registered: 9 years ago Posts: 93 |

Is anyone using marlin to run there kossel revB and doing it successfully with the inductive probe ? I NEED HELP !!!!

im about to throw this thing thru a F$%% window

Edited 1 time(s). Last edit at 01/18/2016 10:39PM by 09zx-6r.

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

im about to throw this thing thru a F$%% window

Edited 1 time(s). Last edit at 01/18/2016 10:39PM by 09zx-6r.

Nophead Mendel90 Remixed in aluminum

Marlin v2.0

Matterhacker Control (latest)

Ramps 1.4

Sainsmart LCD

MK2B heatbed

E3dV6 hotend .4mm tip

1.75mm filaments

dedicated 12v33a psu

dedicated 12v5a laptop psu mod

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 04:05AM |

Registered: 8 years ago Posts: 63 |

Hi everyone. Just completed my Folger Tech Kossel 2020 build (first 3D printer).

Everything went together right the first time, thanks to this forum and some very scattered but helpful videos.

I am up to the point of printing my first test cube, and I'm getting nothing from the nozzle.

The first time I attempted it, I realized I didn't have the filament all the way down to the hot end, so I stopped it, loaded the filament all the way down and started again. Still nothing.

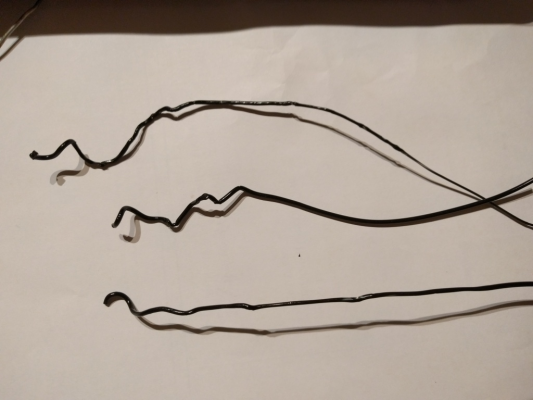

The filament was skipping in the extruder motor gear. I pulled the PTFE tube from the hot end, and a length of squiggly filament. PTFE still disconneced, I turned on the hot end heater manually via Repetier, and then manually extruded filament. Motor / gear worked fine.

I trimmed off the length of filament, Used a flashlight to make sure I could see light from nozzle to compression fitting, and refitted the PTFE tube, fed filament to the hot end, and then tried again. Same thing.

Repeated all from above, except this time turned the heat up from 195c to 205c. Same thing.

One last time I just heated up the hot end to 205c, and checked the hot end with an infrared thermometer, showed 63c from the outside (fan off).

I'm not sure what to try next. Suggestions?

Everything went together right the first time, thanks to this forum and some very scattered but helpful videos.

I am up to the point of printing my first test cube, and I'm getting nothing from the nozzle.

The first time I attempted it, I realized I didn't have the filament all the way down to the hot end, so I stopped it, loaded the filament all the way down and started again. Still nothing.

The filament was skipping in the extruder motor gear. I pulled the PTFE tube from the hot end, and a length of squiggly filament. PTFE still disconneced, I turned on the hot end heater manually via Repetier, and then manually extruded filament. Motor / gear worked fine.

I trimmed off the length of filament, Used a flashlight to make sure I could see light from nozzle to compression fitting, and refitted the PTFE tube, fed filament to the hot end, and then tried again. Same thing.

Repeated all from above, except this time turned the heat up from 195c to 205c. Same thing.

One last time I just heated up the hot end to 205c, and checked the hot end with an infrared thermometer, showed 63c from the outside (fan off).

I'm not sure what to try next. Suggestions?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 06:08AM |

Registered: 8 years ago Posts: 107 |

I'm sorry, that's not the problem. I believe fattman and Captian Tim had the issue I'm referring to which is that when you activate G29, the nozzle heads down to the bed and then starts probing up in large steps instead of going down to find the bed.

Quote

09zx-6r

Quote

Legrand

OK, I'm coming back at the auto leveling problem since my plate keeps getting skewed when I remove parts from it (with the springs under it).

Can anyone who had the "climbing problem" tell me how they fixed it, and Paul, do you have to have some sort of compensation factor, or offset, since you're probing so far from the nozzle?

if ur refering to the nozzle climbing as it reaches the outside of the plate then you need to ADD (+) a dimension to the DELTA RADIUS...(note the BOLD print at the end of the equation)

// Horizontal distance bridged by diagonal push rods when effector is centered.

#define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET+.30)

your number may differ... but if the plate is cupped then you add if its humped then you subtract a number

if the plate to nozzle distance is flat but the plate is tilted, then adjust your endstops

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 06:16AM |

Registered: 8 years ago Posts: 107 |

Betty,

Since your extruder motor is skipping and you measured the hot end at 63°C and you're pulling out those unmelted strands, I'd have to say that your hot end isn't getting up to temperature properly.What type of filament are you trying to print with?

It is heating though, so can you ascertain the temperature that the "software" is telling you it's at? If you send a M105 to the printer (after the hot end is theoretically warmed up) it will report back the temperature.

Since your extruder motor is skipping and you measured the hot end at 63°C and you're pulling out those unmelted strands, I'd have to say that your hot end isn't getting up to temperature properly.What type of filament are you trying to print with?

It is heating though, so can you ascertain the temperature that the "software" is telling you it's at? If you send a M105 to the printer (after the hot end is theoretically warmed up) it will report back the temperature.

Quote

EvilBetty

Hi everyone. Just completed my Folger Tech Kossel 2020 build (first 3D printer).

Everything went together right the first time, thanks to this forum and some very scattered but helpful videos.

I am up to the point of printing my first test cube, and I'm getting nothing from the nozzle.

The first time I attempted it, I realized I didn't have the filament all the way down to the hot end, so I stopped it, loaded the filament all the way down and started again. Still nothing.

The filament was skipping in the extruder motor gear. I pulled the PTFE tube from the hot end, and a length of squiggly filament. PTFE still disconneced, I turned on the hot end heater manually via Repetier, and then manually extruded filament. Motor / gear worked fine.

I trimmed off the length of filament, Used a flashlight to make sure I could see light from nozzle to compression fitting, and refitted the PTFE tube, fed filament to the hot end, and then tried again. Same thing.

Repeated all from above, except this time turned the heat up from 195c to 205c. Same thing.

One last time I just heated up the hot end to 205c, and checked the hot end with an infrared thermometer, showed 63c from the outside (fan off).

I'm not sure what to try next. Suggestions?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 09:18AM |

Registered: 8 years ago Posts: 432 |

Does it show correct room temperature when hot end is cold?

Btw the fan must be on all the time when hot end is hot. The filament must reach melting temperature only inside the square block or it will stick to the wall and clog the tube.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Btw the fan must be on all the time when hot end is hot. The filament must reach melting temperature only inside the square block or it will stick to the wall and clog the tube.

Quote

EvilBetty

Repeated all from above, except this time turned the heat up from 195c to 205c. Same thing.

One last time I just heated up the hot end to 205c, and checked the hot end with an infrared thermometer, showed 63c from the outside (fan off).

I'm not sure what to try next. Suggestions?

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 09:53AM |

Registered: 8 years ago Posts: 107 |

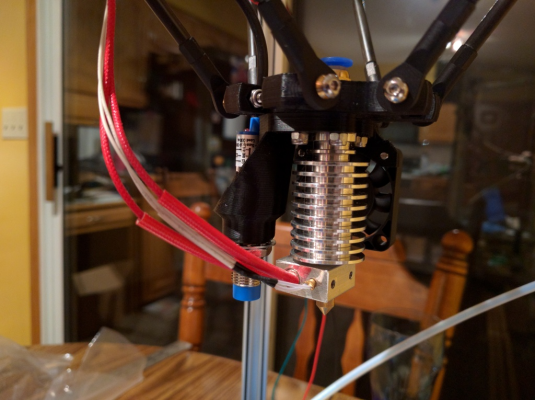

Something else I just remembered as well, when you assemble the square hot end to the radiator (the cylindrical heat sink with lots of grooves in it) you must make sure there is a gap between the square hot end and the cylindrical radiator. If you don't leave a gap, then the radiator will suck too much heat from the hot end and it will never reach he proper temperature. I found out this the hard way.

Quote

paul_delta

Does it show correct room temperature when hot end is cold?

Btw the fan must be on all the time when hot end is hot. The filament must reach melting temperature only inside the square block or it will stick to the wall and clog the tube.

Quote

EvilBetty

Repeated all from above, except this time turned the heat up from 195c to 205c. Same thing.

One last time I just heated up the hot end to 205c, and checked the hot end with an infrared thermometer, showed 63c from the outside (fan off).

I'm not sure what to try next. Suggestions?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 01:58PM |

Registered: 8 years ago Posts: 63 |

Quote

Legrand

Betty,

Since your extruder motor is skipping and you measured the hot end at 63°C and you're pulling out those unmelted strands, I'd have to say that your hot end isn't getting up to temperature properly.What type of filament are you trying to print with?

It is heating though, so can you ascertain the temperature that the "software" is telling you it's at? If you send a M105 to the printer (after the hot end is theoretically warmed up) it will report back the temperature.

Filament: Inland 1.75mm Black PLA 3D Printer Filament - 1kg Spool (2.2 lbs)

Temp: Repetier is reporting the temp at 195°C

There's No Place Like 127.0.0.1

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 02:19PM |

Registered: 8 years ago Posts: 63 |

Quote

paul_delta

Does it show correct room temperature when hot end is cold?

Btw the fan must be on all the time when hot end is hot. The filament must reach melting temperature only inside the square block or it will stick to the wall and clog the tube.

Seems to.

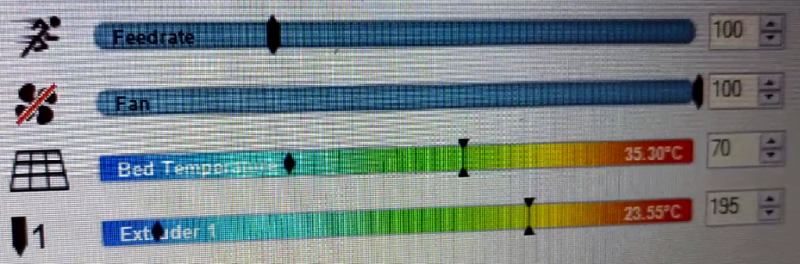

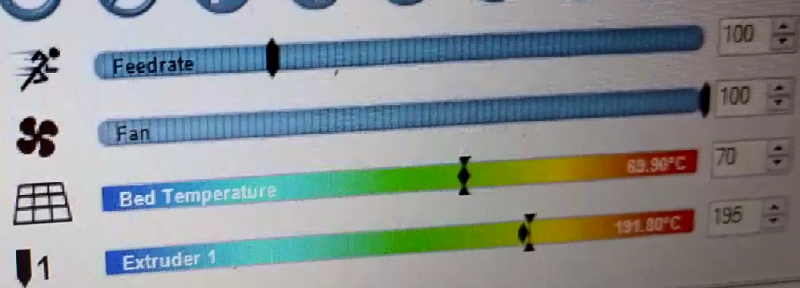

Bed has begun warming, Hot end room temp.

Hot end fully heated.

My fan was off. I believe I have it set to "Auto" in the config.h. I also noticed when turning it on manually it is blowing away from the fins. If there was a shroud I'd leave it that way, but as it is now I'll flip the pins when I get home.

Thanks!

-EB

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 02:20PM |

Registered: 8 years ago Posts: 63 |

Quote

Legrand

Something else I just remembered as well, when you assemble the square hot end to the radiator (the cylindrical heat sink with lots of grooves in it) you must make sure there is a gap between the square hot end and the cylindrical radiator. If you don't leave a gap, then the radiator will suck too much heat from the hot end and it will never reach he proper temperature. I found out this the hard way.

Here's mine:

Thanks,

-EB

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 02:23PM |

Registered: 8 years ago Posts: 63 |

Since I couldn't print and couldn't think of anything else to try, I gave something else a try.

Youtube: Folger Tech Kossel 2020 - "Beverly Hills Cop - Axel F"

(Sorry, can't figure out how to embed on this forum)

Edited 5 time(s). Last edit at 01/19/2016 02:42PM by EvilBetty.

Youtube: Folger Tech Kossel 2020 - "Beverly Hills Cop - Axel F"

(Sorry, can't figure out how to embed on this forum)

Edited 5 time(s). Last edit at 01/19/2016 02:42PM by EvilBetty.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 02:25PM |

Registered: 8 years ago Posts: 107 |

Paul has a simple and effective shroud that I've printed for my machines:

Fan Shroud

Fan Shroud

Quote

EvilBetty

Since I couldn't print and couldn't think of anything else to try, I gave something else a try.

[www.youtube.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 02:34PM |

Registered: 8 years ago Posts: 63 |

It's one of the first things I intend to print (that and a better spool holder)... once I can print.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 19, 2016 06:58PM |

Registered: 8 years ago Posts: 197 |

Quote

EvilBetty

Quote

paul_delta

Does it show correct room temperature when hot end is cold?

Btw the fan must be on all the time when hot end is hot. The filament must reach melting temperature only inside the square block or it will stick to the wall and clog the tube.

Seems to.

Bed has begun warming, Hot end room temp.

Hot end fully heated.

My fan was off. I believe I have it set to "Auto" in the config.h. I also noticed when turning it on manually it is blowing away from the fins. If there was a shroud I'd leave it that way, but as it is now I'll flip the pins when I get home.

Thanks!

-EB

Wait a min

You turn your heatsink fan off?

Thats a no no it should be on when the printer is on. Ran to 12 volts at all times

Next the fan should blow on the fins. You want to push air through them.

Thats probably half of your filament problem.

Sorry, only registered users may post in this forum.