Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level

Posted by Kasahabo

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 29, 2015 09:54PM |

Registered: 8 years ago Posts: 432 |

With previously recommended 230mm I was not able to print LCD box (finally I printed it with lot of support, rotated to 90 degrees) for my Kossel because the real printable diameter is 158mm with 230mm diagonal rod and FolgerTech carriages/rollers. Let us know how it prints with 260mm rods. Is the rod diameter still 5mm? I afraid that 5mm is not enough for 260mm length because of flexibility.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Quote

wrangellboy

Quote

Delta_Stu

New owner of a FT Kossel here. Read through the entire 81 pages.

Was there a concensus on the length of the diagonal rods that allows a good compromise between width and height?

The rev.b manual mentions 240mm total length.

I just re-did my arms. The Rev A. called for 230mm end to end which was frustratingly short. The thing to do is to assemble the frame and measure from one tower at the bottom of your travel to the far opposite side of the bed. Subtract out your effector and truck offsets, and that will give you an arm long enough to reach anywhere on your bed.

I'll measure my new rods when I get home but if memory serves they ended up about 260 end to end, but that's on a rev A with linear sliders so your numbers will be different.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 29, 2015 10:02PM |

Registered: 8 years ago Posts: 13 |

I have been enjoying reading posts of this forum and thanking all of contributors.

Recently I have finished building a rev B printer and having fun with it. After careful measurements and calibration a 20mm cube was printed for testing. As shown in the attached picture, the cube is not straight but tilt along Y axis. I have found that the radius value is slightly different between the three axes (within 2 mm), and suspecting as a possible cause of the tilt. I would appreciate for any suggestions and guides. The Y axis is along the left to the right.

Paul

Recently I have finished building a rev B printer and having fun with it. After careful measurements and calibration a 20mm cube was printed for testing. As shown in the attached picture, the cube is not straight but tilt along Y axis. I have found that the radius value is slightly different between the three axes (within 2 mm), and suspecting as a possible cause of the tilt. I would appreciate for any suggestions and guides. The Y axis is along the left to the right.

Paul

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 29, 2015 10:05PM |

Registered: 8 years ago Posts: 48 |

Quote

paul_delta

With previously recommended 230mm I was not able to print LCD box (finally I printed it with lot of support, rotated to 90 degrees) for my Kossel because the real printable diameter is 158mm with 230mm diagonal rod and FolgerTech carriages/rollers. Let us know how it prints with 260mm rods. Is the rod diameter still 5mm? I afraid that 5mm is not enough for 260mm length because of flexibility.

Quote

wrangellboy

Quote

Delta_Stu

New owner of a FT Kossel here. Read through the entire 81 pages.

Was there a concensus on the length of the diagonal rods that allows a good compromise between width and height?

The rev.b manual mentions 240mm total length.

I just re-did my arms. The Rev A. called for 230mm end to end which was frustratingly short. The thing to do is to assemble the frame and measure from one tower at the bottom of your travel to the far opposite side of the bed. Subtract out your effector and truck offsets, and that will give you an arm long enough to reach anywhere on your bed.

I'll measure my new rods when I get home but if memory serves they ended up about 260 end to end, but that's on a rev A with linear sliders so your numbers will be different.

I just measured, my arms are 255 end to end. That gets me all the way around my 220mm bed with a bit of room to spare. I do have beefier rods than the stock ones.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 30, 2015 05:48PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 30, 2015 06:05PM |

Registered: 8 years ago Posts: 432 |

Quote

guitarhammer

I was having the same problem as MarkM92 with the "mintemp" error. Found that the sensor wires had been cut when crimped into the brass holder. Manufacturer error. Now to get a replacement somehow.

MarkM92 said that thermistor is OK after swapping bed-extruder pins/connectors. So, there are couple of variants:

1. Incorrect PIN/thermistor type configuration in firmware

2. RAMPS pins bad contact/soldering (the resistance is too big) or defective 4.7kOhm resistor or 10mF capacitor.

3. The room temperature is too cold (check firmware min temp. settings, Repetier default min.temp error is -10C)

4. Mega board/chip - RAMPS bad contact

5. Defective Mega chip/board.

Edited 3 time(s). Last edit at 12/30/2015 06:32PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 30, 2015 06:10PM |

Registered: 8 years ago Posts: 432 |

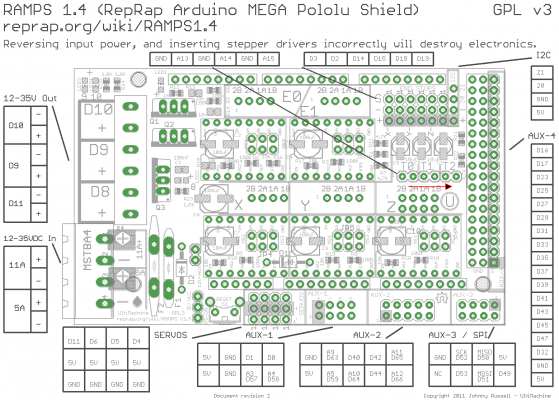

PS: actually, the RAMPS board supports 3 thermistors (bed and 2 extruders), so there is one extra PIN that we can use if we have only one extruder. But we need to change firmware configuration.h and pins.h.

Edited 1 time(s). Last edit at 12/30/2015 06:12PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Edited 1 time(s). Last edit at 12/30/2015 06:12PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 30, 2015 06:22PM |

Registered: 8 years ago Posts: 432 |

Here is the diagram. In Repetier default settings that I used in this case we need to move connector from T0 to T2 and change Configuration.h :

#define EXT0_TEMPSENSOR_PIN TEMP_0_PIN

to

#define EXT0_TEMPSENSOR_PIN TEMP_2_PIN

Edited 2 time(s). Last edit at 12/30/2015 06:54PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

#define EXT0_TEMPSENSOR_PIN TEMP_0_PIN

to

#define EXT0_TEMPSENSOR_PIN TEMP_2_PIN

Edited 2 time(s). Last edit at 12/30/2015 06:54PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 30, 2015 06:36PM |

Registered: 8 years ago Posts: 10 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 01:19AM |

Registered: 8 years ago Posts: 3 |

Recently finished assembling my Rev B machine and have a number of issues, but here's the main one right now: Somehow the temperature readings for my extruder and heated bed are tied together. When I turn on the hot end, the temperature for both the hot end and the heated go up in tandem even though the heated bed is off. It's as if it's using the same sensor for both. When I do the opposite and leave the hot end off and turn the heated bed on, the same thing happens--both temperature readings go up. This seems to suggest they electrically tied together. Anyone run into anything like this before?

What would I need to change in the configuration if I wanted to use T2 for the heated bed thermistor instead of T1 to see if that works independently? I'm using the FT-supplied Marlin firmware.

Thanks in advance for any help!

What would I need to change in the configuration if I wanted to use T2 for the heated bed thermistor instead of T1 to see if that works independently? I'm using the FT-supplied Marlin firmware.

Thanks in advance for any help!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 01:25AM |

Registered: 8 years ago Posts: 432 |

Quote

deisengard

Recently finished assembling my Rev B machine and have a number of issues, but here's the main one right now: Somehow the temperature readings for my extruder and heated bed are tied together. When I turn on the hot end, the temperature for both the hot end and the heated go up in tandem even though the heated bed is off. It's as if it's using the same sensor for both. When I do the opposite and leave the hot end off and turn the heated bed on, the same thing happens--both temperature readings go up. This seems to suggest they electrically tied together. Anyone run into anything like this before?

What would I need to change in the configuration if I wanted to use T2 for the heated bed thermistor instead of T1 to see if that works independently? I'm using the FT-supplied Marlin firmware.

Thanks in advance for any help!

Looks like firmware problem, not hardware. Probably you have the same PIN configured for bed and extruder sensor. If so, no need to move to T2, just make sure to set different PIN for sensors.

Update: sorry, missed the point that it works in both directions. If so, probably it makes sense to move one of sensors to T2.

Edited 1 time(s). Last edit at 12/31/2015 01:29AM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 01:30AM |

Registered: 8 years ago Posts: 432 |

Attach your configuration.h and pins.h.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 02:19AM |

Registered: 8 years ago Posts: 432 |

I've found the FT Marlin firmware, so just open pins.h and change line 450 from:

#define TEMP_BED_PIN 14

to

#define TEMP_BED_PIN 15

This way you will change the bed thermistor pin to 15 which is T2 on RAMPS board.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

#define TEMP_BED_PIN 14

to

#define TEMP_BED_PIN 15

This way you will change the bed thermistor pin to 15 which is T2 on RAMPS board.

Quote

deisengard

What would I need to change in the configuration if I wanted to use T2 for the heated bed thermistor instead of T1 to see if that works independently? I'm using the FT-supplied Marlin firmware.

Thanks in advance for any help!

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:02PM |

Registered: 8 years ago Posts: 3 |

Thanks Paul. I switched the heated bed to T2 and it read different than the extruder, but real low (5 C) vs room temp (21 C) for the extruder. I figured it must not be reading anything on T2, but when I swapped the heated bed and extruder on the board and in software, the readings stayed the same--the heated bed (on T1) read 5C and the extruder (on T2) read 21 C. So T2 seems to be working ok, but maybe not my heated bed thermistor. When I turn on the heated bed, the thermistor reading does go up correspondingly, as though it's just reading 10-15 C lower than it should be. After letting the heated bed cool a while it now seems to be holding at 10 C. So I guess I have a defective heated bed thermistor?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:18PM |

Registered: 8 years ago Posts: 432 |

Check your Configuration.h to make sure that:

#define TEMP_SENSOR_BED 1

If it's 1 - there is a chance that your bed thermistor is not 100k NTC as it should be. If you have a multimeter - measure your thermistor resistance at room temperature and when it is warm (hold it tight for 1-2 minutes in your hand) - the resistance should be around 100k at room temperature and around 60k when it has body temperature.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

#define TEMP_SENSOR_BED 1

If it's 1 - there is a chance that your bed thermistor is not 100k NTC as it should be. If you have a multimeter - measure your thermistor resistance at room temperature and when it is warm (hold it tight for 1-2 minutes in your hand) - the resistance should be around 100k at room temperature and around 60k when it has body temperature.

Quote

deisengard

Thanks Paul. I switched the heated bed to T2 and it read different than the extruder, but real low (5 C) vs room temp (21 C) for the extruder. I figured it must not be reading anything on T2, but when I swapped the heated bed and extruder on the board and in software, the readings stayed the same--the heated bed (on T1) read 5C and the extruder (on T2) read 21 C. So T2 seems to be working ok, but maybe not my heated bed thermistor. When I turn on the heated bed, the thermistor reading does go up correspondingly, as though it's just reading 10-15 C lower than it should be. After letting the heated bed cool a while it now seems to be holding at 10 C. So I guess I have a defective heated bed thermistor?

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:28PM |

Registered: 8 years ago Posts: 432 |

I checked the table, probably your thermistor is 200k, try to change

TEMP_SENSOR_BED 1

to

TEMP_SENSOR_BED 2

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

TEMP_SENSOR_BED 1

to

TEMP_SENSOR_BED 2

Quote

deisengard

Thanks Paul. I switched the heated bed to T2 and it read different than the extruder, but real low (5 C) vs room temp (21 C) for the extruder. I figured it must not be reading anything on T2, but when I swapped the heated bed and extruder on the board and in software, the readings stayed the same--the heated bed (on T1) read 5C and the extruder (on T2) read 21 C. So T2 seems to be working ok, but maybe not my heated bed thermistor. When I turn on the heated bed, the thermistor reading does go up correspondingly, as though it's just reading 10-15 C lower than it should be. After letting the heated bed cool a while it now seems to be holding at 10 C. So I guess I have a defective heated bed thermistor?

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:36PM |

Registered: 8 years ago Posts: 48 |

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:42PM |

Registered: 8 years ago Posts: 432 |

My stock FT hot end (rev.B.) is all metal - no plastic tube inside. I print with PETG, Nylon without any problem.

Edited 1 time(s). Last edit at 12/31/2015 12:42PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

Edited 1 time(s). Last edit at 12/31/2015 12:42PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:46PM |

Registered: 8 years ago Posts: 432 |

Update: oops, looks like you tried exactly the same part.

If your heat break barrel has plastic tube, you can just replace it with all metal one, something like [www.ebay.com]

no need to change the whole hot end that works good.

Edited 1 time(s). Last edit at 12/31/2015 12:50PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

If your heat break barrel has plastic tube, you can just replace it with all metal one, something like [www.ebay.com]

no need to change the whole hot end that works good.

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

Edited 1 time(s). Last edit at 12/31/2015 12:50PM by paul_delta.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:48PM |

Registered: 8 years ago Posts: 48 |

Quote

paul_delta

My stock FT hot end (rev.B.) is all metal - no plastic tube inside. I print with PETG, Nylon without any problem.

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

They must have upgraded the rev B then. My rev A. definitely has a liner. I figured the only difference would be the heat break, but the one I got wasn't really functional at all.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 12:54PM |

Registered: 8 years ago Posts: 432 |

I saw on youtube, some people just remove this plastic part converting to all metal cheap way.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

Quote

wrangellboy

Quote

paul_delta

My stock FT hot end (rev.B.) is all metal - no plastic tube inside. I print with PETG, Nylon without any problem.

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

They must have upgraded the rev B then. My rev A. definitely has a liner. I figured the only difference would be the heat break, but the one I got wasn't really functional at all.

My [www.thingiverse.com] stuff, my configuration of Repetier 0.92.6: [forums.reprap.org] (use Arduino 1.6.5 to compile)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 04:13PM |

Registered: 8 years ago Posts: 48 |

Quote

paul_delta

Update: oops, looks like you tried exactly the same part.

If your heat break barrel has plastic tube, you can just replace it with all metal one, something like [www.ebay.com]

no need to change the whole hot end that works good.

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

Maybe I'll try the metal tube again and just give it a good once over to make sure everything is tight and lining up as it should be. Last time I tried it, any retractions at all would cause jams.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level December 31, 2015 06:45PM |

Registered: 8 years ago Posts: 197 |

Quote

wrangellboy

Anybody ever to try to convert the stock hot end to all metal? I have a couple rolls of petg and printing at 240+ with the stock lined hot end makes me nervous. I ordered this and installed it, but it jammed like mad on PLA. I know the standard answer is to buy an e3d, but petg just isn't worth an $85 hot end for me...

I had that problem with pla and all metal throat.

I believe it transfer heat better, causing the inside to heat up faster and melt the pla.

try adding more fan power to the heatsink

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 01, 2016 03:18AM |

Registered: 8 years ago Posts: 16 |

Awesome thread guys! It took me a few days, but I scanned the first half, and read the rev.B bits pretty thoroughly. Some handy tips and info here, to be sure! Folger Tech should link to this thread in their build guide.

My kit arrives Monday, and I can't wait. It will be my first printer, and a prelude to building a much larger delta in the future. I decided this kit was the best way to wet my feet, and still have a highly useful printer, once I build the big one. I thought it might be useful to share my thoughts on why I went with this kit, and what I plan to do with it. I personally chose the folger tech after a lot of consideration, accepting the shortcomings, vs the competition.

Nearly all competing kits in this price bracket use printed corners. Some of those kits offer linear rails, as opposed to printed carriages and wheels. That's an upgrade in my book, but my thinking is that it's a much easier job to upgrade to rails in the future, than to upgrade from printed to aluminum corners. Beyond that, most of the kits in this range seem very similar. The steppers in this kit are clearly not the beefiest, but seem adequate to get started. That's an easy upgrade at some point, and will leave me with 3 small steppers for a random project. The arduino/ramps arrangement seems pretty standard, if barely adequate for a delta. It will be fine for the foreseeable future, but I definitely would like to upgrade to Duet or Smoothieboard at some point(leaving me electronics for those 3 small steppers, maybe a small reprap?). I've not seen any complaints about the heated bed, and I have no plans of changing or upgrading it, beyond the 220mm glass plate I will be using atop it. If the rev B hotend is all metal, I see no reason to upgrade it unless it gives me trouble. I have no dreams of adding another extruder to this unit. One will do on a machine this size, for my use. I would like to build a flying extruder arrangement for it, but that's a project for well after I get the thing working with the standard configuration. I did add the small LCD/card reader to my kit, for operation without a pc.

So yeah, I'm super excited. Now that winter is actually getting cold, it's nice to know I have a project to keep me busy and tinkering til spring.

thanks for reading

Ken in Cleveland

My kit arrives Monday, and I can't wait. It will be my first printer, and a prelude to building a much larger delta in the future. I decided this kit was the best way to wet my feet, and still have a highly useful printer, once I build the big one. I thought it might be useful to share my thoughts on why I went with this kit, and what I plan to do with it. I personally chose the folger tech after a lot of consideration, accepting the shortcomings, vs the competition.

Nearly all competing kits in this price bracket use printed corners. Some of those kits offer linear rails, as opposed to printed carriages and wheels. That's an upgrade in my book, but my thinking is that it's a much easier job to upgrade to rails in the future, than to upgrade from printed to aluminum corners. Beyond that, most of the kits in this range seem very similar. The steppers in this kit are clearly not the beefiest, but seem adequate to get started. That's an easy upgrade at some point, and will leave me with 3 small steppers for a random project. The arduino/ramps arrangement seems pretty standard, if barely adequate for a delta. It will be fine for the foreseeable future, but I definitely would like to upgrade to Duet or Smoothieboard at some point(leaving me electronics for those 3 small steppers, maybe a small reprap?). I've not seen any complaints about the heated bed, and I have no plans of changing or upgrading it, beyond the 220mm glass plate I will be using atop it. If the rev B hotend is all metal, I see no reason to upgrade it unless it gives me trouble. I have no dreams of adding another extruder to this unit. One will do on a machine this size, for my use. I would like to build a flying extruder arrangement for it, but that's a project for well after I get the thing working with the standard configuration. I did add the small LCD/card reader to my kit, for operation without a pc.

So yeah, I'm super excited. Now that winter is actually getting cold, it's nice to know I have a project to keep me busy and tinkering til spring.

thanks for reading

Ken in Cleveland

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 02, 2016 11:17AM |

Registered: 8 years ago Posts: 3 |

Just built the folger tech kossel Rev B kit, took a few days, but I went slow and made sure everything was correct and to the guide. I flashed it with firmware, ran the pronterface program and tested it out. Motors move well / ok, I had to tighten the belts to make it worked better, but it did. I inverted the extruder motor, so the filament would feed correctly, but when I ran my first print, the sliders move down, catch a few times and the filament would slowly come out of the top hole and no longer be in the hot end. The sliding unit would go down and then the belt would catch and the motors would grind. In a panic I unplugged the PSU from the wall, since motors were making a very bad noise and starting to get very hot. When I plugged the PSU back into the wall I heard a small pop and no light came on. Now nothing turns on. I had wired it to the manuals instructions and had only plugged it in a couple times. I think that I was sent a bad PSU.

I should note I am using there firmware for there Rev A model, I have Rev B, I should probably use the new firmware, but I dialed it all in with Rev A and from what it looks like in terms of general movements it seems fine, I tried the Rev B firmware and then thing went crazy. I should probably spend more time with the newer firmware.

I should note I am using there firmware for there Rev A model, I have Rev B, I should probably use the new firmware, but I dialed it all in with Rev A and from what it looks like in terms of general movements it seems fine, I tried the Rev B firmware and then thing went crazy. I should probably spend more time with the newer firmware.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 02, 2016 11:00PM |

Registered: 8 years ago Posts: 16 |

My kit arrived today(early!). I was at work, so I only just got to go through it. All components are clearly labeled, and it was easy to do a quick check to see that all the major components were there. Kudos to Folger Tech on that. It may be all chinese equipment, but it's nice to have a native english speaker packing and labeling the kit! He could do a little better on the hardware(nuts,bolts,screws,etc), by splitting it up a bit, but I won't ding him any points for that.

The 3d printed components aren't the prettiest, but they seem solid. Well, all but the piece that mounts the fan to the hotend, and secures the hotend to the effector. It's ugly, and looks sure to delaminate, where the fan mount attaches to the clamping piece. I will be printing it, and all the other parts, as soon as I start getting anything decent from my kossel. My hotend was already assembled. Bonus!

Boy those motors aren't exactly beefy, but I guess Folger has to make a little money somewhere. The margins on this kit must be pretty tight. I wish all 4 were the same size as the extruder motor though... Future upgrade(0.9 degree steppers and Duet)...

There are more cut acrylic components than I realized. That won't do. They will be slowly replaced. Hopefully I can get it assembled without cracking any pieces. I swear acrylic cracks if I sneeze near it. Also, I intend to enclose this unit eventually, so the acrylic will have to be gone by then.

After taking inventory, I stripped the 2020 so I could check the lengths. Heavy sigh. There's about a 2mm variance in the length of the horizontal pieces. Fortunately there is a group of 6 that are spot on, then 2 pieces shorter by 1mm, and the last piece short by 2mm. I will assemble the two upper triangles with the 6 identical pieces, then briefly install the vertical rails. I can then assemble the lower triangle in place, using the vertical rails to give the perfect spacing when I tighten it up. It's going to complicate assembly a bit to put the triangles together before adding the motors, but I think it's worth it. Then I can remove the verticals, and proceed with assembly, knowing my triangles are all equilateral, and equal in size. It's a little thing, but if you intend to fine tune your machine to get better and better prints, best to start with as symmetrical a frame as possible, rather than chase it down after everything else is already dialed in.

Wish me luck!

The 3d printed components aren't the prettiest, but they seem solid. Well, all but the piece that mounts the fan to the hotend, and secures the hotend to the effector. It's ugly, and looks sure to delaminate, where the fan mount attaches to the clamping piece. I will be printing it, and all the other parts, as soon as I start getting anything decent from my kossel. My hotend was already assembled. Bonus!

Boy those motors aren't exactly beefy, but I guess Folger has to make a little money somewhere. The margins on this kit must be pretty tight. I wish all 4 were the same size as the extruder motor though... Future upgrade(0.9 degree steppers and Duet)...

There are more cut acrylic components than I realized. That won't do. They will be slowly replaced. Hopefully I can get it assembled without cracking any pieces. I swear acrylic cracks if I sneeze near it. Also, I intend to enclose this unit eventually, so the acrylic will have to be gone by then.

After taking inventory, I stripped the 2020 so I could check the lengths. Heavy sigh. There's about a 2mm variance in the length of the horizontal pieces. Fortunately there is a group of 6 that are spot on, then 2 pieces shorter by 1mm, and the last piece short by 2mm. I will assemble the two upper triangles with the 6 identical pieces, then briefly install the vertical rails. I can then assemble the lower triangle in place, using the vertical rails to give the perfect spacing when I tighten it up. It's going to complicate assembly a bit to put the triangles together before adding the motors, but I think it's worth it. Then I can remove the verticals, and proceed with assembly, knowing my triangles are all equilateral, and equal in size. It's a little thing, but if you intend to fine tune your machine to get better and better prints, best to start with as symmetrical a frame as possible, rather than chase it down after everything else is already dialed in.

Wish me luck!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 03, 2016 12:22AM |

Registered: 8 years ago Posts: 16 |

Hardware sorted! I used an 18 spot egg carton to do my sorting. I cut it in half, and dumped the hardware in the lid half. Then I sorted it into individual egg holes on the egg half, and wrote down what they are on the carton spots:

It seems I'm short two types of screws, if the parts list label is to be believed. I have neither the M3x12, or the M4x10 screws that are listed. Everything else on the list was accounted for. Now I'm going to breeze through the revB pdf and see if those are actually used anywhere, or if they were an unneeded part from the revA.

It seems I'm short two types of screws, if the parts list label is to be believed. I have neither the M3x12, or the M4x10 screws that are listed. Everything else on the list was accounted for. Now I'm going to breeze through the revB pdf and see if those are actually used anywhere, or if they were an unneeded part from the revA.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 03, 2016 03:40AM |

Registered: 8 years ago Posts: 10 |

Got mine built and running. The z is 2 or 3mm higher on the edge of the print bed than in the middle. How do I go about fixing this? I gather it is with end stop offset but I can't figure it out. G29 just makes everything climb to the top and crash into the stops.

Edited 1 time(s). Last edit at 01/03/2016 03:41AM by guitarhammer.

Edited 1 time(s). Last edit at 01/03/2016 03:41AM by guitarhammer.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 03, 2016 09:06AM |

Registered: 10 years ago Posts: 14,672 |

Quote

guitarhammer

Got mine built and running. The z is 2 or 3mm higher on the edge of the print bed than in the middle. How do I go about fixing this? I gather it is with end stop offset but I can't figure it out. G29 just makes everything climb to the top and crash into the stops.

Measure the nozzle height error at a number of points on the bed. The minimum is 4 (traditionally in front of each tower, and in the centre), but 7 or 10 is better. Then plug the nozzle height errors into my delta calibration calculator at [escher3d.com]. That will tell you corrections you need to make to the firmware parameters.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 03, 2016 09:13AM |

Registered: 8 years ago Posts: 3 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level January 03, 2016 02:36PM |

Registered: 8 years ago Posts: 10 |

DC42, Thanks for the answer. I have tried the calculator about 6 times with different points and always get this: M665 RNaN L240.00 M666 XNaN YNaN ZNaN ; Set homed height NaNmm in config.h. (I do have 240mm rods) Not sure what is wrong. I have tried to manually enter a correction with M666 and nothing changes. I am trying to do it in Pronterface, I have read somewhere that does not work. When I try in Repetier the EPROM screen is blank and says it only works for Repetier firmware, the printer is Marlin yes? What am I doing wrong here? Thanks for any help one can give me.

Sorry, only registered users may post in this forum.