|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2015 09:58AM |

Registered: 9 years ago Posts: 30 |

Quote

grisina

If you use D9 for the fan, see my earlier note on this same thread. Using the files at Blomker, you actually have to know what you are doing, it's not plug and play. You have to make sure the arm's length, end switches (TRUE or FALSE), stepper motor speed, etc are properly entered. Otherwise, this could take you hours to configure and tweak. Also the files for Repetier and Marlin are different. I'm currently using Marlin's, but FolgerTech have the files for Repetier. There using to be a google drive like under their blog, but I just try it and it's not there any more. PM me if you need the Marlin's version (which I did modified from blomker).

I just tried the google drive and it works fine.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2015 12:42PM |

Registered: 9 years ago Posts: 12 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2015 04:21PM |

Registered: 9 years ago Posts: 76 |

Quote

juicev85

Can someone confirm the extruder motor specs that come with the kit, even better can you give me a part number? I am curious what the holding torque and step angle is...

Should be this motor:

[folgertech.com]

Making it better for Makers!

[makerfront.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2015 04:24PM |

Registered: 9 years ago Posts: 76 |

Quote

grisina

If you use D9 for the fan, see my earlier note on this same thread. Using the files at Blomker, you actually have to know what you are doing, it's not plug and play. You have to make sure the arm's length, end switches (TRUE or FALSE), stepper motor speed, etc are properly entered. Otherwise, this could take you hours to configure and tweak. Also the files for Repetier and Marlin are different. I'm currently using Marlin's, but FolgerTech have the files for Repetier. There using to be a google drive like under their blog, but I just try it and it's not there any more. PM me if you need the Marlin's version (which I did modified from blomker).

There are pre-configured Marlin FW's for 36 and 20 tooth on my Google Drive (I did the manuals and FW for them). Links are in my signature.

Making it better for Makers!

[makerfront.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 25, 2015 04:27PM |

Registered: 9 years ago Posts: 76 |

Quote

ilotam

Hello everyone.

I just finished building my Kossel with custom dimensions, using 2020 profile. While exploring for firmware, I came across of this forum and decided to use FolgerTech_kossel_firmware_V2 for 20 tooth (modified for 16 tooth pulley).

After manual calibration for surface flatness and correct Z travel (I changed steps/mm because the calculated value using formula above, was giving me some wired results), I tried autolevel function using G29 command. Very strange behavior! it seem to me that it tries to calibrate a plane which is inclined with almost 45 degree and located somewhere in the middle of the print height. Basically it is same as here but plane is inclined: [www.youtube.com]

Does anyone know how to fix this?

I'm using both, Repetier_Host and Pronterface.

Hardware is Ramps 1.4 + Mega 2560 V3 + DRV8825

Just a note, I spent 14 hours customizing the FW for this printer for FolgerTech, hence it is a custom firmware meant for their exact printer. Even though it may work for other printers, you will run into a lot of differences.

Making it better for Makers!

[makerfront.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 26, 2015 10:38AM |

Registered: 9 years ago Posts: 110 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2015 01:49PM |

Registered: 9 years ago Posts: 3 |

Quote

MakerFront

Quote

ilotam

Hello everyone.

I just finished building my Kossel with custom dimensions, using 2020 profile. While exploring for firmware, I came across of this forum and decided to use FolgerTech_kossel_firmware_V2 for 20 tooth (modified for 16 tooth pulley).

After manual calibration for surface flatness and correct Z travel (I changed steps/mm because the calculated value using formula above, was giving me some wired results), I tried autolevel function using G29 command. Very strange behavior! it seem to me that it tries to calibrate a plane which is inclined with almost 45 degree and located somewhere in the middle of the print height. Basically it is same as here but plane is inclined: [www.youtube.com]

Does anyone know how to fix this?

I'm using both, Repetier_Host and Pronterface.

Hardware is Ramps 1.4 + Mega 2560 V3 + DRV8825

Just a note, I spent 14 hours customizing the FW for this printer for FolgerTech, hence it is a custom firmware meant for their exact printer. Even though it may work for other printers, you will run into a lot of differences.

I appreciate you work. I managed to fix problems above, but still decided to switch to Marlin delta, to avoid future problems according to your information. But, there is a problem with that marlin, it's too big and gives low memory warning. Can you give me an advice, how to reduce sketch size? I don't have any memory issues with your version of firmware.

Edited 1 time(s). Last edit at 02/27/2015 01:50PM by ilotam.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level February 27, 2015 02:31PM |

Registered: 9 years ago Posts: 76 |

Quote

ilotam

Quote

MakerFront

Quote

ilotam

Hello everyone.

I just finished building my Kossel with custom dimensions, using 2020 profile. While exploring for firmware, I came across of this forum and decided to use FolgerTech_kossel_firmware_V2 for 20 tooth (modified for 16 tooth pulley).

After manual calibration for surface flatness and correct Z travel (I changed steps/mm because the calculated value using formula above, was giving me some wired results), I tried autolevel function using G29 command. Very strange behavior! it seem to me that it tries to calibrate a plane which is inclined with almost 45 degree and located somewhere in the middle of the print height. Basically it is same as here but plane is inclined: [www.youtube.com]

Does anyone know how to fix this?

I'm using both, Repetier_Host and Pronterface.

Hardware is Ramps 1.4 + Mega 2560 V3 + DRV8825

Just a note, I spent 14 hours customizing the FW for this printer for FolgerTech, hence it is a custom firmware meant for their exact printer. Even though it may work for other printers, you will run into a lot of differences.

I appreciate you work. I managed to fix problems above, but still decided to switch to Marlin delta, to avoid future problems according to your information. But, there is a problem with that marlin, it's too big and gives low memory warning. Can you give me an advice, how to reduce sketch size? I don't have any memory issues with your version of firmware.

You might want to give this a try, you'll have to configure it for your printer, but it may be a good starting point:

[github.com]

Make sure you grab all the latest files in the testing branch.

Making it better for Makers!

[makerfront.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 01, 2015 01:15PM |

Registered: 9 years ago Posts: 1 |

That does not matter at all so long as you set the number of teeth and the step rate and micro-steps properly in marlin it will do all of the calculations. It might also be a benefit if your belts are loose there will be more surface purchase and lest angular pressure on the fibers in the belt. The board will control the rate and distance based on good information in...the actual size does not matter unless the gear binds in a slot or interferes with the carriage in some way.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 01, 2015 10:15PM |

Registered: 9 years ago Posts: 11 |

A big Thank you to everyone on this board for posting all this good info, it did make my mind to buy this printer "Now the waiting game starts"

So this will be my very first printer and right now I am trying to absorbe all I can. I am familiar with arduino and Gshield with GRBL Thats what I use for my homebuilt CNC and now getting into 3D printing also.

Once I get it and assemble I will contribute to the board more for now I will try to read all I can.

So this will be my very first printer and right now I am trying to absorbe all I can. I am familiar with arduino and Gshield with GRBL Thats what I use for my homebuilt CNC and now getting into 3D printing also.

Once I get it and assemble I will contribute to the board more for now I will try to read all I can.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 01, 2015 11:56PM |

Registered: 9 years ago Posts: 9 |

Extruder question...

My extruder does not want to pull filament through unless I give it an extra push. It's not clogged, it's just like it does not have enough strength to pull it (it just wiggles back n forth) but if I add pressure it does feed as expected. I did measure the voltage at .55 as specified. I also tried a new stepper board thinking it may be faulty but same behavior. Any ideas?

My extruder does not want to pull filament through unless I give it an extra push. It's not clogged, it's just like it does not have enough strength to pull it (it just wiggles back n forth) but if I add pressure it does feed as expected. I did measure the voltage at .55 as specified. I also tried a new stepper board thinking it may be faulty but same behavior. Any ideas?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 02, 2015 06:26AM |

Registered: 9 years ago Posts: 63 |

I increased my stepper voltage to .65v to get it to feed well. Since the Extruder motor is larger than the other 3 motors, the extra surface area dissapates heat better, it can handle more current and stillstay cool (The Folgertech manual voltage adjustment should be higher for this motor). You could even go higher than .65v if needed. The only risk you run is having the Polulo driver board get too hot and temporarily go into thermal studown for a couple minutes. I not only mounted the included heat sinks on all my Polulo boards, but I aso mounted a tiny fan to blow across them. I've never once had a single Populo go into termal protection mode, even without the fan.

-- Other than that, you might check your feed rate. If it is too high, it will skip. You will know if this is the case because your prints will have way too much material in each line causing little dropplets every mm or so.

-- Also, if the bearing in the extruder housing does not free wheel when lateral pressure is applied to it (just like it has when the filament presses against it, that can cause your symptom.

-- Make sure your spool is not dragging on the holder. The acrylic one provided in the kit is not adequate.

-- You might have crud in the middle to upper part of your extruder that is blocking the filament path.

My bet is on the voltage being too low.

-- Other than that, you might check your feed rate. If it is too high, it will skip. You will know if this is the case because your prints will have way too much material in each line causing little dropplets every mm or so.

-- Also, if the bearing in the extruder housing does not free wheel when lateral pressure is applied to it (just like it has when the filament presses against it, that can cause your symptom.

-- Make sure your spool is not dragging on the holder. The acrylic one provided in the kit is not adequate.

-- You might have crud in the middle to upper part of your extruder that is blocking the filament path.

My bet is on the voltage being too low.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 02, 2015 06:41AM |

Registered: 11 years ago Posts: 69 |

Quote

Plasticmonkey

Extruder question...

My extruder does not want to pull filament through unless I give it an extra push. It's not clogged, it's just like it does not have enough strength to pull it (it just wiggles back n forth) but if I add pressure it does feed as expected. I did measure the voltage at .55 as specified. I also tried a new stepper board thinking it may be faulty but same behavior. Any ideas?

Can you manually push filament though to make to extrude? You should not have to push too hard. The firmware--i think--seems to do its best to not push too hard and grind a notch in the side of the filament where it is trying to feed. I've eyed other extruder set ups, but the stock one (once dialed in) seems to work fine for me so far.

Is your e-rate set high enough--or too high? Does it move the distance you tell it? If you tell it to feed 50cm, does it move 50cm?

I had my e steps wrong (almost 4x the rate) and it was overfeeding it, evenly jamming my hot end (see pick below).

Can it move the right distance with the Bowden tube disconnected?

Are you sure the pathway is clear? My filament usually catches in the edge of the starting Bowden tube connector unless I put a point on the filament to feed it through. Is the filament catching in the hot end?

It you are using PLA, is the fan blowing full speed on the hot end fins? If it is not cooled, the PLA can soften and make for a nasty jam. Had to completely take apart my hot end fully to pull this jam out:

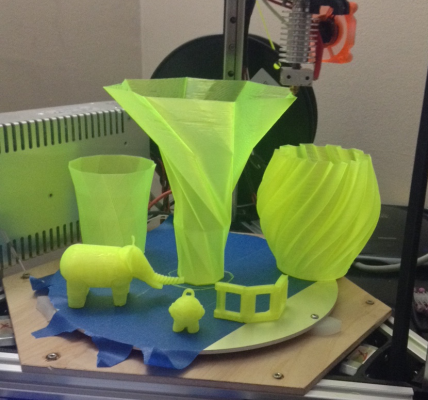

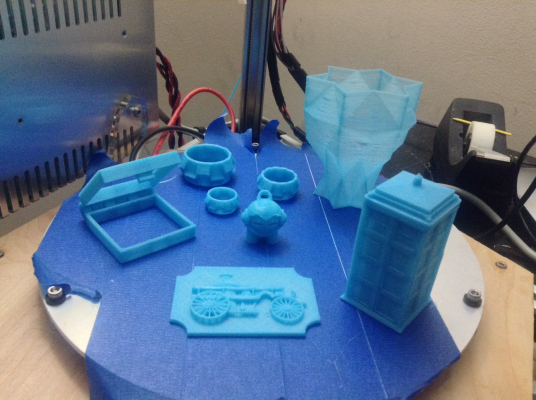

No real solution, just trying to help you troubleshoot it. Mine is finally getting dialed in and making some decent prints:

I need to work on the speed setting for the tall vases. If the head accelerates too much, it does not bond well, or at all to the lower layers.

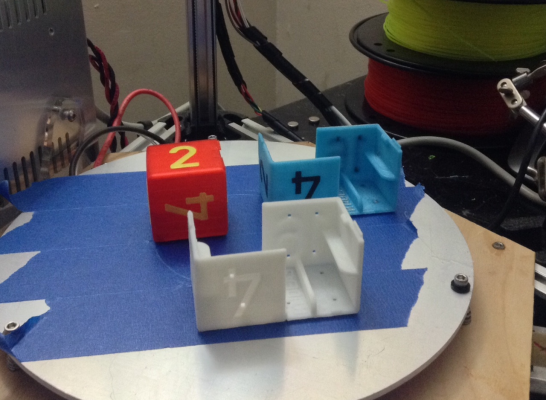

.2mm layer height. 36mm dice boxes with printed hinge:

Took me a month and half to get mine set up and the right parts (Folger Tech has made things right), but is does now print reliably or me. I have over 6 days and 3 hours of print time on it pushing through 1208.1 meters of filament--5 colors and clear t-glase (expensive, and not dialed in yet.) lOts of lost sleep, but eventually I think it is worth it.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 02, 2015 08:30PM |

Registered: 9 years ago Posts: 8 |

Quote

mmcginnis9272

I increased my stepper voltage to .65v to get it to feed well. Since the Extruder motor is larger than the other 3 motors, the extra surface area dissapates heat better, it can handle more current and stillstay cool (The Folgertech manual voltage adjustment should be higher for this motor). You could even go higher than .65v if needed. The only risk you run is having the Polulo driver board get too hot and temporarily go into thermal studown for a couple minutes. I not only mounted the included heat sinks on all my Polulo boards, but I aso mounted a tiny fan to blow across them. I've never once had a single Populo go into termal protection mode, even without the fan.

-- Other than that, you might check your feed rate. If it is too high, it will skip. You will know if this is the case because your prints will have way too much material in each line causing little dropplets every mm or so.

-- Also, if the bearing in the extruder housing does not free wheel when lateral pressure is applied to it (just like it has when the filament presses against it, that can cause your symptom.

-- Make sure your spool is not dragging on the holder. The acrylic one provided in the kit is not adequate.

-- You might have crud in the middle to upper part of your extruder that is blocking the filament path.

My bet is on the voltage being too low.

I had the same voltage issue. Once I raised the voltage, it stopped skipping!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 03, 2015 08:10AM |

Registered: 11 years ago Posts: 69 |

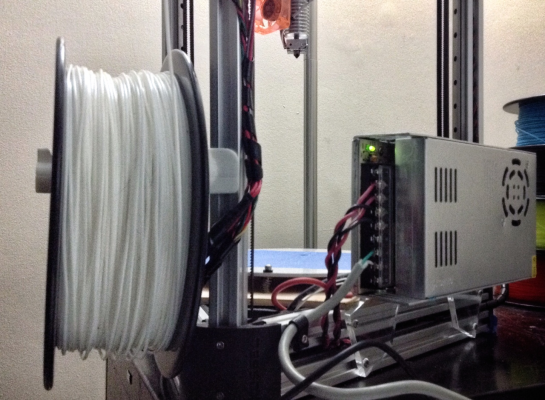

I added a model to Thingiverse for a replacement spool holder. Good for spools up to 70mm wide. I added two--a straight one and an angled one. The angled one's feed path is better and it is flush with one side.

Angled Spool Holder

Straight Spool Holder

Yeah, I ned to clean up my wires.

Angled Spool Holder

Straight Spool Holder

Yeah, I ned to clean up my wires.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 04, 2015 02:16PM |

Registered: 9 years ago Posts: 63 |

I am using basically the same filament holder as you except mine has two roller bearings in it for super low friction movement of the spool. I uploaded my version to thingiverse here:

[www.thingiverse.com]

I got 2 bearings delivered for $3.30 here:

[www.ebay.com]

Edited 1 time(s). Last edit at 03/04/2015 02:31PM by mmcginnis9272.

[www.thingiverse.com]

I got 2 bearings delivered for $3.30 here:

[www.ebay.com]

Edited 1 time(s). Last edit at 03/04/2015 02:31PM by mmcginnis9272.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 04, 2015 03:25PM |

Registered: 11 years ago Posts: 69 |

Very nice. Thought I'd try mine without bearings since the original acrylic seems okay. So far so good on mine. But do like the super low friction idea.Quote

mmcginnis9272

I am using basically the same filament holder as you except mine has two roller bearings in it for super low friction movement of the spool. I uploaded my version to thingiverse here:

[www.thingiverse.com]

I got 2 bearings delivered for $3.30 here:

[www.ebay.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 04, 2015 08:07PM |

Registered: 9 years ago Posts: 23 |

Heaters going crazy...any ideas? Here's what's happening...no changes have been made to the firmware or any heat-related print settings since this started:

- The first issue was the the bed heater would not kick on when the bed was very cold...usually for the first print of the day or after a long break between prints. Since I'm using PLA on painter's tape and don't really need the heated bed right now, I would change the G-code to not wait for the target temperature, start the print, and the bed heater would always start in about 1 minute after the print started. If I didn't start the print and just left the printer there with the hot end at temperature without printing anything, the bed heater would never start. It's almost as if starting the print job was kick-starting the bed heater somehow, but I'm not sure how that could even happen.

- The latest issue is that the hot end heater seems to have lost it's "PID" ability to maintain the temperature in a narrow range. It had always ben able to keep the temperature to within about 1 degree of the target temp, but the other night I noticed it printing with the hot end about 10-15 degrees (C) below the target temp of 215, and just now I noticed it overshoot a change from 215 to 200...it cooled down all the way to about 185 before reversing direction and heading back towards 200. That's what makes me think it's the PID heating algorithms that are somehow causing this, but I've never gone near those settings so I'm not sure if that could be the issue or if it's something else, maybe the heater(s) themselves...

Thanks in advance!

Olivier

- The first issue was the the bed heater would not kick on when the bed was very cold...usually for the first print of the day or after a long break between prints. Since I'm using PLA on painter's tape and don't really need the heated bed right now, I would change the G-code to not wait for the target temperature, start the print, and the bed heater would always start in about 1 minute after the print started. If I didn't start the print and just left the printer there with the hot end at temperature without printing anything, the bed heater would never start. It's almost as if starting the print job was kick-starting the bed heater somehow, but I'm not sure how that could even happen.

- The latest issue is that the hot end heater seems to have lost it's "PID" ability to maintain the temperature in a narrow range. It had always ben able to keep the temperature to within about 1 degree of the target temp, but the other night I noticed it printing with the hot end about 10-15 degrees (C) below the target temp of 215, and just now I noticed it overshoot a change from 215 to 200...it cooled down all the way to about 185 before reversing direction and heading back towards 200. That's what makes me think it's the PID heating algorithms that are somehow causing this, but I've never gone near those settings so I'm not sure if that could be the issue or if it's something else, maybe the heater(s) themselves...

Thanks in advance!

Olivier

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 04, 2015 11:10PM |

Registered: 9 years ago Posts: 9 |

Quote

mmcginnis9272

I increased my stepper voltage to .65v to get it to feed well. Since the Extruder motor is larger than the other 3 motors, the extra surface area dissapates heat better, it can handle more current and stillstay cool (The Folgertech manual voltage adjustment should be higher for this motor). You could even go higher than .65v if needed. The only risk you run is having the Polulo driver board get too hot and temporarily go into thermal studown for a couple minutes. I not only mounted the included heat sinks on all my Polulo boards, but I aso mounted a tiny fan to blow across them. I've never once had a single Populo go into termal protection mode, even without the fan.

-- Other than that, you might check your feed rate. If it is too high, it will skip. You will know if this is the case because your prints will have way too much material in each line causing little dropplets every mm or so.

-- Also, if the bearing in the extruder housing does not free wheel when lateral pressure is applied to it (just like it has when the filament presses against it, that can cause your symptom.

-- Make sure your spool is not dragging on the holder. The acrylic one provided in the kit is not adequate.

-- You might have crud in the middle to upper part of your extruder that is blocking the filament path.

My bet is on the voltage being too low.

That was the issue, set to .65 and now the extruder is cranking...thanks! Now I just need to figure out bed leveling...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 05, 2015 06:48AM |

Registered: 9 years ago Posts: 49 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 05, 2015 07:08AM |

Registered: 9 years ago Posts: 63 |

Quote

ohecht

Heaters going crazy...any ideas? Here's what's happening...no changes have been made to the firmware or any heat-related print settings since this started:

- The first issue was the the bed heater would not kick on when the bed was very cold...usually for the first print of the day or after a long break between prints. Since I'm using PLA on painter's tape and don't really need the heated bed right now, I would change the G-code to not wait for the target temperature, start the print, and the bed heater would always start in about 1 minute after the print started. If I didn't start the print and just left the printer there with the hot end at temperature without printing anything, the bed heater would never start. It's almost as if starting the print job was kick-starting the bed heater somehow, but I'm not sure how that could even happen.

- The latest issue is that the hot end heater seems to have lost it's "PID" ability to maintain the temperature in a narrow range. It had always ben able to keep the temperature to within about 1 degree of the target temp, but the other night I noticed it printing with the hot end about 10-15 degrees (C) below the target temp of 215, and just now I noticed it overshoot a change from 215 to 200...it cooled down all the way to about 185 before reversing direction and heading back towards 200. That's what makes me think it's the PID heating algorithms that are somehow causing this, but I've never gone near those settings so I'm not sure if that could be the issue or if it's something else, maybe the heater(s) themselves...

Thanks in advance!

Olivier

My kit from Folger Tech did not have a fan shroud on the extruder.... does yours? See attached pic from page 15 of the build manual...

I noticed early on that my fan not only kept the fins cool, but it cooled the head..... this is BAD!!! In fact, I could not get my head to heat over 216 degrees. It took the head up to 5 mins to come up to temp from being cold, and if I decreased my temp at any time, it would overshoot (like you described) and then come back. Once I installed a fan shroud to direct the air through the fins and NOT on the head, my temps are rock solid.... I can heat at least up to 270 (haven't tried higher) and my heat times are super quick and no more overshoots.

Folger guys.... I highly recommend you include a shroud in your kits!!! It's a small thing, cheap and easy to include and it improves the abilities of the machine and gives them that "dialed in" feel.

Here are a couple that work:

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 05, 2015 07:24AM |

Registered: 9 years ago Posts: 63 |

Quote

greggo

so my zprobe is always triggered... no matter if its wired to NO or NC, button pressed or not. any ideas?

Make sure your z-probe is connected as in the attached picture.

Also, use a multi-meter in continuity or ohm mode and read the switch at the connector (not attached to the board) and make sure it is working.

Let us know the results...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 05, 2015 05:19PM |

Registered: 9 years ago Posts: 49 |

Quote

mmcginnis9272

Quote

greggo

so my zprobe is always triggered... no matter if its wired to NO or NC, button pressed or not. any ideas?

Make sure your z-probe is connected as in the attached picture.

Also, use a multi-meter in continuity or ohm mode and read the switch at the connector (not attached to the board) and make sure it is working.

Let us know the results...

a frayed piece of copper from the wire was bridging the connection between the two wires in the connector, z probe works fine now (now just gotta get it to probe right!)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 06, 2015 03:08AM |

Registered: 9 years ago Posts: 11 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 06, 2015 04:09AM |

Registered: 9 years ago Posts: 49 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 06, 2015 06:14AM |

Registered: 9 years ago Posts: 63 |

Quote

greggo

Is anyone else having a problem where the g29 code only autocalibrates a little more than half of the build plate?

By "half" do you mean the center half or a half that lies one one side or the other of the build plate?

The rods that came with my kit were too short to reach the outter edges of the plate and thus it only calibrated the inner half or so of the plate. I installed Haydn's magnetic rods that are 288mm in length (longer than really neeeded) on mine to correct this. I am told that 255mm is enough for this model. If memory serves me, the kit rods that are 230mm.

The magnetic rods and effector are really great to remove tha tiny bit of slop in the effector that comes from the Traxxas ball joints.

Haydn's rod discussion is here:

[groups.google.com]

and

[www.maui-3d.com]

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 06, 2015 11:08AM |

Registered: 9 years ago Posts: 49 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 07, 2015 10:45PM |

Registered: 9 years ago Posts: 23 |

Mine has never had a fan shroud...the fan just blows across the cooling fins on the hot end. I don't think my heating issues are fan-related since it was working fine for the first couple of weeks and the fan setup has always been the same. It's printing OK, but having trouble keeping the hotend above 205 degrees and the heated bed still requires a "kickstart" on the first print of the day...

Are there specs on the hot end heater I can check, in terms of resistance, to see if it's going bad? I may try a shroud if I can get one printed just to see if it makes the temps more consistent, but I don't think that's the cause of the heating issues I'm having...

Are there specs on the hot end heater I can check, in terms of resistance, to see if it's going bad? I may try a shroud if I can get one printed just to see if it makes the temps more consistent, but I don't think that's the cause of the heating issues I'm having...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 10, 2015 10:04AM |

Registered: 11 years ago Posts: 4 |

Hi guys,

So some of you have the printer for some time now. What do you think of it? Is it worth it? Any regrets?

I'm thinking of purchasing one at the end of the month. I already have a prusa i3 and BFB3000 plus, and want to try a delta style printer.

Any feedback would be great thanks.

Cheers,

Daniel

So some of you have the printer for some time now. What do you think of it? Is it worth it? Any regrets?

I'm thinking of purchasing one at the end of the month. I already have a prusa i3 and BFB3000 plus, and want to try a delta style printer.

Any feedback would be great thanks.

Cheers,

Daniel

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level March 10, 2015 10:48AM |

Registered: 9 years ago Posts: 63 |

For the price, I personally don't think you can beat it. The quality of the prints from this machine rival many machines that cost a thousand dollars or more. This is my very first experience with a home made 3d Printer( however, I am a service technician for 3D Systems and I work on $85,000 + machines). It was not difficult at all to assemble and I am blown away at the quality that this $400.00 printer makes. While no where near the qulality of the machines I service, it is still impressive for the cost. Yes, it seems to be a beta product, but if you are the tinkering type (and it doesn't take that much), this is a great printer.

My mods:

-- Added a fan shroud to the head. This increased max temp of the head and heating speed and stability drastically.

-- Put longer (250mm) rods on the extruder so the build size is increased.

-- Installed a 40mm fan to the Polulo board to cool the motor drivers.

-- Installed heat sinks on the 3 axis motors to keep them cool (motor mounts melt and warp easy from motor heat)

-- I'm using the Hex wrench type of auto bed leveling system common to Marlin firmware machines.

-- Added feet under the machine to raise it about 1 inch and added a couple more fans underneath the machine to improve air flow. I don't think installing the RAMPS board under the heated bed is a great idea without adequate air flow.

-- Increased reference voltage to my extruder to .65v to prevent skipping

-- traded in the stock 36 tooth motor pullys for 21 tooth pullys to get improved resolution

-- added an LCD display (available from Folger Tech for like $15.00). Also, I printed a case that mounts it to the machine base.

-- printed a new filament spool holder, as my stock one broke a couple days after I built it.

I am currently installing a magnetic effector just to see if I can improve the precision a bit. The only issues I have are spider webs between towers, especially at .1mm layer height and noticable resonance in the CF rods. I have not tried to correct the resonance yet, but I'm hoping the magnetic rods will help. If not, I'll be experimenting with rubber dampeners on the rods.

Overall, I am highly impressed with this machine for the cost. Certainly most parts are chinese and I've had no failures but one dead Polulo driver.

Edited 3 time(s). Last edit at 03/10/2015 10:55AM by mmcginnis9272.

My mods:

-- Added a fan shroud to the head. This increased max temp of the head and heating speed and stability drastically.

-- Put longer (250mm) rods on the extruder so the build size is increased.

-- Installed a 40mm fan to the Polulo board to cool the motor drivers.

-- Installed heat sinks on the 3 axis motors to keep them cool (motor mounts melt and warp easy from motor heat)

-- I'm using the Hex wrench type of auto bed leveling system common to Marlin firmware machines.

-- Added feet under the machine to raise it about 1 inch and added a couple more fans underneath the machine to improve air flow. I don't think installing the RAMPS board under the heated bed is a great idea without adequate air flow.

-- Increased reference voltage to my extruder to .65v to prevent skipping

-- traded in the stock 36 tooth motor pullys for 21 tooth pullys to get improved resolution

-- added an LCD display (available from Folger Tech for like $15.00). Also, I printed a case that mounts it to the machine base.

-- printed a new filament spool holder, as my stock one broke a couple days after I built it.

I am currently installing a magnetic effector just to see if I can improve the precision a bit. The only issues I have are spider webs between towers, especially at .1mm layer height and noticable resonance in the CF rods. I have not tried to correct the resonance yet, but I'm hoping the magnetic rods will help. If not, I'll be experimenting with rubber dampeners on the rods.

Overall, I am highly impressed with this machine for the cost. Certainly most parts are chinese and I've had no failures but one dead Polulo driver.

Edited 3 time(s). Last edit at 03/10/2015 10:55AM by mmcginnis9272.

Sorry, only registered users may post in this forum.