|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 17, 2016 02:10AM |

Registered: 7 years ago Posts: 9 |

Quote

thosmos

Quote

iknownothing

Same issue here. Have been struggling for a two weeks trying to figure out what's been happening. I've been doing the same thing, taking apart the extruder to get to the jam. I even tried letting the heater block hang without the heat sink at 240°, but I still couldn't get it cleared. I ended up having to take apart the nozzle, heater block and M6 collar and using a torch on the nozzle and collar to clear the filament. I also assembled those parts when the heater block is at 240° to reduce the possibility that those pieces would loosen due to heat expansion of the heater block ( this already happened to me during a first print ). I've just been trying PLA with a temp of 190°. Extruder is jammed as I type this and dread having to take it all apart again. I think the issue is heat creep, but don't know how to resolve it. I printed this: [www.thingiverse.com] (at 110% scale my newly acquired Monoprice Mini), to see if would help, but I still got a jam! I may try ABS to see if that makes a difference ( like meq123 ). Odd that since ABS requires higher temps and thosmos has been successful with 240° temps ....

After another catastrophic crash of the printhead into the print bed while trying out a different firmware, it started jamming just about every time. I ordered some replacement print heads (https://www.amazon.com/gp/product/B017OMRP5Y) and now it's workin great on the first print!

Just got replacement nozzle heads on Friday and was able to start printing today. I like the ones you ordered more because they have the large hex part. The smaller ones that are provided dig into the aluminum heater block when tightened, although I'm probably making it too tight!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 19, 2016 11:38AM |

Registered: 7 years ago Posts: 9 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 20, 2016 08:28PM |

Registered: 8 years ago Posts: 121 |

I have yet to print with mine. I got a E3dv6 clone so it does not fit with the sensor. So I played with tinker cad made a holder that would bolt onto the 30mm fan since the E3 has the clip on cooling fan, well now my sensor hits my arms. I have a Wanhoa I3 (clone) to print parts with. I am beginning to think about just removing the inductive sensor so I can use the printer.

Edited 1 time(s). Last edit at 07/20/2016 08:29PM by jasonsaffle13@gmail.com.

Edited 1 time(s). Last edit at 07/20/2016 08:29PM by jasonsaffle13@gmail.com.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 21, 2016 07:51PM |

Registered: 7 years ago Posts: 4 |

Quote

[email protected]

I have yet to print with mine. I got a E3dv6 clone so it does not fit with the sensor. So I played with tinker cad made a holder that would bolt onto the 30mm fan since the E3 has the clip on cooling fan, well now my sensor hits my arms. I have a Wanhoa I3 (clone) to print parts with. I am beginning to think about just removing the inductive sensor so I can use the printer.

The sensor is so inaccurate due to its Z offset. After days of fiddling with the auto-sensing, and other "auto" calibration methods, such as this wizard, I wound up just leveling and calibrating manually using this page as guidance (and using the latest Marlin firmware that has Rich Cattel's M666 G-codes for quick changes) and it's so much better now. I now have just a custom delta radius and diagonal rod length with no endstop offsets, etc. I was beginning to doubt I would ever be able to print further than 40mm from the center. That said, I did wind up re-assembling my frame with much more attention to squareness. I'm now more confident with the hardware build, and I use some bed levelers to avoid tweaking endstop offsets in hardware or software.

Edited 1 time(s). Last edit at 07/21/2016 07:54PM by thosmos.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 27, 2016 05:22PM |

Registered: 7 years ago Posts: 31 |

Quote

spiffcow

Quote

meq123

[...]

I noticed a very novel idea in the way the Micromake effector is designed, where the effector plate is made as a kind of "A" shape with the top of the hot end raised much higher than the pivot points of the arms. That would seem to me that it would reduce the effects (amplitude) of tilt and backlash considerably on the movement of the nozzle tip.

I would think we/one/you could design and print a replacement effector for the FolgerTech unit to mount the hot end the same way - with the added advantage of greater Z-height.

It's not novel.. Similar designs have been around for years. The biggest downside is that it's a PITA to size it for your hotend. It might also be a bit difficult to get a perfect angle on it, since you'll have to make sure the hot end mount is parallel to the bottom of the effector.

If you are just looking for better quality, there's a ton of mods that will be more beneficial to you.. But I'd imagine it'd help out a bit.

Quote

docpayce

@meq123: Yeah, that design was around for quite some time. There wouldn't be any benefit when it comes to backlash, BUT it would resolve tilt-related issues very, very nicely. Also +50 mm or so build height.I was thinking about designing something like that (for E3D V6), but can't find the time right now. Another problem would be proper cooling of the print. The fan(s) would have to be mounted on top of the effector, with air channels going directly through the plate. btw: The upper part being not perfectly parallel to the lower part of the effector wouldn't result in problems: As long as thats a fixed angle, everything should still be very fine.

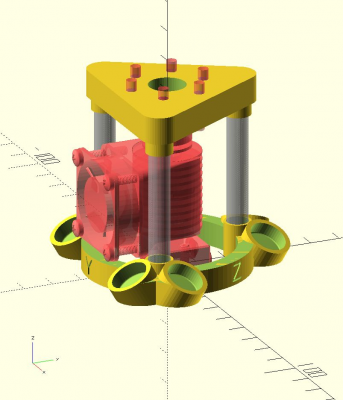

So having come up to speed on OpenSCAD and playing with docpayce's magnetic effector design (how ironic

). I figured "why not convert it to a "raised hotend" design (if there isn't a better name?).

). I figured "why not convert it to a "raised hotend" design (if there isn't a better name?).The screenshots below shows what I have now, based around a V6 hotend STL model I got off thingverse. This is designed to use cut-off carbon rods as the support pillars, either glued and/or screwed in place (former is easier, latter means you can pull it apart). The only fear I have is the proximity of the lower ring to some corners of the heat block. Other than that it seems very workable. If you want a filament cooler you could design a mount to attach to the support pillars, or even zip-ties.

Thoughts? Comments? Ideas?

Edited 1 time(s). Last edit at 07/27/2016 05:54PM by meq123.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 27, 2016 05:41PM |

Registered: 8 years ago Posts: 98 |

Quote

meq123

Quote

spiffcow

Quote

meq123

[...]

I noticed a very novel idea in the way the Micromake effector is designed, where the effector plate is made as a kind of "A" shape with the top of the hot end raised much higher than the pivot points of the arms. That would seem to me that it would reduce the effects (amplitude) of tilt and backlash considerably on the movement of the nozzle tip.

I would think we/one/you could design and print a replacement effector for the FolgerTech unit to mount the hot end the same way - with the added advantage of greater Z-height.

It's not novel.. Similar designs have been around for years. The biggest downside is that it's a PITA to size it for your hotend. It might also be a bit difficult to get a perfect angle on it, since you'll have to make sure the hot end mount is parallel to the bottom of the effector.

If you are just looking for better quality, there's a ton of mods that will be more beneficial to you.. But I'd imagine it'd help out a bit.

Quote

docpayce

@meq123: Yeah, that design was around for quite some time. There wouldn't be any benefit when it comes to backlash, BUT it would resolve tilt-related issues very, very nicely. Also +50 mm or so build height.I was thinking about designing something like that (for E3D V6), but can't find the time right now. Another problem would be proper cooling of the print. The fan(s) would have to be mounted on top of the effector, with air channels going directly through the plate. btw: The upper part being not perfectly parallel to the lower part of the effector wouldn't result in problems: As long as thats a fixed angle, everything should still be very fine.

So having come up to speed on OpenSCAD and playing with docpayce's magnetic effector design (how ironic). I figured "why not convert it to a "raised hotend" design (if there isn't a better name?).

The screenshots below shows what I have now, based around a V6 hotend STL model I got off thingverse. This is designed to use cut-off carbon rods as the support pillars, either glued and/or screwed in place (former is easier, latter means you can pull it apart). The only fear I have is the proximity of the lower ring to some corners of the heat block. Other than that it seems very workable. If you want a filament cooler you could design a mount to attach to the support pillars, or even zip-ties.

Thoughts? Comments? Ideas?

Why not use long bolts for the pillars? A little heavier, but much easier to adjust.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 29, 2016 02:09PM |

Registered: 10 years ago Posts: 56 |

@UncleSas: (Late, but hey, whatever  ) Yes, exactly. It was just about the (China) GT2 belt quality. There are a lot of MUCH better quality belts out there, both GT2's and others. The 3MR version I mentioned is just one possible solution, which is well known for its stiffness.

) Yes, exactly. It was just about the (China) GT2 belt quality. There are a lot of MUCH better quality belts out there, both GT2's and others. The 3MR version I mentioned is just one possible solution, which is well known for its stiffness.

@meq123: Nice! I like it! Imho, you should thicken the walls holding the carbon rods. Using carbon rods is a really nice idea btw. Though, you could also print the upper part completely "with the carbon rods" if you know what I mean. i.e. not use carbon rods but plastic. Comparable to this design: [www.thingiverse.com]

I like it! Imho, you should thicken the walls holding the carbon rods. Using carbon rods is a really nice idea btw. Though, you could also print the upper part completely "with the carbon rods" if you know what I mean. i.e. not use carbon rods but plastic. Comparable to this design: [www.thingiverse.com]

I am really intrigued by the two-part design. Good idea! Makes adjustements much easier (e.g. other versions of the upper part - with additional fans or such). For that upper part: Get rid of the hotend fan and put that on the upper part! Know, what I mean? Another fan on the other edge + channels = print cooling. Like I said, really intrigued!

Know, what I mean? Another fan on the other edge + channels = print cooling. Like I said, really intrigued!

) Yes, exactly. It was just about the (China) GT2 belt quality. There are a lot of MUCH better quality belts out there, both GT2's and others. The 3MR version I mentioned is just one possible solution, which is well known for its stiffness.

) Yes, exactly. It was just about the (China) GT2 belt quality. There are a lot of MUCH better quality belts out there, both GT2's and others. The 3MR version I mentioned is just one possible solution, which is well known for its stiffness.@meq123: Nice!

I like it! Imho, you should thicken the walls holding the carbon rods. Using carbon rods is a really nice idea btw. Though, you could also print the upper part completely "with the carbon rods" if you know what I mean. i.e. not use carbon rods but plastic. Comparable to this design: [www.thingiverse.com]

I like it! Imho, you should thicken the walls holding the carbon rods. Using carbon rods is a really nice idea btw. Though, you could also print the upper part completely "with the carbon rods" if you know what I mean. i.e. not use carbon rods but plastic. Comparable to this design: [www.thingiverse.com]I am really intrigued by the two-part design. Good idea! Makes adjustements much easier (e.g. other versions of the upper part - with additional fans or such). For that upper part: Get rid of the hotend fan and put that on the upper part!

Know, what I mean? Another fan on the other edge + channels = print cooling. Like I said, really intrigued!

Know, what I mean? Another fan on the other edge + channels = print cooling. Like I said, really intrigued!

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 29, 2016 03:59PM |

Registered: 7 years ago Posts: 31 |

Quote

docpayce

@meq123: Nice!I like it! Imho, you should thicken the walls holding the carbon rods. Using carbon rods is a really nice idea btw. Though, you could also print the upper part completely "with the carbon rods" if you know what I mean. i.e. not use carbon rods but plastic. Comparable to this design: [www.thingiverse.com]

I am really intrigued by the two-part design. Good idea! Makes adjustements much easier (e.g. other versions of the upper part - with additional fans or such). For that upper part: Get rid of the hotend fan and put that on the upper part!Know, what I mean? Another fan on the other edge + channels = print cooling. Like I said, really intrigued!

Thanks

EVERYTHING is parameterized, and I've put in a bunch of trig calculations so the dimensions adjust automatically for different sized magnets (well 10 & 12's are basically it, but in theory you can go to 15's if you adjust a couple of other parameters too - like offset). You can change the rod size, wall sizes etc to your heart's content. You could even make the ghost rods real (remove the %) to print it all in plastic - though I prefer the carbon rods for ability to adjust heights for diff hotends, at least in theory.

If you want, I can send you a zip of the scads to play with. Although it's based heavily on your design & code, I've probably re-written 90% of it

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level July 29, 2016 04:27PM |

Registered: 10 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 06, 2016 01:52PM |

Registered: 7 years ago Posts: 18 |

Well, I was planning to upgrade the hotend somewhere down the line, but I got forced to.

I had a filament jam, so I went to unscrew the nozzle. It wouldn't budge, then SNAP and the nozzle came off- still attached to the threaded part.

My guess is some plastic made its way into the threads and acted like Loctite.

So, word of warning- make sure your hotend is assembled correctly and tightened.

I had a filament jam, so I went to unscrew the nozzle. It wouldn't budge, then SNAP and the nozzle came off- still attached to the threaded part.

My guess is some plastic made its way into the threads and acted like Loctite.

So, word of warning- make sure your hotend is assembled correctly and tightened.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 23, 2016 07:52PM |

Registered: 7 years ago Posts: 129 |

@sharkicicles, no, the plastic didn't jam your threads. It's called an interference fit. As the nozzle got hot and cold, the threads tighten. If you have to disassemble a hot end, heat it to printing temperature before applying torque. Once the threads are broken loose, then cool the hot end and unscrew. Grip the hot block, not the cold end or heat sink.

I'm just starting to build a Kossel, and the hot end is one of the few parts I know about. The frame itself is straightforward, but the action is a bit mysterious. I have to cut my own carbon rods, and the manual is quiet about the exact length.

There are design elements about this thing I'd like to copy for my Prusa. The carriages are awesome. Forget chromed rods and linear bearings, I'll take these carriages any day.

I'm just starting to build a Kossel, and the hot end is one of the few parts I know about. The frame itself is straightforward, but the action is a bit mysterious. I have to cut my own carbon rods, and the manual is quiet about the exact length.

There are design elements about this thing I'd like to copy for my Prusa. The carriages are awesome. Forget chromed rods and linear bearings, I'll take these carriages any day.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 23, 2016 11:09PM |

Registered: 7 years ago Posts: 26 |

Quote

av8r1

@sharkicicles, no, the plastic didn't jam your threads. It's called an interference fit. As the nozzle got hot and cold, the threads tighten. If you have to disassemble a hot end, heat it to printing temperature before applying torque. Once the threads are broken loose, then cool the hot end and unscrew. Grip the hot block, not the cold end or heat sink.

Not quite, but almost...

An interference fit is type of friction fit, and some people use the terms interchangeably; though my experience with interference fit parts is that they must be pressed together because the fit is so tight - much moreso than a simple friction fit. Sometimes, an interference fit is called a press fit, because interference fit parts are usually pressed together with significant force. Typically, interference fit parts are smooth sided, though some specialized fasteners, like drive screws are really an interference fit. While this is hardly universal, tapered pins and sprung roll pins have typically been called "friction fit," rather than interference or press fit because they're relatively gently tapped home. The threaded parts of threaded parts are not friction fit, even though friction is a part of why they work the way they do.

It's more probable that there was some galvanic welding which occurred between the heater block and nozzle. Galvanic welding is a type of corrosion that occurs between two dissimlar metals, and is very commonly experienced with carbon steel and aluminum. It's been known to happen with brass and aluminum, too; but typically at a very slow rate. On the other hand, the rate of galvanic corrosion, and therefore the beriod of time before galvanic welding has occurred, is accelerated at high temperatures and in caustic environments or the presence of catalysts. There's not a lot you can do about it. There are a number of good high temperature anti-seize lubricants, but I speculate that they may interfere with the operation of the printer if they get into the print path.

On the gripping hand, unscrewing the nozzle while the hot end is hot is a great idea. While I haven't tried this on anything as small as the heater block on the E3D v5 clone that Folger ships, heating just one side of the female threaded part of the two to be separated is a very effective way to break a threaded parts loose without damaging the parts. While I've typically broken apart 2-3" nuts and bolts (diameter. threaded 2 - 41/2 or 3-4 on excavators, dumptrucks and bulldozers*) using an oxy-acetylene torch setup, I not so dangerously theorize that using a relatively powerful soldering iron to heat up one side of the heater block would work really well to break free nozzles.The reason why this technique works so well is because it causes the diameter of the female threaded part to expand ever so slightly, thus breaking or significantly weakening any corrosion weld and giving the male threaded part more clearance to move.

*And one REALLY HUGE nut on the kingpin of a 30 tone Bucyrus-Erie crane. That was both a huge PITA and very cool to do...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 24, 2016 06:44PM |

Registered: 7 years ago Posts: 129 |

It may be that different industries use terms slightly differently. My aviation background associates threads which are heated, assembled and allowed to cool to lock them into place with the phrase "interference fit." Whatever we choose to call it, the physics are there. The Aluminum heat block expands with temperature more than the steel heat break or brass/steel nozzle, so the threads loosen as the hot end is heated, so it has to be torqued when hot, not cold. It also means that--once torqued hot--the amount of torque required to loosen the cold nozzle may exceed the shear strength of the threads or heat break. More than one E3Dv6 has been killed that way by a printer user trying to change the nozzle or clear a jam.

If the hot end is used without torquing, molten filament can work it's way up the threads and make a mess. Good reason to hot torque the nozzle before use. Should the hot end leak, heating the hot end will also help with disassembly.

Either way, I did find the dimensions for the carbon rod length. Folger hid them in an appendix.

If the hot end is used without torquing, molten filament can work it's way up the threads and make a mess. Good reason to hot torque the nozzle before use. Should the hot end leak, heating the hot end will also help with disassembly.

Either way, I did find the dimensions for the carbon rod length. Folger hid them in an appendix.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 24, 2016 10:42PM |

Registered: 7 years ago Posts: 26 |

Quote

av8r1

It may be that different industries use terms slightly differently. My aviation background associates threads which are heated, assembled and allowed to cool to lock them into place with the phrase "interference fit." Whatever we choose to call it, the physics are there.

That use of "interference fit" is an interesting term of art which I speculate is specific to aviation.

I've done something like that with hoops and bands using a variety of materials; but never anything threaded. I've also gone the other way, with cold fit parts, where the inserted part is chilled first; usually seals and flexible rubber parts.

Boy, howdy... You're not getting those parts apart unless they're hot, as you said. For something as fragile as a brass hot end, breakage seems like it would be pretty much guaranteed.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 25, 2016 01:58AM |

Registered: 8 years ago Posts: 98 |

Quote

UncleSas

Quote

av8r1

It may be that different industries use terms slightly differently. My aviation background associates threads which are heated, assembled and allowed to cool to lock them into place with the phrase "interference fit." Whatever we choose to call it, the physics are there.

That use of "interference fit" is an interesting term of art which I speculate is specific to aviation.

I've done something like that with hoops and bands using a variety of materials; but never anything threaded. I've also gone the other way, with cold fit parts, where the inserted part is chilled first; usually seals and flexible rubber parts.

Boy, howdy... You're not getting those parts apart unless they're hot, as you said. For something as fragile as a brass hot end, breakage seems like it would be pretty much guaranteed.

So buy steel nozzles? They're cheap. I got like 5 of them for $2. I've broken a brass nozzle once, but only when I mixed up the direction I was turning, and even then I could tell something was seriously wrong. If you pay attention to what you're doing it's really not an issue.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 26, 2016 09:38AM |

Registered: 10 years ago Posts: 56 |

Hey guys! It's been a bit silent from my side, but I wanted to give an update on things. Primarily to avoid any redundant work:

1) In addition to a height probe with zero x/y offset (The V3 without pin of this thing: [www.thingiverse.com]) I used the easy interchangability of the magnetic effector to realize a zero x/y/z probe. I.e. the probing position is dead-on the same as the nozzle position - just on another (probe) effector, which is switched out for the actual (hot end) effector. Results were ... meh. Not to much of a difference - I would even say that a zero x/y probe is still better suited than using another probing effector - I do think changing the effector (and thus slightly changing rod pair separations) will induce more measurement errors than a 30 mm z offset will.

2) I pretty much nailed down the fabrication process of carbon rods with steel balls by investing a bunch of bucks into measurement & fabrication equipment. I consistently get to within +/- 0.10 mm of a target seperation value (i.e. I aim for 290 mm -> actual length will be 290 +/- 0.10 mm). But still better: The max deviation from one rod to any other rod of the same set is consistently +/- 0.02 mm. +/- 20 µm! Thats a length variation of half the width of a human hair within 6 carbon rods! (If you didn't guess already: I am really proud of that... ;D)

(If you didn't guess already: I am really proud of that... ;D)

I am thinking about selling these, pls let me know whether you guys would be interested.

3) Just two words as preview: IKEA enclosure.

Hopefully September. Similar to this: [makerhacks.com]

Hopefully September. Similar to this: [makerhacks.com]

4) Still thinking about meq123's design to raise the hotend. I do think this would lessen some problems.

1) In addition to a height probe with zero x/y offset (The V3 without pin of this thing: [www.thingiverse.com]) I used the easy interchangability of the magnetic effector to realize a zero x/y/z probe. I.e. the probing position is dead-on the same as the nozzle position - just on another (probe) effector, which is switched out for the actual (hot end) effector. Results were ... meh. Not to much of a difference - I would even say that a zero x/y probe is still better suited than using another probing effector - I do think changing the effector (and thus slightly changing rod pair separations) will induce more measurement errors than a 30 mm z offset will.

2) I pretty much nailed down the fabrication process of carbon rods with steel balls by investing a bunch of bucks into measurement & fabrication equipment. I consistently get to within +/- 0.10 mm of a target seperation value (i.e. I aim for 290 mm -> actual length will be 290 +/- 0.10 mm). But still better: The max deviation from one rod to any other rod of the same set is consistently +/- 0.02 mm. +/- 20 µm! Thats a length variation of half the width of a human hair within 6 carbon rods!

(If you didn't guess already: I am really proud of that... ;D)

(If you didn't guess already: I am really proud of that... ;D)I am thinking about selling these, pls let me know whether you guys would be interested.

3) Just two words as preview: IKEA enclosure.

Hopefully September. Similar to this: [makerhacks.com]

Hopefully September. Similar to this: [makerhacks.com]4) Still thinking about meq123's design to raise the hotend. I do think this would lessen some problems.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 26, 2016 09:57AM |

Registered: 8 years ago Posts: 98 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 26, 2016 10:06AM |

Registered: 8 years ago Posts: 14 |

Quote

docpayce

Hey guys! It's been a bit silent from my side, but I wanted to give an update on things. Primarily to avoid any redundant work:

1) In addition to a height probe with zero x/y offset (The V3 without pin of this thing: [www.thingiverse.com]) I used the easy interchangability of the magnetic effector to realize a zero x/y/z probe. I.e. the probing position is dead-on the same as the nozzle position - just on another (probe) effector, which is switched out for the actual (hot end) effector. Results were ... meh. Not to much of a difference - I would even say that a zero x/y probe is still better suited than using another probing effector - I do think changing the effector (and thus slightly changing rod pair separations) will induce more measurement errors than a 30 mm z offset will.

2) I pretty much nailed down the fabrication process of carbon rods with steel balls by investing a bunch of bucks into measurement & fabrication equipment. I consistently get to within +/- 0.10 mm of a target seperation value (i.e. I aim for 290 mm -> actual length will be 290 +/- 0.10 mm). But still better: The max deviation from one rod to any other rod of the same set is consistently +/- 0.02 mm. +/- 20 µm! Thats a length variation of half the width of a human hair within 6 carbon rods!(If you didn't guess already: I am really proud of that... ;D)

I am thinking about selling these, pls let me know whether you guys would be interested.

3) Just two words as preview: IKEA enclosure.

Hopefully September. Similar to this: [makerhacks.com]

4) Still thinking about meq123's design to raise the hotend. I do think this would lessen some problems.

1. I also looked at using that probe style but decided on making my own small heater block attachment [www.thingiverse.com] I can just snap my probe (extra end stop) on my hotend and run bed leveling and grid compensatio. I have had some pretty good result since it is a snug fit there is no movement in the probe mount.

4. I also like the idea of a raised effector, have been considering one for quite awhile. Within the last month I found this design that I came to really like [www.thingiverse.com] The only issue I had was the fact the the linear rods where on 35mm centers vs 40mm. Not a huge deal and gave me the motivation to design a new carriage with 35mm centers and self locking belts. With this I have been very happy with how it has turned out. I'm considering using either this or a very similar setup on my newest build.

Edited 1 time(s). Last edit at 08/26/2016 10:07AM by capacitor.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 26, 2016 03:53PM |

Registered: 7 years ago Posts: 18 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 26, 2016 07:08PM |

Registered: 10 years ago Posts: 56 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 28, 2016 10:28PM |

Registered: 7 years ago Posts: 26 |

Quote

spiffcow

Quote

UncleSas

Quote

av8r1

It may be that different industries use terms slightly differently. My aviation background associates threads which are heated, assembled and allowed to cool to lock them into place with the phrase "interference fit." Whatever we choose to call it, the physics are there.

That use of "interference fit" is an interesting term of art which I speculate is specific to aviation.

I've done something like that with hoops and bands using a variety of materials; but never anything threaded. I've also gone the other way, with cold fit parts, where the inserted part is chilled first; usually seals and flexible rubber parts.

Boy, howdy... You're not getting those parts apart unless they're hot, as you said. For something as fragile as a brass hot end, breakage seems like it would be pretty much guaranteed.

So buy steel nozzles? They're cheap. I got like 5 of them for $2. I've broken a brass nozzle once, but only when I mixed up the direction I was turning, and even then I could tell something was seriously wrong. If you pay attention to what you're doing it's really not an issue.

Sorry if I was unclear, but I was thinking specifically if you torque down the nozzle while the heater block is hot that it would be very difficult to remove the nozzle without damaging something unless you heat the block to remove it. Another way that I could see damage occuring would be stripping out the threads in the heater block, since aluminum is pretty soft.

I'd never heard of the technique that av8r1 described until this thread, and I can see a couple places where I'm going to use it.

WIth respect to inadverntantly breaking things because I've overtorqued them, that's mostly in my past. I hope. I haven't done that with the printer...

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 28, 2016 10:31PM |

Registered: 7 years ago Posts: 26 |

Quote

docpayce

@UncleSas: (Late, but hey, whatever) Yes, exactly. It was just about the (China) GT2 belt quality. There are a lot of MUCH better quality belts out there, both GT2's and others. The 3MR version I mentioned is just one possible solution, which is well known for its stiffness.

Do you have any hints for sourcing better quality GT2?

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 28, 2016 10:46PM |

Registered: 7 years ago Posts: 129 |

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 29, 2016 10:56AM |

Registered: 10 years ago Posts: 56 |

Quote

UncleSas

Do you have any hints for sourcing better quality GT2?

Welp, not really. I dove a bit into other belts (GT3's and 3M HTD's; mainly Gates powergrip series) - changing to those better belts would mean an invest of at least 60 Euros or more (belt 30 Euros per 5 m; Pulleys are like 10 bucks a piece). And the benefits will not be SOooo amazing I guess... I do think GT2's are still one of the best options when it comes to 3D printing on a budget. If you don't mind budget, check out the Gates powergrip series (HTD). There are a lot of sources for those online.

Right now I am waiting for a 10 mm wide GT2 belt + pulleys + idlers out of China. I guess that could do a better job compared to the 6 mm wide belt - though I am still quite sceptical whether there will be a significant impact on echoing/ringing etc.

Btw: I did test my China-GT2-6mm-belt once for springiness: Hanging either 0.5 kg or 4.5 kg from the belt, there was no measurable change in the seperation of two markings, which were 200 mm apart. That's quite impressive honestly.

What problems do you have with your belts? Ringing?

@av8r1: What parts do you need specifically? I only ask, because I personally got rid of 90% of the plexiglas parts. They break SO easiliy and there is a better solution for nearly any Folgertech plexiglas part.

Edited 1 time(s). Last edit at 08/29/2016 10:58AM by docpayce.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 29, 2016 12:36PM |

Registered: 8 years ago Posts: 98 |

On the topic of belts.. Have you looked into the white steel-reinforced GT2 belts? It looks like a slightly larger idler at the top would be needed, but the 20 tooth pulleys should be about perfect for it. I have some I'm planning to try as soon as I get my kossel put back together.. I had originally bought them for my core xy printer, but they're not suitable for the 16 tooth profile that it needs.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 29, 2016 03:18PM |

Registered: 7 years ago Posts: 31 |

Quote

docpayce

@av8r1: What parts do you need specifically? I only ask, because I personally got rid of 90% of the plexiglas parts. They break SO easiliy and there is a better solution for nearly any Folgertech plexiglas part.

Yeah, I agree there. I've removed ALL my acrylic bits. Now using: standoff PSU mounts from Thingverse (thanks, docpayce!); birch-ply 2560/RAMPs support that wedges into the 2020 slots; and self-designed/printed end-stop mounts and bed & glass mounts. (Note to self: I REALLY must get an account on Thingverse and post some of these.

)

)

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 30, 2016 02:47AM |

Registered: 7 years ago Posts: 129 |

Mostly I just need the RAMPS/bed mount. I'll probably 3D print some end stop mounts.

I have a bit of a prejudice against using wood in the frame of a 3D printer. Acrylic isn't exactly ideal either, but it has the benefit of being humidity proof, and I can still cut it on my makerspace's laser. I'm going to use Tech2C's compact bowden extruder, which is its own mount, there are dozens of ways to attach the power supply, and an acrylic spool holder? BAHAHAHAHA! The end stop mounts I might print, but I don't see any problem with them being acrylic.

I have a bit of a prejudice against using wood in the frame of a 3D printer. Acrylic isn't exactly ideal either, but it has the benefit of being humidity proof, and I can still cut it on my makerspace's laser. I'm going to use Tech2C's compact bowden extruder, which is its own mount, there are dozens of ways to attach the power supply, and an acrylic spool holder? BAHAHAHAHA! The end stop mounts I might print, but I don't see any problem with them being acrylic.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 30, 2016 06:59AM |

Registered: 10 years ago Posts: 56 |

Steel belts: No, didn't try. I read something about them being a bit to stiff for 20 tooth pulleys? Dunno... Looking forward for your results!

I use this RAMPS mount: [www.thingiverse.com]

(without those stabilizing "wings" - totally fine without those)

And this to hold the bed in place: [www.thingiverse.com]

(printed in ABS for obvious reasons, all leveling done via software)

Yeah, the acrylic spool holder was the very first thing to A ) break and B ) got replaced.

Btw: I am jealous... makerspace laser... maaaaaan...

Edited 1 time(s). Last edit at 08/30/2016 03:06PM by docpayce.

I use this RAMPS mount: [www.thingiverse.com]

(without those stabilizing "wings" - totally fine without those)

And this to hold the bed in place: [www.thingiverse.com]

(printed in ABS for obvious reasons, all leveling done via software)

Yeah, the acrylic spool holder was the very first thing to A ) break and B ) got replaced.

Btw: I am jealous... makerspace laser... maaaaaan...

Edited 1 time(s). Last edit at 08/30/2016 03:06PM by docpayce.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 31, 2016 05:21AM |

Registered: 7 years ago Posts: 129 |

This isn't a particularly good place to put this, but I'll put it here anyway: the firmware makes me nervous.

Not that I think Marlin is out to get me or anything, it's just that I find it a little incomprehensible. What gets me is I'll download the firmware from Github and it will NEVER compile without throwing some cryptic error. No two versions are exactly alike, and if something goes wrong, Google isn't forthcoming. Same thing with my Prusa. I'm using Folger's stock firmware because I'm not very good at finding anything else that will actually compile. I don't know how to do things like enable the EEPROM. My PID is hilariously bad, and i'm not exactly sure how to fix it.

It doesn't help at all when you read things like "uncomment the line //#define FOOBAR 17" and that line isn't anywhere in the code.

I finished the Kossel build, and I turned it on and did some stuff like home the axes, making sure the motors all go the right way, that the end stops work, etc. I've got a 2004 display and it's showing solid blocks in lines 1 and 3. Not sure why. Will attempt to diagnose next time I'm up there.

Edited 1 time(s). Last edit at 08/31/2016 05:23AM by av8r1.

Not that I think Marlin is out to get me or anything, it's just that I find it a little incomprehensible. What gets me is I'll download the firmware from Github and it will NEVER compile without throwing some cryptic error. No two versions are exactly alike, and if something goes wrong, Google isn't forthcoming. Same thing with my Prusa. I'm using Folger's stock firmware because I'm not very good at finding anything else that will actually compile. I don't know how to do things like enable the EEPROM. My PID is hilariously bad, and i'm not exactly sure how to fix it.

It doesn't help at all when you read things like "uncomment the line //#define FOOBAR 17" and that line isn't anywhere in the code.

I finished the Kossel build, and I turned it on and did some stuff like home the axes, making sure the motors all go the right way, that the end stops work, etc. I've got a 2004 display and it's showing solid blocks in lines 1 and 3. Not sure why. Will attempt to diagnose next time I'm up there.

Edited 1 time(s). Last edit at 08/31/2016 05:23AM by av8r1.

|

Re: Folger Tech Kossel Delta 2020 Full 3D Printer Kit w/Auto-Level August 31, 2016 06:09AM |

Registered: 10 years ago Posts: 56 |

[www.repetier.com]

If you need a kickstart for the configuration, paul_delta has his config-file in his signature: [forums.reprap.org]

Once you go Repetier, you wont go back to Marlin. Ask anybody here.

If you need a kickstart for the configuration, paul_delta has his config-file in his signature: [forums.reprap.org]

Once you go Repetier, you wont go back to Marlin. Ask anybody here.

Sorry, only registered users may post in this forum.