MakerGeeks.com Mini Kossel Kit - Junk!

Posted by GeoDave

|

MakerGeeks.com Mini Kossel Kit - Junk! January 19, 2015 01:45PM |

Registered: 9 years ago Posts: 5 |

Posted this to Redit this morning and reposting to RepRap.org to warn others:

I am writing this because I am outraged that MakerGeeks.com is censoring their product reviews! This is paramount to fraud!

I should first point out this Reddit discussion:

[www.reddit.com]

AND this youtube review and the associated comments:

[www.youtube.com]

I wrote a one-star review for the Makergeeks Mini Kossel kit and it never posted! In fact, another one star review on the site was removed about 45 minutes after I posted my review! What a shame!

Here is my review of their Kossel Mini kit:

Josh is very responsive and does provide great customer service but his kit is total junk! I absolutely hate that I have to write this negative review because I do think Makergeeks could be awesome. Josh is going to ruin his business by sending out this junk. This is my first 3D printer build but I have been playing around with microcontrollers for years. Here is a summary of my experience with Makergeeks:

When I received the kit:

- The motors were loose in the box. USPS had to tape the box back up because the motors damaged the box so badly.

- The printed parts were not the color I asked for.

- The kit was missing the SmartLCD screen listed on the website.

- The beams were the silver 2020 rather than the black openbeam(turned out to be a positive thing)

Josh's response: Josh said that the color that ships with the kit depends on what they have in stock when the kit ships. He said that the kit did not include an LCD screen. I had to pull an archive of his website(because they migrated to a new website) to show that when I ordered the kit an LCD screen w/ SD card reader was included. Josh apologized for the damaged packaging and other problems and offered to take the kit back and refund my money. I had already waited 6 weeks so I asked him if he could just send the LCD and offer a partial refund. He ended up sending the LCD, a check for $300, and a free heated bed! Awesome...right? All in all I was happy with his response to the issues.

The build:

- Five of the push rods came unglued as shown on your video. Mine also had string/thread wrapped around the threaded shaft. The others are sure to come unglued soon!

- I am sure it was just me rough handling the printed parts(because this is my first build) but all of the carriage belt clamps broke off when I tried to use them. 4 of the endstops have also cracked. Maybe I caused this issue but the endstops I have since printed are much stronger and haven't broken.

- The all metal hotend constantly jammed and had to be taken apart many many times.

- The autoprobe design never really worked well for me and the sensor ended up breaking because I took the hotend apart so many times.

- One of the linear rails is very loud. Maybe it is missing a bearing?

- The push rods rattle like crazy. I am not sure if this is because rod ends are cheap or what.

- My ramps board failed after two months. Two MOSFETs failed. Maybe not a Makergeeks problem. The board is a low quality Aliexpress type Ramps 1.4 board. You can tell from the sloppy solder joints. Works but you should know what you are getting. I am pretty sure the Arudino Mega is also an Aliexpress knockoff board.

Josh's response: I really only brought up the issue with the hotend. Josh promptly sent a new hotend. Too bad it was a direct drive and not a bowden style! When I asked him why he sent the direct drive he said he didn't have the bowden and that the direct drive would work just fine. I wasn't happy with that so he agreed to have another one machines for me(or so he said). I really think these are the Aliexpress knockoff E3D hotends. E3D's website says not to buy the E3D style hotend from MakeGeeks. I ended up giving up and never sent Josh the hotend. My plan now is to try to use what I have left to make a working printer.

In summary, I really wish I had just sent the kit back to Josh! My printer barely works and there are many major parts I need to replace! I guess I have learned that quality is important when sourcing parts for 3D printers. I do not recommend purchasing the Kossel Mini kit or any other kit from MakerGeeks. They source very cheap parts and charge a premium price for their kit.

I am writing this because I am outraged that MakerGeeks.com is censoring their product reviews! This is paramount to fraud!

I should first point out this Reddit discussion:

[www.reddit.com]

AND this youtube review and the associated comments:

[www.youtube.com]

I wrote a one-star review for the Makergeeks Mini Kossel kit and it never posted! In fact, another one star review on the site was removed about 45 minutes after I posted my review! What a shame!

Here is my review of their Kossel Mini kit:

Josh is very responsive and does provide great customer service but his kit is total junk! I absolutely hate that I have to write this negative review because I do think Makergeeks could be awesome. Josh is going to ruin his business by sending out this junk. This is my first 3D printer build but I have been playing around with microcontrollers for years. Here is a summary of my experience with Makergeeks:

When I received the kit:

- The motors were loose in the box. USPS had to tape the box back up because the motors damaged the box so badly.

- The printed parts were not the color I asked for.

- The kit was missing the SmartLCD screen listed on the website.

- The beams were the silver 2020 rather than the black openbeam(turned out to be a positive thing)

Josh's response: Josh said that the color that ships with the kit depends on what they have in stock when the kit ships. He said that the kit did not include an LCD screen. I had to pull an archive of his website(because they migrated to a new website) to show that when I ordered the kit an LCD screen w/ SD card reader was included. Josh apologized for the damaged packaging and other problems and offered to take the kit back and refund my money. I had already waited 6 weeks so I asked him if he could just send the LCD and offer a partial refund. He ended up sending the LCD, a check for $300, and a free heated bed! Awesome...right? All in all I was happy with his response to the issues.

The build:

- Five of the push rods came unglued as shown on your video. Mine also had string/thread wrapped around the threaded shaft. The others are sure to come unglued soon!

- I am sure it was just me rough handling the printed parts(because this is my first build) but all of the carriage belt clamps broke off when I tried to use them. 4 of the endstops have also cracked. Maybe I caused this issue but the endstops I have since printed are much stronger and haven't broken.

- The all metal hotend constantly jammed and had to be taken apart many many times.

- The autoprobe design never really worked well for me and the sensor ended up breaking because I took the hotend apart so many times.

- One of the linear rails is very loud. Maybe it is missing a bearing?

- The push rods rattle like crazy. I am not sure if this is because rod ends are cheap or what.

- My ramps board failed after two months. Two MOSFETs failed. Maybe not a Makergeeks problem. The board is a low quality Aliexpress type Ramps 1.4 board. You can tell from the sloppy solder joints. Works but you should know what you are getting. I am pretty sure the Arudino Mega is also an Aliexpress knockoff board.

Josh's response: I really only brought up the issue with the hotend. Josh promptly sent a new hotend. Too bad it was a direct drive and not a bowden style! When I asked him why he sent the direct drive he said he didn't have the bowden and that the direct drive would work just fine. I wasn't happy with that so he agreed to have another one machines for me(or so he said). I really think these are the Aliexpress knockoff E3D hotends. E3D's website says not to buy the E3D style hotend from MakeGeeks. I ended up giving up and never sent Josh the hotend. My plan now is to try to use what I have left to make a working printer.

In summary, I really wish I had just sent the kit back to Josh! My printer barely works and there are many major parts I need to replace! I guess I have learned that quality is important when sourcing parts for 3D printers. I do not recommend purchasing the Kossel Mini kit or any other kit from MakerGeeks. They source very cheap parts and charge a premium price for their kit.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 19, 2015 02:36PM |

Registered: 9 years ago Posts: 11 |

I had a similar experience with my kossel mini kit from makergeeks.com Joshua does respond to the issues but I had to replace my hot end with a real E3D V6, I had to replace the extruder with a geared extruder to get any useful printing etc and my review was also never posted or was removed shortly after posting.

Makes me very reluctant to trust makergeeks.com in the future.

Makes me very reluctant to trust makergeeks.com in the future.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 20, 2015 04:11AM |

Registered: 9 years ago Posts: 13 |

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 22, 2015 11:37PM |

Registered: 9 years ago Posts: 280 |

Yah, me too. Im one of the posters on Reddit. 4 months and many upgrades and I STILL cant get a fast nor reliable run.

Plus as a customer I just had one too many really WTF moments and gave up trying to get support. Something going on there that is just not right. I returned some 1.75mm filament I ordered before I realized the kit was 3mm filament, and 9 days after delivery was confirmed by the USPS, I was still trying to get my replacement sent. It was finally sent to me. A week later I got the same useless filament I shipped to them...in a new box! Can anybody explain what that means cause I cant. 420?

Plus as a customer I just had one too many really WTF moments and gave up trying to get support. Something going on there that is just not right. I returned some 1.75mm filament I ordered before I realized the kit was 3mm filament, and 9 days after delivery was confirmed by the USPS, I was still trying to get my replacement sent. It was finally sent to me. A week later I got the same useless filament I shipped to them...in a new box! Can anybody explain what that means cause I cant. 420?

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 23, 2015 03:22PM |

Registered: 9 years ago Posts: 44 |

I had many of the similar experiences but will refrain from posting my full opinions until I actually have the refund check cleared (haven't gotten it yet).

I will say Josh was great to work with and replied to all my issues promptly (but he could just not deliver a satisfactory product to me)

I will say Josh was great to work with and replied to all my issues promptly (but he could just not deliver a satisfactory product to me)

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 02:48AM |

Registered: 9 years ago Posts: 5 |

I'm looking at buying a Kossel as my first printer. I'd already decided not to buy from MakerGeeks afrer seeing the youtube video.

I found this site that looks good (looks dont count for much) and my emails have been responded to quickly and helpfully. Does anyone have any experience with them?

[builda3dprinter.eu]

Any other comments would be helpful too. I have some previous Arduino and multicopter building experience.

I found this site that looks good (looks dont count for much) and my emails have been responded to quickly and helpfully. Does anyone have any experience with them?

[builda3dprinter.eu]

Any other comments would be helpful too. I have some previous Arduino and multicopter building experience.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 03:44PM |

Registered: 10 years ago Posts: 10 |

Quote

rogueqd

I'm looking at buying a Kossel as my first printer. I'd already decided not to buy from MakerGeeks afrer seeing the youtube video.

I found this site that looks good (looks dont count for much) and my emails have been responded to quickly and helpfully. Does anyone have any experience with them?

[builda3dprinter.eu]

Any other comments would be helpful too. I have some previous Arduino and multicopter building experience.

I bought a set of printed parts, rails to wheels conversion kit and the extruder spur gear from builda3dprinter.eu early last year and everything I received from them was high quality:

A photo of my printer is on their showcase page (Tristan's Kossel UK): [builda3dprinter.eu]

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 04:28PM |

Registered: 9 years ago Posts: 5 |

Thanks Tristan. I like the way you've mounted the filament reel at the top did you design that yourself?Quote

Tris

I bought a set of printed parts, rails to wheels conversion kit and the extruder spur gear from builda3dprinter.eu early last year and everything I received from them was high quality:

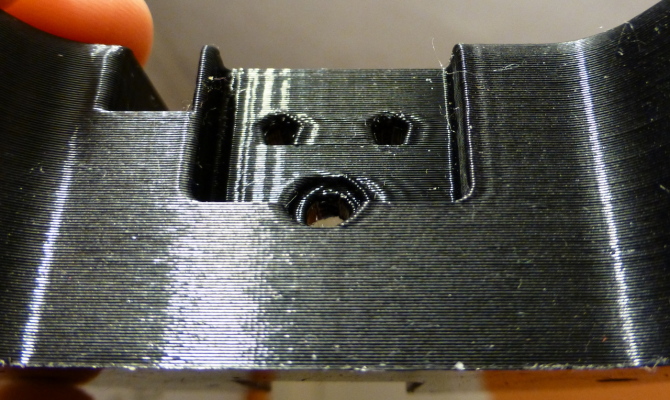

[attachment 47881 KosselParts.jpg]

A photo of my printer is on their showcase page (Tristan's Kossel UK): [builda3dprinter.eu]

After more research I'm wondering if an XL is the way to go. The creator of the Griffin printer said Kossels dont have enough rigidity and can wobble a bit at larger sizes meaning you have to print slower to maintain accuracy. Ardon from builda3dprinter.eu also mentioned they could be wobbly but said it didn't affect the prints. Have you noticed anything like that?

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 04:59PM |

Registered: 10 years ago Posts: 10 |

Quote

rogueqd

Thanks Tristan. I like the way you've mounted the filament reel at the top did you design that yourself?

After more research I'm wondering if an XL is the way to go. The creator of the Griffin printer said Kossels dont have enough rigidity and can wobble a bit at larger sizes meaning you have to print slower to maintain accuracy. Ardon from builda3dprinter.eu also mentioned they could be wobbly but said it didn't affect the prints. Have you noticed anything like that?

Yes, I designed the spool holder myself!

I wanted to make use of the otherwise wasted space at the top. The design is a bit weak where it attaches through the lid but I designed it around some bearings I already had, i.e. cheap!

I wanted to make use of the otherwise wasted space at the top. The design is a bit weak where it attaches through the lid but I designed it around some bearings I already had, i.e. cheap!I have noticed the effects of "frame wobble", it mostly shows up when the extruder changes direction suddenly, like at a 90 degree corner. The result is a "ripple" on vertical walls after the direction change:

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 06:46PM |

Registered: 9 years ago Posts: 2 |

+1 to also ordering the same kit. For an $800 kit I was very disappointed. Overall quality of all parts was junk. The only decent quality part was that it came with injection molded parts, still very upsetting because nothing reflected the pictures and description. Took 5 weeks to ship out, I'm sure the blomker kit would of been much better at half the price.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 06:47PM |

Registered: 9 years ago Posts: 5 |

It's a nice use of the space. Do you think the mass of the filament spool helps prevent the wobble, or makes it worse?Quote

Tris

Yes, I designed the spool holder myself!I wanted to make use of the otherwise wasted space at the top. The design is a bit weak where it attaches through the lid but I designed it around some bearings I already had, i.e. cheap!

I have noticed the effects of "frame wobble", it mostly shows up when the extruder changes direction suddenly, like at a 90 degree corner. The result is a "ripple" on vertical walls after the direction change:

It seems to me that twisting is where the frame is weakest. Do you think little struts from the top bar of the bottom section, near where the motor mounts meet the frame, would hold the uprights stiffer and stop it wobbling? I guess you could even make large triangles from the middle of each side as long as the rollers could still come down far enough.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 07:00PM |

Registered: 10 years ago Posts: 10 |

Quote

rogueqd

It's a nice use of the space. Do you think the mass of the filament spool helps prevent the wobble, or makes it worse?

It seems to me that twisting is where the frame is weakest. Do you think little struts from the top bar of the bottom section, near where the motor mounts meet the frame, would hold the uprights stiffer and stop it wobbling? I guess you could even make large triangles from the middle of each side as long as the rollers could still come down far enough.

It may make it better OR worse, it's all about the resonant frequency of the frame vs how fast the effector is oscillating...

Corner braces would certainly improve rigidity. There's already a good design on Thingiverse for such a brace: [www.thingiverse.com]

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 25, 2015 08:47PM |

Registered: 9 years ago Posts: 5 |

Ok, I get it. I'm not an engineer, but the resonant frequency will come from how springy the frame is, right?Quote

Tris

It may make it better OR worse, it's all about the resonant frequency of the frame vs how fast the effector is oscillating...

Corner braces would certainly improve rigidity. There's already a good design on Thingiverse for such a brace: [www.thingiverse.com]

Nice to see the brace, so I was on the right track then.

Hey it's great having you answer my questions, thanks, but is there a good place for a beginner to go to learn about all these things. Build guides are a good start, but they don't teach you much about the theory or operation. Forums are also great, but you generally have to read through a ton of irrelevant stuff to find the little nuggets of knowledge.

Is there something like a beginners guide to owning a 3D printer? Preferably kossel, or delta, specific?

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 26, 2015 07:22PM |

Registered: 10 years ago Posts: 10 |

All you really need to know is that when the effector is accelerated or decellerated in a particular direction, the frame will want to move in the opposite direction (albeit less as the mass of the frame is much greater than that of the effector!)

If the vertical extrusions are not rigid enough, they absorb the forces exerted by the effector by bending, causing momentarily inaccurate effector placement.

Make the frame as rigid as possible to prevent it from absorbing these forces and deforming. Of course, this energy has to go somewhere so I mounted my printer on vibration dampening rubber feet so the frame can move about slightly as a whole and not distort so much. Doing this also relieves the strain on the moving parts somewhat, especially the ball joints.

As for a beginners guide, I havent seen one yet. I had to do the whole "knowledge nugget" mining thing myself too!

If the vertical extrusions are not rigid enough, they absorb the forces exerted by the effector by bending, causing momentarily inaccurate effector placement.

Make the frame as rigid as possible to prevent it from absorbing these forces and deforming. Of course, this energy has to go somewhere so I mounted my printer on vibration dampening rubber feet so the frame can move about slightly as a whole and not distort so much. Doing this also relieves the strain on the moving parts somewhat, especially the ball joints.

As for a beginners guide, I havent seen one yet. I had to do the whole "knowledge nugget" mining thing myself too!

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! January 27, 2015 02:11PM |

Registered: 9 years ago Posts: 280 |

I've noticed my MakerGeeks Kossel Mini kit frame doesn't seem very stiff AT ALL. Probably the best bang for the buck to stiffen it up would be a large diagonal strut on one of the sides, from top to bottom.

Even better would be a sheet of acrylic because then the entire sheet contributes to diagonal forces.

I was thinking those corner braces would also help a lot, although I was picturing heavy metal ones because the thing is so tall. (and the struts are 20mm)

Even better would be a sheet of acrylic because then the entire sheet contributes to diagonal forces.

I was thinking those corner braces would also help a lot, although I was picturing heavy metal ones because the thing is so tall. (and the struts are 20mm)

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! February 09, 2015 06:02PM |

Registered: 9 years ago Posts: 280 |

I just noticed today (2/9) that Justin apparently been (silently) paying attention.

For the same price he released an upgraded version in January:

It specifically addresses MANY of the issues I encountered. I just wish I did not buy all the problems before the fixes:

-Much bigger power supply, supposedly enough current even drive the optional heat-bed. (Makergeeks bed needs 13 amps alone!) It looks similar to the OEM power supply I bought for myself.

-Redesigned the effector assy, probably because the original design with nozzle-as-probe was a huge fail. (by now I have completely redesigned and built a new effector assembly with pro hot-end from e3D, and higher-tolerance rod/swivel-ball arms.)

-Now includes a fan with the hot-end.

-Full packing list, yay!

-Injection-molded chassis parts (3x top and 3x bottom). These are very important because they determine both rigidity AND squareness, and I frankly have not seen this option elsewhere. My current build is not stiff at all.

-Custom instructions from Makergeeks themselves. Yay!

-Other things not mentioned. I really hope for a better extruder design.

Anyway, I commend Justin, who seems to be paying attention after all!

We will see what the quality of these fixes are. (is the new upgraded supply enough to handle the addition of a heat-bed? Are the injection-molded chassis parts actually stronger and more accurate? Are the included instructions detailed enough or just a throw-together?)

Time will tell.

Edited 1 time(s). Last edit at 02/09/2015 06:07PM by shadowphile.

For the same price he released an upgraded version in January:

It specifically addresses MANY of the issues I encountered. I just wish I did not buy all the problems before the fixes:

-Much bigger power supply, supposedly enough current even drive the optional heat-bed. (Makergeeks bed needs 13 amps alone!) It looks similar to the OEM power supply I bought for myself.

-Redesigned the effector assy, probably because the original design with nozzle-as-probe was a huge fail. (by now I have completely redesigned and built a new effector assembly with pro hot-end from e3D, and higher-tolerance rod/swivel-ball arms.)

-Now includes a fan with the hot-end.

-Full packing list, yay!

-Injection-molded chassis parts (3x top and 3x bottom). These are very important because they determine both rigidity AND squareness, and I frankly have not seen this option elsewhere. My current build is not stiff at all.

-Custom instructions from Makergeeks themselves. Yay!

-Other things not mentioned. I really hope for a better extruder design.

Anyway, I commend Justin, who seems to be paying attention after all!

We will see what the quality of these fixes are. (is the new upgraded supply enough to handle the addition of a heat-bed? Are the injection-molded chassis parts actually stronger and more accurate? Are the included instructions detailed enough or just a throw-together?)

Time will tell.

Edited 1 time(s). Last edit at 02/09/2015 06:07PM by shadowphile.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! February 11, 2015 11:54AM |

Registered: 9 years ago Posts: 1 |

Hi all, i registered today here to describe horrific experience with this kit. I hope that this helps anyone looking for kit to purchase. Simply put if you want good and solid printer, KEEP AWAY from makergeeks.com. Even with upgraded PSU and "fixed" design it is a false advertising. With 10A output it is sufficient just for motors sensors and hotend, however even with fan that i had to order separately it starts to be a bit hungry. Heat bed and lcd are far beyond reach of supplied PSU. Also even when support said it was switched to EU voltage i decided to check it and good thing i did. More over glass print surface is packaged together with CHEAPEST nema motors so it was in PIECES already on delivery. All provided printed parts, screws and caps are of WORST QUALITY ever and all had to be replaced. Did i mention that push fit connectors and fan was NOT DELIVERED. Invoice was also MALFORMED so i had to pay additional tax on this machine hence kit return was not an option. All this mess was well and promptly payed premium price and was late right away almost TWO MONTHS in dispatch. Support is WORST OF ALL, and hiding behind religious comments with service this bad is REALLY risky joke, i would not be surprised if some lightning from above ends this CHEATING business. Makers be warned, over and out.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! February 11, 2015 01:08PM |

Registered: 10 years ago Posts: 14,672 |

If anyone else wants to build a Mini Kossel, I can recommend the kit supplied by Think3DPrint3D.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! February 12, 2015 06:45AM |

Registered: 9 years ago Posts: 32 |

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! February 15, 2015 12:34AM |

Registered: 9 years ago Posts: 16 |

Quote

rogueqd

I'm looking at buying a Kossel as my first printer. I'd already decided not to buy from MakerGeeks afrer seeing the youtube video.

I found this site that looks good (looks dont count for much) and my emails have been responded to quickly and helpfully. Does anyone have any experience with them?

[builda3dprinter.eu]

Any other comments would be helpful too. I have some previous Arduino and multicopter building experience.

Two of my co workers got their kits from them. Shiping was fast (at least to germany) and the quality was very good.

Both of them successfully finished their builds without problems to speak of.

Gruß / regards

Jens

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! March 10, 2015 08:30PM |

Registered: 9 years ago Posts: 5 |

Just a quick update on my makergeeks.com kit. I worked with think3dprint3d and E3D to get my printer up and running and they were great! I wish I would have purchased my kit from think3dprint3d to begin with! E3D even gave me a free E3D v6 in exchange for my MakeGeeks hotend. The total additional cost to get the makergeeks printer kit up and running was close to $300.

Replacement parts included push rods, end effector, extruder(went with reprappro mini), end stops, carriage mounts, power supply, and hotend(went with 1.75mm E3D v6). In other words...most of the printer. E3D recommended going with a 1.75mm hotend for the Delta because of the massive amount of force it takes to push 3mm over the long Bowden tube. I have had no jams with the 1.75mm filament. Also, I just found out that the motors provided by makergeeks.com aren't even close to what is recommended for a 3D printer. I have been having issues with overheating and skipping steps. The ones supplied to me were 12v rated at 0.4amp per phase. If you look at the wiki for the mini kossel they recommend 4.2v at 1.8amp per phase...big difference! I don't care what Josh did to improve his kit! He is a snake oil salesman. Stay away!!!

Edited 1 time(s). Last edit at 03/10/2015 09:40PM by GeoDave.

Replacement parts included push rods, end effector, extruder(went with reprappro mini), end stops, carriage mounts, power supply, and hotend(went with 1.75mm E3D v6). In other words...most of the printer. E3D recommended going with a 1.75mm hotend for the Delta because of the massive amount of force it takes to push 3mm over the long Bowden tube. I have had no jams with the 1.75mm filament. Also, I just found out that the motors provided by makergeeks.com aren't even close to what is recommended for a 3D printer. I have been having issues with overheating and skipping steps. The ones supplied to me were 12v rated at 0.4amp per phase. If you look at the wiki for the mini kossel they recommend 4.2v at 1.8amp per phase...big difference! I don't care what Josh did to improve his kit! He is a snake oil salesman. Stay away!!!

Edited 1 time(s). Last edit at 03/10/2015 09:40PM by GeoDave.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! March 11, 2015 08:56PM |

Registered: 9 years ago Posts: 67 |

You could have said this before I bought it....

I did my first print 30minutes ago. It didn't come out to good but I have some settings to mess with. I have many many opinions and data point to put toward MakerGeek and their kit. I'll wait until I'm printing before I finalize my evaluation but my experience has been marginal to say the least (missing parts, repeated shipments etc - although I will say they did come through eventually so I didn't get stiffed).

Question for you:

What temp are you running the 1.75 filament? I'm 220 L1 and then 215

Are you using the extruder multiplier? I was 1.3.

I'm trying to dial in my 20mm cube. The settings above did not do so well. I'm going 1.0 multiplier on the next run for comparison. Maybe I'm too hot also.

I did my first print 30minutes ago. It didn't come out to good but I have some settings to mess with. I have many many opinions and data point to put toward MakerGeek and their kit. I'll wait until I'm printing before I finalize my evaluation but my experience has been marginal to say the least (missing parts, repeated shipments etc - although I will say they did come through eventually so I didn't get stiffed).

Question for you:

What temp are you running the 1.75 filament? I'm 220 L1 and then 215

Are you using the extruder multiplier? I was 1.3.

I'm trying to dial in my 20mm cube. The settings above did not do so well. I'm going 1.0 multiplier on the next run for comparison. Maybe I'm too hot also.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! March 14, 2015 09:07AM |

Registered: 9 years ago Posts: 6 |

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 17, 2015 11:34PM |

Registered: 9 years ago Posts: 280 |

I am SO close to taking the whole assembly and tossing $1200 in the garbage. I have invested many months of re-engineering and probably another $500 and I still can't get a decent print, if at all. I bought it last October! The entire spider assembly, every part, has been replaced with better or self-designed parts. It has become the biggest waste of time and money I have ever encountered in my life of hobby and professional engineering.

-The hot-end jams too easily, despite that I replaced it with an E3D V6. I don't know how others make 3mm filament work on a delta, it just seems to require too much force..I have to hang a tremendous weight on the extruder hob clamp to keep it from stripping eventually, although that causes it's own problems. It might run for a while but then it starts starving due to hob grinding. Taking it out to unplug the hot-end is such a major pain that haven't heated up the hotend in months, I'm just afraid to deal with it without some hope I have fixed anything. My suspicion is that a 3mm filament has to go slower han a 1.75, which allows heat to actually travel backwards inside the filament and make it squishy, which then causes jamming. I actually got my best prints by stopping attempting to take it slow; I just jumped to 100mm/min print speed and suddenly it worked, for a while anyway. It was a short-lived triumph. No amount of heat-breaking can improve such a thing, only really fast printing!

-The frame has all kinds of skew on it. I've tried to straighten it out and it just can't be done with my tools. I have a sideways skew on my X/Y plane of 1mm on a 100mm square that I can't figure out, but I suspect my towers are not parallel and it's really hard to measure without a good large internal caliper, not to mention that nothing is orthogonal so conventional squaring techniques are also useless. I have inconsistent dimensions from the center to the towers and different types of dimensions seem to contradict each other. It is VERY difficult to de-transform measurements of errors made on a delta back into cartesian space, so intuition is almost useless. G30 autocal just wanders away from realistic parameters the longer it runs, which probably means there are too many separate distortions.

-I am about to lose interest in the whole 3D printer thing anyway if it is going to be so high-maintenance. I have too many other projects to work on and thought the delta could make parts for those projects, and maybe tweak improvements, not become a black hole filled with pus-spewing flames of hell.

-Josh sent me a free box of injection molded vertices but as commented before they are sloppy and useless. Plus the bottom ones were replaced with two smaller ones stacked up so that one delta could use 9 identical parts, a good approach for injection molded parts but now the lower vertices are weaker because they have lost shearing strength! WHAT IS GOING ON OVER THERE?

If I decide to just buy a working assembly how much can I expect to use it vs doing maintenance? Should I bother with a delta or stick with conventional cartesian? It seems like the biggest attraction for most people is 'It looks cool'.

I am generally interested in robotic/mechanical parts for other engineering projects so quality and accuracy are high priority.

BTW, with the zillions of pre-made printers out there, I would like to find some comparative reviews by experienced people, not just 'I had no problems' kind of feedback. Any good places to look? I would probalby go with a Cartesian given the filament limitations of the deltas because of the bowden tube approach. I want full access to the variety of filaments out there and squishy ones are hard to feed in the deltas.

thanks

-The hot-end jams too easily, despite that I replaced it with an E3D V6. I don't know how others make 3mm filament work on a delta, it just seems to require too much force..I have to hang a tremendous weight on the extruder hob clamp to keep it from stripping eventually, although that causes it's own problems. It might run for a while but then it starts starving due to hob grinding. Taking it out to unplug the hot-end is such a major pain that haven't heated up the hotend in months, I'm just afraid to deal with it without some hope I have fixed anything. My suspicion is that a 3mm filament has to go slower han a 1.75, which allows heat to actually travel backwards inside the filament and make it squishy, which then causes jamming. I actually got my best prints by stopping attempting to take it slow; I just jumped to 100mm/min print speed and suddenly it worked, for a while anyway. It was a short-lived triumph. No amount of heat-breaking can improve such a thing, only really fast printing!

-The frame has all kinds of skew on it. I've tried to straighten it out and it just can't be done with my tools. I have a sideways skew on my X/Y plane of 1mm on a 100mm square that I can't figure out, but I suspect my towers are not parallel and it's really hard to measure without a good large internal caliper, not to mention that nothing is orthogonal so conventional squaring techniques are also useless. I have inconsistent dimensions from the center to the towers and different types of dimensions seem to contradict each other. It is VERY difficult to de-transform measurements of errors made on a delta back into cartesian space, so intuition is almost useless. G30 autocal just wanders away from realistic parameters the longer it runs, which probably means there are too many separate distortions.

-I am about to lose interest in the whole 3D printer thing anyway if it is going to be so high-maintenance. I have too many other projects to work on and thought the delta could make parts for those projects, and maybe tweak improvements, not become a black hole filled with pus-spewing flames of hell.

-Josh sent me a free box of injection molded vertices but as commented before they are sloppy and useless. Plus the bottom ones were replaced with two smaller ones stacked up so that one delta could use 9 identical parts, a good approach for injection molded parts but now the lower vertices are weaker because they have lost shearing strength! WHAT IS GOING ON OVER THERE?

If I decide to just buy a working assembly how much can I expect to use it vs doing maintenance? Should I bother with a delta or stick with conventional cartesian? It seems like the biggest attraction for most people is 'It looks cool'.

I am generally interested in robotic/mechanical parts for other engineering projects so quality and accuracy are high priority.

BTW, with the zillions of pre-made printers out there, I would like to find some comparative reviews by experienced people, not just 'I had no problems' kind of feedback. Any good places to look? I would probalby go with a Cartesian given the filament limitations of the deltas because of the bowden tube approach. I want full access to the variety of filaments out there and squishy ones are hard to feed in the deltas.

thanks

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 03:55AM |

Registered: 10 years ago Posts: 14,672 |

I had a Mini Kossel kit from Think3Dprint3D, and although the kit was of high quality, I recognise two of the issues you describe:

1. Towers not quite perpendicular to the bed. In my case, there was no slop in the corner pieces, but I wasn't careful to ensure that the vertical and horizontal extrusions were perpendicular when i assembled it. Also, I had to hammer the extrusions through the corner pieces (as described in the instructions), which peels off shavings of plastic, and this could lead to the holes ending up not quite straight even if they were initially. I tried loosening some of the screws, pushing the frame square, and tightening the screws again, but I wasn't able to improve on it much. The effect of non-perpendicular towers was that after doing the usual 4-factor calibration (i.e. endstops and delta radius), the nozzle height was wrong along radial lines midway between the towers. I solved it by implementing 7-factor autocalibration from a single set of probe points in the firmware. What the autocalibration actually does is to adjust the tower positions, which to a first approximation compensates for the leaning towers. The firmware I am using also supports orthogonal axis compensation, so I don't have to put up with leaning prints.

When I rebuilt the machine to increase the printable diameter to 300mm, I printed new corners and took more care when assembling the frame. Despite this, the towers still lean slightly.

I am currently converting the machine to use 2020 extrusion because I want more printing height. As I am a perfectionist and would like to eliminate the lean, this time I am using metal corners from Robotdigg.

2. Extruder grinding through the filament, resulting in loss of traction. This plagued me for a long time, but I solved it eventually by reducing the extruder motor current from 800mA to 500mA. The reason is that if the motor can't push the filament, e.g. because the nozzle is not hot enough, or too close to the bed, or over-extruding, then it's important that the motor skips steps in preference to grinding through the filament.

With these fixed, my Kossel produces prints more reliably and more quickly than my Cartesian printer. It also takes up less desk space. So I definitely prefer Delta over Cartesian. I wouldn't run a delta on Arduino Mega/RAMPS/Marlin, because the processor lacks the performance to drive a delta easily and the firmware lacks the features I need, but it appears that a lot of of people do.

I can't comment on 3mm vs.1.75mm because I've never used 3mm filament. However, I don't see why 3mm would need any more force than 1.5mm, for the same extrusion rate and nozzle size.

I'd offer to send you my 1515 Kossel vertices, but as you are quoting prices in $, I'm guessing you are in the USA, and I am in the UK to the postage could get expensive.

Edited 6 time(s). Last edit at 05/18/2015 04:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. Towers not quite perpendicular to the bed. In my case, there was no slop in the corner pieces, but I wasn't careful to ensure that the vertical and horizontal extrusions were perpendicular when i assembled it. Also, I had to hammer the extrusions through the corner pieces (as described in the instructions), which peels off shavings of plastic, and this could lead to the holes ending up not quite straight even if they were initially. I tried loosening some of the screws, pushing the frame square, and tightening the screws again, but I wasn't able to improve on it much. The effect of non-perpendicular towers was that after doing the usual 4-factor calibration (i.e. endstops and delta radius), the nozzle height was wrong along radial lines midway between the towers. I solved it by implementing 7-factor autocalibration from a single set of probe points in the firmware. What the autocalibration actually does is to adjust the tower positions, which to a first approximation compensates for the leaning towers. The firmware I am using also supports orthogonal axis compensation, so I don't have to put up with leaning prints.

When I rebuilt the machine to increase the printable diameter to 300mm, I printed new corners and took more care when assembling the frame. Despite this, the towers still lean slightly.

I am currently converting the machine to use 2020 extrusion because I want more printing height. As I am a perfectionist and would like to eliminate the lean, this time I am using metal corners from Robotdigg.

2. Extruder grinding through the filament, resulting in loss of traction. This plagued me for a long time, but I solved it eventually by reducing the extruder motor current from 800mA to 500mA. The reason is that if the motor can't push the filament, e.g. because the nozzle is not hot enough, or too close to the bed, or over-extruding, then it's important that the motor skips steps in preference to grinding through the filament.

With these fixed, my Kossel produces prints more reliably and more quickly than my Cartesian printer. It also takes up less desk space. So I definitely prefer Delta over Cartesian. I wouldn't run a delta on Arduino Mega/RAMPS/Marlin, because the processor lacks the performance to drive a delta easily and the firmware lacks the features I need, but it appears that a lot of of people do.

I can't comment on 3mm vs.1.75mm because I've never used 3mm filament. However, I don't see why 3mm would need any more force than 1.5mm, for the same extrusion rate and nozzle size.

I'd offer to send you my 1515 Kossel vertices, but as you are quoting prices in $, I'm guessing you are in the USA, and I am in the UK to the postage could get expensive.

Edited 6 time(s). Last edit at 05/18/2015 04:03AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 07:42AM |

Registered: 9 years ago Posts: 67 |

I have a lot of sympathy for you. I agree with many of your statements. With the help of many on the forum I have got myself mostly running good. I replaced the extruder mechanism with a more powerful one (it's a beast). That worked until this past week. It keeps getting jammed lately. All the other issue I have been able to sort out. Josh is responsive, I will give him that, but I'm not impressed with anything else. Even though I am running I will never buy from them again. Zero chance of that. Super unethical review practices really torque me up as well. I may buy another hot end. Not sure yet. Good luck.

Edited 1 time(s). Last edit at 05/18/2015 07:44AM by Dark Skunk.

Edited 1 time(s). Last edit at 05/18/2015 07:44AM by Dark Skunk.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 12:32PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

However, I don't see why 3mm would need any more force than 1.5mm, for the same extrusion rate and nozzle size.

To feed the same volume of plastic you need to feed it (3/1.75)^2 = ~ 3 times slower but it takes ~3 times the force because the same pressure acts over three times the area.

[www.hydraraptor.blogspot.com]

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 02:15PM |

Registered: 10 years ago Posts: 14,672 |

Quote

nophead

Quote

However, I don't see why 3mm would need any more force than 1.5mm, for the same extrusion rate and nozzle size.

To feed the same volume of plastic you need to feed it (3/1.75)^2 = ~ 3 times slower but it takes ~3 times the force because the same pressure acts over three times the area.

Yes, that makes sense to me.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 05:25PM |

Registered: 9 years ago Posts: 280 |

Thanks everybody for all the cool-headed sympathy and feedback; my boiling point has risen to productive levels again.

Thanks for the feedback dc42, I appreciate it. The forums have been responsive but sometimes seem to run out of ideas. (especially jamming)

I took too much for granted with the kit. I will have to tear it all down and start over with more care. I seems to me that the easiest way to ensure squareness would be some kind of plate with at least four attachments between each tower; I am picturing clear acrylic, although this is where I hate the deltas: interfacing with non-orthogonal components. A handful of 60 degree adapters would be awesome and I've designed some for printing.

One Idea I had last night was to remove and rotate the spider assembly 120 degrees. If the errors stayed the same, it is due to the chassis, otherwise is something in the spider assy. After the swap, my skewed XY box (with perfect dimensions) turned into some kind of more complicated combination of skew and dimension errors. I will have to do some repeats to see if these are real, but if so, I will have to look at the spider assy again; I rebuilt my own rods and printed my own effector platform (on a expensive commercial printer) so that is still TBD.

I have since realized that the standard 170 diameter plate is too small for many of my desires; if I have the patience (and cost of different parts), I would definitely move up to a 220 or bigger. I can't imagine parts taller than the current Kossel, but just changing the uprights and the belts is a REALLY easy upgrade in the future. The extrusions from the MakerGeeks kit are one of the few parts I would reuse.

And thanks for the heads-up up on the Robotdigg parts! One factor I've observed of the reprap paradigm is the focus on saving $ and the general DIY mentality that tends to focus on low-cost/easy-to-procure items. If this is going to be a precision tool, I don't want to cut corners. Self-replication is a cool idea, until it gets in the way of quality and/or required baby-sitting. I'm not interested in tweaking 'my baby' to keep it running well as a project. Considering that the delta's have no diagonal components, the quality and properties of the vertex parts are critical. And I would stick with the 2020 parts are well.

Funny, I upped the current a lot because my extruder was skipping too easily. Whether the extruder skips constantly or comes to complete halt because of chewed-through filament, the end result is a failed part. What I want and have designed in my head is a much better extruder with more grip. Even a drive with a second opposing hob would double the grip. A spread-out rubber opposing tank-tread grip would be ideal but of course a lot more complicated.

Less desk space, +1. Unlimited height possible, +1. Faster speed, +1. I don't have experience with the cartesians (this is my first step into the 3D printing world) so I can't compare very well.

I am curious though how you worked out that the the electronics combo you mentioned (which comes with the MakerGeeks kit and NOT one of the issues I've had) is under-powered. Have you observed timing errors?

One of the strong arguments for the cartesians is the bowden tube. Clever solution but it was a compromise. Soft materials are hard (or impossible) to push, and the extra tube-drag doesn't help the extruder grip problem. That is another area that I have been pondering: how to bring the grip on the filament back to the effector while keeping the motor elsewhere. This is critical if you want to keep delta speeds with more than one hot-end. I've pictured a pair of steel-cabled bowdens driving the gripping mechanism on the effector platform, using an oscillatory quadrature feed mechanism instead of the current linear method, but that is definitely going into the cool-project zone, not a fix.

As for the force comments, here is an alternative perspective (the one my physics-background jumped to: less mathematical, more conceptual).

-Same extrusion rate means same amount of power required. Thinner filaments must mean faster feedrates. Since power = velocity times force, then the force must be lower. In that sense the 1.75 makes more sense unless the stepper can't go fast enough. High speeds don't seem like limiting factors in these designs whereas high torques and forces mean higher strains and lower efficiency with any power electronics. For this reason alone I have seriously toyed with converting to 1.75, although that eliminates any possibility of flexible materials (I want material options!) and I already pre-purchased lots of 3mm filament in anticipation of printing all kinds of cool designs.

Does anybody have suggestions about working out the jamming issues? That is the scary part for me because it is so hard to get feedback about what is happening. Either it is sticking to something, or the hole is clogging, or the filament flow properties have changed somehow. Trying to troubleshoot all three seems to reduce to: try,try, try! Maybe there is better forum or thread for this issue? It's not really delta specific.

Quote

dc42

1. Towers not quite perpendicular to the bed. In my case, there was no slop in the corner pieces, but I wasn't careful to ensure that the vertical and horizontal extrusions were perpendicular when i assembled it. Also, I had to hammer the extrusions through the corner pieces (as described in the instructions), which peels off shavings of plastic, and this could lead to the holes ending up not quite straight even if they were initially. I tried loosening some of the screws, pushing the frame square, and tightening the screws again, but I wasn't able to improve on it much. The effect of non-perpendicular towers was that after doing the usual 4-factor calibration (i.e. endstops and delta radius), the nozzle height was wrong along radial lines midway between the towers. I solved it by implementing 7-factor autocalibration from a single set of probe points in the firmware. What the autocalibration actually does is to adjust the tower positions, which to a first approximation compensates for the leaning towers. The firmware I am using also supports orthogonal axis compensation, so I don't have to put up with leaning prints.

Thanks for the feedback dc42, I appreciate it. The forums have been responsive but sometimes seem to run out of ideas. (especially jamming)

I took too much for granted with the kit. I will have to tear it all down and start over with more care. I seems to me that the easiest way to ensure squareness would be some kind of plate with at least four attachments between each tower; I am picturing clear acrylic, although this is where I hate the deltas: interfacing with non-orthogonal components. A handful of 60 degree adapters would be awesome and I've designed some for printing.

One Idea I had last night was to remove and rotate the spider assembly 120 degrees. If the errors stayed the same, it is due to the chassis, otherwise is something in the spider assy. After the swap, my skewed XY box (with perfect dimensions) turned into some kind of more complicated combination of skew and dimension errors. I will have to do some repeats to see if these are real, but if so, I will have to look at the spider assy again; I rebuilt my own rods and printed my own effector platform (on a expensive commercial printer) so that is still TBD.

Quote

dc42

When I rebuilt the machine to increase the printable diameter to 300mm, I printed new corners and took more care when assembling the frame. Despite this, the towers still lean slightly.

I am currently converting the machine to use 2020 extrusion because I want more printing height. As I am a perfectionist and would like to eliminate the lean, this time I am using metal corners from Robotdigg.

I have since realized that the standard 170 diameter plate is too small for many of my desires; if I have the patience (and cost of different parts), I would definitely move up to a 220 or bigger. I can't imagine parts taller than the current Kossel, but just changing the uprights and the belts is a REALLY easy upgrade in the future. The extrusions from the MakerGeeks kit are one of the few parts I would reuse.

And thanks for the heads-up up on the Robotdigg parts! One factor I've observed of the reprap paradigm is the focus on saving $ and the general DIY mentality that tends to focus on low-cost/easy-to-procure items. If this is going to be a precision tool, I don't want to cut corners. Self-replication is a cool idea, until it gets in the way of quality and/or required baby-sitting. I'm not interested in tweaking 'my baby' to keep it running well as a project. Considering that the delta's have no diagonal components, the quality and properties of the vertex parts are critical. And I would stick with the 2020 parts are well.

Quote

dc42

2. Extruder grinding through the filament, resulting in loss of traction. This plagued me for a long time, but I solved it eventually by reducing the extruder motor current from 800mA to 500mA. The reason is that if the motor can't push the filament, e.g. because the nozzle is not hot enough, or too close to the bed, or over-extruding, then it's important that the motor skips steps in preference to grinding through the filament.

Funny, I upped the current a lot because my extruder was skipping too easily. Whether the extruder skips constantly or comes to complete halt because of chewed-through filament, the end result is a failed part. What I want and have designed in my head is a much better extruder with more grip. Even a drive with a second opposing hob would double the grip. A spread-out rubber opposing tank-tread grip would be ideal but of course a lot more complicated.

Quote

dc42

With these fixed, my Kossel produces prints more reliably and more quickly than my Cartesian printer. It also takes up less desk space. So I definitely prefer Delta over Cartesian. I wouldn't run a delta on Arduino Mega/RAMPS/Marlin, because the processor lacks the performance to drive a delta easily and the firmware lacks the features I need, but it appears that a lot of of people do.

Less desk space, +1. Unlimited height possible, +1. Faster speed, +1. I don't have experience with the cartesians (this is my first step into the 3D printing world) so I can't compare very well.

I am curious though how you worked out that the the electronics combo you mentioned (which comes with the MakerGeeks kit and NOT one of the issues I've had) is under-powered. Have you observed timing errors?

One of the strong arguments for the cartesians is the bowden tube. Clever solution but it was a compromise. Soft materials are hard (or impossible) to push, and the extra tube-drag doesn't help the extruder grip problem. That is another area that I have been pondering: how to bring the grip on the filament back to the effector while keeping the motor elsewhere. This is critical if you want to keep delta speeds with more than one hot-end. I've pictured a pair of steel-cabled bowdens driving the gripping mechanism on the effector platform, using an oscillatory quadrature feed mechanism instead of the current linear method, but that is definitely going into the cool-project zone, not a fix.

Thanks, but I'm going to stick with the 2020 design I currently have.Quote

dc42

I'd offer to send you my 1515 Kossel vertices, but as you are quoting prices in $, I'm guessing you are in the USA, and I am in the UK to the postage could get expensive.

As for the force comments, here is an alternative perspective (the one my physics-background jumped to: less mathematical, more conceptual).

-Same extrusion rate means same amount of power required. Thinner filaments must mean faster feedrates. Since power = velocity times force, then the force must be lower. In that sense the 1.75 makes more sense unless the stepper can't go fast enough. High speeds don't seem like limiting factors in these designs whereas high torques and forces mean higher strains and lower efficiency with any power electronics. For this reason alone I have seriously toyed with converting to 1.75, although that eliminates any possibility of flexible materials (I want material options!) and I already pre-purchased lots of 3mm filament in anticipation of printing all kinds of cool designs.

Does anybody have suggestions about working out the jamming issues? That is the scary part for me because it is so hard to get feedback about what is happening. Either it is sticking to something, or the hole is clogging, or the filament flow properties have changed somehow. Trying to troubleshoot all three seems to reduce to: try,try, try! Maybe there is better forum or thread for this issue? It's not really delta specific.

|

Re: MakerGeeks.com Mini Kossel Kit - Junk! May 18, 2015 07:39PM |

Registered: 8 years ago Posts: 7 |

I have a Kossel Mini from think3dprint3d and it's an excellent machine. Some parts of it are being upgraded over time, z probe and then extruder so far. But overall it's a decent quality, good value kit. Mine had one little packaging glitch, but it was minor and I didn't bother to raise the issue. I would buy another kit from think3dprint3d happily if I didn't have the ability to print for myself now.

Sorry, only registered users may post in this forum.