Best settings for thin members with a delta?

Posted by Rett Mikhal

|

Best settings for thin members with a delta? February 20, 2015 11:01AM |

Registered: 9 years ago Posts: 25 |

So after several successful prints over the last few months, I decided to try my hand at a thin membered part to test my device. Namely this number, right here:

[www.thingiverse.com]

The problem seems to be that my mini Kossel really doesn't like thin vertical members. Thin, horizontal members with support is just fine. I first found this out with my X-wing print, which had thin vertical lasers that looked awful, but the rest of it printed nicely. It seems that as the printer lays down thin vertical members, the print nozzle starts to rub against the material, moving it slightly, which result in mis-aligned layers and thus a rough appearance. For reference:

Solid Parts:

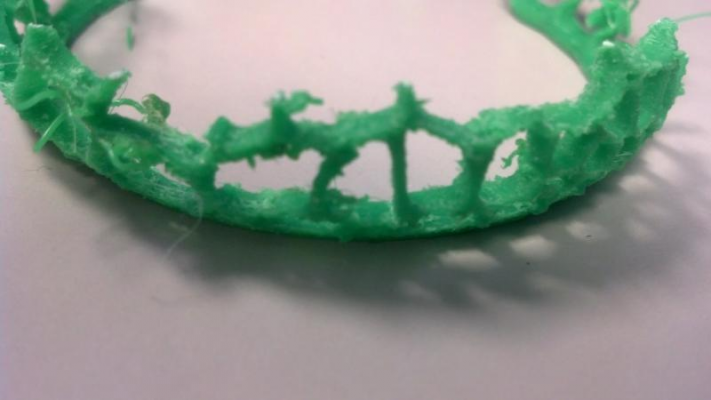

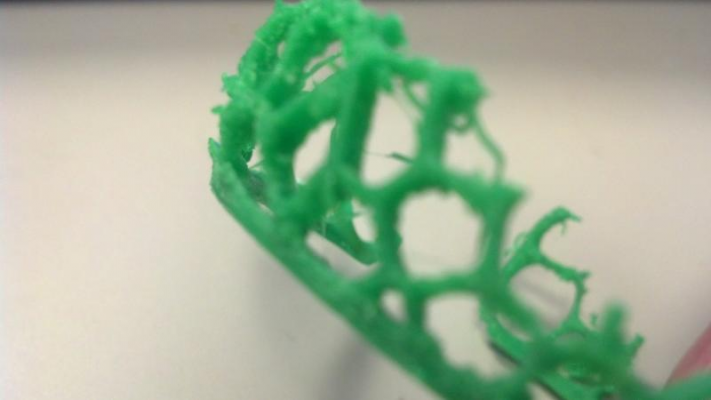

Thin parts:

So far I've tried reducing the print speed, increasing heat, decreasing layer height, decreasing travel speed, and the all important and elusive setting of Z-hop, which Cura recommends a value of 0.075 works very well on Deltas. This resulted in printing 50% of the part or so, which was better than the first round where those tiny little sections snapped off after the third pass, but still not a complete print and not with good quality.

Are there any other settings I should change? Right now I'm at 0.05 mm layer height, 20% infill, 40 mm/s print speed, 100mm/s travel speed, 240/120 extrude/bed temperature, 0.075 mm Z hop. This is a slow speed for my printer, usually I use 60/220 mm/s

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

[www.thingiverse.com]

The problem seems to be that my mini Kossel really doesn't like thin vertical members. Thin, horizontal members with support is just fine. I first found this out with my X-wing print, which had thin vertical lasers that looked awful, but the rest of it printed nicely. It seems that as the printer lays down thin vertical members, the print nozzle starts to rub against the material, moving it slightly, which result in mis-aligned layers and thus a rough appearance. For reference:

Solid Parts:

Thin parts:

So far I've tried reducing the print speed, increasing heat, decreasing layer height, decreasing travel speed, and the all important and elusive setting of Z-hop, which Cura recommends a value of 0.075 works very well on Deltas. This resulted in printing 50% of the part or so, which was better than the first round where those tiny little sections snapped off after the third pass, but still not a complete print and not with good quality.

Are there any other settings I should change? Right now I'm at 0.05 mm layer height, 20% infill, 40 mm/s print speed, 100mm/s travel speed, 240/120 extrude/bed temperature, 0.075 mm Z hop. This is a slow speed for my printer, usually I use 60/220 mm/s

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

|

Re: Best settings for thin members with a delta? February 20, 2015 01:05PM |

Registered: 10 years ago Posts: 14,672 |

Assuming you are printing in PLA, you probably need a print cooling fan to improve the print quality for that sort of part.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best settings for thin members with a delta? February 20, 2015 01:19PM |

Registered: 9 years ago Posts: 25 |

Good point, I forgot to mention it is ABS. So a print cooling fan will, I assume, solidify the part faster and thus keep it more rigid. I have a fan on my print head, but I have seen modifications on the Kossel with multiple 45 degree angle fans blowing on the part.

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

|

Re: Best settings for thin members with a delta? February 20, 2015 01:52PM |

Registered: 10 years ago Posts: 14,672 |

I'm not an expert in ABS printing, but my understanding is you don't normally want to use a cooling fan because of the danger of warping. Have you tried a lower extruder temperature?

The problem you describe isn't unique to delta printers, so you may be better off posting it in the Printing sub-forum.

Edited 1 time(s). Last edit at 02/20/2015 01:53PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The problem you describe isn't unique to delta printers, so you may be better off posting it in the Printing sub-forum.

Edited 1 time(s). Last edit at 02/20/2015 01:53PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Best settings for thin members with a delta? February 20, 2015 02:08PM |

Registered: 10 years ago Posts: 732 |

|

Re: Best settings for thin members with a delta? February 20, 2015 02:36PM |

Registered: 10 years ago Posts: 903 |

|

Re: Best settings for thin members with a delta? February 20, 2015 02:47PM |

Registered: 9 years ago Posts: 25 |

I figured it was common, but I also hypothesized that Cartesian and Delta solutions would differ based on their different modes of transportation.

My retraction is set to the Cura default; 4.5mm at 40.0 mm/s. I found a good blog on ABS printing that agreed with your assessment that fans on ABS is a bad idea. They recommend going up or down in 5 degree increments depending on if you have mush (go down) or rough layers (go up). I'm trying a run now having increased temperature by 5 degrees, I'll see if it improves the quality by any significant margin. I should also try playing with different speeds for different parts, such as slowing it down for the thin bottoms but leaving it normal speed for raft and the ring support.

As for the Bowden synchronization, the Bowden is all I have for now and it is calibrated very precisely. I understand Bowden has hystersis problems, but there's nothing I can do at the moment for that.

Edited 1 time(s). Last edit at 02/20/2015 02:48PM by Rett Mikhal.

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

My retraction is set to the Cura default; 4.5mm at 40.0 mm/s. I found a good blog on ABS printing that agreed with your assessment that fans on ABS is a bad idea. They recommend going up or down in 5 degree increments depending on if you have mush (go down) or rough layers (go up). I'm trying a run now having increased temperature by 5 degrees, I'll see if it improves the quality by any significant margin. I should also try playing with different speeds for different parts, such as slowing it down for the thin bottoms but leaving it normal speed for raft and the ring support.

As for the Bowden synchronization, the Bowden is all I have for now and it is calibrated very precisely. I understand Bowden has hystersis problems, but there's nothing I can do at the moment for that.

Edited 1 time(s). Last edit at 02/20/2015 02:48PM by Rett Mikhal.

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

|

Re: Best settings for thin members with a delta? February 21, 2015 04:05PM |

Registered: 9 years ago Posts: 102 |

|

Re: Best settings for thin members with a delta? February 23, 2015 12:43PM |

Registered: 9 years ago Posts: 25 |

It is for a bracelet so it will have to have some strength. However a hard coating will most likely give it more than enough strength than is necessary. I could test it with my simulation tools, if I knew the material properties of extruded ABS under different temperatures. I should put together a test for that for future reference.

If this next test at super slow speed and 250 doesn't work maybe I'll try going down in temp, instead.

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

If this next test at super slow speed and 250 doesn't work maybe I'll try going down in temp, instead.

"Pfft. Third dimension... what dimension do we even live in?" - Charlie Kelly

Sorry, only registered users may post in this forum.