Delta Printer bad prints - Part II (ABS)

Posted by Stephanel

|

Delta Printer bad prints - Part II (ABS) February 24, 2015 03:13PM |

Registered: 9 years ago Posts: 113 |

Hey!

In another post, we discussed my bad prints with PLA on my new Delta Printer. I thought it might be interesting to discuss my next bad prints, given that I now added a heated bed and am printing ABS instead of PLA.

First, the start and result of our discussions last time:

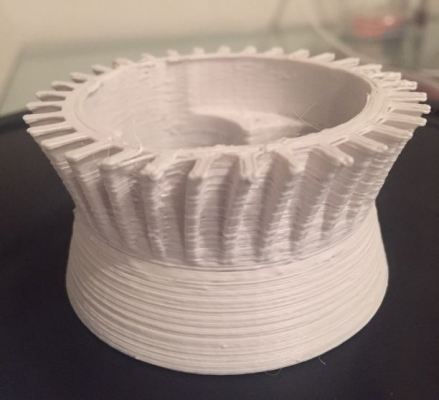

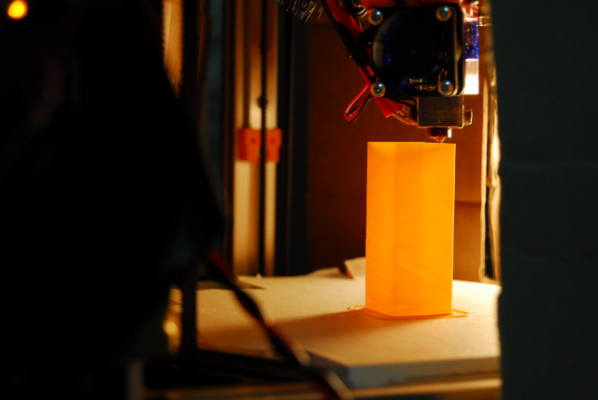

Before calibration, tweaking and fixing stuff:

After:

I couldn't have gotten to the last picture without your help! Thanks!!

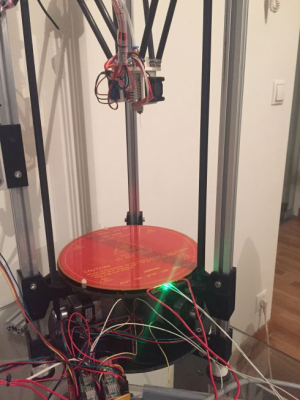

So now I have added a heated bed:

And naturally, I have to start over again... I have done the calibration again (which was surprisingly difficult, as my auto calibration apparently didn't function as well as I had hoped)... Now I am within tolerance (I think) to print. Sadly, the results are still underwhelming:

In the first picture, you can clearly see that this print's quality is significantly worse than the print above of the same object. Also, I had to abort the print because of a step miss (I think), as you can see in the top layer. Anyway, the print was bad...

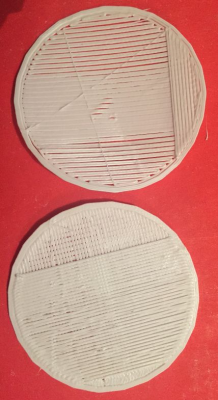

The last pictures again show quite some distance between the lines in the first layer. This although I have set the first layer extrusion width to 200% in Slic3r. That the lines come together in the top print, is because there still was a bit of uncalibration (0.15mm) to the edges of the print bed. I fixed that in the second. The gaps between the lines stayed there, but the gaps were equal everywhere.

The tension of the belts seems fine to me, but I find that quite difficult to assess. I have put the tensioner to it's max, so I cannot do much in any case anymore...

I will not start with fiddling with the settings again :-) I will also double check my calibration, as this often is the key to the solution...

In another post, we discussed my bad prints with PLA on my new Delta Printer. I thought it might be interesting to discuss my next bad prints, given that I now added a heated bed and am printing ABS instead of PLA.

First, the start and result of our discussions last time:

Before calibration, tweaking and fixing stuff:

After:

I couldn't have gotten to the last picture without your help! Thanks!!

So now I have added a heated bed:

And naturally, I have to start over again... I have done the calibration again (which was surprisingly difficult, as my auto calibration apparently didn't function as well as I had hoped)... Now I am within tolerance (I think) to print. Sadly, the results are still underwhelming:

In the first picture, you can clearly see that this print's quality is significantly worse than the print above of the same object. Also, I had to abort the print because of a step miss (I think), as you can see in the top layer. Anyway, the print was bad...

The last pictures again show quite some distance between the lines in the first layer. This although I have set the first layer extrusion width to 200% in Slic3r. That the lines come together in the top print, is because there still was a bit of uncalibration (0.15mm) to the edges of the print bed. I fixed that in the second. The gaps between the lines stayed there, but the gaps were equal everywhere.

The tension of the belts seems fine to me, but I find that quite difficult to assess. I have put the tensioner to it's max, so I cannot do much in any case anymore...

I will not start with fiddling with the settings again :-) I will also double check my calibration, as this often is the key to the solution...

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 03:46PM |

Registered: 10 years ago Posts: 469 |

Instead of tearing you hair out with slicer, why not try cura? It supports delta machine nicely.

One more thing, with the ribbing I notice on there. I think you need to tighten the belts and make sure you have a keyway filed on your motors. Then tighten those pulleys down. You learn early on with a delta that any pulley slip causes hard to trace problems.

One more thing the second one looks like it was printed at high speed and thick layers, you need to up the temp to do that without it turning into crap. try 230-240c on the hot end.

my .02c

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

One more thing, with the ribbing I notice on there. I think you need to tighten the belts and make sure you have a keyway filed on your motors. Then tighten those pulleys down. You learn early on with a delta that any pulley slip causes hard to trace problems.

One more thing the second one looks like it was printed at high speed and thick layers, you need to up the temp to do that without it turning into crap. try 230-240c on the hot end.

my .02c

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 04:23PM |

Registered: 9 years ago Posts: 113 |

Hey!

Thanks! I tried using cura, but ended up with Slic3r. Didn't know it was so much better, seemed like Slic3r has all the necessary options as well... It printed nicely with PLA :-) But indeed, might be worthwhile trying out Cura now...

The problem with my current design is that I have no way to easily tighten the belts without a tensioner :-( Let me look into another method to tension this, or print yet another tensioner!

The hot end indeed is about 210degC. I will increase it, but my little power supply already has quite some difficulties managing the bed and hot end. Kinda strange as it is a 30A 12V power supply?...

Thanks! I tried using cura, but ended up with Slic3r. Didn't know it was so much better, seemed like Slic3r has all the necessary options as well... It printed nicely with PLA :-) But indeed, might be worthwhile trying out Cura now...

The problem with my current design is that I have no way to easily tighten the belts without a tensioner :-( Let me look into another method to tension this, or print yet another tensioner!

The hot end indeed is about 210degC. I will increase it, but my little power supply already has quite some difficulties managing the bed and hot end. Kinda strange as it is a 30A 12V power supply?...

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 04:53PM |

Registered: 10 years ago Posts: 14,672 |

Two things:

1. 210C is indeed not hot enough for ABS printing.

2. Did you calibrate your printer with the heated bed and hot end at ABS printing temperatures? In particular, the homed height will vary with temperature by a significant fraction of a mm.

Cura does some things better than slic3r (e.g. support I think), but it won't solve the problems indicated by the photos you posted.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. 210C is indeed not hot enough for ABS printing.

2. Did you calibrate your printer with the heated bed and hot end at ABS printing temperatures? In particular, the homed height will vary with temperature by a significant fraction of a mm.

Cura does some things better than slic3r (e.g. support I think), but it won't solve the problems indicated by the photos you posted.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 05:03PM |

Registered: 9 years ago Posts: 113 |

Mm :-) 230 really is quite hot! I will try tomorrow with the increased temp. I did already add (3!) tensioners to each belt, and if they now aren't tightened, they will never be :-)

I indeed calibrated with the hot bed at 100degC and the extruder at 210degC. I did not do it at 230degC, but I assume that doesn't count for much...

I will have a look at Cura once I get these prints fine.

BTW: how much amperage do you have for your power source (if you use a heated bed, and have Nema 17 0.7A motors or similar)? Seems like 30A still is kinda stretching it...

I indeed calibrated with the hot bed at 100degC and the extruder at 210degC. I did not do it at 230degC, but I assume that doesn't count for much...

I will have a look at Cura once I get these prints fine.

BTW: how much amperage do you have for your power source (if you use a heated bed, and have Nema 17 0.7A motors or similar)? Seems like 30A still is kinda stretching it...

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 05:48PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Stephanel

BTW: how much amperage do you have for your power source (if you use a heated bed, and have Nema 17 0.7A motors or similar)? Seems like 30A still is kinda stretching it...

The current required depends mostly on the resistance of the heated bed. What heated bed are you using, and do you know its resistance?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 05:59PM |

Registered: 9 years ago Posts: 113 |

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 06:01PM |

Registered: 9 years ago Posts: 189 |

Have you done temperature calibration for the ABS filament?

It takes less than one hour.

[www.thingiverse.com]

I found 190 - 200 degrees Celsius is the sweet spot for the 1.75mm PLA filament I use.

I learned that to have good quality printing, flow rate and feed rate of the extruder need to be done, and printing speed per model.

It takes less than one hour.

[www.thingiverse.com]

I found 190 - 200 degrees Celsius is the sweet spot for the 1.75mm PLA filament I use.

I learned that to have good quality printing, flow rate and feed rate of the extruder need to be done, and printing speed per model.

|

Re: Delta Printer bad prints - Part II (ABS) February 24, 2015 06:06PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Stephanel

I use am MK2Y 200 heated bed. I do not know what the resistance of that bed is. It's not listed on the sale page either...

If you have a multimeter, then you can measure it. My guess is that a bed of that size should take around 10A @ 12V. In which case, your 30A PSU would be plenty. I use a 25A PSU to power a dual nozzle printer with a 210mm x 200mm bed, which it does easily.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 12:29AM |

Registered: 10 years ago Posts: 469 |

I am not one to ask about psu power. Mine does 60+ amps at 110v. Or about 110amps at 220. I like server psus for this reason . I am putting in a DC converter in to run the bed at 13 to 14v. ......

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 02:51AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Stephanel

Hey!

Thanks! I tried using cura, but ended up with Slic3r. Didn't know it was so much better, seemed like Slic3r has all the necessary options as well... It printed nicely with PLA :-) But indeed, might be worthwhile trying out Cura now...

The problem with my current design is that I have no way to easily tighten the belts without a tensioner :-( Let me look into another method to tension this, or print yet another tensioner!

The hot end indeed is about 210degC. I will increase it, but my little power supply already has quite some difficulties managing the bed and hot end. Kinda strange as it is a 30A 12V power supply?...

This sounds like a similar problem I had in the early days.

I guess you are still using a Ramps board.

1 put a heatsink on the hotbed FET.

2 Get a fan blowing over the board.

when that Fet get's hot it starts to effectively shut down and doesn't let the amount of current to flow that is required.

Untill I did these 2 things I could barely get my hot bed to 90C (took about 40 mins to get there as well) with the 2 mods then 115 is easy and takes around 15 mins now.

and for what it's worth I print ABS at 110 bed 245 extruder temps (the extruder temp will vary depending on the filament you use. I use ESUN Filament which is excellent by the way and can be got from www.hobbyking.com make sure you are ordering from the EU Warehouse tho and not the HK one not only is it excellent quality it is very cheap approx. 15eur/Kg)

HTH

Doug

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 08:47AM |

Registered: 9 years ago Posts: 113 |

Quote

dougal1957

Quote

Stephanel

Hey!

Thanks! I tried using cura, but ended up with Slic3r. Didn't know it was so much better, seemed like Slic3r has all the necessary options as well... It printed nicely with PLA :-) But indeed, might be worthwhile trying out Cura now...

The problem with my current design is that I have no way to easily tighten the belts without a tensioner :-( Let me look into another method to tension this, or print yet another tensioner!

The hot end indeed is about 210degC. I will increase it, but my little power supply already has quite some difficulties managing the bed and hot end. Kinda strange as it is a 30A 12V power supply?...

This sounds like a similar problem I had in the early days.

I guess you are still using a Ramps board.

1 put a heatsink on the hotbed FET.

2 Get a fan blowing over the board.

when that Fet get's hot it starts to effectively shut down and doesn't let the amount of current to flow that is required.

Untill I did these 2 things I could barely get my hot bed to 90C (took about 40 mins to get there as well) with the 2 mods then 115 is easy and takes around 15 mins now.

and for what it's worth I print ABS at 110 bed 245 extruder temps (the extruder temp will vary depending on the filament you use. I use ESUN Filament which is excellent by the way and can be got from www.hobbyking.com make sure you are ordering from the EU Warehouse tho and not the HK one not only is it excellent quality it is very cheap approx. 15eur/Kg)

HTH

Doug

Thanks Doug, I indeed use a RAMPS board. I have now put a fan and 2 heat sinks on both mosfets of the heated bed and the extruder. However, for some reason beyond me, the temperature cannot creep above 250degC for the extruder. Even when I disable the heated bed, the extruder won't go higher... I wanted to start at 260degC to test the filament calibration, as this is the max temp for that ABS filament. But guess that I will have to start with 250degC and going down...

Edited 1 time(s). Last edit at 02/25/2015 08:47AM by Stephanel.

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 09:32AM |

Registered: 9 years ago Posts: 113 |

It is really quite frustrating  For some reason, when I start a print at eg 250degC and 100degC heated bed, the extrusion temperature just refuses to go above 238degC. It keeps on hovering around that value.

For some reason, when I start a print at eg 250degC and 100degC heated bed, the extrusion temperature just refuses to go above 238degC. It keeps on hovering around that value.

My power source is 30amps 12V, I put two (!) fans (one external) on my mosfets and I put a heat sinks on both the heated bed and the extruder mosfet.

Any idea what is going wrong?

For some reason, when I start a print at eg 250degC and 100degC heated bed, the extrusion temperature just refuses to go above 238degC. It keeps on hovering around that value.

For some reason, when I start a print at eg 250degC and 100degC heated bed, the extrusion temperature just refuses to go above 238degC. It keeps on hovering around that value.My power source is 30amps 12V, I put two (!) fans (one external) on my mosfets and I put a heat sinks on both the heated bed and the extruder mosfet.

Any idea what is going wrong?

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 09:35AM |

Registered: 9 years ago Posts: 113 |

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 09:41AM |

Registered: 10 years ago Posts: 14,672 |

If the hot end won't exceed 250C then it sounds to me that either your hot end heater is a little weak, or the power supply voltage is somewhat under 12V.

Either way, if your 12V 30A PSU is one of the generic Chinese ones, then it has a voltage adjustment potentiometer. If you don't have an LCD display or anything other external load on the Arduino/RAMPS 5V rail, then you can safely turn the voltage up to 13V or 14V. 13V should be enough to get to 260C. If you go above 13V then it's a good idea to put two 1N4001 or similar diodes in series with the fans, to drop the voltage back to near 12V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Either way, if your 12V 30A PSU is one of the generic Chinese ones, then it has a voltage adjustment potentiometer. If you don't have an LCD display or anything other external load on the Arduino/RAMPS 5V rail, then you can safely turn the voltage up to 13V or 14V. 13V should be enough to get to 260C. If you go above 13V then it's a good idea to put two 1N4001 or similar diodes in series with the fans, to drop the voltage back to near 12V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 09:51AM |

Registered: 9 years ago Posts: 113 |

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 09:56AM |

Registered: 9 years ago Posts: 113 |

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 10:38AM |

Registered: 9 years ago Posts: 113 |

It is probably like you say, the cardridge heater seems not to be able to heat the block up to 250degC. I have increased the power supply voltage to 13.5V and the supply at the RAMPS board to the extruder now reads about 11.7V. Still the extruder cannot exceed 238-242degC.

Strange, because I thought this was a standard 3D printer cardridge. Apparently, it is not and I have to look for a better one. Any suggestions as to what you use?

Edited 1 time(s). Last edit at 02/25/2015 10:39AM by Stephanel.

Strange, because I thought this was a standard 3D printer cardridge. Apparently, it is not and I have to look for a better one. Any suggestions as to what you use?

Edited 1 time(s). Last edit at 02/25/2015 10:39AM by Stephanel.

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:05AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Stephanel

It is probably like you say, the cardridge heater seems not to be able to heat the block up to 250degC. I have increased the power supply voltage to 13.5V and the supply at the RAMPS board to the extruder now reads about 11.7V. Still the extruder cannot exceed 238-242degC.

Strange, because I thought this was a standard 3D printer cardridge. Apparently, it is not and I have to look for a better one. Any suggestions as to what you use?

I wonder if you may have got a 24V Heater by mistake any 12V 40 watt one should be able to take you towards 400-500 C easily (There are photos on here somewhere showing one glowing Red which is towards 900c or more for steel (Can't remember exactly been out of Mech Engineering for to long to remember those facts lol).

try one from RepRapWorld 12v 40W heater cartridge (they are in the Hague Netherlands)

Doug

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:07AM |

Registered: 9 years ago Posts: 113 |

Damn, think I wrecked my RAMPS board. A heat sink fell off and hit the driver of the extruder. Now the extruder won't work anymore. I tried to put the extruder motor on the X axes, and it still works. Exchanged the motor driver, but that didn't help. Probably the board has blown a fuse or so... :-(

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:10AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Stephanel

It is probably like you say, the cardridge heater seems not to be able to heat the block up to 250degC. I have increased the power supply voltage to 13.5V and the supply at the RAMPS board to the extruder now reads about 11.7V.

You should not be losing nearly 2V in the wiring, the maximum voltage loss should be no more than 0.5V with the bed heater on and much less than that with the bed heater off. Check the following:

1. Are the 12V wires from the PSU to the RAMPS board thick enough? The RAMPS board has 2 pairs of 12V inputs, and those PSUs normally provide 3 12V and 3 ground outputs. So I suggest you run 2 or 3 pairs of thick cable between the PSU and the RAMPS. Heavy-duty loudspeaker cable is suitable.

2. Are the screw terminals on the RAMPS board tight?

3. Is the extruder mosfet getting hot? If so, that probably means that the 5V supply is low so that the mosfet is not turning on fully.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:22AM |

Registered: 9 years ago Posts: 113 |

I use a rather thick cable which normally is used for lighting etc. The voltage at the power inlet of the RAMPS board is 13.5V as set in the power supply now.

All screws are tight.

That might be a reason. I feed the board with 5V through the USB port coming from my PC. The laptop is plugged in. Not sure if it provides sufficient power? I also did not find another way to power the 5V without PC...

All screws are tight.

That might be a reason. I feed the board with 5V through the USB port coming from my PC. The laptop is plugged in. Not sure if it provides sufficient power? I also did not find another way to power the 5V without PC...

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:40AM |

Registered: 10 years ago Posts: 14,672 |

I'm wondering whether the firmware you are using (Marlin?) has a facillity to limit the maximum PWM value used on the extruder heater. That couold account for the voltage loss. If so, you may need to disable that feature, or increase the maximum allowed PWM.

If you are losing 2V in the extruder control mosfet instead, then it will be getting very hot.

Edited 1 time(s). Last edit at 02/25/2015 11:40AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you are losing 2V in the extruder control mosfet instead, then it will be getting very hot.

Edited 1 time(s). Last edit at 02/25/2015 11:40AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:42AM |

Registered: 9 years ago Posts: 113 |

Mine looks exactly like that, and has the same specifications... Not sure how to test these things if they indeed are 24V.Quote

dougal1957

Quote

Stephanel

It is probably like you say, the cardridge heater seems not to be able to heat the block up to 250degC. I have increased the power supply voltage to 13.5V and the supply at the RAMPS board to the extruder now reads about 11.7V. Still the extruder cannot exceed 238-242degC.

Strange, because I thought this was a standard 3D printer cardridge. Apparently, it is not and I have to look for a better one. Any suggestions as to what you use?

I wonder if you may have got a 24V Heater by mistake any 12V 40 watt one should be able to take you towards 400-500 C easily (There are photos on here somewhere showing one glowing Red which is towards 900c or more for steel (Can't remember exactly been out of Mech Engineering for to long to remember those facts lol).

try one from RepRapWorld 12v 40W heater cartridge (they are in the Hague Netherlands)

Doug

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 11:55AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Stephanel

Mine looks exactly like that, and has the same specifications... Not sure how to test these things if they indeed are 24V.

Measure the resistance. These heaters are normally designed to put out 40W. So the resistance will be about 3.6 ohms if it is a 12V heater, and about 15 ohms if it is 24V.

However, if it were a 24V heater, I don't think it would be reaching 240C on 11.7V.

Edited 2 time(s). Last edit at 02/25/2015 11:56AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 12:29PM |

Registered: 9 years ago Posts: 113 |

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 02:10PM |

Registered: 10 years ago Posts: 14,672 |

So it's a 12V heater, but with a power of only about 33W instead of 40W if your multimeter reading is accurate.

You need to find out why the voltage at the RAMPS extruder output is 1.9V lower than the voltage at the RAMPS input. If you get rid of that then you will get around 30% more power to the extruder heater.

I suggest this. Set the extruder temperature very high, e.g. 300C. Make sure the heated bed is off. Measure the voltage between the +ve input from the PSU and the +ve output to the extruder. It should be very low, probably no more than 0.2V. If it is much higher, then measure the voltage drop across the 5A fuse on the RAMPS in case that is the culprit.

Then measure the voltage between the -ve PSU input and the -v2 output to the extruder. If the PWM is 100% then you should only get the voltage drop in the mosfet, which should again be no more than 0.1V. If it is more, then either the mosfet is not turning on fully and will be getting hot, or the firmware is restricting the PWM to less than 100%.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You need to find out why the voltage at the RAMPS extruder output is 1.9V lower than the voltage at the RAMPS input. If you get rid of that then you will get around 30% more power to the extruder heater.

I suggest this. Set the extruder temperature very high, e.g. 300C. Make sure the heated bed is off. Measure the voltage between the +ve input from the PSU and the +ve output to the extruder. It should be very low, probably no more than 0.2V. If it is much higher, then measure the voltage drop across the 5A fuse on the RAMPS in case that is the culprit.

Then measure the voltage between the -ve PSU input and the -v2 output to the extruder. If the PWM is 100% then you should only get the voltage drop in the mosfet, which should again be no more than 0.1V. If it is more, then either the mosfet is not turning on fully and will be getting hot, or the firmware is restricting the PWM to less than 100%.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 04:40PM |

Registered: 10 years ago Posts: 580 |

The lower voltage is possible due to PWM, as mentioned above, check that the max PWM in your config for the extruder is 255. You should be able to see what the PWM rate is if you are using Pronterface.

Also, you should probably do a new PID auto config.

For Extruder 0 for 250C use: M303 E0 S250

That's pretty hot, hope your extruder is made for that.

Also you could insulate the hot end - j-head part, you could use some fiberglass tape like this on Amazon. Make sure you are not going to use over it's rated temp.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

Also, you should probably do a new PID auto config.

For Extruder 0 for 250C use: M303 E0 S250

That's pretty hot, hope your extruder is made for that.

Also you could insulate the hot end - j-head part, you could use some fiberglass tape like this on Amazon. Make sure you are not going to use over it's rated temp.

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 06:18PM |

Registered: 9 years ago Posts: 113 |

It is very strange. I never tried to do a heatup to 300degC, as I didn't want to risk it. However, now I did, and for some reason, the heater could get to 268degC (after which the program reset, as this was max temp). Then I reset the setpoint temp to 250degC, and it just would not go over 240degC...

I did however do the measurements:

ve+ - ve+ = 0.26V

ve- - ve- = 1.4V

As you say, this might indeed be a firmware setting issue. I however do not know how I can change the Marlin firmware to set the correct PWM. I only see this mentioned for the heated bed.

Do you know where I can find this PWM setting in Marlin firmware? It does not seem to be in the configuration.h file... I tried looking in the other source files, but there doesn't seem to be a match for the extruder. All PWM is linked to the heated bed...

I did however try the auto tune command (wasn't aware of that command!), and it does reach 250 when finding the parameters. However, I input them in the firmware, and afterwards tried to reach 250 again, and still it keeps on hovering at 240degC. It seems like there's some kind of hardcoded max working here?... I looked in the source files, but there's nowhere a field that puts it on 240 (hardcoded), but it might be some kind of calculation...

I did however do the measurements:

ve+ - ve+ = 0.26V

ve- - ve- = 1.4V

As you say, this might indeed be a firmware setting issue. I however do not know how I can change the Marlin firmware to set the correct PWM. I only see this mentioned for the heated bed.

Do you know where I can find this PWM setting in Marlin firmware? It does not seem to be in the configuration.h file... I tried looking in the other source files, but there doesn't seem to be a match for the extruder. All PWM is linked to the heated bed...

I did however try the auto tune command (wasn't aware of that command!), and it does reach 250 when finding the parameters. However, I input them in the firmware, and afterwards tried to reach 250 again, and still it keeps on hovering at 240degC. It seems like there's some kind of hardcoded max working here?... I looked in the source files, but there's nowhere a field that puts it on 240 (hardcoded), but it might be some kind of calculation...

|

Re: Delta Printer bad prints - Part II (ABS) February 25, 2015 07:38PM |

Registered: 10 years ago Posts: 580 |

It's good that it reached the correct temp during the PID test - that's confirmation that PID was set incorrectly - it's different for every extruder.

After you do the auto-tune, then it will display the values in your host program, you need to enter those three values in the configuration.h file and re-flash.

After you do the auto-tune, then it will display the values in your host program, you need to enter those three values in the configuration.h file and re-flash.

Sorry, only registered users may post in this forum.