The Delta Steel, a slightly modified Delta-Pi

Posted by AndrewBCN

|

The Delta Steel, a slightly modified Delta-Pi March 02, 2015 08:18AM |

Registered: 9 years ago Posts: 977 |

Hi,

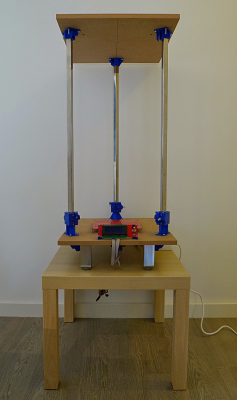

I am working on assembling the Delta Steel prototype, essentially a Delta-Pi with a mini Kossel effector and Traxxas 5347 ball joints.

Mike Pauwee has done an awesome job designing the Delta-Pi and I really liked his mechanical design for the columns/carriages. At the same time, I think the mini Kossel effector is also quite neat, so I remixed Mike's carriage design to accommodate the mini Kossel "horns" to attach the Traxxas ball joints. I made small changes to most of the other printed parts.

The main focus for my remix of the Delta-Pi is to have an extremely inexpensive and easy to build linear delta of similar dimensions to the original Rostock.

Right now I am posting the details about the build on a specific blog, but I intend to replicate all the information in the RepRap.org wiki at a later stage.

The blog is at: [deltasteel3dprinter.blogspot.com.es]

Comments, suggestions and constructive criticism are invited.

Andrew

I am working on assembling the Delta Steel prototype, essentially a Delta-Pi with a mini Kossel effector and Traxxas 5347 ball joints.

Mike Pauwee has done an awesome job designing the Delta-Pi and I really liked his mechanical design for the columns/carriages. At the same time, I think the mini Kossel effector is also quite neat, so I remixed Mike's carriage design to accommodate the mini Kossel "horns" to attach the Traxxas ball joints. I made small changes to most of the other printed parts.

The main focus for my remix of the Delta-Pi is to have an extremely inexpensive and easy to build linear delta of similar dimensions to the original Rostock.

Right now I am posting the details about the build on a specific blog, but I intend to replicate all the information in the RepRap.org wiki at a later stage.

The blog is at: [deltasteel3dprinter.blogspot.com.es]

Comments, suggestions and constructive criticism are invited.

Andrew

|

Re: The Delta Steel, a slightly modified Delta-Pi March 09, 2015 07:07AM |

Registered: 9 years ago Posts: 50 |

|

Re: The Delta Steel, a slightly modified Delta-Pi March 09, 2015 09:01AM |

Registered: 9 years ago Posts: 977 |

Hi Denny,

Thanks! Progress is slow (it's not like I am putting together a kit), but I keep working on it. I just published my latest blog post with a photo of my first test fit of the entire structure.

More details in the blog: [deltasteel3dprinter.blogspot.com.es]

Thanks! Progress is slow (it's not like I am putting together a kit), but I keep working on it. I just published my latest blog post with a photo of my first test fit of the entire structure.

More details in the blog: [deltasteel3dprinter.blogspot.com.es]

|

Re: The Delta Steel, a slightly modified Delta-Pi March 15, 2015 01:27PM |

Registered: 9 years ago Posts: 977 |

Just a quick update: 14 blog posts after I got started on this project and I am getting ready for the final assembly of the printer.

These days I overcame one major hurdle, which was the design of a belt tensioning system that uses a single knurled knob on top of the printer.

I couldn't find anything similar to this for the Rostock or Kossel or any variant of these so I had to design my own.

It can be retrofitted to a normal Delta-Pi and I posted it on Thingiverse, and Mike Paauwe (the original designer of the Delta-Pi) posted a comment saying he liked it, so there's the official stamp of approval right there!

Also I decided on a first direct-drive extruder which I am going to test.

Details and pics in the blog: [deltasteel3dprinter.blogspot.com.es]

These days I overcame one major hurdle, which was the design of a belt tensioning system that uses a single knurled knob on top of the printer.

I couldn't find anything similar to this for the Rostock or Kossel or any variant of these so I had to design my own.

It can be retrofitted to a normal Delta-Pi and I posted it on Thingiverse, and Mike Paauwe (the original designer of the Delta-Pi) posted a comment saying he liked it, so there's the official stamp of approval right there!

Also I decided on a first direct-drive extruder which I am going to test.

Details and pics in the blog: [deltasteel3dprinter.blogspot.com.es]

|

Re: The Delta Steel, a slightly modified Delta-Pi March 21, 2015 05:32AM |

Registered: 9 years ago Posts: 50 |

|

Re: The Delta Steel, a slightly modified Delta-Pi March 21, 2015 06:52AM |

Registered: 9 years ago Posts: 977 |

Hi Denny,

Sorry for the slow progress, but I keep working on it at least a few minutes every day.

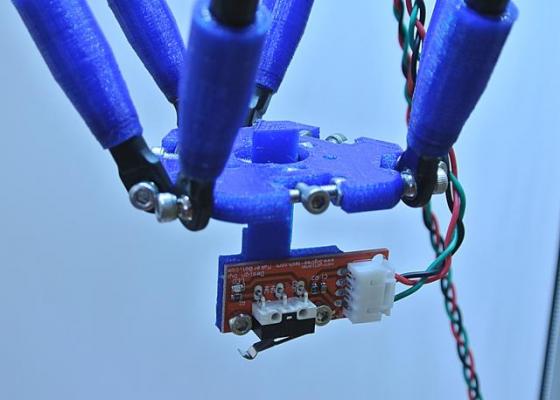

I have now reached the point where I am getting started on the final assembly of the printer i.e. I am going to put the steppers in place, install the belts, the arms and the effector, wire the endstops and the heatbed, effectively test the electronics and finally attempt the first moves of the effector. The extruder and hotend installation are for later.

So you can expect a few more blog posts in the coming days, but it will take some time until I reach my first print.

Cheers,

Andrew

Sorry for the slow progress, but I keep working on it at least a few minutes every day.

I have now reached the point where I am getting started on the final assembly of the printer i.e. I am going to put the steppers in place, install the belts, the arms and the effector, wire the endstops and the heatbed, effectively test the electronics and finally attempt the first moves of the effector. The extruder and hotend installation are for later.

So you can expect a few more blog posts in the coming days, but it will take some time until I reach my first print.

Cheers,

Andrew

|

Re: The Delta Steel, a slightly modified Delta-Pi April 04, 2015 09:16PM |

Registered: 9 years ago Posts: 977 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 05, 2015 07:14AM |

Registered: 9 years ago Posts: 60 |

Just watched your video. - Very impressed.

I was wondering though with your dry run, what geode file did you use for the test?

I am building a RichRap 3dr and am at the test running phase and could not get any of the files I created with Slic3r to work, presumably because they were waiting for things to get up to temperature etc. I hand crafted some simple gcode which worked but was looking for something to exercise the printer a little more.

Z

I was wondering though with your dry run, what geode file did you use for the test?

I am building a RichRap 3dr and am at the test running phase and could not get any of the files I created with Slic3r to work, presumably because they were waiting for things to get up to temperature etc. I hand crafted some simple gcode which worked but was looking for something to exercise the printer a little more.

Z

|

Re: The Delta Steel, a slightly modified Delta-Pi April 05, 2015 07:46AM |

Registered: 9 years ago Posts: 977 |

Quote

zitman

Just watched your video. - Very impressed.

I was wondering though with your dry run, what geode file did you use for the test?

I am building a RichRap 3dr and am at the test running phase and could not get any of the files I created with Slic3r to work, presumably because they were waiting for things to get up to temperature etc. I hand crafted some simple gcode which worked but was looking for something to exercise the printer a little more.

Z

Hi Z,

Thanks!

I sliced the effector STL in Cura and then edited the Gcode file, removing the temperature setting command right at the top of the file. I'll include a screenshot of the editor window showing how I did it in the blog post.

Cheers,

Andrew

|

Re: The Delta Steel, a slightly modified Delta-Pi April 05, 2015 07:59AM |

Registered: 9 years ago Posts: 60 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 05, 2015 10:48PM |

Registered: 9 years ago Posts: 189 |

It looks good.

I'm planning to build a big Delta 3D Printer, probably a variant of Mini Kossel.

Except the linear movement, I'll have replaced every thing.

The build volume in my mind is 350 mm in diameter and 500 mm in height.

Few questions:

Did you bolt down the base plate on the stand?

Is the square tube made out of stainless steel or other metal?

Is the square tube hollow or solid?

How much clearance do you have on the plastic carriage and the square tube?

I'm planning to build a big Delta 3D Printer, probably a variant of Mini Kossel.

Except the linear movement, I'll have replaced every thing.

The build volume in my mind is 350 mm in diameter and 500 mm in height.

Few questions:

Did you bolt down the base plate on the stand?

Is the square tube made out of stainless steel or other metal?

Is the square tube hollow or solid?

How much clearance do you have on the plastic carriage and the square tube?

|

Re: The Delta Steel, a slightly modified Delta-Pi April 05, 2015 11:31PM |

Registered: 9 years ago Posts: 977 |

Quote

janpenguin

It looks good.

I'm planning to build a big Delta 3D Printer, probably a variant of Mini Kossel.

Except the linear movement, I'll have replaced every thing.

The build volume in my mind is 350 mm in diameter and 500 mm in height.

Few questions:

Did you bolt down the base plate on the stand?

Is the square tube made out of stainless steel or other metal?

Is the square tube hollow or solid?

How much clearance do you have on the plastic carriage and the square tube?

Hi,

Thanks! Answering your questions one by one:

- The printer stands on the four chromed plastic feet which I bought at a hardware store, which you can see in some of the pictures. And as a stand I am using the small Ikea table, but no, the printer is not bolted to the table. I have added a felt pad under each one of the plastic feet.

- Yes, the square tube is polished stainless steel, 20mm x 20mm square.

- It's hollow, the walls are 1mm thick I believe. And it's incredibly rigid.

- There is no clearance per se, the carriage slides on 8 x 623zz bearings, you can see how the carriage is assembled in one of the posts in the blog.

Edited 1 time(s). Last edit at 04/05/2015 11:34PM by AndrewBCN.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 07, 2015 11:25AM |

Registered: 9 years ago Posts: 977 |

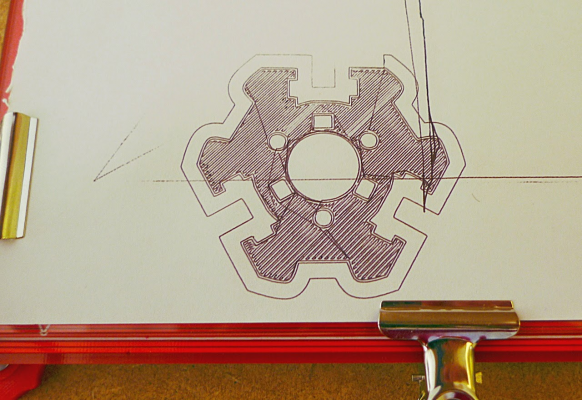

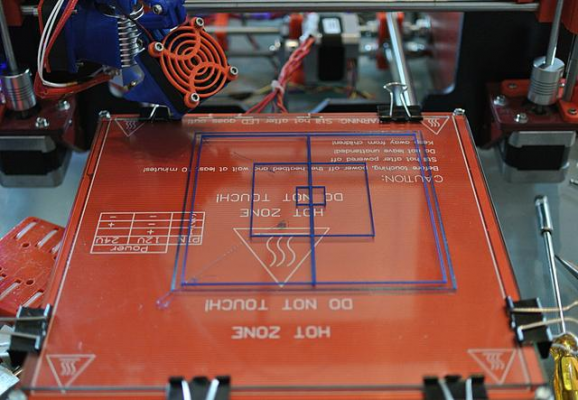

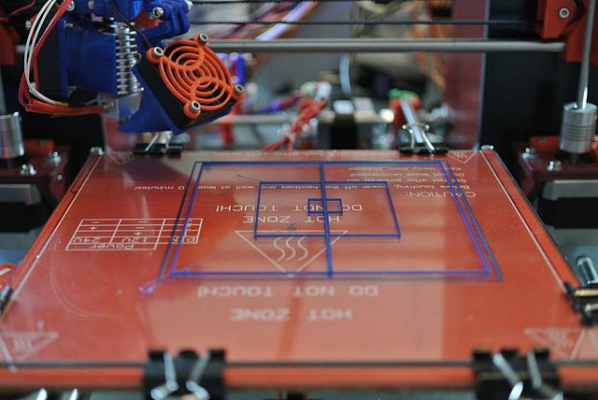

First "print" after the basic (4 points) calibration procedure:

YouTube video: [youtu.be]

PS: my apologies to Mike Paauwe, the designer of the Delta-Pi on which the Delta Steel is based, I misspelled his name in the first post in this thread and now I cannot edit that post anymore.

Edited 2 time(s). Last edit at 04/07/2015 12:17PM by AndrewBCN.

YouTube video: [youtu.be]

PS: my apologies to Mike Paauwe, the designer of the Delta-Pi on which the Delta Steel is based, I misspelled his name in the first post in this thread and now I cannot edit that post anymore.

Edited 2 time(s). Last edit at 04/07/2015 12:17PM by AndrewBCN.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 07, 2015 10:23PM |

Registered: 9 years ago Posts: 189 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 07, 2015 10:30PM |

Registered: 9 years ago Posts: 977 |

Quote

janpenguin

That's really simple and effective technique for bed level calibration.

I am following the steps outlined in this document: [delta-calibration.s3-website-us-west-2.amazonaws.com]

|

Re: The Delta Steel, a slightly modified Delta-Pi April 10, 2015 09:26PM |

Registered: 9 years ago Posts: 977 |

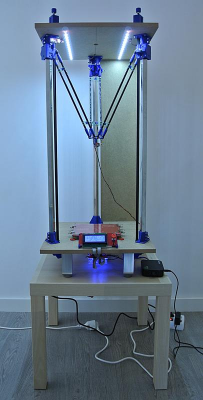

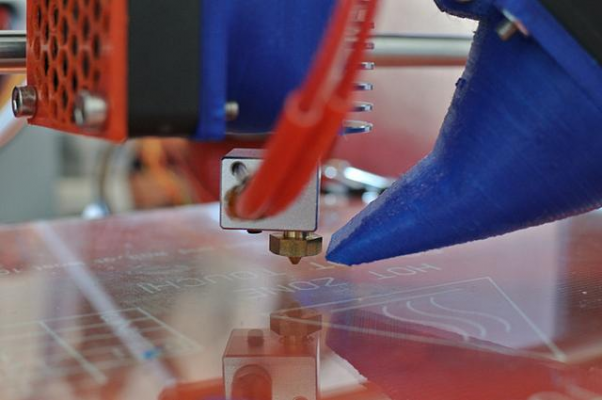

Upgrades!

LED lights (5V LED strips)!

And a temporary calibration Z-probe, so I can check various delta calibration methods/algorithms:

The endstop is connected to the RAMPS Z-Min input. I have just tested it with Rich Cattell's fork of Marlin (Testing branch) and it worked fine.

Edited 1 time(s). Last edit at 04/10/2015 09:32PM by AndrewBCN.

LED lights (5V LED strips)!

And a temporary calibration Z-probe, so I can check various delta calibration methods/algorithms:

The endstop is connected to the RAMPS Z-Min input. I have just tested it with Rich Cattell's fork of Marlin (Testing branch) and it worked fine.

Edited 1 time(s). Last edit at 04/10/2015 09:32PM by AndrewBCN.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 11, 2015 07:13AM |

Registered: 9 years ago Posts: 977 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 12, 2015 02:36PM |

Registered: 9 years ago Posts: 977 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 12, 2015 10:33PM |

Registered: 9 years ago Posts: 50 |

Hello Andrew,

What's the Torsional strength like with this machine? It certainly looks torsionally stronger than the original Rostock because I would think it's a lot harder to twist 20mm square tubes around itself than 8mm rods. Also noticed the MDF backplate, that would add strength too. Also I could print the structural printed parts with a 100% fill to make it as strong as possible.

Cheers

What's the Torsional strength like with this machine? It certainly looks torsionally stronger than the original Rostock because I would think it's a lot harder to twist 20mm square tubes around itself than 8mm rods. Also noticed the MDF backplate, that would add strength too. Also I could print the structural printed parts with a 100% fill to make it as strong as possible.

Cheers

|

Re: The Delta Steel, a slightly modified Delta-Pi April 12, 2015 10:51PM |

Registered: 9 years ago Posts: 977 |

Hi Denny,

The prototype is rather strong with respect to torsion, and I guess you can make it as strong as you want by completely covering the sides and back with MDF and adding some 90 degrees reinforcements, but I honestly believe that would be overkill, and it would make the printer much heavier. Right now I can easily pick up the printer and lay it on its side for access to the steppers, etc, and I am not worried that I will twist the structure or anything.

I also feel that the printed parts don't need to be printed with more than 40% infill, they are rather strong already.

I have most of the parts for a second prototype already here, and if I build one, it will be 50~60mm smaller in diameter and 100~120mm shorter in height, I am now leaning towards smaller, lighter printers as you'll notice if you read my blog.

The prototype is rather strong with respect to torsion, and I guess you can make it as strong as you want by completely covering the sides and back with MDF and adding some 90 degrees reinforcements, but I honestly believe that would be overkill, and it would make the printer much heavier. Right now I can easily pick up the printer and lay it on its side for access to the steppers, etc, and I am not worried that I will twist the structure or anything.

I also feel that the printed parts don't need to be printed with more than 40% infill, they are rather strong already.

I have most of the parts for a second prototype already here, and if I build one, it will be 50~60mm smaller in diameter and 100~120mm shorter in height, I am now leaning towards smaller, lighter printers as you'll notice if you read my blog.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 20, 2015 12:09AM |

Registered: 9 years ago Posts: 189 |

I have left over steel round tubes, 26.70 mm in diameter, 6 m in length, wall thickness is 2 mm.

One concern is that using three round tubes as linear rails might create twisting motion of the effector.

So I'm planning to use three bigger tubes for the linear rails where the carriages move up and down,

three small tubes as the guide which prevents twisting motion of the carriages in motion.

Do you think it's a workable design?

Regards,

Hughe

One concern is that using three round tubes as linear rails might create twisting motion of the effector.

So I'm planning to use three bigger tubes for the linear rails where the carriages move up and down,

three small tubes as the guide which prevents twisting motion of the carriages in motion.

Do you think it's a workable design?

Regards,

Hughe

|

Re: The Delta Steel, a slightly modified Delta-Pi April 20, 2015 01:22AM |

Registered: 9 years ago Posts: 977 |

Hi Hughe,

It will have a little bit more friction than the square stainless steel tube version, but it should still be a workable design.

However, you'll have to redesign not only the carriage, but also the clamps, the tensioner, and the motor mount, and that's a lot of time and energy spent redesigning things that are already tried and proven. So I am not sure it's a good idea if you are saving a few dollars but spending so much time on the other hand.

Also make sure your round steel tubes are stainless steel with a good surface finish, carbon steel tubes are not adequate for use as linear rails.

Cheers,

Andrew

It will have a little bit more friction than the square stainless steel tube version, but it should still be a workable design.

However, you'll have to redesign not only the carriage, but also the clamps, the tensioner, and the motor mount, and that's a lot of time and energy spent redesigning things that are already tried and proven. So I am not sure it's a good idea if you are saving a few dollars but spending so much time on the other hand.

Also make sure your round steel tubes are stainless steel with a good surface finish, carbon steel tubes are not adequate for use as linear rails.

Cheers,

Andrew

|

Re: The Delta Steel, a slightly modified Delta-Pi April 20, 2015 03:35PM |

Registered: 9 years ago Posts: 189 |

|

Re: The Delta Steel, a slightly modified Delta-Pi April 20, 2015 05:28PM |

Registered: 9 years ago Posts: 977 |

Just a quick update on my progress:

I have been working on the firmware for the Delta Steel, more specifically I merged Rich Cattell's auto-calibration code into Johann C. Rocholl's deltabot branch of Marlin. I had to finish the merge manually and then I tested auto-calibration on my Delta Steel. It works!

The code is in my GitHub repository: [github.com]

Note the branch is called delta_auto_calibration.

I will create a new branch to work on integrating dc42's fast least squares fit algorithm that finds an optimal solution in less than a second, this new branch will be called delta_auto_calibration-dev.

About the Bowden extruder and hotend mount on the effector: I am working on these, slowly but steadily, they'll be ready ASAP (rough ETA: less than two weeks).

I have been working on the firmware for the Delta Steel, more specifically I merged Rich Cattell's auto-calibration code into Johann C. Rocholl's deltabot branch of Marlin. I had to finish the merge manually and then I tested auto-calibration on my Delta Steel. It works!

The code is in my GitHub repository: [github.com]

Note the branch is called delta_auto_calibration.

I will create a new branch to work on integrating dc42's fast least squares fit algorithm that finds an optimal solution in less than a second, this new branch will be called delta_auto_calibration-dev.

About the Bowden extruder and hotend mount on the effector: I am working on these, slowly but steadily, they'll be ready ASAP (rough ETA: less than two weeks).

|

Re: The Delta Steel, a slightly modified Delta-Pi April 21, 2015 08:17PM |

Registered: 9 years ago Posts: 189 |

I started sourcing parts. I give two weeks for getting the critical parts and ready to build.

Parts I have:

Smoothie board x1

Stainless steel tube, 20.00 mm x 20.00 mm, wall thickness 2.0 mm, little over 1.2 m x4

12 ball studs on the way

Hotend x1

Parts I'll buy or build:

Aluminium tube, OD 6.00 mm, wall thickness 1.5 mm

NEMA 17 Stepper motor, x5

Bearing for linear movement, x12

Bearing for timing belt idler, x3

Pulley for timing belt, x3

GT2 timing belt, 8 m

Aluminium print bed, x1

Steel or aluminium round plate, x2 (laser cut)

24V Power supply, x1

220V heater, x1

--

Build envelope is 300.00 mm in diameter, 500.00 mm in height.

I came up with about 500.00 mm of DR (diagonal rod) length which produces little over 310.00 mm of build diameter.

Minimum rail length is 1,062.40 (mm) plus the offset.

X_length(theta) = DR * cos(theta)

Theta_zero: rod angle at home position, 60 degree

Theta_min: rod angle at the far end of negative x axis, 20 degree

Theta_max: rod angle at the far end of positive x axis, 80 degree

X_zero = 250.00

X_min = 86.82

X_max = 469.84

Arrange above values in line

X_max, X_zero, X_min

(X_zero - X_max), (X_zero - X_zero), (X_zero - Xmin)

(250.00 - 469.84), (250.00 - 250.00), (250.00 - 86.82)

-219.84, 0.00, 163.00

It safely covers build radius of 150.00.

To get approximate minimum tower length,

Z(theta) = DR * sin(theta)

Theta_max, 80 degree pushes the diagonal rod to uppermost position.

Z(80) = 500.00 * sin(80) = 492.40

The height of nozzle becomes 500.00 when it prints the last layer of height 500.00 mm object.

500.00 + 492.40 + 75.00 (effector and hotend height) = 1,062.40 (mm)

Edited 3 time(s). Last edit at 04/21/2015 08:26PM by janpenguin.

Parts I have:

Smoothie board x1

Stainless steel tube, 20.00 mm x 20.00 mm, wall thickness 2.0 mm, little over 1.2 m x4

12 ball studs on the way

Hotend x1

Parts I'll buy or build:

Aluminium tube, OD 6.00 mm, wall thickness 1.5 mm

NEMA 17 Stepper motor, x5

Bearing for linear movement, x12

Bearing for timing belt idler, x3

Pulley for timing belt, x3

GT2 timing belt, 8 m

Aluminium print bed, x1

Steel or aluminium round plate, x2 (laser cut)

24V Power supply, x1

220V heater, x1

--

Build envelope is 300.00 mm in diameter, 500.00 mm in height.

I came up with about 500.00 mm of DR (diagonal rod) length which produces little over 310.00 mm of build diameter.

Minimum rail length is 1,062.40 (mm) plus the offset.

X_length(theta) = DR * cos(theta)

Theta_zero: rod angle at home position, 60 degree

Theta_min: rod angle at the far end of negative x axis, 20 degree

Theta_max: rod angle at the far end of positive x axis, 80 degree

X_zero = 250.00

X_min = 86.82

X_max = 469.84

Arrange above values in line

X_max, X_zero, X_min

(X_zero - X_max), (X_zero - X_zero), (X_zero - Xmin)

(250.00 - 469.84), (250.00 - 250.00), (250.00 - 86.82)

-219.84, 0.00, 163.00

It safely covers build radius of 150.00.

To get approximate minimum tower length,

Z(theta) = DR * sin(theta)

Theta_max, 80 degree pushes the diagonal rod to uppermost position.

Z(80) = 500.00 * sin(80) = 492.40

The height of nozzle becomes 500.00 when it prints the last layer of height 500.00 mm object.

500.00 + 492.40 + 75.00 (effector and hotend height) = 1,062.40 (mm)

Edited 3 time(s). Last edit at 04/21/2015 08:26PM by janpenguin.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 21, 2015 08:55PM |

Registered: 9 years ago Posts: 977 |

Hello Hughe,

I believe there is a small mistake somewhere in your calculations, both your rods and square tubes are too long apparently.

I am using 372mm total length diagonal rods in the Delta Steel prototype and I could use a 300mm diameter heatbed if I wanted to.

There is a neat delta printer simulator web page here, check it out: [www.thinkyhead.com]

it helped me to verify the dimensions for the prototype.

Also please note that you need 10 small 623zz bearings per column (8 per carriage and 2 for the idler pulley), 30 total. These cost around $0.15 each in quantity so it's not a large expense.

I believe there is a small mistake somewhere in your calculations, both your rods and square tubes are too long apparently.

I am using 372mm total length diagonal rods in the Delta Steel prototype and I could use a 300mm diameter heatbed if I wanted to.

There is a neat delta printer simulator web page here, check it out: [www.thinkyhead.com]

it helped me to verify the dimensions for the prototype.

Also please note that you need 10 small 623zz bearings per column (8 per carriage and 2 for the idler pulley), 30 total. These cost around $0.15 each in quantity so it's not a large expense.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 22, 2015 10:01AM |

Registered: 9 years ago Posts: 189 |

@AndrewBCN

Thanks.

I think the diagonal rod length is not derived from simple cosine law for Delta 3D Printer. I must have missed something in my calculation.

Here is what I got from the calculator.

Radius: 200 mm

Height: 1000 mm

Arm Len: 325 mm

Z height: 655 mm

[www.thinkyhead.com]

Edited 1 time(s). Last edit at 04/22/2015 10:11AM by janpenguin.

Thanks.

I think the diagonal rod length is not derived from simple cosine law for Delta 3D Printer. I must have missed something in my calculation.

Here is what I got from the calculator.

Radius: 200 mm

Height: 1000 mm

Arm Len: 325 mm

Z height: 655 mm

[www.thinkyhead.com]

Edited 1 time(s). Last edit at 04/22/2015 10:11AM by janpenguin.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 22, 2015 11:52AM |

Registered: 9 years ago Posts: 977 |

Hi Hughe,

OK, now that you have the arm length/radius sorted out, I would suggest you think about how often you would need to print any object as tall as 655mm? Probably never? A good print height in your case would be around 300~400mm, so you could have your square steel tubes cut down to 750mm.

The taller the printer, the less stable it will be, and you also lose a lot of rigidity, the GT2 belts will have more backlash, etc. Conversely, the shorter the printer, the more stable and rigid it becomes, you can use shorter belts with less backlash, etc.

I built the Delta Steel prototype with 800mm steel tubes, and I ended up with a print height a little less than 400mm, but now I am seriously considering building a second prototype with 600~650mm steel tubes.

Cheers,

Andrew

OK, now that you have the arm length/radius sorted out, I would suggest you think about how often you would need to print any object as tall as 655mm? Probably never? A good print height in your case would be around 300~400mm, so you could have your square steel tubes cut down to 750mm.

The taller the printer, the less stable it will be, and you also lose a lot of rigidity, the GT2 belts will have more backlash, etc. Conversely, the shorter the printer, the more stable and rigid it becomes, you can use shorter belts with less backlash, etc.

I built the Delta Steel prototype with 800mm steel tubes, and I ended up with a print height a little less than 400mm, but now I am seriously considering building a second prototype with 600~650mm steel tubes.

Cheers,

Andrew

|

Re: The Delta Steel, a slightly modified Delta-Pi April 25, 2015 07:14AM |

Registered: 9 years ago Posts: 977 |

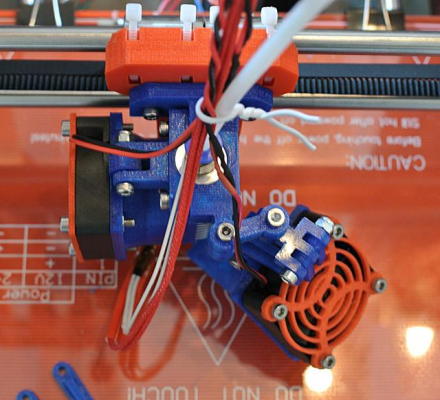

I have tested my 1.75mm Bowden extruder and the E3D V5 clone hotend which I am going to use in the Delta Pi on my just-finished Prusa i3 Twelvepro. The results are really good in terms of print quality: even though I am using an 0.4mm nozzle, the surface finish is just as good as the one I am used to getting on my P3Steel, which uses a Greg's Wade's geared extruder and a 0.3mm nozzle.

The next step is to install the extruder on top of the Delta Steel and print the required parts to mount the E3D hotend and fans on the Kossel Mini effector.

As usual, more details in my blog.

The next step is to install the extruder on top of the Delta Steel and print the required parts to mount the E3D hotend and fans on the Kossel Mini effector.

As usual, more details in my blog.

|

Re: The Delta Steel, a slightly modified Delta-Pi April 25, 2015 07:32AM |

Registered: 9 years ago Posts: 977 |

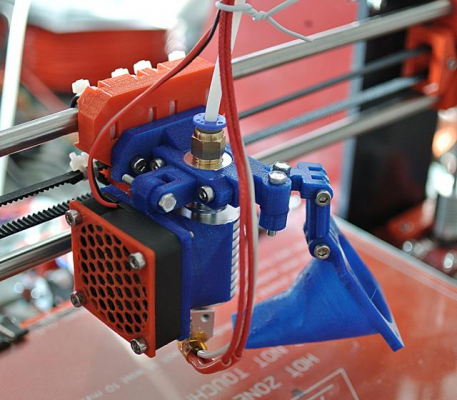

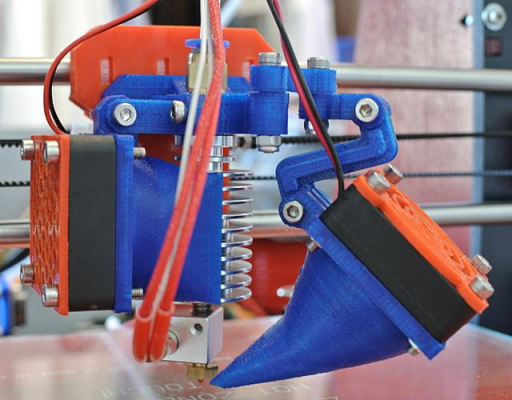

Here is the minimalistic extruder I am using:

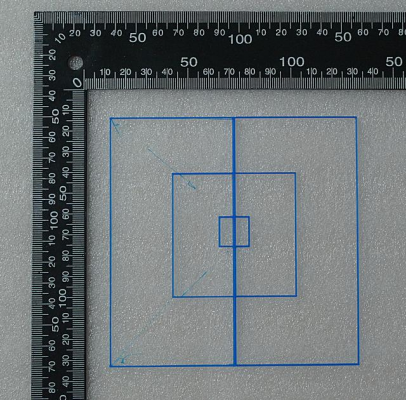

And a couple more pictures of the results I am getting. For the 5mm square steps test I had the retraction length and speed properly configured => perfect retracts.

And a couple more pictures of the results I am getting. For the 5mm square steps test I had the retraction length and speed properly configured => perfect retracts.

Sorry, only registered users may post in this forum.