Kossel Extruder Motor: I presume it's blown? Best Alternative?

Posted by Dark Skunk

|

Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 03:00PM |

Registered: 9 years ago Posts: 67 |

I'm still working to get my MakerGeek Kossel rolling. I think I found the problem. The extruder motor seems to get stuck in one particular spot (under stress it stops turning in a consistent spot).

Questions:

1. Am I diagnosing correct? I'm guessing yes.

2. I have a relatively large NEMA17 high torque motor (Double the length of the tower drivers). Do I simply get another one of those or should I go with something else. Any suggestions on a better choice? I see some on Amazon that have planetary gears and some that look even more intense ($80 though with feed kit and gear).

Any feedback is greatly appreciated. This forum is the only reason I haven't tossed this thing...

PS: This MakerGeeks kit is really pushing my buttons. I read a few reviews on here after my purchase. Make me nervous....

-Mike

Questions:

1. Am I diagnosing correct? I'm guessing yes.

2. I have a relatively large NEMA17 high torque motor (Double the length of the tower drivers). Do I simply get another one of those or should I go with something else. Any suggestions on a better choice? I see some on Amazon that have planetary gears and some that look even more intense ($80 though with feed kit and gear).

Any feedback is greatly appreciated. This forum is the only reason I haven't tossed this thing...

PS: This MakerGeeks kit is really pushing my buttons. I read a few reviews on here after my purchase. Make me nervous....

-Mike

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 03:20PM |

Registered: 10 years ago Posts: 14,672 |

1. If you are using a geared extruder, the problem could lie in the gears.

2. Check whether the motor spins fairly freely by itself. If it is getting stuck, take it apart and clean out any debris inside it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

2. Check whether the motor spins fairly freely by itself. If it is getting stuck, take it apart and clean out any debris inside it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 03:26PM |

Registered: 9 years ago Posts: 67 |

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 05:24PM |

Registered: 10 years ago Posts: 903 |

If it has a hob on the motor shaft as the filament drive, check to see that the set screw isn't hitting any part of the extruder body at that spot. My very expensive all-metal geared extruder kept stopping at the same spot in its rotation, and I wound up having to file a groove in the housing so the exposed set screw could pass through.....

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 06:19PM |

Registered: 9 years ago Posts: 67 |

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 14, 2015 06:36PM |

Registered: 10 years ago Posts: 903 |

I have only used geared stepper motors on my extruders. A gotcha to look out for is that the shaft on a geared stepper is 8mm diameter, whereas the shaft on a regular stepper is 5mm. You'll need to change hobs. The bolt patterns also differ.

Does the motor bind up even when it is detached from the extruder?????

Does the motor bind up even when it is detached from the extruder?????

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 12:20PM |

Registered: 9 years ago Posts: 67 |

If I undo the spring and get the filament out of the way, it does go in first rotations without any issues. If I put resistance on the gear when it's turning (even two fingers simply putting pressure on the pinion, it will stop until I let go. I'm putting moderate pressure on it but nothing crazy.

Not sure if the motor is bad or something else. I've been considering a geared one but am not positive what it will take to mount it. I haven't gotten a single print off this machine yet. Kind of sucks...

Not sure if the motor is bad or something else. I've been considering a geared one but am not positive what it will take to mount it. I haven't gotten a single print off this machine yet. Kind of sucks...

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 01:49PM |

Registered: 11 years ago Posts: 469 |

Quote

Dark Skunk

If I undo the spring and get the filament out of the way, it does go in first rotations without any issues. If I put resistance on the gear when it's turning (even two fingers simply putting pressure on the pinion, it will stop until I let go. I'm putting moderate pressure on it but nothing crazy.

Not sure if the motor is bad or something else. I've been considering a geared one but am not positive what it will take to mount it. I haven't gotten a single print off this machine yet. Kind of sucks...

Sounds a bit like your stepper driver is stalling and needs calibrating. Having said that i would still take it apart in make sure the mechanics of the thing are working correctly. While open check the wire connections as well . A bad joint maybe preventing 1 coil from drawing sufficient current.

Good luck

Edited 1 time(s). Last edit at 03/15/2015 01:52PM by bigfilsing.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 02:45PM |

Registered: 9 years ago Posts: 67 |

So I pulled the motor so it was all by itself. I undid the 4 screws that appear to be the only thing holding it together. I cannot get it apart. Either super strong magenta or I don't know what I'm doing.

Bench test wise.

I can run the motor in either direction with no issues IF no load.

Now I have the pinion off and I can stop the motor and turn it reverse of the direction it was going (basically with no leverage since I'm holding the shaft with my figures. Not sure what the story is with this motor.

I just ordered the link below. Probably over priced but I don't know enough to do differently. I went with 3mm as the tube and presumably the extruder were designed for.

[www.ebay.com]

Bench test wise.

I can run the motor in either direction with no issues IF no load.

Now I have the pinion off and I can stop the motor and turn it reverse of the direction it was going (basically with no leverage since I'm holding the shaft with my figures. Not sure what the story is with this motor.

I just ordered the link below. Probably over priced but I don't know enough to do differently. I went with 3mm as the tube and presumably the extruder were designed for.

[www.ebay.com]

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 02:56PM |

Registered: 9 years ago Posts: 67 |

UPDATE:

So I think I know most if not all of the problem is. I didn't confirm the length that the extruder was 'extruding'. Maybe I missed that step. In any case, when I put in 2mm it's goes 30mm (based on pronterface input). That can't be good. Maybe the problem is that I'm simple forcing the crap out of the filament and the extruder.

I'm going to calibrate and see if it's works. Probably a small chance. Likely beat the motor up already. That's on me...

So I think I know most if not all of the problem is. I didn't confirm the length that the extruder was 'extruding'. Maybe I missed that step. In any case, when I put in 2mm it's goes 30mm (based on pronterface input). That can't be good. Maybe the problem is that I'm simple forcing the crap out of the filament and the extruder.

I'm going to calibrate and see if it's works. Probably a small chance. Likely beat the motor up already. That's on me...

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 03:05PM |

Registered: 9 years ago Posts: 1,159 |

Quote

Dark Skunk

UPDATE:

So I think I know most if not all of the problem is. I didn't confirm the length that the extruder was 'extruding'. Maybe I missed that step. In any case, when I put in 2mm it's goes 30mm (based on pronterface input). That can't be good. Maybe the problem is that I'm simple forcing the crap out of the filament and the extruder.

I'm going to calibrate and see if it's works. Probably a small chance. Likely beat the motor up already. That's on me...

Sounds like you haven't got the 3 jumper's installed under the pololu driver board (these set to 16 microsteps without them you do full steps) this would account for you extruding 16 rimes more than you think.

HTH

Doug

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 04:12PM |

Registered: 9 years ago Posts: 67 |

I'm interested in your statement. I don't think I missed any jumpers. I do recall putting some on prior to putting the other board on top of it.

I just calibrated the extruder so now it's 1mm to 1mm. Still no luck though. It just won't extrude. I'm running 220 temp for PLA. Should be gushing I would think. 225 for the first layer. I have this now:

#define DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 6.3} // ( Was {100, 100, 100, 450} Makergeek said 94.1176 for x,y,z and 92.3 for e)

I don't know....

I just calibrated the extruder so now it's 1mm to 1mm. Still no luck though. It just won't extrude. I'm running 220 temp for PLA. Should be gushing I would think. 225 for the first layer. I have this now:

#define DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 6.3} // ( Was {100, 100, 100, 450} Makergeek said 94.1176 for x,y,z and 92.3 for e)

I don't know....

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 04:25PM |

Registered: 11 years ago Posts: 469 |

6.3 steps isnt right...it cant be unless as pointed out you dont have micro steps enabled. Check under the stepper driver ....are all the jumpers installed ??Quote

Dark Skunk

I'm interested in your statement. I don't think I missed any jumpers. I do recall putting some on prior to putting the other board on top of it.

I just calibrated the extruder so now it's 1mm to 1mm. Still no luck though. It just won't extrude. I'm running 220 temp for PLA. Should be gushing I would think. 225 for the first layer. I have this now:

#define DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 6.3} // ( Was {100, 100, 100, 450} Makergeek said 94.1176 for x,y,z and 92.3 for e)

I don't know....

I cant find any info on the extruder included in the kit ...

The spec sheet says 22 tooth spur gear and OD of 12mm and an ID of 8mm If the ID is indeed 8 mm

then you should have (200*16) 3200 ( = micro steps per revolution)

8 (mm) * 3.142 = 25.136

3200 / 25.135 = 127.30 E steps

can you take a picture then we can go someway to getting you back on track

For example on my direct drive Nema 17 ( no gearbox) with MK8 drive bush my e -steps are 177.4

Edited 2 time(s). Last edit at 03/15/2015 04:42PM by bigfilsing.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 04:48PM |

Registered: 10 years ago Posts: 903 |

Quote

Dark Skunk

I just ordered the link below. Probably over priced but I don't know enough to do differently. I went with 3mm as the tube and presumably the extruder were designed for.

[www.ebay.com]

For what it's worth, the extruder above comes with a 14:1 geared stepper motor. It is NOT direct drive.

Stupid question - did you adjust the stepper driver current with a multimeter? Perhaps that stepper motor needs more current?????

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 09:01PM |

Registered: 9 years ago Posts: 67 |

This is what I'm looking at. It's a 5mm spindle on the motor (direct drive) with an 11mm OD. I'm struggling to understand why the ID is important but this is what I'm looking at.

Question: Jumpers. Are these jumpers below the stepper for the extruder or are they on the 'bottom' board prior to the secondary board? I remember putting jumpers on but don't remember where exactly. I'm going through the instructions again.

Multi-meter note: I don't know how to do that (ashamed, yes...). I have like 5 multi-meters but don't know why to set it on or where to put the leads (never had to check amps before I guess, i'm not a huge electronics guy although I'm coming around...).

Edited 1 time(s). Last edit at 03/15/2015 09:03PM by Dark Skunk.

Question: Jumpers. Are these jumpers below the stepper for the extruder or are they on the 'bottom' board prior to the secondary board? I remember putting jumpers on but don't remember where exactly. I'm going through the instructions again.

Multi-meter note: I don't know how to do that (ashamed, yes...). I have like 5 multi-meters but don't know why to set it on or where to put the leads (never had to check amps before I guess, i'm not a huge electronics guy although I'm coming around...).

Edited 1 time(s). Last edit at 03/15/2015 09:03PM by Dark Skunk.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 09:09PM |

Registered: 9 years ago Posts: 67 |

Ok, I think you are right about the micro-steps. I'm guessing I missed it when assembling. I pulled the extruder and X stepper off and the X stepper is probably what it's supposed to look like and the extruder I must have skipped. I'm popping those babies on now.

Pic of what I found:

Pic of what I found:

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 09:21PM |

Registered: 9 years ago Posts: 67 |

The jumpers worked. Now I'm running what the MakerGeek calibration stated and it looks money. Time to try printing again.

#define DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 92.3} // (Was {100, 100, 100, 450} Makergeek said 94.1176 for x,y,z and 92.3 for e)

UPDATE:

It started off looking good but then went dry. The motor i just not pushing the filament I think. Pic of the base that started really good (best yet) and then it stopped flowing. Then a small vid of the motor being stuck.

Not sure what that means.

Edited 1 time(s). Last edit at 03/15/2015 09:59PM by Dark Skunk.

#define DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 92.3} // (Was {100, 100, 100, 450} Makergeek said 94.1176 for x,y,z and 92.3 for e)

UPDATE:

It started off looking good but then went dry. The motor i just not pushing the filament I think. Pic of the base that started really good (best yet) and then it stopped flowing. Then a small vid of the motor being stuck.

Not sure what that means.

Edited 1 time(s). Last edit at 03/15/2015 09:59PM by Dark Skunk.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 15, 2015 11:35PM |

Registered: 11 years ago Posts: 469 |

Well at least some progress.

Ok the term ID is a bit deceptive on the makergeek spec. What it should refer to is the effective diameter when the spur gear bites into the filament. So if the OD of the teeth is +/- 11mm then we should be looking at +/- 10 for the ED effective diameter

So (200(steps) *16(microsteps)) / ( 10 * 3.142) = 101.84 E steps

From what we see in your photo of the spur gear being 10.97 mm i would set your esteps at 100 as a starting point then calibrate using the feed thru method i,e, when you tell it to feed 10mm measure how much it actually feeds ( measured where the filament go into the extruder)

Now you have the jumpers installed at least we know its micro stepping so anywhere between 90 & 100 E steps should work as a basic starting point.

Multimeter

Dont worry its not very difficult but you do have to be careful when measuring you don't touch anything you shouldn't and short it out on the board. The stepper drivers are easy to fry !!!!

What we want to know is the current going to the motor . The actual current going thru one of the stepper wires, would be tricky to read accurately as per definition its a series of steps (pulses). So most stepper drivers have a test point that will give you a voltage that corresponds to the current amps being sent to the board. We need to know which stepper drivers you have ( photo?) to advise on how to set up.

I suspect you have A 4988's but please check.

Have a read here >>[reprap.org]

Extruder issues

So im trying to understand whats happening. Things to check

you have youre slicer set up for 3mm filament ?? thats what diameter it look like in your pics.

you have a 3mm hotend ...correct ??

You have the correct nozzel diameter set up in your slicer ?

Did you build the hotend your self ?? Are you confident the thermisistor is working correctly? Have you checked the FW to see if its correct in config.h

Im just thinking that either the hotend is too cold or your feeding too much filament or theres a problem with the hotend.

From the video and pics i can see you can print something so the hotend is probably working. Check the settings mentioned above and report back

Good luck

Ok the term ID is a bit deceptive on the makergeek spec. What it should refer to is the effective diameter when the spur gear bites into the filament. So if the OD of the teeth is +/- 11mm then we should be looking at +/- 10 for the ED effective diameter

So (200(steps) *16(microsteps)) / ( 10 * 3.142) = 101.84 E steps

From what we see in your photo of the spur gear being 10.97 mm i would set your esteps at 100 as a starting point then calibrate using the feed thru method i,e, when you tell it to feed 10mm measure how much it actually feeds ( measured where the filament go into the extruder)

Now you have the jumpers installed at least we know its micro stepping so anywhere between 90 & 100 E steps should work as a basic starting point.

Multimeter

Dont worry its not very difficult but you do have to be careful when measuring you don't touch anything you shouldn't and short it out on the board. The stepper drivers are easy to fry !!!!

What we want to know is the current going to the motor . The actual current going thru one of the stepper wires, would be tricky to read accurately as per definition its a series of steps (pulses). So most stepper drivers have a test point that will give you a voltage that corresponds to the current amps being sent to the board. We need to know which stepper drivers you have ( photo?) to advise on how to set up.

I suspect you have A 4988's but please check.

Have a read here >>[reprap.org]

Extruder issues

So im trying to understand whats happening. Things to check

you have youre slicer set up for 3mm filament ?? thats what diameter it look like in your pics.

you have a 3mm hotend ...correct ??

You have the correct nozzel diameter set up in your slicer ?

Did you build the hotend your self ?? Are you confident the thermisistor is working correctly? Have you checked the FW to see if its correct in config.h

Im just thinking that either the hotend is too cold or your feeding too much filament or theres a problem with the hotend.

From the video and pics i can see you can print something so the hotend is probably working. Check the settings mentioned above and report back

Good luck

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 16, 2015 12:05AM |

Registered: 11 years ago Posts: 469 |

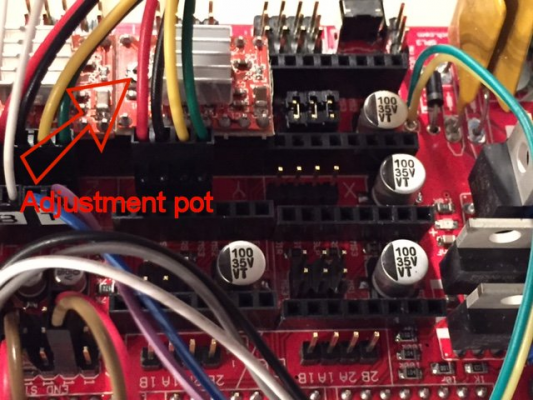

Just realised that in your pic of the missing jumpers we can see you stepper drivers

just in front of the heat sink theres an adjustment pot ( potentiometer) see attached pic

you can see its metalic with a cross in the middle. You should be reading 0.4 volts DC here to give 1 amp of current to the stepper.

With the black probe on GND put the red probe on the metalic cross and check the reading.

0.4 volts is the standard for the A4988 but there are variants ...read the wiki posted earlier

Edited 1 time(s). Last edit at 03/16/2015 06:36AM by bigfilsing.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 16, 2015 12:06AM |

Registered: 11 years ago Posts: 469 |

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 16, 2015 06:40PM |

Registered: 9 years ago Posts: 67 |

Couple things i have done:

1. I cannot 100% confirm that I have a 3mm JHEAD although, I did pull the top off and the filament fits through the whole and when the extruder is turning, material does come out. I'm guessing I'm good there. MakerGeek told me by email is should be 1.75mm BUT there website says 3mm. I don't think they know what they are talking about.

2. The Slic3r is set for 3mm. No multiplier.

3. The nozzle is 4mm.

4. I did not build the hot end. It is getting to temperature, I can confirm that.

5. I don't know what you mean by FW in the Config.h.

6. On the checking for 0.04 volts whenever I put the black lead to negative or ground and the hot lead on the pot, the motor would not turn. Once I took it off, it turned again.

7. I will get material flow WHEN the motor turns. I think the hot end is good.

UPDATE: I am fairly confident either the motor or the driver is the problem. The material flows pretty good from the hot end with the 3mm filament (220 deg). It works good until I hit one spot on the motor. Then the motor hesitates.

SO: I think I need to figure out the amp / volt measurement from stepper. That, IMO is the last step prior to saying the motor is blown. I ordered a new geared one either way.

BTW: Thank you all so much for the help. Forums are the greatest thing...

Edited 1 time(s). Last edit at 03/16/2015 06:44PM by Dark Skunk.

1. I cannot 100% confirm that I have a 3mm JHEAD although, I did pull the top off and the filament fits through the whole and when the extruder is turning, material does come out. I'm guessing I'm good there. MakerGeek told me by email is should be 1.75mm BUT there website says 3mm. I don't think they know what they are talking about.

2. The Slic3r is set for 3mm. No multiplier.

3. The nozzle is 4mm.

4. I did not build the hot end. It is getting to temperature, I can confirm that.

5. I don't know what you mean by FW in the Config.h.

6. On the checking for 0.04 volts whenever I put the black lead to negative or ground and the hot lead on the pot, the motor would not turn. Once I took it off, it turned again.

7. I will get material flow WHEN the motor turns. I think the hot end is good.

UPDATE: I am fairly confident either the motor or the driver is the problem. The material flows pretty good from the hot end with the 3mm filament (220 deg). It works good until I hit one spot on the motor. Then the motor hesitates.

SO: I think I need to figure out the amp / volt measurement from stepper. That, IMO is the last step prior to saying the motor is blown. I ordered a new geared one either way.

BTW: Thank you all so much for the help. Forums are the greatest thing...

Edited 1 time(s). Last edit at 03/16/2015 06:44PM by Dark Skunk.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 16, 2015 09:41PM |

Registered: 11 years ago Posts: 469 |

Ok for the time being we will assume the hot end is OK

FW is short for firmware and config.h is a file that is part of the firmware. Its the configuration file where you input the settings of your specific printer and upload them to your controller.

In previous posts you mention changing the E steps setting for the extruder . How have you been doing that ??

Stepper motors, unlike "normal" motors, draw current all the time. Thats how they maintain position even when not turning. They dont need to be turning in order to take a current reading on the stepper driver.

They dont draw more or less current depending on load . The coil(s) is energised with a set current according to its rating/ specification.

Thats why you have a larger motor for your extruder motor . Basically >Larger motor = larger coils = more current(amps) = more energy = more force = more rotational torque.

This is also why we need to adjust the stepper driver to suit the motor thats installed. If we dont give the stepper enough current it cant generate the torque to turn when under load.

When you say the motor turns but you can stop it with your fingers it sounds like its working but isnt getting enough current.

Ok back to calibration

DO you understand how to set your multimeter to read DC volts ?? Send a pic of the front of the multimeter and ill try to indicate which setting you need.

Step by step

1/Turn on your machines power supply. You DONT need to connect to your PC or even have to have USB connected or do anything else

2/ Set your multimeter to Volts DC ...on the range scale set it to something bigger than 12 volts

3/ Measure the incoming voltage to the Ramps board ...What is it ?

4/ Set the multi meter to a lower value on the DC volts range .....but more than 2 volts

5/ Keep the black lead on the negative incoming supply and touch the red probe on the metalic cross of the extruder stepper driver . What reading do you get

6/ Do the same for the X.Y & Z stepper drivers . What are the readings ?

Even when the new motor arrives you will need to calibrate it so its important you understand how to

Im still not sure you have a bad motor

With out any power applied to the system can you turn it completely in full rotations. You will feel steps but you should be able to turn it all the way through complete revolutions ??

Get back to me on the above readings and we can move to the next step

FW is short for firmware and config.h is a file that is part of the firmware. Its the configuration file where you input the settings of your specific printer and upload them to your controller.

In previous posts you mention changing the E steps setting for the extruder . How have you been doing that ??

Stepper motors, unlike "normal" motors, draw current all the time. Thats how they maintain position even when not turning. They dont need to be turning in order to take a current reading on the stepper driver.

They dont draw more or less current depending on load . The coil(s) is energised with a set current according to its rating/ specification.

Thats why you have a larger motor for your extruder motor . Basically >Larger motor = larger coils = more current(amps) = more energy = more force = more rotational torque.

This is also why we need to adjust the stepper driver to suit the motor thats installed. If we dont give the stepper enough current it cant generate the torque to turn when under load.

When you say the motor turns but you can stop it with your fingers it sounds like its working but isnt getting enough current.

Ok back to calibration

DO you understand how to set your multimeter to read DC volts ?? Send a pic of the front of the multimeter and ill try to indicate which setting you need.

Step by step

1/Turn on your machines power supply. You DONT need to connect to your PC or even have to have USB connected or do anything else

2/ Set your multimeter to Volts DC ...on the range scale set it to something bigger than 12 volts

3/ Measure the incoming voltage to the Ramps board ...What is it ?

4/ Set the multi meter to a lower value on the DC volts range .....but more than 2 volts

5/ Keep the black lead on the negative incoming supply and touch the red probe on the metalic cross of the extruder stepper driver . What reading do you get

6/ Do the same for the X.Y & Z stepper drivers . What are the readings ?

Even when the new motor arrives you will need to calibrate it so its important you understand how to

Im still not sure you have a bad motor

With out any power applied to the system can you turn it completely in full rotations. You will feel steps but you should be able to turn it all the way through complete revolutions ??

Get back to me on the above readings and we can move to the next step

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 17, 2015 05:40PM |

Registered: 9 years ago Posts: 67 |

Here is where I am at:

Answers:

1. FW E-Steps, I originally did not have my jumpers under the extruder driver. I do now so I changed the Ext to a normal number. Here is what I have which is matching input 1mm = 1mm

Status: Was - DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 6.3} but now it is - DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 92.3}

2. FW Homing feedrate. I did change the homing rate if that is relevant. It was a bit too violent originally.

Status: Was - HOMING_FEEDRATE {200*60, 200*60, 100*60, 0} but now HOMING_FEEDRATE {100*60, 100*60, 100*60, 0}

3. Volts: I get 12.6 volts across the input to the board.

4. Volts: The x, y, z steppers show 110mv. The extruder shows 11.9mv.

5. Amps: I show zero mA on x, y, z and 4mA on the extruder.

I'm pretty sure the measuring is correct. I was definitely in the right locations and my multi-meter has one location for volts and I think it adjusts as necessary (scale wise). I tried my analog multi-meter at 5 volts but got nothing discernable.

I think that covers the requested data.

Edited 1 time(s). Last edit at 03/17/2015 05:41PM by Dark Skunk.

Answers:

1. FW E-Steps, I originally did not have my jumpers under the extruder driver. I do now so I changed the Ext to a normal number. Here is what I have which is matching input 1mm = 1mm

Status: Was - DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 6.3} but now it is - DEFAULT_AXIS_STEPS_PER_UNIT {94.1, 94.1, 94.1, 92.3}

2. FW Homing feedrate. I did change the homing rate if that is relevant. It was a bit too violent originally.

Status: Was - HOMING_FEEDRATE {200*60, 200*60, 100*60, 0} but now HOMING_FEEDRATE {100*60, 100*60, 100*60, 0}

3. Volts: I get 12.6 volts across the input to the board.

4. Volts: The x, y, z steppers show 110mv. The extruder shows 11.9mv.

5. Amps: I show zero mA on x, y, z and 4mA on the extruder.

I'm pretty sure the measuring is correct. I was definitely in the right locations and my multi-meter has one location for volts and I think it adjusts as necessary (scale wise). I tried my analog multi-meter at 5 volts but got nothing discernable.

I think that covers the requested data.

Edited 1 time(s). Last edit at 03/17/2015 05:41PM by Dark Skunk.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 17, 2015 11:15PM |

Registered: 11 years ago Posts: 469 |

Hi

Point 4 ...are you sure its 11.9mV and not 119mV ??

Point 5...dont measure amps. There's no amps readings to be had and you stand a small chance of cooking things if your not careful.

The XYZ reading is good in as much as they are the same but lower than expected but then again you may have slightly different drivers and as noted on the wiki, some boards have different value shunt resistors and therefore

may give different readings

Applying ( for the moment) if it aint broke dont fix it i would leave the XYZ drivers as they are

Get back to me on the 11.9 or 119 thing

In the mean time, one thing you could do is swap the driver for the X axis with the Extruder driver That will at least confirm if the motor is faulty

Be sure to switch off the power of course and i always disconnect the USB as well to be safe when changing / swapping stepper drivers

Cheers

Point 4 ...are you sure its 11.9mV and not 119mV ??

Point 5...dont measure amps. There's no amps readings to be had and you stand a small chance of cooking things if your not careful.

The XYZ reading is good in as much as they are the same but lower than expected but then again you may have slightly different drivers and as noted on the wiki, some boards have different value shunt resistors and therefore

may give different readings

Applying ( for the moment) if it aint broke dont fix it i would leave the XYZ drivers as they are

Get back to me on the 11.9 or 119 thing

In the mean time, one thing you could do is swap the driver for the X axis with the Extruder driver That will at least confirm if the motor is faulty

Be sure to switch off the power of course and i always disconnect the USB as well to be safe when changing / swapping stepper drivers

Cheers

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 18, 2015 01:51PM |

Registered: 9 years ago Posts: 67 |

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 18, 2015 02:26PM |

Registered: 11 years ago Posts: 469 |

well if thats the case that explains the extruder stepper stallingQuote

Dark Skunk

It is 11.9, NOT 119. so much lower. I will swap the stepper driver tonight with one of the others. I just ordered a back up in case that's the issue.

Start by adjusting it to match the others .

What i suggest you do is either swap it out with one of the others to prove the point

or without any power switched on give it 1/8 or a turn clockwise then power on and re measure. Keep repeating the process till you reach 110 mV then see if you can still "stop" the stepper motor from rotating with your fingers

Good luck

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 18, 2015 08:39PM |

Registered: 9 years ago Posts: 67 |

This is what I found:

First I tried tweaking the pot up a bit per your note. The volts were going up but very very little with a quarter turn (1mv)

Next I swapped the E stepper driver with the X stepper. The X motor won't work now. That supports the stepper driver is not good.

BUT....The extruder motor, didn't change or if it did, not much. I can still stop it although it seems to take more force than I remember. The 3 'good' steppers are showing 0.6volts and the bad one is showing 7mv.

I did get my new geared extruder today. Looks pretty beefy. I think I will wait until friday when my stepper driver gets in though. I would like to run this setup with the new driver first and then if necessary move to new extruder.

Question: If I try to hit extrude without doing G28, one of the tower motors will move. Once I home it, then the extruder motor will work. Is that odd? Can't say this hasn't been a challenge...

First I tried tweaking the pot up a bit per your note. The volts were going up but very very little with a quarter turn (1mv)

Next I swapped the E stepper driver with the X stepper. The X motor won't work now. That supports the stepper driver is not good.

BUT....The extruder motor, didn't change or if it did, not much. I can still stop it although it seems to take more force than I remember. The 3 'good' steppers are showing 0.6volts and the bad one is showing 7mv.

I did get my new geared extruder today. Looks pretty beefy. I think I will wait until friday when my stepper driver gets in though. I would like to run this setup with the new driver first and then if necessary move to new extruder.

Question: If I try to hit extrude without doing G28, one of the tower motors will move. Once I home it, then the extruder motor will work. Is that odd? Can't say this hasn't been a challenge...

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 18, 2015 10:46PM |

Registered: 11 years ago Posts: 469 |

Hi

It does indeed seem that the stepper driver isnt working . Im surprised the extruder stepper didnt work on the X channel though . That's a bit of a worry.

I guess we will have to wait till the new stepper driver arrives to make any conclusions.

It might be worth trying the driver and stepper motor on the E1 channel instead of E0, just to see if there's any difference.

Your G28 /Extrude issue is a bit odd. Having said that, until the all axis have been homed i get some weird things occasionally as well.

While waiting for the new driver to arrive you could investigate the "weak" extruder stepper motor further. Disconnect it and measure the resistance on both coils

You should be able to look up on the net what it should be according to its spec sheet.

CHeers

It does indeed seem that the stepper driver isnt working . Im surprised the extruder stepper didnt work on the X channel though . That's a bit of a worry.

I guess we will have to wait till the new stepper driver arrives to make any conclusions.

It might be worth trying the driver and stepper motor on the E1 channel instead of E0, just to see if there's any difference.

Your G28 /Extrude issue is a bit odd. Having said that, until the all axis have been homed i get some weird things occasionally as well.

While waiting for the new driver to arrive you could investigate the "weak" extruder stepper motor further. Disconnect it and measure the resistance on both coils

You should be able to look up on the net what it should be according to its spec sheet.

CHeers

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 20, 2015 07:57PM |

Registered: 9 years ago Posts: 67 |

I blew it. Literally. I put the new stepper on but I had two of the prongs handing off the end of the slot (so 1 slot off). Whole board is cooked.

I'm showing .3v on the new stepper at the extruder and the other steppers show .5v. Display is blank, I cannot connect with Pronterface and I can't upload with Ardruino.

Do I need to buy both the primary board and the secondary board? Probably. Sucks. So much for my weekend plan.

I'm showing .3v on the new stepper at the extruder and the other steppers show .5v. Display is blank, I cannot connect with Pronterface and I can't upload with Ardruino.

Do I need to buy both the primary board and the secondary board? Probably. Sucks. So much for my weekend plan.

|

Re: Kossel Extruder Motor: I presume it's blown? Best Alternative? March 21, 2015 01:23AM |

Registered: 11 years ago Posts: 469 |

thats not good

anyway

if youre lucky the automatic fuses saved the board . Its unlikely thou as they seem to work when they feel like it rather than when its needed

Separate the 2 PCBs and try the arduino mega on its own. See if you can connect to pronterface or upload a simple sketch. You may have blown the voltage regulator on the mega

which can be fixed but its a tricky job

maybe take a look at . [www.youtube.com]

anyway

if youre lucky the automatic fuses saved the board . Its unlikely thou as they seem to work when they feel like it rather than when its needed

Separate the 2 PCBs and try the arduino mega on its own. See if you can connect to pronterface or upload a simple sketch. You may have blown the voltage regulator on the mega

which can be fixed but its a tricky job

maybe take a look at . [www.youtube.com]

Sorry, only registered users may post in this forum.