Delta bed high and low spots - Need help

Posted by Mils24

|

Delta bed high and low spots - Need help April 03, 2015 04:25PM |

Registered: 9 years ago Posts: 54 |

Hi Guys

I have been having A LOT of first layer problems with my delta printer (Kickstarter kit)

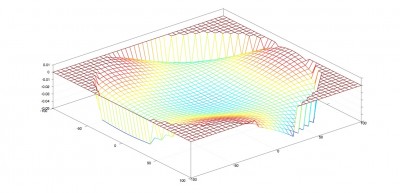

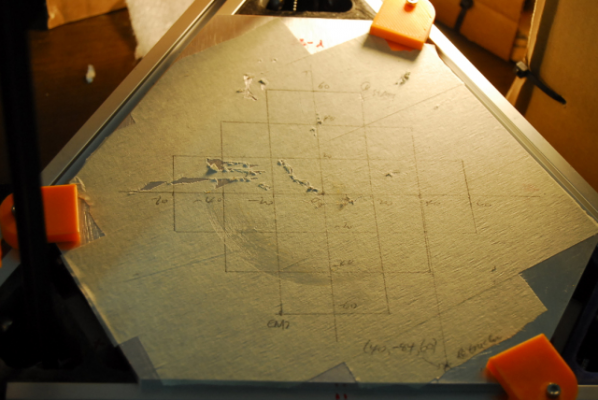

I have calibrated and re calibrated using Repetier host and the manual 'paper calibration' and still the first layer is showing high and low spots. Generally it is high in front of each tower and low between them. (See embedded pic for best description of this effect)

I have researched online and read many forums posts showing various problems and solutions such as rod length, horizontal offset and end effector offsets not being correct. I have checked and tweaked these values on my own machine with no luck!

If any of you guys out there can help me at all I would be greatly appreciative!!

A little info on the machine:

Kickstarter project - Deltatrix

Wooden frame construction with Igus dry linear rails for sliders.

280mm carbon rods with rod end bearings

275mm dia printable bed

Arduino DUE wid RADDS shield

20tooth pullys with GT2 belts

32bit microstepping with 0.9deg nema 17 steppers

Repetier 0.92 firmware

If there is any further info I can give you to help me solve this issue I will, please ask.

Many thanks in advance for any help you can give!

I have been having A LOT of first layer problems with my delta printer (Kickstarter kit)

I have calibrated and re calibrated using Repetier host and the manual 'paper calibration' and still the first layer is showing high and low spots. Generally it is high in front of each tower and low between them. (See embedded pic for best description of this effect)

I have researched online and read many forums posts showing various problems and solutions such as rod length, horizontal offset and end effector offsets not being correct. I have checked and tweaked these values on my own machine with no luck!

If any of you guys out there can help me at all I would be greatly appreciative!!

A little info on the machine:

Kickstarter project - Deltatrix

Wooden frame construction with Igus dry linear rails for sliders.

280mm carbon rods with rod end bearings

275mm dia printable bed

Arduino DUE wid RADDS shield

20tooth pullys with GT2 belts

32bit microstepping with 0.9deg nema 17 steppers

Repetier 0.92 firmware

If there is any further info I can give you to help me solve this issue I will, please ask.

Many thanks in advance for any help you can give!

|

Re: Delta bed high and low spots - Need help April 03, 2015 05:31PM |

Registered: 10 years ago Posts: 14,672 |

Your configured diagonal rod length needs adjusting. More precisely, the product of diagonal rod length and axis steps/mm needs adjusting. This is something I discovered when I implemented single iteration 7-factor delta calibration in the firmware for Duet electronics, as I describe in another thread. When I adjusted only the endstops and the tower positions, I ended up with exactly the effect you describe, only inverted.

Edited 1 time(s). Last edit at 04/03/2015 05:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/03/2015 05:32PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta bed high and low spots - Need help April 03, 2015 05:46PM |

Registered: 9 years ago Posts: 54 |

|

Re: Delta bed high and low spots - Need help April 03, 2015 05:55PM |

Registered: 10 years ago Posts: 14,672 |

The other thread is here [forums.reprap.org], however it's an automatic process using a mathematically accurate technique that AFAIK nobody else has implemented. So it's not going to help you much because you are using different electronics and firmware. If you are using Marlin firmware, then you could try Rich Cattel's fork, which has a mode in which it adjusts the diagonal rod length as well as other things.

Edited 1 time(s). Last edit at 04/03/2015 05:56PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 04/03/2015 05:56PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta bed high and low spots - Need help April 03, 2015 07:26PM |

Registered: 9 years ago Posts: 54 |

|

Re: Delta bed high and low spots - Need help April 03, 2015 07:42PM |

Registered: 10 years ago Posts: 903 |

Quote

Mils24

When you say that the diagonal rod length is incorrect surely this has to be the exact length of the rods and therefor cannot change? or can you alter this value to trick the software and force it to print flat?

One thing that I've discovered over the past year after calibrating several revisions to my own design is that 3D printers cannot read rulers. Try shortening the rod length by 2mm in the firmware and see if it looks any better/worse. Unfortunately, it is a trial-and-error process.....

Edited 1 time(s). Last edit at 04/03/2015 07:42PM by vreihen.

|

Re: Delta bed high and low spots - Need help April 03, 2015 07:46PM |

Registered: 9 years ago Posts: 54 |

|

Re: Delta bed high and low spots - Need help April 03, 2015 07:58PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Mils24

When you say that the diagonal rod length is incorrect surely this has to be the exact length of the rods and therefor cannot change? or can you alter this value to trick the software and force it to print flat?

Ive measured my rods and the firmware value is correct.

Thanks

I used to think that too, but as I said before, it turns out that it's actually the product of diagonal rod length and motor steps/mm that matters. If the belts are very slightly out of tolerance or slightly stretched because of the tension in them, and you don't correct for it by changing the steps/mm setting, then you need to change the diagonal rod length to compensate, in order to avoid the effect you observed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta bed high and low spots - Need help April 03, 2015 08:57PM |

Registered: 10 years ago Posts: 732 |

The type of error you have looks like wrong diagonal rod and delta radius at the same time. These two errors can partially compensate each other (but not completely). Because the compensation is not complete you get the type of error you see. Also notice that wrong steps per mm behaves similarly as both wrong diagonal rod and delta radius. So, as dc42 indicated, you get it when steps per mm is wrong too (and you can include wrong diagonal rod in it as well  ).

).

If you have a precise enough method to measure your diagonal rods then use that number. Do not try to use obviously fake values for diagonal rod length in firmware configuration values. You would be only hiding (partially compensating) other kind of calibration errors. Many people can get away with it because errors can often partially compensate each other and one will not notice them especially if their diagonal rods are significantly longer than 2 * deltaRadius so your arms never get to almost horizontal position. (The errors get better visible when you can reach positions when one pair of arms is almost horizontal.)

).

).If you have a precise enough method to measure your diagonal rods then use that number. Do not try to use obviously fake values for diagonal rod length in firmware configuration values. You would be only hiding (partially compensating) other kind of calibration errors. Many people can get away with it because errors can often partially compensate each other and one will not notice them especially if their diagonal rods are significantly longer than 2 * deltaRadius so your arms never get to almost horizontal position. (The errors get better visible when you can reach positions when one pair of arms is almost horizontal.)

|

Re: Delta bed high and low spots - Need help April 04, 2015 07:23AM |

Registered: 9 years ago Posts: 54 |

Thanks dc42 and hercek

I have looked this morning at the various things you mentioned.

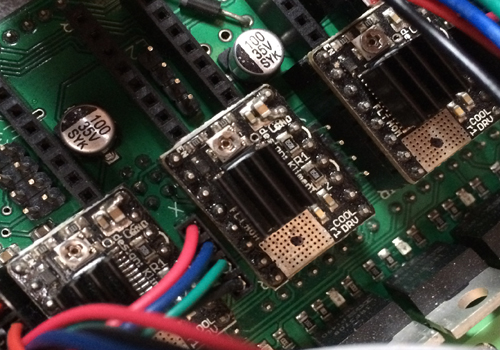

My printer has 20 teeth pulleys, GT2 belts with 2mm pitch, Wantai Stepper Motor (model 42BYGHM809) 0.9deg and a DRV8825 Kliment version Pololu driver set to 1/32 bit stepping according to the Kickstarter creator.

I get this to give a STEPS_PER_MM value of 320steps/mm

(400 * 32) / (2 * 20) = 320.0

I have also over the past week 3D modelled my printer using available CAD files from the KS creator via Instrucables (I had to modify some of them as they were early models). This I thought would allow me to get accurate measurements for the 'hard to measure' parts such as, END_EFFECTOR_HORIZONTAL_OFFSET (55mm) , CARRIAGE_HORIZONTAL_OFFSET (18.3mm) , PRINTER_RADIUS (213.5mm) + DELTA_HORIZONTAL_ROD_RADIUS (140.2mm)

My rod length is 280mm according to the KS creator and unfortunately I do not have a calliper big enough to accurately measure this but laying it on an engineering steel rule which shows half mm markings they look to be closer to 280.2

I have calibrated the printer using the 4 point paper calibration using these values and had to raise the DELTA_HORIZONTAL_ROD_RADIUS value to around 143 (cant remember exactly) to eliminate the convex movement across the bed.

(I also re-calibrated again changing the DELTA_DIAGONAL_ROD value to 280.2)

With all this I still get the high and low movement as it passes around the circular bed (bed is attached at 6 points) as seen in the original post.

(NOTE - the picture in the original post is one I found online to depict the problem I have, it is NOT a picture I made from my machine therefore the scale down the left of the image is not a true deviation of my printer)

If ANY of you have any further information I would be very thankful!!

Cheers

I have looked this morning at the various things you mentioned.

My printer has 20 teeth pulleys, GT2 belts with 2mm pitch, Wantai Stepper Motor (model 42BYGHM809) 0.9deg and a DRV8825 Kliment version Pololu driver set to 1/32 bit stepping according to the Kickstarter creator.

I get this to give a STEPS_PER_MM value of 320steps/mm

(400 * 32) / (2 * 20) = 320.0

I have also over the past week 3D modelled my printer using available CAD files from the KS creator via Instrucables (I had to modify some of them as they were early models). This I thought would allow me to get accurate measurements for the 'hard to measure' parts such as, END_EFFECTOR_HORIZONTAL_OFFSET (55mm) , CARRIAGE_HORIZONTAL_OFFSET (18.3mm) , PRINTER_RADIUS (213.5mm) + DELTA_HORIZONTAL_ROD_RADIUS (140.2mm)

My rod length is 280mm according to the KS creator and unfortunately I do not have a calliper big enough to accurately measure this but laying it on an engineering steel rule which shows half mm markings they look to be closer to 280.2

I have calibrated the printer using the 4 point paper calibration using these values and had to raise the DELTA_HORIZONTAL_ROD_RADIUS value to around 143 (cant remember exactly) to eliminate the convex movement across the bed.

(I also re-calibrated again changing the DELTA_DIAGONAL_ROD value to 280.2)

With all this I still get the high and low movement as it passes around the circular bed (bed is attached at 6 points) as seen in the original post.

(NOTE - the picture in the original post is one I found online to depict the problem I have, it is NOT a picture I made from my machine therefore the scale down the left of the image is not a true deviation of my printer)

If ANY of you have any further information I would be very thankful!!

Cheers

|

Re: Delta bed high and low spots - Need help April 04, 2015 09:05AM |

Registered: 10 years ago Posts: 903 |

Mark your carriage locations on the three extrusions when homed. Z down 100mm. Measure the difference. If it isn't 100.00mm, adjust the steps/mm until it is. Once this is set, you will never need to change it again. Then, start with trying different rod lengths in the firmware to find what works. When everything looks flat, the last thing that I do is put the nozzle at 0,0,0 - mark the spot, and then move Y+100mm. (Important to use Y!) If the nozzle doesn't move 100.00mm, start over again with the rod length in firmware and repeat the whole process.....

|

Re: Delta bed high and low spots - Need help April 04, 2015 10:56AM |

Registered: 10 years ago Posts: 14,672 |

I know the belt is supposed to have exactly 2mm pitch, but in practice there will be a tolerance on it, and it will vary a little with temperature and tension in the belt. When I run 7-factor autocalibration on my Mini Kossel, it increases the delta diagonal rod length by 2.458mm (a little over 1%), and I believe this is because the steps/mm of my belts is about 1% lower than the nominal value. So I suggest you check that the tension in the belts is as you want it, then follow vreihen's advice.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta bed high and low spots - Need help April 04, 2015 07:54PM |

Registered: 10 years ago Posts: 732 |

I use T2.5 belts with steel core and I never noticed that they would change their length.

dc42, do you use GT2 belts with glass fibre core? (Glass fibre is significantly more elastic than steel.)

The method I published requires 8 points to converge properly. At least that was an observation found by Dejay Rezme. He implemented a simulator of incorrectly calibrated linear delta printers and tested the method with various printer sizes and calibration errors. His conclusion was that at least 8 probe points are needed to make sure the method always converges to the proper solution. It is a bit counter intuitive since only 7 parameters are optimized. I did not try to find out why it is so.

dc42, do you use GT2 belts with glass fibre core? (Glass fibre is significantly more elastic than steel.)

The method I published requires 8 points to converge properly. At least that was an observation found by Dejay Rezme. He implemented a simulator of incorrectly calibrated linear delta printers and tested the method with various printer sizes and calibration errors. His conclusion was that at least 8 probe points are needed to make sure the method always converges to the proper solution. It is a bit counter intuitive since only 7 parameters are optimized. I did not try to find out why it is so.

|

Re: Delta bed high and low spots - Need help April 05, 2015 05:22PM |

Registered: 9 years ago Posts: 54 |

Thanks for all your help guys

I have done what you said vreihen and my STEPS_PER_MM value is fine. I marked all 3 carriages and moved the effector down by 100mm using Repetier host. Re marked and measured and they all moved exactly 100mm. I also moved the nozzle to 0,0,0 and marked it. Then moved Y +100mm and re marked. Measured and it was exactly 100mm too.

One thing that has changed however is the location of the high and low spots. Today I was taking some measurements of the frame and towers etc to check they were ok. To make this easier I took off the rods and the effector. While I had the rods off I decided to add a little oil to them. When I put them back on again and continued to work at the calibration, on my first test print (200mm dia Circle) I noticed that it is now high from tower Z to approx. tower X and then it is low for the rest of the perimeter. So now it is only high at roughly 1/3 of the circumference of a 200mm circle and low on the other 2/3's.

Saying that this high and low movement has changed when my rods were taken on and off, could this mean my rods are bad? I have measured them the other day and they are all the same length however.

Thanks

I have done what you said vreihen and my STEPS_PER_MM value is fine. I marked all 3 carriages and moved the effector down by 100mm using Repetier host. Re marked and measured and they all moved exactly 100mm. I also moved the nozzle to 0,0,0 and marked it. Then moved Y +100mm and re marked. Measured and it was exactly 100mm too.

One thing that has changed however is the location of the high and low spots. Today I was taking some measurements of the frame and towers etc to check they were ok. To make this easier I took off the rods and the effector. While I had the rods off I decided to add a little oil to them. When I put them back on again and continued to work at the calibration, on my first test print (200mm dia Circle) I noticed that it is now high from tower Z to approx. tower X and then it is low for the rest of the perimeter. So now it is only high at roughly 1/3 of the circumference of a 200mm circle and low on the other 2/3's.

Saying that this high and low movement has changed when my rods were taken on and off, could this mean my rods are bad? I have measured them the other day and they are all the same length however.

Thanks

|

Re: Delta bed high and low spots - Need help April 05, 2015 05:53PM |

Registered: 10 years ago Posts: 14,672 |

The rods only need to differ in length by about 0.1mm for the printer to need recalibrating if you swap them around. Are you sure they are the same length to that precision?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Delta bed high and low spots - Need help April 05, 2015 06:48PM |

Registered: 10 years ago Posts: 732 |

How did you measure the rods?Quote

Mils24

Saying that this high and low movement has changed when my rods were taken on and off, could this mean my rods are bad? I have measured them the other day and they are all the same length however.

When you built the rods you should have done it based on a jig. All the rods must fit the jig tightly with about the same force. Then to measure the rod, do it when it is the jig and use callipers. If your callipers are short then drive a nail into the middle of your jig and measure two distances (both from rod ends to the nail). Compute the right length of the rods from the two numbers.

Looks like you must have rods of unequal size or platform (the part to which hotend is mounted) is distorted. I assume you did not mess with towers and carriages. Or soma bad play at rod end mount points. Otherwise your error shape could not change.

|

Re: Delta bed high and low spots - Need help April 06, 2015 12:02PM |

Registered: 9 years ago Posts: 54 |

dc42 and hercek

I did not make these rods, it was a kickstarter kit I backed and received.

I have checked the rods again just now using your idea hercek about mounting them on a piece of wood and using a middle nail to get overall length as my callipers only measure 150mm max.

I have now found that my rods are 280.3 instead of 280 but more importantly 1 of them is shorter than the rest by about 0.3 / 0.4mm!

Is one bad rod enough to cause such a large deviation across the bed or is there more issues potentially still uncovered?

Thanks

I did not make these rods, it was a kickstarter kit I backed and received.

I have checked the rods again just now using your idea hercek about mounting them on a piece of wood and using a middle nail to get overall length as my callipers only measure 150mm max.

I have now found that my rods are 280.3 instead of 280 but more importantly 1 of them is shorter than the rest by about 0.3 / 0.4mm!

Is one bad rod enough to cause such a large deviation across the bed or is there more issues potentially still uncovered?

Thanks

|

Re: Delta bed high and low spots - Need help April 06, 2015 12:12PM |

Registered: 9 years ago Posts: 54 |

Also just to mention, I swapped all the rods around before measuring them. Tower Z -> Tower X ->, Tower X -> Tower Y + Tower Y -> Tower Z etc and re checked the test print (200mm dia circle)

The movement did not change and it was still high at one side and low at the other.

I swapped the rods around several times and also rotated the rods 180deg (end at carriage -> end at platform/effector and vice versa) and still no different in movement issues.

Surely if the one short rod was causing the problem as I moved the rods between the towers the movement error would of changed too?

Thanks

The movement did not change and it was still high at one side and low at the other.

I swapped the rods around several times and also rotated the rods 180deg (end at carriage -> end at platform/effector and vice versa) and still no different in movement issues.

Surely if the one short rod was causing the problem as I moved the rods between the towers the movement error would of changed too?

Thanks

|

Re: Delta bed high and low spots - Need help April 06, 2015 04:01PM |

Registered: 10 years ago Posts: 732 |

Ok, so one rod is about 0.35 mm different from the others. My guess is that it should cause at most about the same error in z-height (i.e. about 0.35 mm). The error will be different on different locations of the bed. Anyway z-height wrong by 0.35 mm will result in your first layer not sticking on the places where the head is too high. This wrong rod will also lead to rotations of the platform/hotend. These will cause XY error and it can be more than 0.35 mm depending how much longer your hotend goes below platform compared to the diagonal rod distance. Again depends also on the XY position.

Since the nature of the error changed when you modified the printer the first time and the diagonal rod error looks to me like not that big, my guess is you changed also something else or the original picture of the Z-height error did not correspond to your z-error.

In general based on the error description in your message from April 05, 2015 10:22PM:

Edit: If you have a zprobe and can use dc42's firmware then do it. It should make your problem much easier to fix. If you cannot use dc42's firmware (e.g. because you do not have ARM controller) and are good at math and have a zprobe then you can try this too: [github.com]

Edited 1 time(s). Last edit at 04/06/2015 04:06PM by hercek.

Since the nature of the error changed when you modified the printer the first time and the diagonal rod error looks to me like not that big, my guess is you changed also something else or the original picture of the Z-height error did not correspond to your z-error.

In general based on the error description in your message from April 05, 2015 10:22PM:

- get the wrong rod fixed (you can try continuing without it, and my guess is that it will not matter that much if you care only about z-height)

- set diagonal rod to the properly measured rod length (280.3)

- you need to adjust delta radius so that the height in the centre is the same as at the 2/3 of the perimeter

- you should finish correctly everywhere except the position against the tower Y (i.e. between Z and X); at that position you will be high; try to move position of tower X diagonally (i.e. nearer/further from the centre) to fix that

Edit: If you have a zprobe and can use dc42's firmware then do it. It should make your problem much easier to fix. If you cannot use dc42's firmware (e.g. because you do not have ARM controller) and are good at math and have a zprobe then you can try this too: [github.com]

Edited 1 time(s). Last edit at 04/06/2015 04:06PM by hercek.

|

Re: Delta bed high and low spots - Need help April 06, 2015 06:51PM |

Registered: 9 years ago Posts: 54 |

Quote

hercek

Ok, so one rod is about 0.35 mm different from the others. My guess is that it should cause at most about the same error in z-height (i.e. about 0.35 mm). The error will be different on different locations of the bed. Anyway z-height wrong by 0.35 mm will result in your first layer not sticking on the places where the head is too high. This wrong rod will also lead to rotations of the platform/hotend. These will cause XY error and it can be more than 0.35 mm depending how much longer your hotend goes below platform compared to the diagonal rod distance. Again depends also on the XY position.

Since the nature of the error changed when you modified the printer the first time and the diagonal rod error looks to me like not that big, my guess is you changed also something else or the original picture of the Z-height error did not correspond to your z-error.

In general based on the error description in your message from April 05, 2015 10:22PM:Good luck. Based on the description you provided, your position of tower X is not precise. It may be also tilted, which would be worse situation since I do not know a firmware which can fix tilted towers.

- get the wrong rod fixed (you can try continuing without it, and my guess is that it will not matter that much if you care only about z-height)

- set diagonal rod to the properly measured rod length (280.3)

- you need to adjust delta radius so that the height in the centre is the same as at the 2/3 of the perimeter

- you should finish correctly everywhere except the position against the tower Y (i.e. between Z and X); at that position you will be high; try to move position of tower X diagonally (i.e. nearer/further from the centre) to fix that

Edit: If you have a zprobe and can use dc42's firmware then do it. It should make your problem much easier to fix. If you cannot use dc42's firmware (e.g. because you do not have ARM controller) and are good at math and have a zprobe then you can try this too: [github.com]

Thanks Hercek

However Im not too sure what you mean with your last point?

Also when you say to adjust the DELTA_RADIUS to get the centre the same as the other points I have already done that. I can get all 4 points to be perfect with regards the paper calibration but its when I try and actually print it starts to lift on the Z axis.

As well today I used a 6" set square to check the squareness of the frame and all is ok so I dont think it is tilted. I have also previously measured the gap between the towers, both top and bottom and all is ok.

With regards the dc42 firmware for z probing. I have a few microswitches and the end effector loom has a connector to add a Z probe but I need to design a mechanism to hold it on the end effector. I was hoping to get the printer to print flatter first but it is now looking like this may be my best solution to fixing this problem. I do not have a clue about where to start with the dc42 firmware. Is there an instruction file anywhere or an easy to follow forum thread?

I am currently running Repetier 0.92. Does dc42's run alongside or do I need to totally change what I have installed?

Thanks again for all the help to date. I REALLY appreciate it guys!!

|

Re: Delta bed high and low spots - Need help April 06, 2015 07:09PM |

Registered: 10 years ago Posts: 732 |

In repetier, it is trying some small non-zero values for DELTA_RADIUS_CORRECTION_B.Quote

Mils24

However Im not too sure what you mean with your last point?

This indicates you may have some unwanted play in the joints or between belt and pulleys on steppers. Make sure you have no unwanted play there. Make sure your belts are tight. If the machine is solid then there should not be difference between paper measurements and actual printing. If you used paper method while hotend and bed are cold the only difference can by in total z-height (since bed/hotend expand a bit when heated).Quote

Also when you say to adjust the DELTA_RADIUS to get the centre the same as the other points I have already done that. I can get all 4 points to be perfect with regards the paper calibration but its when I try and actually print it starts to lift on the Z axis.

|

Re: Delta bed high and low spots - Need help April 07, 2015 10:14AM |

Registered: 9 years ago Posts: 189 |

@Mils24

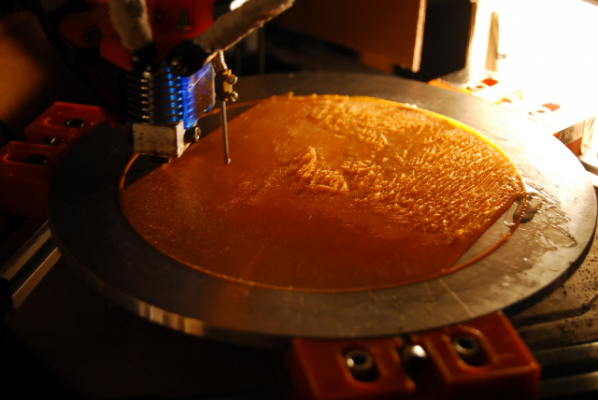

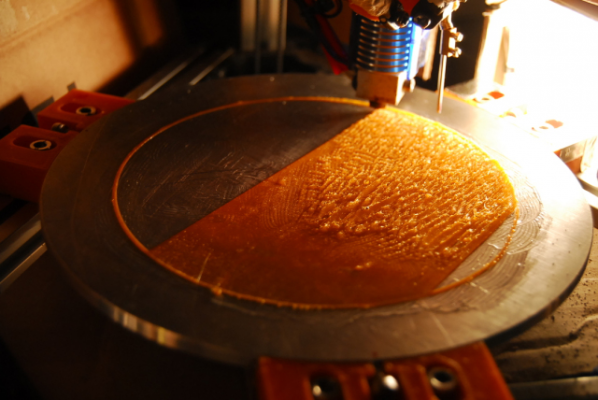

I'm pretty sure improvised diagonal rods of my Mini Kossel causes uneven print level when it prints large object.

The plate's diameter is around 130.00 mm.

First printing

Second printing

I learned that the length variation of six diagonal rods should less than hundred micron (0.1 mm) to use auto calibration effectively.

Few weeks ago the nozzle grinds the print bed while printing. So I had patched up the joint of six diagonal rods.

Edited 2 time(s). Last edit at 04/07/2015 10:20AM by janpenguin.

I'm pretty sure improvised diagonal rods of my Mini Kossel causes uneven print level when it prints large object.

The plate's diameter is around 130.00 mm.

First printing

Second printing

I learned that the length variation of six diagonal rods should less than hundred micron (0.1 mm) to use auto calibration effectively.

Few weeks ago the nozzle grinds the print bed while printing. So I had patched up the joint of six diagonal rods.

Edited 2 time(s). Last edit at 04/07/2015 10:20AM by janpenguin.

|

Re: Delta bed high and low spots - Need help April 07, 2015 11:01AM |

Registered: 9 years ago Posts: 54 |

|

Re: Delta bed high and low spots - Need help February 26, 2018 02:25PM |

Registered: 6 years ago Posts: 4 |

Hello Mils24,

I have been reading this forum and it seems like you had the exact same problem I am currently having. However I do not have an auto levelling system on my printer.

How did you manage to fix the problem in the end? I haven't measured my rods yet but is there a way to fix this without having to buy new rods?

Thanks

I have been reading this forum and it seems like you had the exact same problem I am currently having. However I do not have an auto levelling system on my printer.

How did you manage to fix the problem in the end? I haven't measured my rods yet but is there a way to fix this without having to buy new rods?

Thanks

Sorry, only registered users may post in this forum.