Cherry Pi ball sockets: corner cubes?

Posted by dc42

|

Cherry Pi ball sockets: corner cubes? May 25, 2015 04:30AM |

Registered: 10 years ago Posts: 14,672 |

At least two people have had problems using my differential IR probe on the Cherry Pi. The reason in both cases was that the effector is not staying in the same plane (i.e. parallel to the bed) as it translates. Since the IR sensor has to be offset from the nozzle a little, any tilt of the effector changes the relative heights of the sensor and the nozzle, leading to height errors.

Using the nozzle itself as the probe (e.g. with FSRs or with Andy's effector with integrated Z probe) avoids this particular issue; but if the effector is tilting then that is going to make it impossible to get a flat printing plane anyway. So the issue needs to be addressed.

I took a look at the Cherry Pi files on Thingyverse, and I see that it has printed spherical sockets to accept the balls. I can't see how you can ever get enough print accuracy to get the balls to be a good fit in the sockets with no slop - and to get the sockets in each pair exactly the same depth. I have seen the suggestion to use a ball-end mill, and I guess that might work if the mill is exactly the right size for the balls and the holes are milled very precisely - but that is likely to be difficult to achieve.

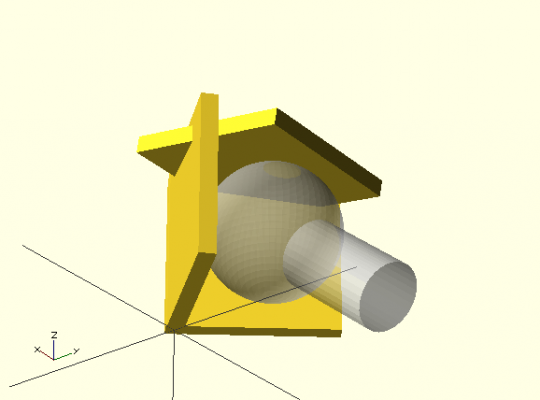

Has anyone tried a corner cube (i.e. 3 planes intersecting at right angles) for the socket, instead of spherical sockets? The corner cube would need to be oriented such that the ball is held in positive contact with all 3 planes at all normal angles of the rods. I'm thinking of one plane inclined at perhaps 5 degrees to the horizontal, falling towards the centre axis of the machine. This would allow for the rods being vertical or nearly so when the effector is close to a tower, with the rod angle falling to 10 degrees from the horizontal when the effector is opposite a tower. Then two more planes at right angles to that and below it on the carriages, above it on the effector.

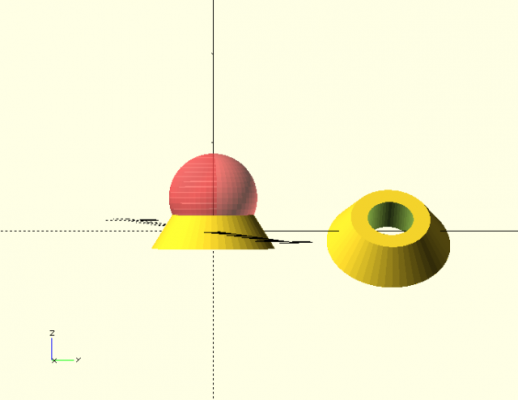

It's possible to have the planes intersect at angles sharper than 90 degrees, if 90 degrees doesn't provide enough movement range while retaining positive contact with all 3 planes. For example, imagine two planes intersecting at about 80 degrees in a vertical line. Then put the third plane across the top, angled at about 10 degrees to the horizontal. Like this:

I guess another way of improving the sockets would be to use a CNC machine and a ball-end mill (exactly the same size as the balls) to mill the sockets in a block of PTFE, which is then screwed to the effector or the carriage. But that makes it less of a DIY design.

Edited 1 time(s). Last edit at 05/25/2015 07:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Using the nozzle itself as the probe (e.g. with FSRs or with Andy's effector with integrated Z probe) avoids this particular issue; but if the effector is tilting then that is going to make it impossible to get a flat printing plane anyway. So the issue needs to be addressed.

I took a look at the Cherry Pi files on Thingyverse, and I see that it has printed spherical sockets to accept the balls. I can't see how you can ever get enough print accuracy to get the balls to be a good fit in the sockets with no slop - and to get the sockets in each pair exactly the same depth. I have seen the suggestion to use a ball-end mill, and I guess that might work if the mill is exactly the right size for the balls and the holes are milled very precisely - but that is likely to be difficult to achieve.

Has anyone tried a corner cube (i.e. 3 planes intersecting at right angles) for the socket, instead of spherical sockets? The corner cube would need to be oriented such that the ball is held in positive contact with all 3 planes at all normal angles of the rods. I'm thinking of one plane inclined at perhaps 5 degrees to the horizontal, falling towards the centre axis of the machine. This would allow for the rods being vertical or nearly so when the effector is close to a tower, with the rod angle falling to 10 degrees from the horizontal when the effector is opposite a tower. Then two more planes at right angles to that and below it on the carriages, above it on the effector.

It's possible to have the planes intersect at angles sharper than 90 degrees, if 90 degrees doesn't provide enough movement range while retaining positive contact with all 3 planes. For example, imagine two planes intersecting at about 80 degrees in a vertical line. Then put the third plane across the top, angled at about 10 degrees to the horizontal. Like this:

I guess another way of improving the sockets would be to use a CNC machine and a ball-end mill (exactly the same size as the balls) to mill the sockets in a block of PTFE, which is then screwed to the effector or the carriage. But that makes it less of a DIY design.

Edited 1 time(s). Last edit at 05/25/2015 07:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 06:54AM |

Registered: 10 years ago Posts: 903 |

My only concern with using three planes in a printed socket is wear.

For kicks and giggles, I just looked up the cost of PTFE and graphite sheets to see if it was practical to CNC an entire replacement effector plate and carriages. Unless someone can find a kitchen cutting board or some other domestic product that uses one of these materials to use as raw stock, the material probably costs more than the machining labor.....

For kicks and giggles, I just looked up the cost of PTFE and graphite sheets to see if it was practical to CNC an entire replacement effector plate and carriages. Unless someone can find a kitchen cutting board or some other domestic product that uses one of these materials to use as raw stock, the material probably costs more than the machining labor.....

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 07:10AM |

Registered: 9 years ago Posts: 189 |

@dc42

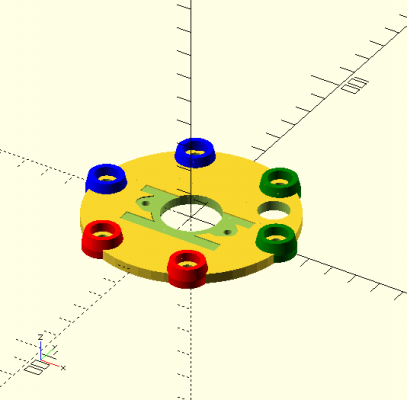

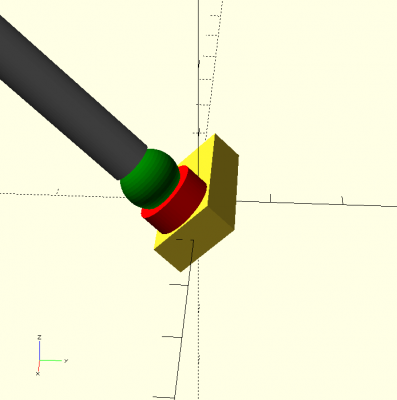

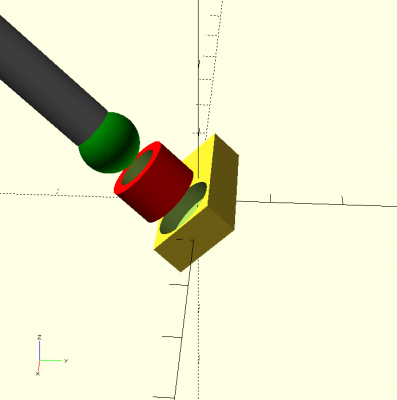

I abandoned magentic / spring loaded ball stud system like below image because of the issues you described. And I've designed effector and carriages.

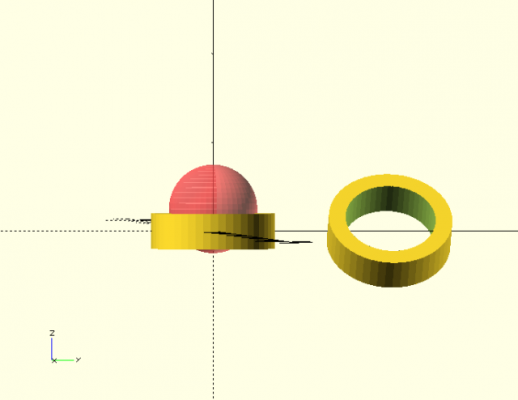

I designed the ball seat that has flat top. The ball stud sits on top and sinks by given angle of seat module.

OpenSCAD code

90 degree

45 degree

30 degree

@vreihen

In my case PLA adaptor of diagonal rod will wear out.

Regards,

Hughe

I abandoned magentic / spring loaded ball stud system like below image because of the issues you described. And I've designed effector and carriages.

I designed the ball seat that has flat top. The ball stud sits on top and sinks by given angle of seat module.

OpenSCAD code

ball_diameter = 10;

ball_radius = ball_diameter/2;

theta = 90;

sunk_height = ball_radius * sin(theta);

seat_radius = ball_radius * sin(theta);

wall_thickness = 2;

seat_height = 4;

$fn =50;

module ball_seat()

{

difference()

{

cylinder(h=seat_height, r1=ball_radius+wall_thickness, r2=seat_radius+wall_thickness, center=true);

cylinder(h=seat_height+2, r=seat_radius+0.1, center=true);

}

}

translate([0, 0, (ball_radius-sunk_height)/2+ball_radius/2])

# sphere(r=ball_radius, center=true);

ball_seat();

translate([0, 20, 0]) rotate([0, 45, 0]) ball_seat();

90 degree

45 degree

30 degree

@vreihen

In my case PLA adaptor of diagonal rod will wear out.

Regards,

Hughe

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 07:25AM |

Registered: 10 years ago Posts: 14,672 |

Quote

vreihen

My only concern with using three planes in a printed socket is wear.

Any wear should result in spherical indentations that perfectly match the ball. It might even be a good idea to put some grinding paste (softer than the steel balls) in the joints and then execute a gcode file that exercises them for a few hours, to run the joints in!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 04:22PM |

Registered: 9 years ago Posts: 893 |

At the risk of sounding like a traitor to the CherryPi cause - wouldn't it be easier and cheaper to fit Traxxas ball joints on the rods, as on the Kossel?

I have heard that they have their own problems (usually caused by wear) but they do sound like an answer to this particular problem...

I have heard that they have their own problems (usually caused by wear) but they do sound like an answer to this particular problem...

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 04:28PM |

Registered: 9 years ago Posts: 483 |

Quote

dc42

Quote

vreihen

My only concern with using three planes in a printed socket is wear.

Any wear should result in spherical indentations that perfectly match the ball. It might even be a good idea to put some grinding paste (softer than the steel balls) in the joints and then execute a gcode file that exercises them for a few hours, to run the joints in!

The grinding paste will embed itself in the softer plastic and grind down the steel balls. This is a basic principal of lapping. It will also be virtually impossible to remove all of the grinding particles from the plastic.

|

Re: Cherry Pi ball sockets: corner cubes? May 25, 2015 06:45PM |

Registered: 10 years ago Posts: 14,672 |

Quote

etfrench

Quote

dc42

Quote

vreihen

My only concern with using three planes in a printed socket is wear.

Any wear should result in spherical indentations that perfectly match the ball. It might even be a good idea to put some grinding paste (softer than the steel balls) in the joints and then execute a gcode file that exercises them for a few hours, to run the joints in!

The grinding paste will embed itself in the softer plastic and grind down the steel balls. This is a basic principal of lapping. It will also be virtually impossible to remove all of the grinding particles from the plastic.

Good point! Grinding paste isn't a good idea after all, it would be better with a suitable grease.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 03:33AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Quote

etfrench

Quote

dc42

Quote

vreihen

My only concern with using three planes in a printed socket is wear.

Any wear should result in spherical indentations that perfectly match the ball. It might even be a good idea to put some grinding paste (softer than the steel balls) in the joints and then execute a gcode file that exercises them for a few hours, to run the joints in!

The grinding paste will embed itself in the softer plastic and grind down the steel balls. This is a basic principal of lapping. It will also be virtually impossible to remove all of the grinding particles from the plastic.

Good point! Grinding paste isn't a good idea after all, it would be better with a suitable grease.

Tried the Grease (Silicon) Dave doesn't allow for miss-alignment though

Doug

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 04:06AM |

Registered: 9 years ago Posts: 893 |

I've been having a few random thoughts overnight - how well would an 8mm bearing run on a well-turned metal ring? Would it last a decent amount of time in the context of a delta printer's rods?

I was thinking of metal tubes fitted over 3D printed pegs in the rod carriers and effector plate. The builder would probably need a lathe (I have two!) to make decent tubes, unless something could be bought commercially.

I was thinking of metal tubes fitted over 3D printed pegs in the rod carriers and effector plate. The builder would probably need a lathe (I have two!) to make decent tubes, unless something could be bought commercially.

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 04:10AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Tried the Grease (Silicon) Dave doesn't allow for miss-alignment though

The reason I suggested corner cubes is to try to make the alignment more precise. The original design requires printing a spherical socket with a very tight tolerance on the the radius, and if that's anything like printing holes, it's impossible to do. Using corner cubes just requires printing 3 flat perimeters, which should be much easier.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 04:26AM |

Registered: 9 years ago Posts: 1,159 |

Quote

David J

I've been having a few random thoughts overnight - how well would an 8mm bearing run on a well-turned metal ring? Would it last a decent amount of time in the context of a delta printer's rods?

I was thinking of metal tubes fitted over 3D printed pegs in the rod carriers and effector plate. The builder would probably need a lathe (I have two!) to make decent tubes, unless something could be bought commercially.

OK not a bad idea that but how about attaching the balls to the effector and carriages (solidly mind) and then having some cups made out of say PTFE or Delrin bar turned to suit which could then be glued into either Aluminium or Carbon Fibre tube (My Preference would be for Carbon tube tho)

Delrin bar can be found here Delrin Bar at around £3 for a 500 mm length of 16 mm diameter

PTFE Bar can be obtained here PTFE 10 mm diam Bar at around £2.5 for a 500 mm length.

What do you think (PTFE would be my choice for it's self lubricating Qualities and you could use a ball mill in the tailstock to cut the cup

Doug

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 04:59AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Quote

David J

I've been having a few random thoughts overnight - how well would an 8mm bearing run on a well-turned metal ring? Would it last a decent amount of time in the context of a delta printer's rods?

I was thinking of metal tubes fitted over 3D printed pegs in the rod carriers and effector plate. The builder would probably need a lathe (I have two!) to make decent tubes, unless something could be bought commercially.

OK not a bad idea that but how about attaching the balls to the effector and carriages (solidly mind) and then having some cups made out of say PTFE or Delrin bar turned to suit which could then be glued into either Aluminium or Carbon Fibre tube (My Preference would be for Carbon tube tho)

Delrin bar can be found here Delrin Bar at around £3 for a 500 mm length of 16 mm diameter

PTFE Bar can be obtained here PTFE 10 mm diam Bar at around £2.5 for a 500 mm length.

What do you think (PTFE would be my choice for it's self lubricating Qualities and you could use a ball mill in the tailstock to cut the cup

Doug

Sound good to me, however the ball mill would need to be exactly the same size as the steel balls to allow it to fit without any slop. I would be more inclined to use a conical milling tool. A conical socket for the ball would work on much the same principle as a corner cube, but with the support provided at all the points in a circle instead of at 3 points.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 05:31AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Quote

dougal1957

Quote

David J

I've been having a few random thoughts overnight - how well would an 8mm bearing run on a well-turned metal ring? Would it last a decent amount of time in the context of a delta printer's rods?

I was thinking of metal tubes fitted over 3D printed pegs in the rod carriers and effector plate. The builder would probably need a lathe (I have two!) to make decent tubes, unless something could be bought commercially.

OK not a bad idea that but how about attaching the balls to the effector and carriages (solidly mind) and then having some cups made out of say PTFE or Delrin bar turned to suit which could then be glued into either Aluminium or Carbon Fibre tube (My Preference would be for Carbon tube tho)

Delrin bar can be found here Delrin Bar at around £3 for a 500 mm length of 16 mm diameter

PTFE Bar can be obtained here PTFE 10 mm diam Bar at around £2.5 for a 500 mm length.

What do you think (PTFE would be my choice for it's self lubricating Qualities and you could use a ball mill in the tailstock to cut the cup

Doug

Sound good to me, however the ball mill would need to be exactly the same size as the steel balls to allow it to fit without any slop. I would be more inclined to use a conical milling tool. A conical socket for the ball would work on much the same principle as a corner cube, but with the support provided at all the points in a circle instead of at 3 points.

Or could even be with a Counter sink bit

Doug

ps wish I had a lathe now but for the little I would use it it can't be justified.

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 05:39AM |

Registered: 10 years ago Posts: 14,672 |

I have a contact with a rotary CNC machine. He owes me a favour, so I might be able to get something turned for you.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 06:27AM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

I have a contact with a rotary CNC machine. He owes me a favour, so I might be able to get something turned for you.

OOh that would be nice have just ordered some 10 mm Dia balls with M4 threaded holes which will fit to the Effector/Carriages Which material do you reckon for the Cups PTFE or Delrin or Maybe Nylon or do you have any other suggestions?

Doug

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 09:46AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Quote

dc42

I have a contact with a rotary CNC machine. He owes me a favour, so I might be able to get something turned for you.

OOh that would be nice have just ordered some 10 mm Dia balls with M4 threaded holes which will fit to the Effector/Carriages Which material do you reckon for the Cups PTFE or Delrin or Maybe Nylon or do you have any other suggestions?

Doug

I would go with PTFE. You could put an M4 threaded hole in it, screw an M4 set screw into that, and epoxy the other end of the set screw into the carbon fibre tube as for the Kossel.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cherry Pi ball sockets: corner cubes? May 26, 2015 09:53AM |

Registered: 9 years ago Posts: 893 |

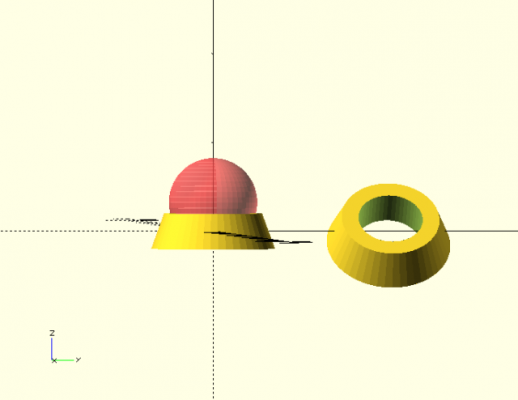

This is what I might have a play with...

The red bit is an oilite bearing like this one, set 3mm into the printed part (yellow) - although I'd probably try to find a cheaper source! The hole in the printed part would have to be a snug fit as these bearings are impregnated with oil and almost certainly ungluable. I could make something in phosphor bronze or steel that could be glued, but I'd rather buy something off the shelf if possible. They may well need to be sunk deeper into the printed part to avoid wobbling. I'm not sure what the ideal inside diameter would be - this one is 6mm, but maybe it should be a little larger.

I shall have to experiment on a test piece.

Edited 2 time(s). Last edit at 05/26/2015 11:58AM by David J.

The red bit is an oilite bearing like this one, set 3mm into the printed part (yellow) - although I'd probably try to find a cheaper source! The hole in the printed part would have to be a snug fit as these bearings are impregnated with oil and almost certainly ungluable. I could make something in phosphor bronze or steel that could be glued, but I'd rather buy something off the shelf if possible. They may well need to be sunk deeper into the printed part to avoid wobbling. I'm not sure what the ideal inside diameter would be - this one is 6mm, but maybe it should be a little larger.

I shall have to experiment on a test piece.

Edited 2 time(s). Last edit at 05/26/2015 11:58AM by David J.

|

Re: Cherry Pi ball sockets: corner cubes? June 01, 2015 04:30AM |

Registered: 11 years ago Posts: 364 |

have the same problem on my 3dr ..

@david j

the idea is great but it would be better to mount the balls ( threaded holes ) vertically on the arm platform and micro platform and glue the bearing/bushing to the rod. If you print the socket at 45 degrees you will not get it accurate enough and cause the same problem with the printed socket..

@david j

the idea is great but it would be better to mount the balls ( threaded holes ) vertically on the arm platform and micro platform and glue the bearing/bushing to the rod. If you print the socket at 45 degrees you will not get it accurate enough and cause the same problem with the printed socket..

Sorry, only registered users may post in this forum.