How to offset the X Y values in Marlin for Rostock?

Posted by emmett_Brown

|

How to offset the X Y values in Marlin for Rostock? May 28, 2015 10:46AM |

Registered: 10 years ago Posts: 95 |

Hello, I have built a Delta Rostock 3D printer and I have some diffcluties to adjust the X Y and Z zero.

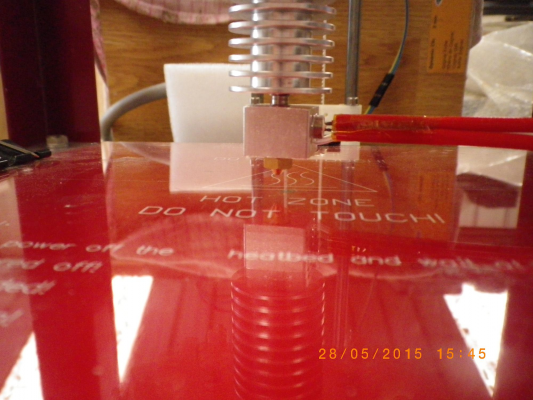

As you can see on the picture, I have three optical endstop wich can not easely be adjusted:

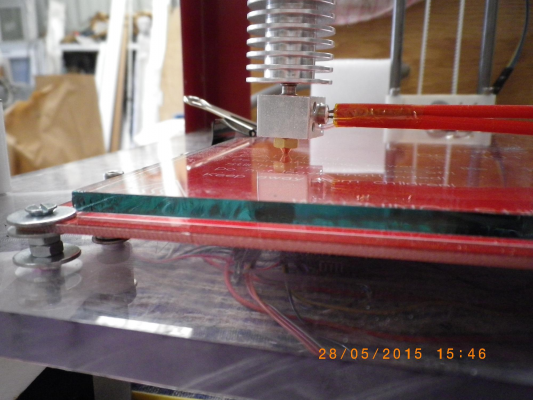

So, I have to raising up the Z lentgh travel like this:

in order to not break my glass bed when I check the X tower:

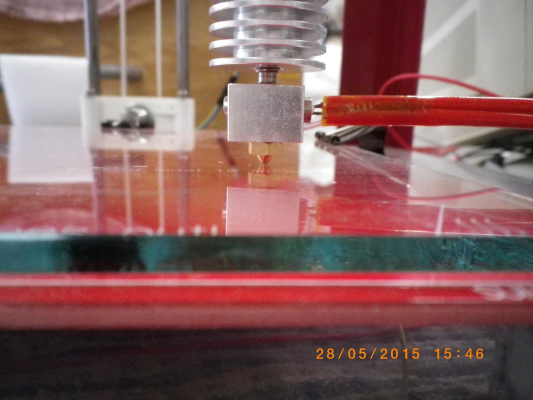

idem for the Y tower:

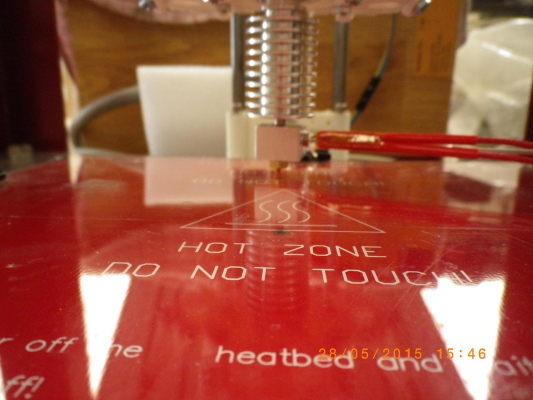

and for the Z tower:

How can I do to offset the zero value of each tower in Marlin because I can't do it with my endstop?

Edited 1 time(s). Last edit at 05/28/2015 11:07AM by emmett_Brown.

As you can see on the picture, I have three optical endstop wich can not easely be adjusted:

So, I have to raising up the Z lentgh travel like this:

in order to not break my glass bed when I check the X tower:

idem for the Y tower:

and for the Z tower:

How can I do to offset the zero value of each tower in Marlin because I can't do it with my endstop?

Edited 1 time(s). Last edit at 05/28/2015 11:07AM by emmett_Brown.

|

Re: How to offset the X Y values in Marlin for Rostock? May 28, 2015 01:32PM |

Registered: 10 years ago Posts: 14,672 |

I don't use Marlin, however most delta firmwares including some versions of Marlin support the M666 command, see [reprap.org].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: How to offset the X Y values in Marlin for Rostock? May 28, 2015 04:45PM |

Registered: 9 years ago Posts: 76 |

|

Re: How to offset the X Y values in Marlin for Rostock? June 14, 2015 11:58PM |

Registered: 9 years ago Posts: 280 |

It might be pointless at this late date, but I use Marlin.

(numbers are examples only)

1)Use 'M666 X-2.3' to adjust the X-tower end-stop offset by -2.3mm.

2)Same for the Y and Z towers. You can mix and match any that you want.

3)These three offsets MUST be negative for some reason.

4)This means the max z-height must be smaller than actual height so that the negative offset values will 'pull' it down to the actual bed height.

4)M666 H220 will set the max height between the nozzle and the bed surface to 220mm (for example). Use a ruler to measure the max z-height and enter that with the H prefix.

I won't get into how to flatten a bed or calibrate the dimensions because the forums are full of that stuff and calibration is a deep subject.

(numbers are examples only)

1)Use 'M666 X-2.3' to adjust the X-tower end-stop offset by -2.3mm.

2)Same for the Y and Z towers. You can mix and match any that you want.

3)These three offsets MUST be negative for some reason.

4)This means the max z-height must be smaller than actual height so that the negative offset values will 'pull' it down to the actual bed height.

4)M666 H220 will set the max height between the nozzle and the bed surface to 220mm (for example). Use a ruler to measure the max z-height and enter that with the H prefix.

I won't get into how to flatten a bed or calibrate the dimensions because the forums are full of that stuff and calibration is a deep subject.

|

Re: How to offset the X Y values in Marlin for Rostock? June 15, 2015 09:28PM |

Registered: 11 years ago Posts: 805 |

Sorry, only registered users may post in this forum.