Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources)

Posted by Dejay

|

Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 13, 2015 03:43PM |

Registered: 9 years ago Posts: 210 |

So the current discount for shipping costs on openbuilds for V-Slot send me into a deep cycle of looking, comparing, discarding, thinking and brain overheating again. It's about linear motion again. And yes I know I shouldn't waste my precious few brain cells on problems where plenty of engineering solutions already exist... but I can't help it! A single wheel on a V-Slot still costs $5 and you need at least 3 of them AND a special extrusion!

So there are a couple of solution: rails, linear bearings on rods, wheels on standard 2020 extrusions, friction gliders, and Johann's recirculating balls in a 3D printed linear motion carriage. Recirculating balls are probably the cheapest you could possibly go. And you might be able to improve them with a more flat surface where the balls roll over (either use a small sheet of POM or print the center part separate on printbed for more flatness). There is also a professional slider for 2020 but it's expensive. But for some reason I really like this design. Use any type of extrusion with a customizable 3D printed carriage.

But I haven't seen anyone use 8 miniature ball bearings / rollers on the flat parts of aluminium extrusions before. Ideally you'd use bearings of about 10mm diameter. There are even teeny tiny ball bearings of 5mm diameter. They can be got for 50 to 60 cents so you'd end up with with 8 * 0.6 = 5€ for the complete carriage. Wheels on four sides should also make the carriage more stiff to perpendicular forces or twisting.

Problem is steel on aluminium might be noisy and wear out. So you'd want durable plastic as a wheel, put a plastic tape on the extrusions or use plastic bearings in the first place. So ideally you'd want plastic bearings to use as rollers or make wheels. Cutting POM tubes could work if you find the right size but what I've seen isn't made for precision. Or print a really smooth wheel yourself of course.

Of course enclosing the extrusion with the carriage has disadvantages too. You can't mount anything to the outside or make an enclosure as easily.

So where can you buy cheap tiny plastic bearings? I've seen only a few listing but it's larger than I'd like or it's a bit too expensive ($1.6 per bearing). Do these have big disadvantages / why aren't they used as rollers already? What is their normal use case?

What are the limitations of really tiny 5 or 7mm bearings? Would they have more friction at the speed of a delta carriage? Can they take the (moderate?) loads of a delta?

So for a 2020 extrusion you could simply print 2 corner edge pieces that take 4 bearings each. You could preload with 4 bolts. But I'm really more interested in larger extrusions like 2040 or 4040 for a largish delta or coreXY. Even 4040 standard extrusions are cheaper than 2020 V-Slot.

Has this idea already been discussed and discarded somewhere? (I imagine it was).

So there are a couple of solution: rails, linear bearings on rods, wheels on standard 2020 extrusions, friction gliders, and Johann's recirculating balls in a 3D printed linear motion carriage. Recirculating balls are probably the cheapest you could possibly go. And you might be able to improve them with a more flat surface where the balls roll over (either use a small sheet of POM or print the center part separate on printbed for more flatness). There is also a professional slider for 2020 but it's expensive. But for some reason I really like this design. Use any type of extrusion with a customizable 3D printed carriage.

But I haven't seen anyone use 8 miniature ball bearings / rollers on the flat parts of aluminium extrusions before. Ideally you'd use bearings of about 10mm diameter. There are even teeny tiny ball bearings of 5mm diameter. They can be got for 50 to 60 cents so you'd end up with with 8 * 0.6 = 5€ for the complete carriage. Wheels on four sides should also make the carriage more stiff to perpendicular forces or twisting.

Problem is steel on aluminium might be noisy and wear out. So you'd want durable plastic as a wheel, put a plastic tape on the extrusions or use plastic bearings in the first place. So ideally you'd want plastic bearings to use as rollers or make wheels. Cutting POM tubes could work if you find the right size but what I've seen isn't made for precision. Or print a really smooth wheel yourself of course.

Of course enclosing the extrusion with the carriage has disadvantages too. You can't mount anything to the outside or make an enclosure as easily.

So where can you buy cheap tiny plastic bearings? I've seen only a few listing but it's larger than I'd like or it's a bit too expensive ($1.6 per bearing). Do these have big disadvantages / why aren't they used as rollers already? What is their normal use case?

What are the limitations of really tiny 5 or 7mm bearings? Would they have more friction at the speed of a delta carriage? Can they take the (moderate?) loads of a delta?

So for a 2020 extrusion you could simply print 2 corner edge pieces that take 4 bearings each. You could preload with 4 bolts. But I'm really more interested in larger extrusions like 2040 or 4040 for a largish delta or coreXY. Even 4040 standard extrusions are cheaper than 2020 V-Slot.

Has this idea already been discussed and discarded somewhere? (I imagine it was).

|

Re: Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 13, 2015 06:09PM |

Registered: 10 years ago Posts: 903 |

Quote

Dejay

Has this idea already been discussed and discarded somewhere? (I imagine it was).

AndyCart did it on the original Cherry Pi. Feel free to look it up on Thingiverse.

Regarding the metal-on-metal, I think that he was at one point going to try putting a thin "tire" over the bearing, either heat shrink tubing or something else. I don't remember what ever came of that, but the fact that the Cherry Pi II/III/IIIs do not use this setup is probably a bad sign for the idea.

I had suggested trying a strip of electrical tape on the extrusion as a rolling surface to keep the wheels off of the extrusions, but never tested the idea and have my doubts about the long-term durability.....

|

Re: Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 13, 2015 06:12PM |

Registered: 10 years ago Posts: 903 |

|

Re: Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 13, 2015 06:20PM |

Registered: 9 years ago Posts: 210 |

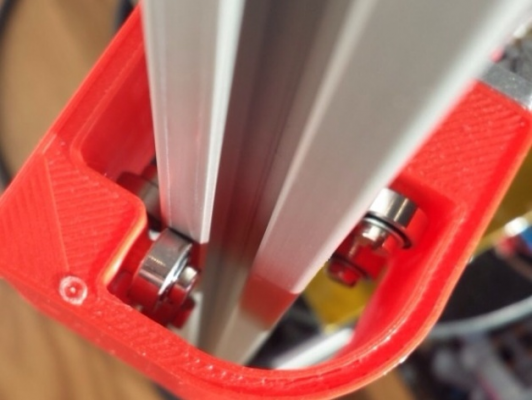

Ah thank you! I was just looking it up (easy enough to find) but you posted the perfect picture. It seems 6 bearings is enough too.

My guess the weakness is that you still need wheels out of durable material. A tape would be messy. And yeah I thought about heat shrink tubing for a second but it's probably a good approach. Cheap bearings and cheap heat shrink. And it's even available with different materials like PTFE (Teflon) or silicone rubber. It might become loose over time though. Maybe glue it.

I'll read in the thread I'm sure there is some discussion about the pro/cons about this approach.

My guess the weakness is that you still need wheels out of durable material. A tape would be messy. And yeah I thought about heat shrink tubing for a second but it's probably a good approach. Cheap bearings and cheap heat shrink. And it's even available with different materials like PTFE (Teflon) or silicone rubber. It might become loose over time though. Maybe glue it.

I'll read in the thread I'm sure there is some discussion about the pro/cons about this approach.

|

Re: Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 14, 2015 02:00PM |

Registered: 10 years ago Posts: 20 |

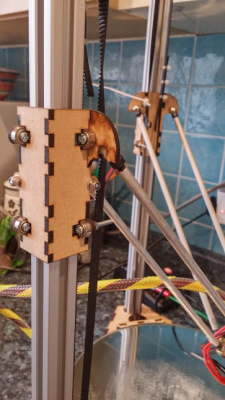

I've used this approach in my delta and so far it's working well for me. My particular design is all laser-cut 3mm MDF sheet as I only had access to a laser-cutter during construction, not a 3D printer.

design files are available here: https://github.com/barnyrelph/lasercut-delta

The only change I'd make if re-building these would be to not put in adjustment slots for the bearings. It's far easier to put exact holes in for the M3 bolts to hold the bearings in place, then assemble the carriages in 2 halves, mount the bearings, then glue the two halves together under a little tension (elastic bands).

I did also wonder about rather than fitting rubber to the wheels, whether just running a strip of tape along the extrusion would have the same effect and allow for very quick and easy replacement.

Thanks

Barny

design files are available here: https://github.com/barnyrelph/lasercut-delta

The only change I'd make if re-building these would be to not put in adjustment slots for the bearings. It's far easier to put exact holes in for the M3 bolts to hold the bearings in place, then assemble the carriages in 2 halves, mount the bearings, then glue the two halves together under a little tension (elastic bands).

I did also wonder about rather than fitting rubber to the wheels, whether just running a strip of tape along the extrusion would have the same effect and allow for very quick and easy replacement.

Thanks

Barny

|

Re: Flat bearing rollers on all four sides of an extrusion for carriage? (Looking for ideas / sources) June 14, 2015 07:46PM |

Registered: 9 years ago Posts: 210 |

Thanks you for the pictures ybanrab! Those carriages look pretty nice. The lasercut MDF plates and the "wings" create a very cool "gothic" style

I guess from the M3 bolts you used 623 bearings (3x10x4 mm). The mini V wheels use MR105 5x10x4mm bearings - the same outer diameter but thicker inner diameter. So the bearing balls are actually even smaller there. So 623 should be fine.

And yeah I agree for 2020 two opposing corners that are pressed together would create a very good preload. With 3D printed carriages you could design it so that the bolts for the bearings are long enough to connect to the other side and can be adjusted to create the preload as well. But I want to use 2040 extrusions so this might not work so well for a rectangle.

Another consideration about the V-Slot wheels and also T-Slot wheels is that I think they create more friction and wear than flat wheels on a surface. If you think about it the rotation of the "V" part on the outside and the inside of the V groove is different, so this should create small areas that are sliding and are not rolling on the extrusion. But it's delrin / POM and it's probably not that big of a deal anyway. But still ideally you'd want to have flat wheels rolling on a flat part with maybe a guide in the groove. I know robocutters sells wheels like that.

Sigh... but after all this thinking and talking... I'm still tempted to just take advantage of the sale and order some 3m of V-Slot 2040 and 12x V wheels.

I guess from the M3 bolts you used 623 bearings (3x10x4 mm). The mini V wheels use MR105 5x10x4mm bearings - the same outer diameter but thicker inner diameter. So the bearing balls are actually even smaller there. So 623 should be fine.

And yeah I agree for 2020 two opposing corners that are pressed together would create a very good preload. With 3D printed carriages you could design it so that the bolts for the bearings are long enough to connect to the other side and can be adjusted to create the preload as well. But I want to use 2040 extrusions so this might not work so well for a rectangle.

Another consideration about the V-Slot wheels and also T-Slot wheels is that I think they create more friction and wear than flat wheels on a surface. If you think about it the rotation of the "V" part on the outside and the inside of the V groove is different, so this should create small areas that are sliding and are not rolling on the extrusion. But it's delrin / POM and it's probably not that big of a deal anyway. But still ideally you'd want to have flat wheels rolling on a flat part with maybe a guide in the groove. I know robocutters sells wheels like that.

Sigh... but after all this thinking and talking... I'm still tempted to just take advantage of the sale and order some 3m of V-Slot 2040 and 12x V wheels.

Sorry, only registered users may post in this forum.