Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit September 03, 2015 04:17PM |

Registered: 10 years ago Posts: 14,672 |

Most likely your towers are not equally spaced, or they are leaning (which I believe may be a common problem when using printed corners).. Either way, unless you can correct your build, the tower positions need to be adjusted in the firmware. The problem is knowing what the corrections should be. I had a similar problem with my Mini Kossel, and I didn't manage to resolve it completely until I implemented a precise auto calibration feature in the firmware.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 03, 2015 06:50PM |

Registered: 10 years ago Posts: 62 |

Nebbian,

Getting close myself. Two (probably real silly) questions:

1. Did you use the Sintron Marlin firmeware? [www.dropbox.com]

2. Did you do the G28 (home) followed by a G29 (auto level) before printing? Sintron's software seems to be set up to handle it.

If this didn't work I will just wait for my Duet to arive before proceeding.

Roger

Getting close myself. Two (probably real silly) questions:

1. Did you use the Sintron Marlin firmeware? [www.dropbox.com]

2. Did you do the G28 (home) followed by a G29 (auto level) before printing? Sintron's software seems to be set up to handle it.

If this didn't work I will just wait for my Duet to arive before proceeding.

Roger

|

Re: Ebay SINTRON Kossel Mini full kit September 03, 2015 09:32PM |

Registered: 8 years ago Posts: 916 |

Quote

Miamicraft

1. Did you use the Sintron Marlin firmeware? [www.dropbox.com]

2. Did you do the G28 (home) followed by a G29 (auto level) before printing? Sintron's software seems to be set up to handle it.

Thanks Roger, good to hear that you're getting close! I'm keen to have another working printer to compare notes on.

Answers as follows:

1) I used the software that was linked in the Sintron PDF, which may or may not be identical to the one you linked to.

2) I tried G29 earlier, but had all sorts of issues with it (sensor dragging over the bed, head crashing into the bed, it doing a walk upwards in thin air, pressing "Motor stop" while calibrating having no effect) so decided to see what happened when just going old school with manual calibration.

Thinking about this some more I think that the issue is one of tuning / calibration. I had to lower the smooth rod offset quite a bit from what was measured to get a "flat" print surface (measured next to the towers and the center), which means that it doesn't match the other numbers -- the ratio between them will be out. One thing I haven't measured is the steps per mm for the carriages, this might have something to do with it. The error I'm getting is 3-way symmetrical, it's like a crinkle washer which leads me to believe that it's not one of poor build geometry. I think it's because marlin thinks the towers are further apart than they actually are.

If you're close, then please do what you can to get yours built! I'd love to have another pair of eyes to look over the problem.

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 12:57AM |

Registered: 10 years ago Posts: 62 |

Nebbian,

I'm just going to throw out some suggestions. May or may not help....

There was an issue reported on Marlin that sounds a lot like what you describe. You might want to load the development version of Marlin (https://github.com/MarlinFirmware/Marlin/tree/1.0.x), merge your config.h and see if that makes any difference. You also might want to do a windiff between the config.h you have and the one referenced on dropbox. Also try a M119 to check if your probe switch is wired the same as your config (NO, NC), it should not be triggered when in air.

I am going to be busy Saturday and Sunday but hope to get some work done in the evenings. On top of that my workstation's hard drive crashed today and I'm now working off my laptop.

Will keep you posted.

Roger

I'm just going to throw out some suggestions. May or may not help....

There was an issue reported on Marlin that sounds a lot like what you describe. You might want to load the development version of Marlin (https://github.com/MarlinFirmware/Marlin/tree/1.0.x), merge your config.h and see if that makes any difference. You also might want to do a windiff between the config.h you have and the one referenced on dropbox. Also try a M119 to check if your probe switch is wired the same as your config (NO, NC), it should not be triggered when in air.

I am going to be busy Saturday and Sunday but hope to get some work done in the evenings. On top of that my workstation's hard drive crashed today and I'm now working off my laptop.

Will keep you posted.

Roger

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 02:47AM |

Registered: 8 years ago Posts: 916 |

It's a good idea to use the development version, I'll do that tonight. Thanks for the idea!

The limit switch works perfectly, and my printer can run through a complete calibration (including deploying and retracting the probe) just fine... most of the time. Sometimes, however, it goes totally crazy. I don't know if this is related to heat, software or gremlins. Who knows. In a related note, having a machine run off on its own doing random crazy moves with no position feedback is a bit scary the first time it happens. I highly recommend having a power supply you can easily switch off.

Once I've sorted out this 3-way crinkle in the print surface I'll try the auto calibration again. I think the idea of the auto calibration is to handle small changes due to temperature etc, not take up the slack of a poorly configured set of parameters .

.

More to come. Happy friday!

The limit switch works perfectly, and my printer can run through a complete calibration (including deploying and retracting the probe) just fine... most of the time. Sometimes, however, it goes totally crazy. I don't know if this is related to heat, software or gremlins. Who knows. In a related note, having a machine run off on its own doing random crazy moves with no position feedback is a bit scary the first time it happens. I highly recommend having a power supply you can easily switch off.

Once I've sorted out this 3-way crinkle in the print surface I'll try the auto calibration again. I think the idea of the auto calibration is to handle small changes due to temperature etc, not take up the slack of a poorly configured set of parameters

.

.More to come. Happy friday!

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 04:35AM |

Registered: 8 years ago Posts: 5,232 |

Try to reduce the delta_printable radius, maybe it helps against gremlins?

I´ve also seen configs, where the delta_radius was set with a fixed value instead of an equation. ( although not recommended )

Maybe that helps against your triple crinkle area, when you leave the other variables as_is and only change delta_radius and delta_rod_lenght.

-Olaf

The problem I see with the marlin DEV version: the main man busy with debugging the ABL routine, doesn´t have a delta printer for testing...

I´ve also seen configs, where the delta_radius was set with a fixed value instead of an equation. ( although not recommended )

Maybe that helps against your triple crinkle area, when you leave the other variables as_is and only change delta_radius and delta_rod_lenght.

-Olaf

The problem I see with the marlin DEV version: the main man busy with debugging the ABL routine, doesn´t have a delta printer for testing...

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 04:57AM |

Registered: 10 years ago Posts: 14,672 |

Are you sure that the diagonal rod length is configured correctly in the firmware? A misconfigured value there would explain the symmetrical crinkle and the large adjustment to the delta radius. It should match the bearing-to-bearing length of the rods.

Edited 1 time(s). Last edit at 09/04/2015 04:58AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 09/04/2015 04:58AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 10:47AM |

Registered: 8 years ago Posts: 5,232 |

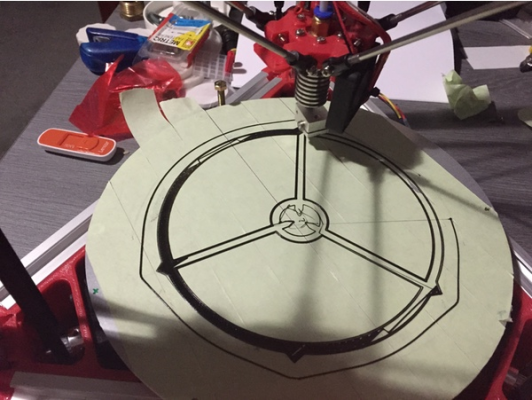

Today I started calibrating my delta with marlin. ( not sintron, but same design )

I found all the variables are spot on, when you figure out, what they are actually asking you.

1st. the delta_smooth_rod_offset is hard to find. How do I know, where the center of the printer is? I don´t even have a smooth rod. (They are talking about the center of the v-slot rollers in modern world )

2nd. delta_effector_offset. I was ~10mm wrong at first, because I took the distance from center to one of the ball joints. WRONG, it is the distance from center to the virtual middle of two ball joints (a pair off balljoints which go to one of the carriers )

The picture I attached might be helpful, although the effector offset can still be misread.

-Olaf

Edited 1 time(s). Last edit at 09/04/2015 10:49AM by o_lampe.

I found all the variables are spot on, when you figure out, what they are actually asking you.

1st. the delta_smooth_rod_offset is hard to find. How do I know, where the center of the printer is? I don´t even have a smooth rod. (They are talking about the center of the v-slot rollers in modern world )

2nd. delta_effector_offset. I was ~10mm wrong at first, because I took the distance from center to one of the ball joints. WRONG, it is the distance from center to the virtual middle of two ball joints (a pair off balljoints which go to one of the carriers )

The picture I attached might be helpful, although the effector offset can still be misread.

-Olaf

Edited 1 time(s). Last edit at 09/04/2015 10:49AM by o_lampe.

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 11:11AM |

Registered: 8 years ago Posts: 916 |

My issue turned out to be related to the steps per unit value. My marlin config had this set to 100, it should have been 80. The sintron kit uses 20 teeth on each pulley.

Progress! The crinkled print surface is now gone.

I'll post my config soon when I'm confident that it's correct. It's looking good now though.

Progress! The crinkled print surface is now gone.

I'll post my config soon when I'm confident that it's correct. It's looking good now though.

|

Re: Ebay SINTRON Kossel Mini full kit September 04, 2015 11:30AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

Today I started calibrating my delta with marlin. ( not sintron, but same design )

I found all the variables are spot on, when you figure out, what they are actually asking you.

1st. the delta_smooth_rod_offset is hard to find. How do I know, where the center of the printer is? I don´t even have a smooth rod. (They are talking about the center of the v-slot rollers in modern world )

2nd. delta_effector_offset. I was ~10mm wrong at first, because I took the distance from center to one of the ball joints. WRONG, it is the distance from center to the virtual middle of two ball joints (a pair off balljoints which go to one of the carriers )

The picture I attached might be helpful, although the effector offset can still be misread.

-Olaf

I don't know why Marlin makes it so complicated. The only dimension it actually needs is the delta radius. This is the horizontal distance subtended by any one of the diagonal rods when the effector is central, which is quite easy to estimate using a ruler

Edited 2 time(s). Last edit at 09/06/2015 04:26AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 05, 2015 03:22AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit September 05, 2015 05:45PM |

Registered: 8 years ago Posts: 89 |

Did that. Just got a reply that they will ship my kit with traxxas ends.Quote

nebbian

I would ask them if they can substitute the traxxas ends for the metal ball joints before buying, as the metal joints are totally unsuitable.

...

Thanks for the hints. Also good to see positive messages of people that got their printer running. Gives me hope

|

Re: Ebay SINTRON Kossel Mini full kit September 06, 2015 03:44AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit September 06, 2015 05:05AM |

Registered: 8 years ago Posts: 916 |

I got sick of endlessly printing calibration prints, so printed something actually useful.

This is a bath plug that had broken. It took about half an hour to model up, and something like 5 minutes to print. I'm quite pleased with the result

I also got the LCD panel working, it seems fine. Now I just need to wait the 4.5 hours it will take to print out the case!

I think that there's nothing inherently wrong with this kit, like anything it takes a bit of patience and perseverence to get good results. I think that this would be the same for every kit out there.

I'm quite pleased with the purchase, it's really enjoyable to see something work nicely when you've put it all together yourself.

This is a bath plug that had broken. It took about half an hour to model up, and something like 5 minutes to print. I'm quite pleased with the result

I also got the LCD panel working, it seems fine. Now I just need to wait the 4.5 hours it will take to print out the case!

I think that there's nothing inherently wrong with this kit, like anything it takes a bit of patience and perseverence to get good results. I think that this would be the same for every kit out there.

I'm quite pleased with the purchase, it's really enjoyable to see something work nicely when you've put it all together yourself.

|

Re: Ebay SINTRON Kossel Mini full kit September 06, 2015 02:08PM |

Registered: 10 years ago Posts: 62 |

|

Re: Ebay SINTRON Kossel Mini full kit September 06, 2015 09:00PM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 02:34AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 11:11AM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

Can you tell us the height of your endstops? Otherwise the blind use of the file could end in a headcrash.

-Olaf

Thanks Olaf, my nozzle is exactly 204.8 mm above the bed when the carriages trigger the endstops.

I'm glad they give you 5 stepper drivers in the kit, as I broke one today. The little plus-shaped piece of metal that lives on the top of the pot just flipped off, and shorted out some other components on the board. This killed the stepper driver, and seriously hurt the 5V regulator. I replaced the stepper driver with the spare in the kit, and replaced the 5V regulator on the arduino board with a spare 7805. Now we're back in business!

I bumped up the stepper motor driver regulators from 0.35V to 0.45V. Hopefully this might resolve some slight striping issues I've been having when printing large areas (more on this in a later post when I get to the bottom of it).

I'm not convinced that this system can handle the load of a heated bed. Whenever I try to heat it up the board goes a bit spastic after a while. The motors start making weird noises and stop moving, and won't respond to pronterface. The orange polyfuses, and the heating FETs get quite hot as well. I thought that this was due to the board heating up underneath the heatbed but now I'm not sure, as it showed the same problem with the board mounted outside the base. (well, mounted is being generous, it's sitting on the desk in a rats nest of wires). The bed might be over rated for the FETs. I might try rewiring it to not use so much current (or lower the duty cycle or something).

Also quite annoying is the way that you have to have pronterface in the foreground when printing. Otherwise the printer will pause after 30 seconds or so of doing something else (like typing this message).

Glue stick is OK, but this doesn't stop the part from lifting in the corners. I seemed to have better success with painters tape.

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 11:58AM |

Registered: 10 years ago Posts: 14,672 |

Quote

nebbian

I'm glad they give you 5 stepper drivers in the kit, as I broke one today. The little plus-shaped piece of metal that lives on the top of the pot just flipped off, and shorted out some other components on the board. This killed the stepper driver, and seriously hurt the 5V regulator. I replaced the stepper driver with the spare in the kit, and replaced the 5V regulator on the arduino board with a spare 7805. Now we're back in business!

...

I'm not convinced that this system can handle the load of a heated bed. Whenever I try to heat it up the board goes a bit spastic after a while. The motors start making weird noises and stop moving, and won't respond to pronterface. The orange polyfuses, and the heating FETs get quite hot as well. I thought that this was due to the board heating up underneath the heatbed but now I'm not sure, as it showed the same problem with the board mounted outside the base. (well, mounted is being generous, it's sitting on the desk in a rats nest of wires). The bed might be over rated for the FETs. I might try rewiring it to not use so much current (or lower the duty cycle or something).

Also quite annoying is the way that you have to have pronterface in the foreground when printing. Otherwise the printer will pause after 30 seconds or so of doing something else (like typing this message).

Sadly, most kits (including yours) use cheap Arduino/RAMPS electronics. Blown drivers, blown 5V regulators and overheating mosfets are common on that electronics. You can replace the mosfets with better ones. However, the problems you get when the heated bed has been on for a while might be due to the 12V power supply not handling the load, or a poor connection between the power supply and the RAMPS. I suggest you monitor the voltage on the 12V input terminals of the RAMPS when the bed is operating.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 02:11PM |

Registered: 8 years ago Posts: 89 |

Just got this message from sintron:

Dear

by the way , i've just talked about this with our engineer .

and our engineer already figure out the problem.

and already revised the plastic parts. so the ends are ok now.

so if we can make sure the rod ends are ok for each parts.

is it ok we send them directly ?

--

and by the way , we will send notice for this to all our customers , because if there are problems , we will be fully responsible for this.

--

so please help to check and confirm if this is ok for you .

thanks.

james.

Dear

by the way , i've just talked about this with our engineer .

and our engineer already figure out the problem.

and already revised the plastic parts. so the ends are ok now.

so if we can make sure the rod ends are ok for each parts.

is it ok we send them directly ?

--

and by the way , we will send notice for this to all our customers , because if there are problems , we will be fully responsible for this.

--

so please help to check and confirm if this is ok for you .

thanks.

james.

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 04:53PM |

Registered: 10 years ago Posts: 62 |

Tha_Reaper,

The only way they could make the old rod ends work is to modify the machines geometry. You are likely going to have to change some variables such as Delta Radius to allow calibration. That is part of the reason why I went with the traxxis ends.

dc42,

I've had good experience with Ramps and Marlin on a couple of machines over the past couple of years on x/y machines. Any problems have been my own fault.

Roger

The only way they could make the old rod ends work is to modify the machines geometry. You are likely going to have to change some variables such as Delta Radius to allow calibration. That is part of the reason why I went with the traxxis ends.

dc42,

I've had good experience with Ramps and Marlin on a couple of machines over the past couple of years on x/y machines. Any problems have been my own fault.

Roger

|

Re: Ebay SINTRON Kossel Mini full kit September 07, 2015 05:00PM |

Registered: 8 years ago Posts: 89 |

I still asked for the traxxas ends. Mostly because they are a lot lighter than the stock ends. As I understood from earlier conversations that reduced weight will have a positive effect on speed and quality... right?

I'm really looking forward to start tinkering... my old printer is making new horrible sounds every day. I don't know how much longer until something breaks again.

I'm really looking forward to start tinkering... my old printer is making new horrible sounds every day. I don't know how much longer until something breaks again.

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 12:35AM |

Registered: 8 years ago Posts: 916 |

Quote

Tha_Reaper

I still asked for the traxxas ends. Mostly because they are a lot lighter than the stock ends. As I understood from earlier conversations that reduced weight will have a positive effect on speed and quality... right?

I'm really looking forward to start tinkering... my old printer is making new horrible sounds every day. I don't know how much longer until something breaks again.

Good stuff Reaper, the Traxxas ends are the way to go. Not only are they lighter, but they have a 3mm hole in the ball instead of a 4mm hole. Sintron don't provide 4mm bolts, so you're left with the rod end flopping around with no real way to centre it properly. Those metal rod ends they specify are totally unsuitable.

I received the HobbyKing metal 3mm rod ends recently... and they're unsuitable as well! The ball has a fair bit of slop inside the rod end. So the best solution is still the Traxxas ends. Good luck with your build.

DC42: Good idea checking the voltage level. This power supply is rated for 20 amps, and I'm using good quality 16AWG cable with a connector rated for 60 amps to connect the power supply to the RAMPS board. I've used this size wire and connector to pull 40 amps before, it's good quality. I don't remember seeing the power supply go into current limit mode, but it might be doing that I guess. I'll check. Maybe a good quality ATX power supply might be the way to go.

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 03:32AM |

Registered: 8 years ago Posts: 5,232 |

Quote

nebbian

Also quite annoying is the way that you have to have pronterface in the foreground when printing

I´ve read, that you can change "priority" settings in windows to allow it running in the background.

I´ve never printed thru USB, always use SD card.

@The_Reaper

If you want to save more weight, use carbon rods instead of the steel ones.

Sintron seems to be a bunch of morons, but at least their customer service seems better than average.

Although they use customers as guinea pigs, they improve their kits later.

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 03:38AM |

Registered: 8 years ago Posts: 89 |

Quote

o_lampe

@The_Reaper

If you want to save more weight, use carbon rods instead of the steel ones.

Sintron seems to be a bunch of morons, but at least their customer service seems better than average.

Although they use customers as guinea pigs, they improve their kits later.

-Olaf

In the end they refunded me 14 bucks to buy myself some traxxas ends. I guess the person that promised me that they would ship it with traxxas ends didnt realise they didnt have those or something. I'll Use those 14 bucks (as a start) to buy myself a traxxas ends+carbon rods kit from ebay.

Is there a specific length rods that i should go for?

EDIT: and not knowing the difference: are traxxas parts 5347 or 5525 the ones i should go for?

Edited 1 time(s). Last edit at 09/08/2015 03:41AM by Tha_Reaper.

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 04:20AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Tha_Reaper

Quote

o_lampe

@The_Reaper

If you want to save more weight, use carbon rods instead of the steel ones.

Sintron seems to be a bunch of morons, but at least their customer service seems better than average.

Although they use customers as guinea pigs, they improve their kits later.

-Olaf

In the end they refunded me 14 bucks to buy myself some traxxas ends. I guess the person that promised me that they would ship it with traxxas ends didnt realise they didnt have those or something. I'll Use those 14 bucks (as a start) to buy myself a traxxas ends+carbon rods kit from ebay.

Is there a specific length rods that i should go for?

EDIT: and not knowing the difference: are traxxas parts 5347 or 5525 the ones i should go for?

5347's are the ones normally used they are a little longer than the 5525's IIRC they have a hole that is just right to tame a M4 setscrew which can then be epoxied into a 4mm id Carbon Tube I use 6mm o/d x 4 mm I/D for mine.

As for the length of Rods I am not sure but certain that someone will chime in with that information (They don't have to be exactly the same length as the std ones BUT THEY MUST ALL BE THE SAME).

HTH Doug

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 07:13AM |

Registered: 10 years ago Posts: 14,672 |

When epoxying the M4 set screws into the carbon fibre tube, make up a jig so that you can get all the rods exactly the same length, bearing-to-bearing. Here [www.thingiverse.com] is one podsible design.

When assembling the Traxxas joints, use the hot/cold assembly method and a jig such as this [www.thingiverse.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

When assembling the Traxxas joints, use the hot/cold assembly method and a jig such as this [www.thingiverse.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 10:07AM |

Registered: 8 years ago Posts: 916 |

Quote

dc42

Sadly, most kits (including yours) use cheap Arduino/RAMPS electronics. Blown drivers, blown 5V regulators and overheating mosfets are common on that electronics. You can replace the mosfets with better ones. However, the problems you get when the heated bed has been on for a while might be due to the 12V power supply not handling the load, or a poor connection between the power supply and the RAMPS. I suggest you monitor the voltage on the 12V input terminals of the RAMPS when the bed is operating.

It turns out that the heated bed draws more current than the polyfuse can handle. There is an easy fix, just reduce the duty cycle of the bed in the software:

#define MAX_BED_POWER 128 // limits duty cycle to bed; 255=full current

Setting it to half power seems to work just fine, and it easily got to 60 degrees which is perfect for PLA. I'm now printing a part with no lifted corners, whereas the same model yesterday had badly lifted corners with no bed heating.

I'm happy with this solution. Much better than an underpowered bed

|

Re: Ebay SINTRON Kossel Mini full kit September 08, 2015 10:17AM |

Registered: 10 years ago Posts: 14,672 |

Quote

nebbian

It turns out that the heated bed draws more current than the polyfuse can handle. There is an easy fix, just reduce the duty cycle of the bed in the software:

#define MAX_BED_POWER 128 // limits duty cycle to bed; 255=full current

Setting it to half power seems to work just fine, and it easily got to 60 degrees which is perfect for PLA. I'm now printing a part with no lifted corners, whereas the same model yesterday had badly lifted corners with no bed heating.

I'm happy with this solution. Much better than an underpowered bed

Interesting - reports of underpowered bed heaters are common, but I've never seen a report of an over-powerful PCB bed heater before now. Or it is some other kind of bed heater supplied with that kit?

Edited 1 time(s). Last edit at 09/08/2015 10:17AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit September 09, 2015 02:56AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.