Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit September 17, 2015 01:04PM |

Registered: 8 years ago Posts: 89 |

Thanks. I guess i overlooked those.Quote

squall

Miamicraft posted the links on page 2 of this thread.

Here's the PDF:

https://www.dropbox.com/s/2w56ruepec5hgxo/Kossel mini instrution by sintron technology_v2.pdf

password : Sintron_Technology

I had to buy a dremel and dremel some of the parts myself as well to get them to fit nicely.

i held everything together and the carriages and huge ball ends will never fit. other than that i think its mostly fine. The effector seems to fit nicely. I dont think that will require a dremel attack.

Now i just have to find myself a good mallet to beat those extrusions into the corner pieces, and start building!

|

Re: Ebay SINTRON Kossel Mini full kit September 18, 2015 03:24AM |

Registered: 8 years ago Posts: 5,232 |

@GRandAG

You could replace the heatbarrier with one that has a PTFE inliner. They are usually M6 x 26mm long. Compare the length with yours.

You could also buy a three piece M6 thread cutter and use the third bit to cut the thread deeper in the heatsink. But don`t forget, the heatbarrier needs a tight fit to stay put in the heatsink.

Then check the bore of the heatbarrier. Perhaps you´ll find a rough surface that tends to jam. It should be polished.

-Olaf

Edited 1 time(s). Last edit at 09/18/2015 03:25AM by o_lampe.

You could replace the heatbarrier with one that has a PTFE inliner. They are usually M6 x 26mm long. Compare the length with yours.

You could also buy a three piece M6 thread cutter and use the third bit to cut the thread deeper in the heatsink. But don`t forget, the heatbarrier needs a tight fit to stay put in the heatsink.

Then check the bore of the heatbarrier. Perhaps you´ll find a rough surface that tends to jam. It should be polished.

-Olaf

Edited 1 time(s). Last edit at 09/18/2015 03:25AM by o_lampe.

|

Re: Ebay SINTRON Kossel Mini full kit September 18, 2015 05:27PM |

Registered: 10 years ago Posts: 62 |

Well... finally getting back to Sintron. It is fully assembled and (temporarily) wired. Still waiting on 32 bit controller board.

Fried my Arduino. No problem as I have spares.

No problem as I have spares.

Very interesting. On my big CNC mill the servo drives light up when I manually back dive the axis with the power off. This happens because the DC servo motors are basically generators. This doesn't cause a problem as the servo drives are industrial and way over rated and I can't turn the motors by hand as fast as the machine does under power.

This probably is not true of Arduino/Ramps. I was doing manual setup and moving the print head around fairly quickly with power off. Moving three steppers at once probably generated enough current/voltage (back EMF) to fry the Arduino. I can't be sure but sure suspect that was the issue as everything worked before I stated moving everything and didn't afterwards.

I never had this problem with 3 axis RepRaps where you are at most moving 2 axis at a time and also I usually have a power supply connected even if it is off.

I have modified the config.h to work with version 1.0.x of Marlin. Did a mashup of Sintron files, Nebians and Kossel sample files. Really love free WinMerge program. Will post when/if it works.

Glad to see you all making good progress.

Roger

Fried my Arduino.

No problem as I have spares.

No problem as I have spares. Very interesting. On my big CNC mill the servo drives light up when I manually back dive the axis with the power off. This happens because the DC servo motors are basically generators. This doesn't cause a problem as the servo drives are industrial and way over rated and I can't turn the motors by hand as fast as the machine does under power.

This probably is not true of Arduino/Ramps. I was doing manual setup and moving the print head around fairly quickly with power off. Moving three steppers at once probably generated enough current/voltage (back EMF) to fry the Arduino. I can't be sure but sure suspect that was the issue as everything worked before I stated moving everything and didn't afterwards.

I never had this problem with 3 axis RepRaps where you are at most moving 2 axis at a time and also I usually have a power supply connected even if it is off.

I have modified the config.h to work with version 1.0.x of Marlin. Did a mashup of Sintron files, Nebians and Kossel sample files. Really love free WinMerge program. Will post when/if it works.

Glad to see you all making good progress.

Roger

|

Re: Ebay SINTRON Kossel Mini full kit September 20, 2015 06:54AM |

Registered: 8 years ago Posts: 104 |

Quote

o_lampe

You could replace the heatbarrier with one that has a PTFE inliner.

I thought that types of heat barriers (with teflon tube inside) is primarily for direct-drive extruder.

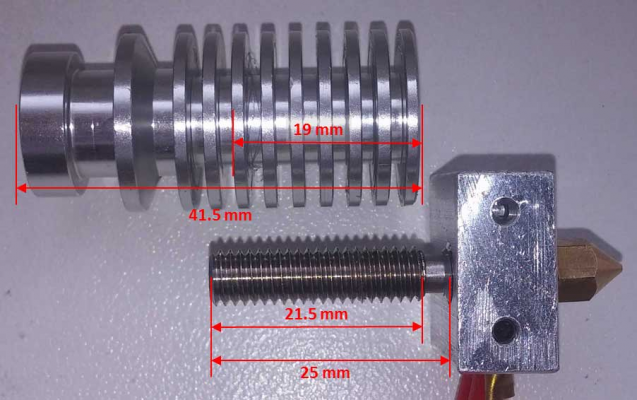

Anyway, I've got a caliper and made some measurements of my hot-end.

The hole inside of heatsink is 19mm in deep. But heatbarrier goes only to 16.5mm inside. Even if the hole will be full threaded it still needs 2.5mm of deepness.

Not sure, but perhaps the heat barrier itself is too long?

|

Re: Ebay SINTRON Kossel Mini full kit September 21, 2015 05:02AM |

Registered: 8 years ago Posts: 5,232 |

@GrandAG

There are all kinds of heat barriers out there. I meant the ones with a short PTFE tube inside the hotend to prevent jamming.

With the incomplete thread inside the heatsink you´ll have a gap where the filament isn´t guided.

With my e3d-clones it was really difficult to feed in new filament without disassembling the PTFE tube and pushfit connector.

So I drilled the heatsink and pushfit connector open to 4.2mm and pushed the Bowden PTFE tube right down to the throat of the heat barrier.

I wouldn´t try to short the heat barrier, but mainly because stainless steel kills your saw blades

If you don´t bother, cut it off ( by 5mm ) and countersink the throat again.

-Olaf

There are all kinds of heat barriers out there. I meant the ones with a short PTFE tube inside the hotend to prevent jamming.

With the incomplete thread inside the heatsink you´ll have a gap where the filament isn´t guided.

With my e3d-clones it was really difficult to feed in new filament without disassembling the PTFE tube and pushfit connector.

So I drilled the heatsink and pushfit connector open to 4.2mm and pushed the Bowden PTFE tube right down to the throat of the heat barrier.

I wouldn´t try to short the heat barrier, but mainly because stainless steel kills your saw blades

If you don´t bother, cut it off ( by 5mm ) and countersink the throat again.

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit September 21, 2015 10:59AM |

Registered: 8 years ago Posts: 104 |

In my case PTFE tube goes through heatsink down to contact heat barrier by design, even if heat barrier is not screwed enough.Quote

o_lampe

So I drilled the heatsink and pushfit connector open to 4.2mm and pushed the Bowden PTFE tube right down to the throat of the heat barrier.

Ok, I will try the hot-end as is. If there will be issues, I will replace the hot barrier.

|

Re: Ebay SINTRON Kossel Mini full kit September 22, 2015 11:28AM |

Registered: 8 years ago Posts: 916 |

@GrandAG: My hotend has 4.5mm of heatbreak showing, measured between the heat block and the heatsink. Not sure if this helps.

I just installed a PEI build plate, and HOOOLY DOOLY it's FANTASTIC!! No problem with adhesion, the PLA just sticks to it straight out of the nozzle, and the parts just peel/pop off once you cool the bed down a bit. No glue, no mess, no fuss. Perfect prints every time. I can highly recommend doing it.

I just installed a PEI build plate, and HOOOLY DOOLY it's FANTASTIC!! No problem with adhesion, the PLA just sticks to it straight out of the nozzle, and the parts just peel/pop off once you cool the bed down a bit. No glue, no mess, no fuss. Perfect prints every time. I can highly recommend doing it.

|

Re: Ebay SINTRON Kossel Mini full kit September 23, 2015 09:24PM |

Registered: 8 years ago Posts: 916 |

I tried printing in ABS last night. It didn't work very well at first:

I tried all sorts of combinations of extrusion rate and hotend temperature, without much success.

I then added a short length of aluminium tube, which seemed to sort out the issues.

I tried all sorts of combinations of extrusion rate and hotend temperature, without much success.

I then added a short length of aluminium tube, which seemed to sort out the issues.

|

Re: Ebay SINTRON Kossel Mini full kit September 24, 2015 04:53AM |

Registered: 8 years ago Posts: 5,232 |

@nebbian

I did a similar thing with my direct drive extruder, but use PTFE tube.

I was wondering, why so many deltas have their extruder stepper on top of the frame? It requires such a long PTFE tube.

I´ve put my extruder on one of the vertical extrusions roughly half height. I can use a much shorter tube now.

-Olaf

I did a similar thing with my direct drive extruder, but use PTFE tube.

I was wondering, why so many deltas have their extruder stepper on top of the frame? It requires such a long PTFE tube.

I´ve put my extruder on one of the vertical extrusions roughly half height. I can use a much shorter tube now.

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit September 24, 2015 06:26PM |

Registered: 11 years ago Posts: 66 |

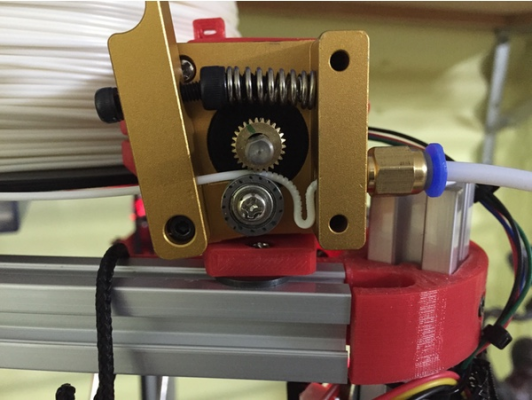

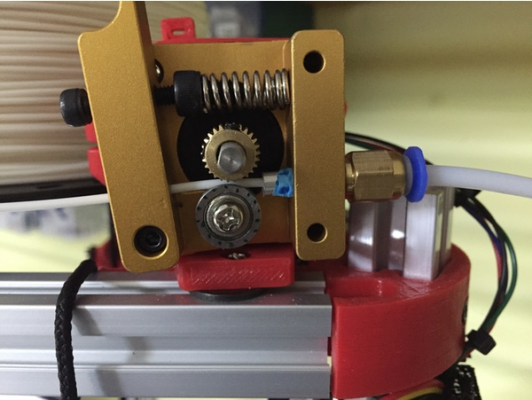

Aluminum tube?

Edit: I see now! uuuuggggly ABS droop.

Maybe print a different extruder/drive? I avoided the Sintron metal extruder, not sure why but went a printed direction.

Has a much smaller footprint, nowhere for the ABS to droop. Take a look, very nice.

You'll need a small(er) bearing though, maybe the metal one has one you can take.

[www.thingiverse.com]

I also don't like where the extruder is placed on their design, I'm doing what I can to lower the drag on the gear - less drag is better.

(keep in mind, I'm redesigning little pieces all the time).

I'm feeding from top > down, better flow.

Also, I'm using their mount differently

My extruder will move down onto one of the vertical rods (on side of machine).

I finally have my axis's moving on their own!

Got my AZSMZ connected, PSU wired.

I only have steppers connected but they all move.

Next up, I got WIFI printing to work! (ESP8266 module).

Also, I have a wireless SD card (ez-share), so I'll be able to load up STL's/GCODE to my SD from computer then print from LCD!

True headless printing!!

The Wifi is not working like I want yet, will take awhile but is working.

Edited 3 time(s). Last edit at 09/24/2015 07:02PM by kingoddball.

Edit: I see now! uuuuggggly ABS droop.

Maybe print a different extruder/drive? I avoided the Sintron metal extruder, not sure why but went a printed direction.

Has a much smaller footprint, nowhere for the ABS to droop. Take a look, very nice.

You'll need a small(er) bearing though, maybe the metal one has one you can take.

[www.thingiverse.com]

I also don't like where the extruder is placed on their design, I'm doing what I can to lower the drag on the gear - less drag is better.

(keep in mind, I'm redesigning little pieces all the time).

I'm feeding from top > down, better flow.

Also, I'm using their mount differently

My extruder will move down onto one of the vertical rods (on side of machine).

I finally have my axis's moving on their own!

Got my AZSMZ connected, PSU wired.

I only have steppers connected but they all move.

Next up, I got WIFI printing to work! (ESP8266 module).

Also, I have a wireless SD card (ez-share), so I'll be able to load up STL's/GCODE to my SD from computer then print from LCD!

True headless printing!!

The Wifi is not working like I want yet, will take awhile but is working.

Edited 3 time(s). Last edit at 09/24/2015 07:02PM by kingoddball.

|

Re: Ebay SINTRON Kossel Mini full kit September 25, 2015 06:50AM |

Registered: 8 years ago Posts: 14 |

@nebbian, is the PEI plate re-usable? or do you have to replace it after x prints?

@kingoddball, wifi sounds really cool! really wish I had something like that on mine.

Sintron sent me replacement ramps and motor drivers and now my printer works properly

My first print came out as a blob of plastic as I didn't really know how to use slicer properly and just used the defaults which were all wrong. (Was trying to print a 1cm calibration cube). The second attempt worked a bit better.

I tweaked some more values, and tried something a bit more ambitious for my third try and it came out better than I expected. I hardly notice any layering on it at all. The ears came out a bit funny though. And a blob near the base was due to my computer going to sleep while it was printing.

Going to experiment some more this weekend.

@kingoddball, wifi sounds really cool! really wish I had something like that on mine.

Sintron sent me replacement ramps and motor drivers and now my printer works properly

My first print came out as a blob of plastic as I didn't really know how to use slicer properly and just used the defaults which were all wrong. (Was trying to print a 1cm calibration cube). The second attempt worked a bit better.

I tweaked some more values, and tried something a bit more ambitious for my third try and it came out better than I expected. I hardly notice any layering on it at all. The ears came out a bit funny though. And a blob near the base was due to my computer going to sleep while it was printing.

Going to experiment some more this weekend.

|

Re: Ebay SINTRON Kossel Mini full kit September 25, 2015 07:42AM |

Registered: 8 years ago Posts: 916 |

Squall, congratulations! That's a very nice knight :-) Great to see another Sintron printing nicely.

The PEI plate should be good for many hundreds of prints, as far as I can tell it's the best surface you can get. I'm very happy with it.

I'm considering getting a different hobbed gear for my extruder, mine seems to slip a bit when printing fast.

The PEI plate should be good for many hundreds of prints, as far as I can tell it's the best surface you can get. I'm very happy with it.

I'm considering getting a different hobbed gear for my extruder, mine seems to slip a bit when printing fast.

|

Re: Ebay SINTRON Kossel Mini full kit September 25, 2015 11:42AM |

Registered: 8 years ago Posts: 5,232 |

Quote

nebbian

I'm considering getting a different hobbed gear for my extruder, mine seems to slip a bit when printing fast.

That will be difficult. A smaller gear ( like MK8 ) will cause the filament to be offline between the two filament guide holes.

You`d consider printing a direct drive Bowden extruder that matches the new hobbed gear.

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit September 26, 2015 10:38AM |

Registered: 8 years ago Posts: 89 |

ran into some small frustrations. I was at the point there the vertical extrusions needed to be hammered into the bottom corner pieces.

All fun and games, but on 1 corner one of the special nuts that should hold the vertical extrusion into place got stuck, and pulled down with the extrusion, now i have a stuck extrusion there, a half broken stuck nut, and a misaligned vertical extrusion. I have no idea yet how im going to fix that.

Second frustration: hammering in the vertical extrusions loosened like ALL the nuts that hold the bottom part together. While tightening them again, 2 started to slip, and it seems like i have to take it all apart again just to replace those 2.

Also it seems that my towers are not perfectly aligned. Would it be OK to force them into the top corner parts, or do i need them to align perfectly (and if i do, how?).

All fun and games, but on 1 corner one of the special nuts that should hold the vertical extrusion into place got stuck, and pulled down with the extrusion, now i have a stuck extrusion there, a half broken stuck nut, and a misaligned vertical extrusion. I have no idea yet how im going to fix that.

Second frustration: hammering in the vertical extrusions loosened like ALL the nuts that hold the bottom part together. While tightening them again, 2 started to slip, and it seems like i have to take it all apart again just to replace those 2.

Also it seems that my towers are not perfectly aligned. Would it be OK to force them into the top corner parts, or do i need them to align perfectly (and if i do, how?).

|

Re: Ebay SINTRON Kossel Mini full kit September 26, 2015 10:52AM |

Registered: 9 years ago Posts: 67 |

|

Re: Ebay SINTRON Kossel Mini full kit September 27, 2015 03:32AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit September 27, 2015 06:07AM |

Registered: 8 years ago Posts: 89 |

Solved the problems so far. I put the extrusion and the corner piece in nearly boiling water. Let it soak for 1 minute, and then i got it out and hammered on the corner piece to get the extrusion out. Works perfectly.

Trough trial and error i found that the best way to use the T-nuts that sintron provide is by tightening it all the way, and placing the t-nut parallel with the slot in the extrusion. That way it will not interfere with, or grab onto the extrusion when you drive it in, or when you slide one of the horizontal extrusions in. When the extrusion is in place, loosen the screw with 2-3 turns, then tighten it again. The t-nut will now turn 90 degrees and grab onto the extrusion and hold it tight.

I just assembled the carriers. now i'm working on tapping the traxxas ends, and finding a way to get all my rods the same length.

I broke 2 of my top corner pieces by the way. Need to glue them, and if that doesn't work i'll need to ask a friend to print those again or try to get my printer to work with broken corners and print them myself.

I'm surprised by how fast i'm progressing with the build by the way. I'm not skilled, i lack basic tools, and i don't know shit about building a printer, but so far, so good.

I did need to buy M4 washers by the way for the top pieces. they were not included in the kit.

Trough trial and error i found that the best way to use the T-nuts that sintron provide is by tightening it all the way, and placing the t-nut parallel with the slot in the extrusion. That way it will not interfere with, or grab onto the extrusion when you drive it in, or when you slide one of the horizontal extrusions in. When the extrusion is in place, loosen the screw with 2-3 turns, then tighten it again. The t-nut will now turn 90 degrees and grab onto the extrusion and hold it tight.

I just assembled the carriers. now i'm working on tapping the traxxas ends, and finding a way to get all my rods the same length.

I broke 2 of my top corner pieces by the way. Need to glue them, and if that doesn't work i'll need to ask a friend to print those again or try to get my printer to work with broken corners and print them myself.

I'm surprised by how fast i'm progressing with the build by the way. I'm not skilled, i lack basic tools, and i don't know shit about building a printer, but so far, so good.

I did need to buy M4 washers by the way for the top pieces. they were not included in the kit.

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 02:44PM |

Registered: 8 years ago Posts: 104 |

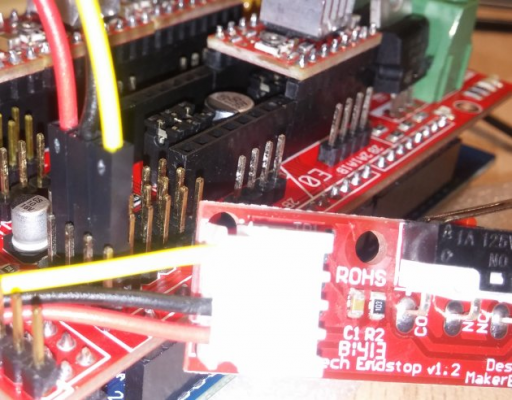

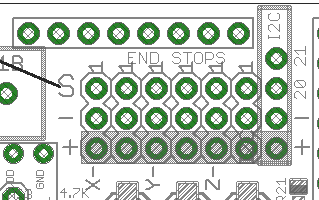

I can't understand what is correct connection of stop-ends? Is it wired properly on the picture below? Or yellow and red wires must be swapped (on RAMPS)?

Edited 1 time(s). Last edit at 09/28/2015 02:45PM by GrAndAG.

Edited 1 time(s). Last edit at 09/28/2015 02:45PM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 04:37PM |

Registered: 8 years ago Posts: 14 |

@GrAndAG My black is connected where your yellow is and my red is connected where your black is. (I didn't connect yellow so it doesn't really matter which is red and black for me)

Unless you really, really want the led lights to work on the end stops, it's safer not to connect the yellow one (which most likely should go where your red one is connected to). I think nebbian connected his so he would be able to tell you for sure.

Edited 3 time(s). Last edit at 09/28/2015 05:12PM by squall.

Unless you really, really want the led lights to work on the end stops, it's safer not to connect the yellow one (which most likely should go where your red one is connected to). I think nebbian connected his so he would be able to tell you for sure.

Edited 3 time(s). Last edit at 09/28/2015 05:12PM by squall.

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 05:27PM |

Registered: 8 years ago Posts: 104 |

From RAMPS schematics:

I connected "red" wire to VCC, "black" to GND and "yellow" one to signal pin. But I'm not sure that red wire is actually VCC connection on end-stop itself. And the same regarding yellow wire.

I connected "red" wire to VCC, "black" to GND and "yellow" one to signal pin. But I'm not sure that red wire is actually VCC connection on end-stop itself. And the same regarding yellow wire.

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 05:37PM |

Registered: 8 years ago Posts: 255 |

Quote

GrAndAG

I can't understand what is correct connection of stop-ends? Is it wired properly on the picture below? Or yellow and red wires must be swapped (on RAMPS)?

[attachment 63109 stop-ends_wiring.jpg]

Hello, this is my first message, so feel free to welcome me ;-), I've been reading this thread for a while now while assembling the kit ;-) So I thought I'd pay back.

I've just done my first prints and my endstops are connected the same way, black to -, red to +, yellow to S. As far as I can tell they work as expected.

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 06:25PM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 06:46PM |

Registered: 8 years ago Posts: 255 |

Quote

nebbian

Welcome aboard Hacker :-)

Thanks ;-) Now that I'm not in stealth mode anymore, I have a few questions to confirm I did the right thing.

First, I was determined not to go for too much modifications and try my best to assemble the kit I received and not just some random printer using some of the parts provided. So, like many of you, I encountered the problem with rods bumping into each other and instead of buying traxxas thingies I just emails Sintron instead. They said that they finally recognize the problem and redesigned the effector and carriages and offered to send me new ones. I absolutely didn't feel like waiting for two weeks, so I asked them for STLs and printed them out on a good old cartesian printer. Admittedly the replacements are better (as I said I've done first prints), but the print radius is some 50-55 mm before you start having problems. But now that I'm done with original design I am considering changing to either traxxas or magnetic joints. Also, with the redesigned effector rod bumps into hotend retainer part so I had to cut the corner away.

Actually, now that I think of it I have only one question — after connecting motors according to instructions (blue-red-green-black IIRC) I had to invert steppers direction in the firmware. Is that me or is it what you also experienced?

BTW, I have also configured repetier firmware for this thing. Just in case anyone wants to fiddle with it, I'm attaching the config.

And I'm still to get z-probe working… And compile modern marlin…

|

Re: Ebay SINTRON Kossel Mini full kit September 28, 2015 09:31PM |

Registered: 8 years ago Posts: 916 |

Quote

hacker

Actually, now that I think of it I have only one question — after connecting motors according to instructions (blue-red-green-black IIRC) I had to invert steppers direction in the firmware. Is that me or is it what you also experienced?

Yep. I couldn't spin my connectors around as they would only fit one way on one of the outputs (Z maybe?) that had two rows of pins. So I did it in the firmware which worked fine.

Thanks for the repetier config, I downloaded it a couple of days ago and will be trying it out soon.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 12:47AM |

Registered: 8 years ago Posts: 319 |

Hello all. This is my first printer build. I am also having the same issues that you all are having but worse. This is a doubly whammy for me. This is my first 3d printer ever. I have no knowledge of gcode with the exception of what I am learning from youtube and making the unit. It has been 1.5 months and all the electronics are in place. I am constantly talking with "James" of sintron. Initially they sent me a bad arduino board. It would not connect with my PC. They sent me a new one and after 10 days of waiting for it to arrive from china that one works fine.

Yes my effector rods bind. So I made the print radius smaller than normal and within that small radius it works fine. Finally got the z probe to work after I saw a youtube video on the bolt trick. So now the z probe goes to the side of the machine and disengages once it hits the bolt after a G29. Did a dozen G28 G29 and checked the homing and its right on even with the binding effector rods.

Then I fried my wires going into the heatbed. Learned they were too small gauge. So I bought 14 AWG wire. Now it heats really fast. Fired up my extruder to 230 deg for ABS and my heatbed to 95 deg for abs. Temp got up and it held just fine. Fed the abs manually so it would extrude hot abs from the extruder. Worked. realized that sintron gave me a bad wiring diagram for the extruder motor. It is backwars. The stepper motor wires are blue, red, green, black as per their pdf. So is the wiring for their extruder motor. But after trial and error, the extruder motor wiring really should be black green red blue (with the USB port to the left im talking left to right in color orientation).

So got extruder motor working in the correct direction after typing in M302

At the final pages of the sintron pdf. Load file into pronterface. So I Put in the 10mm calibration cube file. Heatbed is 95 deg. Extruder is 230 deg. HIT PRINT and the nozzle starts to do G28 but then the tip goes to 0, 0, 0 and shuts off the fans. It shuts it all down. The heatbed goes down in temp. The extruder goes down in temp. BUT the arduino, LCD, and Ramps are still on? I dont know what happened. I asked sintron for help and they want me to video tape what is happening. Email it to them before they respond?

Can anyone help me?

Also during heatbed warm up the F2 PTC got fried. So I replaced it with an inline automotive 15 amp fuse. Now it works fine.

Edited 1 time(s). Last edit at 09/29/2015 12:50AM by DRTak.

Yes my effector rods bind. So I made the print radius smaller than normal and within that small radius it works fine. Finally got the z probe to work after I saw a youtube video on the bolt trick. So now the z probe goes to the side of the machine and disengages once it hits the bolt after a G29. Did a dozen G28 G29 and checked the homing and its right on even with the binding effector rods.

Then I fried my wires going into the heatbed. Learned they were too small gauge. So I bought 14 AWG wire. Now it heats really fast. Fired up my extruder to 230 deg for ABS and my heatbed to 95 deg for abs. Temp got up and it held just fine. Fed the abs manually so it would extrude hot abs from the extruder. Worked. realized that sintron gave me a bad wiring diagram for the extruder motor. It is backwars. The stepper motor wires are blue, red, green, black as per their pdf. So is the wiring for their extruder motor. But after trial and error, the extruder motor wiring really should be black green red blue (with the USB port to the left im talking left to right in color orientation).

So got extruder motor working in the correct direction after typing in M302

At the final pages of the sintron pdf. Load file into pronterface. So I Put in the 10mm calibration cube file. Heatbed is 95 deg. Extruder is 230 deg. HIT PRINT and the nozzle starts to do G28 but then the tip goes to 0, 0, 0 and shuts off the fans. It shuts it all down. The heatbed goes down in temp. The extruder goes down in temp. BUT the arduino, LCD, and Ramps are still on? I dont know what happened. I asked sintron for help and they want me to video tape what is happening. Email it to them before they respond?

Can anyone help me?

Also during heatbed warm up the F2 PTC got fried. So I replaced it with an inline automotive 15 amp fuse. Now it works fine.

Edited 1 time(s). Last edit at 09/29/2015 12:50AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 12:53AM |

Registered: 8 years ago Posts: 916 |

DrTak,

Well done on getting to the stage you're at. You're very close!

I think the problem you're having is that the polyfuses have heated up and tripped out. I had similar problems, before I attached a fan that is blowing directly onto the big yellow rectangular polyfuses on the RAMPS board.

You can also put a layer of cardboard between the heatbed and your RAMPS board, which helps a bit to keep the heatbed heat from getting to the RAMPS board. However a 40mm fan blowing directly on the polyfuses really helped me.

Well done on getting to the stage you're at. You're very close!

I think the problem you're having is that the polyfuses have heated up and tripped out. I had similar problems, before I attached a fan that is blowing directly onto the big yellow rectangular polyfuses on the RAMPS board.

You can also put a layer of cardboard between the heatbed and your RAMPS board, which helps a bit to keep the heatbed heat from getting to the RAMPS board. However a 40mm fan blowing directly on the polyfuses really helped me.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 04:24AM |

Registered: 8 years ago Posts: 5,232 |

Quote

DrTak

At the final pages of the sintron pdf. Load file into pronterface. So I Put in the 10mm calibration cube file.

Seems like pronterface isn´t configured yet for a delta printer?

See attached picture and choose values to match your printer.

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 05:53AM |

Registered: 8 years ago Posts: 255 |

Quote

nebbian

Quote

hacker

Actually, now that I think of it I have only one question — after connecting motors according to instructions (blue-red-green-black IIRC) I had to invert steppers direction in the firmware. Is that me or is it what you also experienced?

Yep. I couldn't spin my connectors around as they would only fit one way on one of the outputs (Z maybe?) that had two rows of pins. So I did it in the firmware which worked fine.

Thanks for the repetier config, I downloaded it a couple of days ago and will be trying it out soon.

I feel stupid now. I looked at the big connectors and immediately thought that they're surely not for this board so I cut them off without even trying ;-) So I *could* connect motors other way, but as I said I was determined to build as much *this* kit as possible, so I connected according to the manual (the mostly plagiarised one, yes

). And yes, it seems to be the way connectors are wired.

). And yes, it seems to be the way connectors are wired.I later found out I forgot to enable heated bed in repetier, but that's a start anyway, for anyone who wants to fiddle with it.

Now I got clogged nozzle, presumably because of this heatbreak configuration. But since I'm done with trying to stick to sintron's idea of the printer, it' about time to change to the e3d lite that I have lying around. At least it will prettify the fan assembly ;-)

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 05:57AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

At the final pages of the sintron pdf. Load file into pronterface. So I Put in the 10mm calibration cube file. Heatbed is 95 deg. Extruder is 230 deg. HIT PRINT and the nozzle starts to do G28 but then the tip goes to 0, 0, 0 and shuts off the fans. It shuts it all down. The heatbed goes down in temp. The extruder goes down in temp. BUT the arduino, LCD, and Ramps are still on? I dont know what happened. I asked sintron for help and they want me to video tape what is happening. Email it to them before they respond?

To me that sounds pretty much like job is finished. Maybe slicer generated no g-code? I remember I had similar surprise when tried to print thin walls piece with 0.6 nozzle and since the walls were too thin, slic3r simply left g-code pretty much empty. But 10mm cube sounds like something solid… At any rate, probably pronterface has some indication of what it's doing?

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 11:43AM |

Registered: 8 years ago Posts: 319 |

So I have a fan on the F1 polyfuse and the polyfuse doesnt heat up that much. I checked the inline automotive fuse and its intact. I checked my pronterface and you are right. It was a square printbed. So I adjusted the values to be a round bed. Now it looks great on pronterface. But When I load the test cube the cube is off the plate bed in space. So then I went to plate building tool and hit CENTER. Now the cube is in the center. Im warming the heatbed and extruder now. I have the extruder fan going and a fan blowing on the F1 polyfuse. We will see what happens when I hit PRINT

Upate? The extruder goes to top to HOME but then starts to crash into the endstops at the top over and over. So I hit the kill switch? Any ideas?

Edited 1 time(s). Last edit at 09/29/2015 12:17PM by DRTak.

Upate? The extruder goes to top to HOME but then starts to crash into the endstops at the top over and over. So I hit the kill switch? Any ideas?

Edited 1 time(s). Last edit at 09/29/2015 12:17PM by DRTak.

Sorry, only registered users may post in this forum.