Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 01:16PM |

Registered: 9 years ago Posts: 67 |

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 01:17PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Upate? The extruder goes to top to HOME but then starts to crash into the endstops at the top over and over. So I hit the kill switch? Any ideas?

It is easier to make sense of the behaviour if you correlate it with the commands sent to printer. Do you see what G-code pronterface sends? I hardly ever use pronterface, so I don't remember whether it shows g-code (besides I'm on the mac), but if it doesn't maybe you should try something like repetier-host?

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 01:36PM |

Registered: 8 years ago Posts: 319 |

tempgcode/2342.gcode, 2544 lines

436.68mm of filament used in this print

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

Estimated duration: 33 layers, 0:08:17

I dont see any G28 or G29 in there?

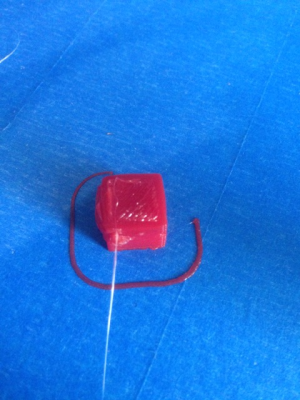

attached a picture of where I am at and the gcode for the cube.

Also downloading repetier host right now

Updated. Newest repetier host installed. I noted that the gcode i had involved M107? which shut all of my fans off when using pronterface? Found the edit G code button on repetier and edited out the M107 and replaced with M106. Saved the file.

One more thing. does anyone have the setup info for the Sintron Kossel Mini using repetier firmware. Right now I am using Marlin Delta 2? And James at Sintron told me NOT to use Arduino 1.6.5 but go back to stable 1.0.5 and use marlin firmware so that is what I am using

Next I tried G28 using repetier host and the Y axis crashed into the sidewall? It now says Echo: enstop hit: X: 0.64. Did a check and the motor wires got loose. So reattached them and G28 and G29 work.

Edited 8 time(s). Last edit at 09/29/2015 03:34PM by DRTak.

436.68mm of filament used in this print

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

Estimated duration: 33 layers, 0:08:17

I dont see any G28 or G29 in there?

attached a picture of where I am at and the gcode for the cube.

Also downloading repetier host right now

Updated. Newest repetier host installed. I noted that the gcode i had involved M107? which shut all of my fans off when using pronterface? Found the edit G code button on repetier and edited out the M107 and replaced with M106. Saved the file.

One more thing. does anyone have the setup info for the Sintron Kossel Mini using repetier firmware. Right now I am using Marlin Delta 2? And James at Sintron told me NOT to use Arduino 1.6.5 but go back to stable 1.0.5 and use marlin firmware so that is what I am using

Next I tried G28 using repetier host and the Y axis crashed into the sidewall? It now says Echo: enstop hit: X: 0.64. Did a check and the motor wires got loose. So reattached them and G28 and G29 work.

Edited 8 time(s). Last edit at 09/29/2015 03:34PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 03:38PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

tempgcode/2342.gcode, 2544 lines

436.68mm of filament used in this print

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

Estimated duration: 33 layers, 0:08:17

I dont see any G28 or G29 in there?

attached a picture of where I am at and the gcode for the cube.

Also downloading repetier host right now

Updated. Newest repetier host installed. I noted that the gcode i had involved M107? which shut all of my fans off when using pronterface? Found the edit G code button on repetier and edited out the M107 and replaced with M106. Saved the file.

One more thing. does anyone have the setup info for the Sintron Kossel Mini using repetier firmware. Right now I am using Marlin Delta 2? And James at Sintron told me NOT to use Arduino 1.6.5 but go back to stable 1.0.5 so that is what I am using

Next I tried G28 using repetier host and the Y axis crashed into the sidewall? It now says Echo: enstop hit: X: 0.64. Did the software invert the wiring?

Most likely the M107 comes from your start G-code. It sounds like not so bad an idea to shut down the fan when heating extruder, besides, print setup often keeps fan off for the first layer. BUT! This is about object cooler, NOT the fan you have in sintron kit which is for cooling heatsink. The instructions seem to imply you want to control this fan from G-code, which is what you probably don't want. Instead you want to keep it always on and connect it to the power source directly.

You need arduino 1.0.x to compile Marlin they supply you with. Modern Marlin works with modern Arduino. But I haven't got as far as getting it reasonably working yet. A few posts above I attached my configuration for repetier firmware. You can start from that, but keep in mind that A. my dimensions, especially error corrections may differ from yours, B. my steppers have inverted direction, which may or may not be the case with yours. C. I forgot to turn on heated bed in the config, but since I refrained from modifying .h directly and kept it in sync with .json, you can just use my .json as a start for their configurator on the web, so that shouldn't be too hard to adjust.

You g-code seems to be alright, except for maybe 0.4 first layer is a bit too much, but you can deal with it later. It should home, perform autoleveling (never quite worked for me yet) and then sit and wait for extruder to heat before starting to print…

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 03:59PM |

Registered: 8 years ago Posts: 319 |

Thanks so much for the reply. I have been testing over and over and calibration is done. I have found that it homes great and goes back to zero. I will try and test and see if I can now run the system with the fans ON and it will hopefully extrude instead of shutting the whole system down. And more lately, after I hit print. It crashes into the sidewall? And I have to hit the KIll switch on the LCD screen. Thanks for your files.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 03:59PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 06:53PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Thanks so much for the reply. I have been testing over and over and calibration is done. I have found that it homes great and goes back to zero. I will try and test and see if I can now run the system with the fans ON and it will hopefully extrude instead of shutting the whole system down. And more lately, after I hit print. It crashes into the sidewall? And I have to hit the KIll switch on the LCD screen. Thanks for your files.

Immediately? Or after heating 40mm above the floor? With this g-code, you mean, right? That sounds like something's badly wrong with firmware configuration, though I don't think I have a good idea what could that be… Do you use the firmware they supplied with their configuration? Something "Marline-deltabot something sintron something" (don't remember the name)?

As a sidenote… If you try repetier I think you better don't try autoprobing, it didn't do me any good and it may bend your z-probe, because as far as I can tell it first goes down with extruder at the target point and then offsets the extruder so that probe is there. I didn't exactly like this behaviour…

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 09:51PM |

Registered: 9 years ago Posts: 67 |

M119 is not calibrating anything. It just shows the current state of the endstopps. Not working endstops are the most common reason for crashes during the setup phase.

If you screenshot shows your current calibration, you are still far off. Without ABL you need to be far better then a laierheight. With ABL ~ i'd recomend better then a 1mm. You have more then 4.6mm.

Edited 1 time(s). Last edit at 09/29/2015 09:52PM by AnHardt.

If you screenshot shows your current calibration, you are still far off. Without ABL you need to be far better then a laierheight. With ABL ~ i'd recomend better then a 1mm. You have more then 4.6mm.

Edited 1 time(s). Last edit at 09/29/2015 09:52PM by AnHardt.

|

Re: Ebay SINTRON Kossel Mini full kit September 29, 2015 11:06PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 04:10AM |

Registered: 8 years ago Posts: 14 |

Did you calibrate the printer manually first before using the z-probe? Try calibrating manually and not using z-probe and see if that works (the Marlin firmware will 'forget' the z-probe settings everytime a home command (G28) is set). The gcode generated by slic3r puts a G28 command in, but probably doesn't have the z-probe command in it (which you have to manually add if you're using the z-probe).

(btw, my preview model is offset when loaded into pronterface, but prints out correctly in the center of the plate). I'll have to double check later, but I think my offset is set to 0,0,0 in slic3r.

(btw, my preview model is offset when loaded into pronterface, but prints out correctly in the center of the plate). I'll have to double check later, but I think my offset is set to 0,0,0 in slic3r.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 05:06AM |

Registered: 8 years ago Posts: 255 |

Quote

squall

Did you calibrate the printer manually first before using the z-probe? Try calibrating manually and not using z-probe and see if that works (the Marlin firmware will 'forget' the z-probe settings everytime a home command (G28) is set). The gcode generated by slic3r puts a G28 command in, but probably doesn't have the z-probe command in it (which you have to manually add if you're using the z-probe).

(btw, my preview model is offset when loaded into pronterface, but prints out correctly in the center of the plate). I'll have to double check later, but I think my offset is set to 0,0,0 in slic3r.

IIRC, the g-code has G29 after G28, probably in that same start code (I don't think slic3r puts G28, it's usually a part of start gcode). I also don't think miscalibration would explain crashing in the side wall. That is, if I properly picture what it means. Because there are no walls after all ;-)

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:16AM |

Registered: 8 years ago Posts: 14 |

Somehow missed page 8 of this thread :/

Your pronterface output definitely looks wrong:

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

The center of the bed should be at 0, 0, 0.

An X/Y of 111.71mm is just past the edge of the bed which is why you see it hitting the invisible wall.

You can try manually setting a move command to those co-ords and you'll probably see the same behaviour.

My pronterface output is:

The print goes:

- from -11.89mm to 11.89mm in X and is 23.78mm wide

...

I would play around with the slic3r to make sure that is correct first.

Your pronterface output definitely looks wrong:

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

The center of the bed should be at 0, 0, 0.

An X/Y of 111.71mm is just past the edge of the bed which is why you see it hitting the invisible wall.

You can try manually setting a move command to those co-ords and you'll probably see the same behaviour.

My pronterface output is:

The print goes:

- from -11.89mm to 11.89mm in X and is 23.78mm wide

...

I would play around with the slic3r to make sure that is correct first.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:28AM |

Registered: 8 years ago Posts: 255 |

Quote

squall

Somehow missed page 8 of this thread :/

Your pronterface output definitely looks wrong:

The print goes:

- from 88.29 mm to 111.71 mm in X and is 23.43 mm wide

- from 88.29 mm to 111.71 mm in Y and is 23.43 mm deep

- from 0.00 mm to 10.00 mm in Z and is 10.00 mm high

The center of the bed should be at 0, 0, 0.

An X/Y of 111.71mm is just past the edge of the bed which is why you see it hitting the invisible wall.

You can try manually setting a move command to those co-ords and you'll probably see the same behaviour.

My pronterface output is:

The print goes:

- from -11.89mm to 11.89mm in X and is 23.78mm wide

...

I would play around with the slic3r to make sure that is correct first.

Where did you get those numbers? Going to 111 would actually explain why the sideway crash, but I don't see these numbers?

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:39AM |

Registered: 8 years ago Posts: 14 |

The numbers were from the pronterface output he posted.

I think you're right that the gcode is correct as I just loaded the one he posted and it shows the correct values:

-11.71mm to 11.71mm in X and is 23.43 mm wide

This means it's probably his pronterface settings that are wrong (maybe when he tried to correct the preview to be centered).

I'm not sure if other peoples previews in pronterface are offset, but mine definitely are, but the values print out correctly.

I think you're right that the gcode is correct as I just loaded the one he posted and it shows the correct values:

-11.71mm to 11.71mm in X and is 23.43 mm wide

This means it's probably his pronterface settings that are wrong (maybe when he tried to correct the preview to be centered).

I'm not sure if other peoples previews in pronterface are offset, but mine definitely are, but the values print out correctly.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:51AM |

Registered: 8 years ago Posts: 255 |

Quote

squall

The numbers were from the pronterface output he posted.

I think you're right that the gcode is correct as I just loaded the one he posted and it shows the correct values:

-11.71mm to 11.71mm in X and is 23.43 mm wide

This means it's probably his pronterface settings that are wrong (maybe when he tried to correct the preview to be centered).

I'm not sure if other peoples previews in pronterface are offset, but mine definitely are, but the values print out correctly.

Oh, as I didn't really know what should pronterface print (as I said I'm on mac which has things different and even there I rarely use pronterface), so I mostly skipped that… G-Code is right, so yes, maybe pronterface setup…

I even went as far as printing this g-code (after all printers are quite similar).

(why is one side blobby is another question, but I've just changed the hotend to e3d lite, perhaps it's tilted or something).

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 02:13PM |

Registered: 8 years ago Posts: 319 |

I dont know which is better. Your cube or mine. I finally got it to work. Thanks all for your help. My 1st test cube didnt turn out that well since the ABS spools snapped during the early part of the print. So I quickly fixed it and hand fed the line again. Thus there is a large gap in the cube.

2nd print. Not pictured. The Kapton tape tore off from my z probe not being fully retracted. So the Kapton tape was imbedded into the cube.

3rd print on the black background not so bad. I got the bed temp to 86deg and the extruder to 224 deg then it started to print after the temp jumped to 230deg and back to 224deg and activated the print mode. But as you guys have anylzyed my gcode. The cube is 11.7mm wide on one side and 12mm wide on the other side? UGH. Have no idea how to calibrate to get it down to 10mm.

Now I just have to fine tune it which I dont know how to do. HAHAHA

Edited 1 time(s). Last edit at 09/30/2015 03:10PM by DRTak.

2nd print. Not pictured. The Kapton tape tore off from my z probe not being fully retracted. So the Kapton tape was imbedded into the cube.

3rd print on the black background not so bad. I got the bed temp to 86deg and the extruder to 224 deg then it started to print after the temp jumped to 230deg and back to 224deg and activated the print mode. But as you guys have anylzyed my gcode. The cube is 11.7mm wide on one side and 12mm wide on the other side? UGH. Have no idea how to calibrate to get it down to 10mm.

Now I just have to fine tune it which I dont know how to do. HAHAHA

Edited 1 time(s). Last edit at 09/30/2015 03:10PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 03:09PM |

Registered: 8 years ago Posts: 89 |

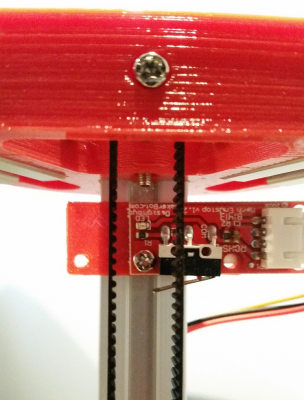

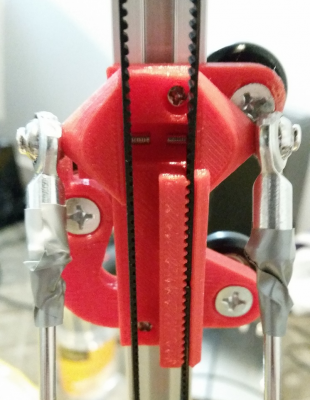

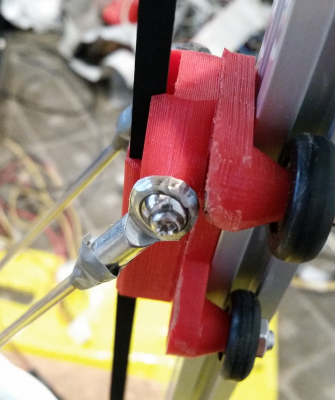

Can someone with a working kit post closeups of their carriages? I have some doubts and questions about them...

1: I just need to cut off the belt where the 2 sides meet inside the carriage?

2: As shown on the attached picture, the place where the belt locks in the carriage is about 2-3 mm more sunken towards the extrusion then the free-running belt is. Is it OK like this, or should i adjust the pulley on my axis motors and the bearings on the top corners to position the free belt exactly next to the "locked" belt?

[imgur.com]

3: how much tension is needed on the belts? i can adjust it a bit with the belt tensioners on the top corners (had to improvise to create those), but not much...

BTW: what was the person that designed the plastic insulators for the endstop smoking when he thought "this is where the middle hole should go"...? they are completely useless!

1: I just need to cut off the belt where the 2 sides meet inside the carriage?

2: As shown on the attached picture, the place where the belt locks in the carriage is about 2-3 mm more sunken towards the extrusion then the free-running belt is. Is it OK like this, or should i adjust the pulley on my axis motors and the bearings on the top corners to position the free belt exactly next to the "locked" belt?

[imgur.com]

3: how much tension is needed on the belts? i can adjust it a bit with the belt tensioners on the top corners (had to improvise to create those), but not much...

BTW: what was the person that designed the plastic insulators for the endstop smoking when he thought "this is where the middle hole should go"...? they are completely useless!

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 03:32PM |

Registered: 8 years ago Posts: 319 |

Here is a picture of my carriage but I am a noob. Whatever you do do not cut it too short. Mine looks short because Sintrons pdf is old and wrong. You dont need the tensioner on top anymore. I didnt know this so I cut mine too short. Then I pushed the top triangle to the end of the aluminum. And luckily I was able to squeeze the belt to barely work. I would suggest a lot of tension. Otherwise your system will snap like mine when it is loose. It makes a snap snap sound as the belt slips off the motor.

Next, I am too cheap and I am using their metal rods. I need to dremel them down so they dont bind. But the binding is an issue. It messes up calibration 1/2 of the time.

Edited 1 time(s). Last edit at 09/30/2015 05:05PM by DRTak.

Next, I am too cheap and I am using their metal rods. I need to dremel them down so they dont bind. But the binding is an issue. It messes up calibration 1/2 of the time.

Edited 1 time(s). Last edit at 09/30/2015 05:05PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 05:12PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

I dont know which is better. Your cube or mine. I finally got it to work. Thanks all for your help. My 1st test cube didnt turn out that well since the ABS spools snapped during the early part of the print. So I quickly fixed it and hand fed the line again. Thus there is a large gap in the cube.

2nd print. Not pictured. The Kapton tape tore off from my z probe not being fully retracted. So the Kapton tape was imbedded into the cube.

3rd print on the black background not so bad. I got the bed temp to 86deg and the extruder to 224 deg then it started to print after the temp jumped to 230deg and back to 224deg and activated the print mode. But as you guys have anylzyed my gcode. The cube is 11.7mm wide on one side and 12mm wide on the other side? UGH. Have no idea how to calibrate to get it down to 10mm.

Now I just have to fine tune it which I dont know how to do. HAHAHA

Don't know if one is better, but as long as we're not taking part in cube beauty contest it doesn't matter much ;-) The important thing is that you have one. Congrats on the successful print! Was that pronterface something?

I'd start calibrating with measuring dimensions (primarily diagonal rod lengths) and comparing to what you have in firmware. But I'd rather not give advice as I haven't calibrated mine due to the lack of time and haven't even checked dimensions of that cube ;-)

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 05:24PM |

Registered: 8 years ago Posts: 255 |

Quote

Tha_Reaper

Can someone with a working kit post closeups of their carriages? I have some doubts and questions about them...

1: I just need to cut off the belt where the 2 sides meet inside the carriage?

2: As shown on the attached picture, the place where the belt locks in the carriage is about 2-3 mm more sunken towards the extrusion then the free-running belt is. Is it OK like this, or should i adjust the pulley on my axis motors and the bearings on the top corners to position the free belt exactly next to the "locked" belt?

[imgur.com]

3: how much tension is needed on the belts? i can adjust it a bit with the belt tensioners on the top corners (had to improvise to create those), but not much...

BTW: what was the person that designed the plastic insulators for the endstop smoking when he thought "this is where the middle hole should go"...? they are completely useless!

I can't take a picture right now, but it looks pretty much like DRTak's one except the belt ends are closer to each other (on one carriage even touching).

1. I believe yes.

2. I think you should add a nut on the other side of the idler on top and depending on where your motor pulley is move that one too. Being a lazy one I haven't done that yet, so it looks pretty much like yours ;-) I have no idea if it has a perceivable impact on the print…

3. Not sure about the exact pitch, but I believe you should be able to pluck it as a bass string. Perhaps I should check the pitch using some smartphone tuner ;-)

The insulators are alright in terms of usability, maybe you need to flip it, you don't need all holes, but I had a good laugh too ;-)

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:05PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

Tha_Reaper

Can someone with a working kit post closeups of their carriages? I have some doubts and questions about them...

1: I just need to cut off the belt where the 2 sides meet inside the carriage?

2: As shown on the attached picture, the place where the belt locks in the carriage is about 2-3 mm more sunken towards the extrusion then the free-running belt is. Is it OK like this, or should i adjust the pulley on my axis motors and the bearings on the top corners to position the free belt exactly next to the "locked" belt?

[imgur.com]

3: how much tension is needed on the belts? i can adjust it a bit with the belt tensioners on the top corners (had to improvise to create those), but not much...

BTW: what was the person that designed the plastic insulators for the endstop smoking when he thought "this is where the middle hole should go"...? they are completely useless!

I can't take a picture right now, but it looks pretty much like DRTak's one except the belt ends are closer to each other (on one carriage even touching).

1. I believe yes.

2. I think you should add a nut on the other side of the idler on top and depending on where your motor pulley is move that one too. Being a lazy one I haven't done that yet, so it looks pretty much like yours ;-) I have no idea if it has a perceivable impact on the print…

3. Not sure about the exact pitch, but I believe you should be able to pluck it as a bass string. Perhaps I should check the pitch using some smartphone tuner ;-)

The insulators are alright in terms of usability, maybe you need to flip it, you don't need all holes, but I had a good laugh too ;-)

A bass string tension sounds about right. When you pluck it, it wobbles a bit but feels stiff. The insulators I use. But I would like to print the ones listed on this page since they look more rugged.

I am taking apart my rods right now. I am filing them down so they dont bind. I also noted that if you tighten them down enough, the screw head fits in the universal joint and centers it. So the 3mm into a 4mm hole idea (which is bad) is minimized so I think.

My kids found out that I got the printer working and now they want a barbie sized tennis racquet and a Lego sniper rifle. I said Im still testing.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 06:38PM |

Registered: 8 years ago Posts: 14 |

@DrTak

You'll first need to make sure you diagonal rod length matches up with the values in the firmware.

If they do, you'll probably need to adjust motor steps and recalibrate again.

You should also check that your tower is fully parallel and at correct 60degrees angles to each other (I just printed out a 60deg triangle onto some paper and made sure the towers matched perfectly)

@Tha_Reaper

1. I cut mine off so they meet right at the center so you get the best grip.

2. It's better for the belts to be parallel to each other. My pulleys at the top, the motor and the carriage belts should all line up.

3. They should be no slop on the belts. When moving, they shouldn't wobble at all.

Here's some pictures of my carriage and endpoint. I probably have the ugliest ones here lol .

.

I pretty muched used all Sintron parts apart from a few odds and ends. I had to dremel my rods (all twelve of them! ), but there's no binding on any of the rods after that)

), but there's no binding on any of the rods after that)

I installed their endpoint plastic thing differently to provide better grip.

You'll first need to make sure you diagonal rod length matches up with the values in the firmware.

If they do, you'll probably need to adjust motor steps and recalibrate again.

You should also check that your tower is fully parallel and at correct 60degrees angles to each other (I just printed out a 60deg triangle onto some paper and made sure the towers matched perfectly)

@Tha_Reaper

1. I cut mine off so they meet right at the center so you get the best grip.

2. It's better for the belts to be parallel to each other. My pulleys at the top, the motor and the carriage belts should all line up.

3. They should be no slop on the belts. When moving, they shouldn't wobble at all.

Here's some pictures of my carriage and endpoint. I probably have the ugliest ones here lol

.

.I pretty muched used all Sintron parts apart from a few odds and ends. I had to dremel my rods (all twelve of them!

), but there's no binding on any of the rods after that)

), but there's no binding on any of the rods after that)I installed their endpoint plastic thing differently to provide better grip.

|

Re: Ebay SINTRON Kossel Mini full kit September 30, 2015 08:24PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 04:15AM |

Registered: 8 years ago Posts: 89 |

you can push wire in the outside of the extrusions and tape over them. There they are out of sight, and dont interfere with the rollers. You can bundle the wires from the hotend as much as you can with tie-rips. and lead them to the side.All the other things... push it as much under the bed as you can. Or print seperate enclosures. Thats how ive seen most people do it.Quote

DRTak

But in the interim, how do you hide the wires to make this look pretty. I had friend come over and he was NOT impressed. He had this look like it looks like a rats nest.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 11:40AM |

Registered: 8 years ago Posts: 197 |

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 12:07PM |

Registered: 8 years ago Posts: 319 |

Quote

xile6

Just a tip for those with the melted looking cubes.

I had this problem on pla with my micromake.

Its due to not having a cooling fan on the nozzle while printing.

try aiming a fan at the bed while printing and see if it improves.

OK. I will do that. I was worried the bed would get too cold and there would be bad adhesion. Im using abs.

also THA_Reaper. Thanks. Ill try to tuck all the wires away. I would really like to put the RAMPS and arudino under the heatbed but its a tight fit given the the LCD cables are so high. But that other post thats how the guy did it.

I just spent 3 hrs with a angle grinder trimming metal off the rods. I attached them to the extruder plate. NO binding. Totally worth it. But now I have to recalibrate.

Edited 1 time(s). Last edit at 10/01/2015 12:27PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 01:22PM |

Registered: 10 years ago Posts: 14,672 |

I published some printable cable tidies to manage the homing switch wires running down the towers of a Kossel here [www.thingiverse.com]. I run them all down the back of the Z tower.

Edited 1 time(s). Last edit at 10/01/2015 01:22PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 10/01/2015 01:22PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 03:15PM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

I published some printable cable tidies to manage the homing switch wires running down the towers of a Kossel here [www.thingiverse.com]. I run them all down the back of the Z tower.

Thats what I was looking for thanks. Im not at the point where I can print anything correctly. I bought a whole spool of ABS. But I think I am too noobish for that. All the files on thinigverse appear to be for PLA? I think Ill get some PLA to play with.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 03:51PM |

Registered: 10 years ago Posts: 14,672 |

PLA is easier to print than ABS, so it makes sense to gain experience with PLA before progressing to more difficult plastics.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 04:33PM |

Registered: 8 years ago Posts: 89 |

thanks for the pictures. They help a lot. I cut the belts, and i've decided to adjust the pulley and the top corners later.

I just installed the endstops with the endstop brackets from the second page of this topic. they fit, but there is a little problem that you cant get to the screw to move the endstop up and down without physicly removing the endstop first. Ive tried to measure it out so that they are in the same spot, but that will probably be off by a mm or so. do they need to be at the exact same hight?

Also i have 6 endstops in my kit... i know where to place 3 of them, but why do i need 6?! Everyone got 6?

I have build a little blog by the way about the building progress. [kosselreprap.blogspot.be]

Not much usefull info there, but for people that want to start building maybe a good place to check for what to expect.

Edited 1 time(s). Last edit at 10/01/2015 04:37PM by Tha_Reaper.

I just installed the endstops with the endstop brackets from the second page of this topic. they fit, but there is a little problem that you cant get to the screw to move the endstop up and down without physicly removing the endstop first. Ive tried to measure it out so that they are in the same spot, but that will probably be off by a mm or so. do they need to be at the exact same hight?

Also i have 6 endstops in my kit... i know where to place 3 of them, but why do i need 6?! Everyone got 6?

I have build a little blog by the way about the building progress. [kosselreprap.blogspot.be]

Not much usefull info there, but for people that want to start building maybe a good place to check for what to expect.

Edited 1 time(s). Last edit at 10/01/2015 04:37PM by Tha_Reaper.

Sorry, only registered users may post in this forum.