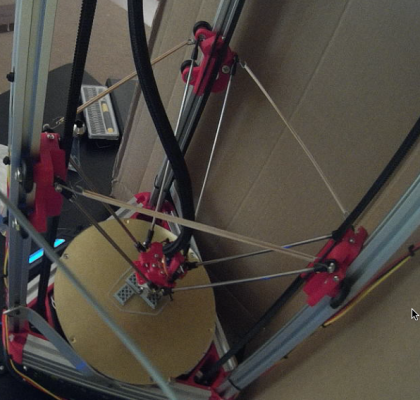

Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 10:37AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Quote

Tha_Reaper

How did everyone fix/clip/screw his printbed to the structure?

EDIT: And i'm a little confused by the printhead assembly and how its supposed to fit onto the effector. the manual just seems to skip that whole part.

Well I learned a lesson on this topic. I emailed Sintron and they sent me a pic and it is not what everyone else is showing.

[www.dropbox.com]

[www.dropbox.com]

[www.dropbox.com]

I first listened to what they said and I put it in as pictured. And the z probe works. Well I noticed that if you did it the way they said the plate that holds the hotend does not sit flush with the effector plate. So I did what everyone else did and dremel ou the U shaped part. BAD idea. Now the z probe when retracted does not go up high enough and still hits the heat bed. So I reversed the work I did and put it on as the pictures show above even though the surfaces DO not mate very well.

I also emailed them about this problem and they were saying one thing, picturing the other, then reversed to saying that yes, what they meant is as pictured, that is not flush with effector, but now they recommend to put it the other way… Since by now I've installed the e3d lite hotend that was lying around it doesn't matter much anymore, since I just cut off that fan mount and happily use fan sitting on the hotend.

But I don't see how can it possibly affect z-probe — I think the retainer part isn't even there, where z-probe is. Or at least it doesn't have to be there.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 11:03AM |

Registered: 8 years ago Posts: 319 |

Still calibrating. I changed my DEFAULT_AXIS_STEPS_PER_UNIT back to 80 for x y and z. Re calibrated. Then used the info on that delta printer calibration site and changed my DELTA_DIAGONAL_ROD_LENGTH. So I increased this value of diagn rod which is supposed to decrease the size of the object.

Results. Now my cube is exactly 10mm in height. But the x and y are still 10.5mm in size? So I made a rectangle. Any ideas how to fix this?

Results. Now my cube is exactly 10mm in height. But the x and y are still 10.5mm in size? So I made a rectangle. Any ideas how to fix this?

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 11:26AM |

Registered: 8 years ago Posts: 916 |

Quote

Tha_Reaper

found that picture, but mine looks like this: [www.dropbox.com]Quote

nebbian

The hotend just slides into the effector... but you do need to remove some material with a dremel. I think I posted a picture on page 3 or thereabouts.

Its kind of snug without the dremel work. would this also work, or does it needs to sit below that ridge?

And after that? i just use 6 screws to scre it to the effector, attach the fan, and the z-probe?

your bed leveling system sounds nice, but i have trouble picturing where the loctite comes into place... do you have pictures or a schematic?

If it works, it works I guess. Who knows if they changed the design of the effector between when they printed mine and when they printed yours. You've just got to experiment and do your own engineering to get it to work. Part of the fun of dealing with chinese manufacturers :-)

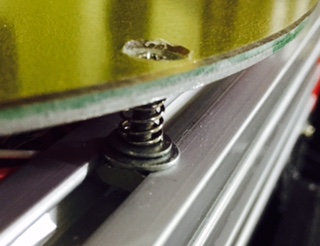

Here's a picture of the bed levelling system. Hopefully it's clear enough.

Regarding the calibration, I went through this as well. In the end you need to measure your diagonal rod length exactly, and just plug that number in. Then adjust the smooth rod offset so you get a flat print surface. I tried for days to tweak the diagonal rod length to get a dimensionally accurate print... and in the end I discovered that I was off because of extrusion width. Seriously save yourself the headache, measure your diagonal rod lengths and just plug that number in. Then stuff around with the smooth rod offset to get a flat surface... and then go print.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 11:41AM |

Registered: 8 years ago Posts: 916 |

Quote

DRTak

Thats exactly what I did. I was wondering why Sintron gave us 3 springs. So I made a bed which you can level and it has helped me a lot. I actually had to go to hardware store and buy bigger bolts and bigger springs. Now I can adjust the bed angle to match my hotend. Yes it is a bit tilted and its not related to concave or convex surface. For some reason my hotend likes to slide up the X axis at a 2deg angle evenly? SO I just adjusted my bed to NOT be level to the earth but level to the hotend.

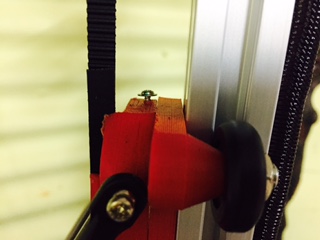

Sounds to me like your end stops aren't at the same distance from the bed when it's level.

The way to adjust this is:

1) Add a screw to each carriage so that you can adjust the endstop trigger position easily

2) Set your bed to be exactly 90 degrees to all the towers

3) Do the paper test at a position near each tower, and adjust the carriage screws until the Z value of the M114 command is exactly the same when you do the paper test near each tower.

If you continue with your printer set up with a tilted bed, then your parts will also have a 2 degree tilt.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 12:00PM |

Registered: 9 years ago Posts: 445 |

Quote

DRTak

Still calibrating. I changed my DEFAULT_AXIS_STEPS_PER_UNIT back to 80 for x y and z. Re calibrated. Then used the info on that delta printer calibration site and changed my DELTA_DIAGONAL_ROD_LENGTH. So I increased this value of diagn rod which is supposed to decrease the size of the object.

Results. Now my cube is exactly 10mm in height. But the x and y are still 10.5mm in size? So I made a rectangle. Any ideas how to fix this?

Yes, more corrections to the diagonal rods, see this: "Measured Length / Expected Length * DIAGONAL_ROD_LENGTH"

But it is better to print a bigger object to get the correct dimensions, I suggest this object that way you can also see if your towers are at the correct angles.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 03:48PM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Quote

DRTak

Thats exactly what I did. I was wondering why Sintron gave us 3 springs. So I made a bed which you can level and it has helped me a lot. I actually had to go to hardware store and buy bigger bolts and bigger springs. Now I can adjust the bed angle to match my hotend. Yes it is a bit tilted and its not related to concave or convex surface. For some reason my hotend likes to slide up the X axis at a 2deg angle evenly? SO I just adjusted my bed to NOT be level to the earth but level to the hotend.

Sounds to me like your end stops aren't at the same distance from the bed when it's level.

The way to adjust this is:

1) Add a screw to each carriage so that you can adjust the endstop trigger position easily

2) Set your bed to be exactly 90 degrees to all the towers

3) Do the paper test at a position near each tower, and adjust the carriage screws until the Z value of the M114 command is exactly the same when you do the paper test near each tower.

[attachment 63460 2015-10-03_carriage.jpg]

If you continue with your printer set up with a tilted bed, then your parts will also have a 2 degree tilt.

I noticed that my test cube was a little tilted so even at 10mm I can notice a tilt. So I read that calibration manual for delta printers and checked to see if my corner were true and found out that actually the Y axis sunk? Somehow the screw got loose and it sunk by 10mm. So I fixed it. Only to have it sink again once I put the belt on. So I put a screw and nut below the plastic top part to hold it in place better. I also DID put that screw on each carriage. That was a genius idea. I have each tower the same height now. Finally when I calibrate the hotend doesnt go up into space on the right side. It is nice and level. Thanks all for the help. Now Im waiting for PLA to arrive to do the fine calibration.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 03:49PM |

Registered: 8 years ago Posts: 319 |

Quote

Koenig

Quote

DRTak

Still calibrating. I changed my DEFAULT_AXIS_STEPS_PER_UNIT back to 80 for x y and z. Re calibrated. Then used the info on that delta printer calibration site and changed my DELTA_DIAGONAL_ROD_LENGTH. So I increased this value of diagn rod which is supposed to decrease the size of the object.

Results. Now my cube is exactly 10mm in height. But the x and y are still 10.5mm in size? So I made a rectangle. Any ideas how to fix this?

Yes, more corrections to the diagonal rods, see this: "Measured Length / Expected Length * DIAGONAL_ROD_LENGTH"

But it is better to print a bigger object to get the correct dimensions, I suggest this object that way you can also see if your towers are at the correct angles.

I just ordered some PLA to do that test calibration part. So that will take a week to get to me even though its from a USA seller on ebay.

ORIGINAL ISSUE: Until then I have a new issue. I noticed that if I HOME and then bring the nozzle to the hotplate center. It is spot on with the z height. However, when I hit HOME and then type G29. The nozzle at its center is -0.7mm. In other words. The nozzle is ramming into the bed thinking it can go another .7mm down? Any ideas?

FIX: I trolled through multiple forums. G28 and G29 do NOT correlate well. So I am going to ignore the Z height difference between the 2. I adjusted this value: void retract_z_probe() { Where it says current position. I raised it to +40 from +20. Now all is good. NO more z probe crashing into my bed and scratching it.

I also figured out that with Repetier I can use the SCALE OBJECT button and it works great.

FIXED: From my other posts. I had issues with poor adhesion of my prints. Turns out I had a nozzle JAM. So I fixed that and now printing is great.

Edited 4 time(s). Last edit at 10/05/2015 09:56AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 07, 2015 09:14AM |

Registered: 8 years ago Posts: 255 |

Quote

o_lampe

@nebbian Sorry for OT, but could you put the sloppy Traxxas joints in cooking water for 10mins. and let them cool down in it?

We used to do that with all plastic parts back in RC-Car days...

I´d like to know, if the slop is gone by the treatment..

THX

-Olaf

I ordered two sets and some 5-6 turned out sloppy. Treatment fixed approximately half them.Three are still sloppy.

|

Re: Ebay SINTRON Kossel Mini full kit October 08, 2015 03:54AM |

Registered: 8 years ago Posts: 5,232 |

Quote

hacker

Quote

o_lampe

@nebbian Sorry for OT, but could you put the sloppy Traxxas joints in cooking water for 10mins. and let them cool down in it?

We used to do that with all plastic parts back in RC-Car days...

I´d like to know, if the slop is gone by the treatment..

THX

-Olaf

I ordered two sets and some 5-6 turned out sloppy. Treatment fixed approximately half them.Three are still sloppy.

Thanks for the feedback

I must've been lucky, all my Traxxas joints are perfect. But time will tell...

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit October 08, 2015 05:52AM |

Registered: 8 years ago Posts: 255 |

Quote

o_lampe

Quote

hacker

Quote

o_lampe

@nebbian Sorry for OT, but could you put the sloppy Traxxas joints in cooking water for 10mins. and let them cool down in it?

We used to do that with all plastic parts back in RC-Car days...

I´d like to know, if the slop is gone by the treatment..

THX

-Olaf

I ordered two sets and some 5-6 turned out sloppy. Treatment fixed approximately half them.Three are still sloppy.

Thanks for the feedback

I must've been lucky, all my Traxxas joints are perfect. But time will tell...

-Olaf

I'm not so lucky, three of my original (sintron's) ends won't get off of rods

|

Re: Ebay SINTRON Kossel Mini full kit October 10, 2015 12:04PM |

Registered: 8 years ago Posts: 89 |

I'm having trouble with the z-probe. the probe is so close to the heatsink, that the plastic block that keeps the spring in place is rubbing against the heatsink, blocking movement of the probe.

[www.dropbox.com]

There is another place where i can place the probe, further from the nozzle... seems more inaccurate if i place it there...?

[www.dropbox.com]

[www.dropbox.com]

There is another place where i can place the probe, further from the nozzle... seems more inaccurate if i place it there...?

[www.dropbox.com]

|

Re: Ebay SINTRON Kossel Mini full kit October 10, 2015 12:12PM |

Registered: 8 years ago Posts: 255 |

Quote

Tha_Reaper

I'm having trouble with the z-probe. the probe is so close to the heatsink, that the plastic block that keeps the spring in place is rubbing against the heatsink, blocking movement of the probe.

[www.dropbox.com]

There is another place where i can place the probe, further from the nozzle... seems more inaccurate if i place it there...?

[www.dropbox.com]

I haven't made Z-probe work at all yet, but I think maybe you want to go nebbian's way — [forums.reprap.org]

I also consider something like this — [www.thingiverse.com] — but obviously you need to be able to print first…

|

Re: Ebay SINTRON Kossel Mini full kit October 10, 2015 12:35PM |

Registered: 8 years ago Posts: 89 |

|

Re: Ebay SINTRON Kossel Mini full kit October 10, 2015 04:40PM |

Registered: 8 years ago Posts: 255 |

Quote

Tha_Reaper

Just found nebbiqns post on page 3. i'll try that for sure. Thanks!

And i can print. i have a second (crappy) printer. its just not accurate...

Then maybe that's also an option. And indeed it looks like when trying to assemble this kit you better have another printer ;-)

I'm printing out this probe holder now (and doing it on this printer, not my prusa i3 ;-)). In my case it's kinda mandatary because I already mounted my e3d lite hotend instead of the original, so I can't possibly use the original probe.

|

Re: Ebay SINTRON Kossel Mini full kit October 11, 2015 05:50PM |

Registered: 8 years ago Posts: 255 |

Quote

nebbian

It turns out that the heated bed draws more current than the polyfuse can handle. There is an easy fix, just reduce the duty cycle of the bed in the software:

#define MAX_BED_POWER 128 // limits duty cycle to bed; 255=full current

Setting it to half power seems to work just fine, and it easily got to 60 degrees which is perfect for PLA. I'm now printing a part with no lifted corners, whereas the same model yesterday had badly lifted corners with no bed heating.

I'm happy with this solution. Much better than an underpowered bed

Got this problem, cooling the fuse seems to do the trick for now, consider either replacing the fuse or going for your solution now. A bit reluctant to recompile the firmware now… On the other head I'm equally reluctant to change the fuse ;-)

|

Re: Ebay SINTRON Kossel Mini full kit October 12, 2015 05:23PM |

Registered: 8 years ago Posts: 104 |

Fuf... Soldering the heatbed is real pain. I do not have a powerful soldering station or whatever, just small regular soldering iron. And even on full power it sticks to pads, so good aluminum table goes heat away. But I did a trick: I soldered wires somehow, and then powered heatbed for a couple minutes, so it heated itself. Then I re-soldered wires. It's much easier to get semi-good joints if heatbed is warm.

|

Re: Ebay SINTRON Kossel Mini full kit October 12, 2015 09:45PM |

Registered: 8 years ago Posts: 3 |

|

Re: Ebay SINTRON Kossel Mini full kit October 13, 2015 10:13AM |

Registered: 9 years ago Posts: 67 |

|

Re: Ebay SINTRON Kossel Mini full kit October 15, 2015 08:35PM |

Registered: 11 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit October 15, 2015 09:06PM |

Registered: 8 years ago Posts: 916 |

Quote

kingoddball

Does anyone have the arm length and radius for sintron metal + traxxas ends?

Trying to configure a firmware but not at home right now.

arm_length 196.8 # this is the length of an arm from hinge to hinge

arm_radius 101.9 # this is the horizontal distance from hinge to hinge

Here are my settings, they are working well for me:

// Center-to-center distance of the holes in the diagonal push rods. #define DELTA_DIAGONAL_ROD 217.2 // mm (215.0) // Horizontal offset from middle of printer to smooth rod center. #define DELTA_SMOOTH_ROD_OFFSET 161.5 // mm (136.5) // Horizontal offset of the universal joints on the end effector. #define DELTA_EFFECTOR_OFFSET 20 // mm (19.9) // Horizontal offset of the universal joints on the carriages. #define DELTA_CARRIAGE_OFFSET 22.0 // mm (19.5) // Effective horizontal distance bridged by diagonal push rods. #define DELTA_RADIUS (DELTA_SMOOTH_ROD_OFFSET-DELTA_EFFECTOR_OFFSET-DELTA_CARRIAGE_OFFSET)

|

Re: Ebay SINTRON Kossel Mini full kit October 15, 2015 09:23PM |

Registered: 11 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit October 15, 2015 09:40PM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit October 15, 2015 10:49PM |

Registered: 8 years ago Posts: 916 |

By the way if anyone is interested in removing the backlash from your wobbly carriage bearings, here's a cheap solution.

Add some wire to each screw that holds in your rod ends, and bend a hook into the wire. Then connect the hooks with rubber bands. Works well.

Add some wire to each screw that holds in your rod ends, and bend a hook into the wire. Then connect the hooks with rubber bands. Works well.

|

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 04:21AM |

Registered: 8 years ago Posts: 5,232 |

I disagree with nebbians rubberband theory.

When the rubbers tension is unequal, the carriers will be dragged in one direction. As the tension changes, the carriers will be dragged the other way...

You'd get "forced wobble".

What if you use one string/fishing line and a spring instead of three rubbers?

The string would run through rollers and the tension would always be equal for all three carriers.

Just my 2cent

-Olaf

When the rubbers tension is unequal, the carriers will be dragged in one direction. As the tension changes, the carriers will be dragged the other way...

You'd get "forced wobble".

What if you use one string/fishing line and a spring instead of three rubbers?

The string would run through rollers and the tension would always be equal for all three carriers.

Just my 2cent

-Olaf

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 04:23AM |

Hi everybody,

bought one of these sets too.

Like most of you I had the Problem, the rod-ends were simply to big on the carriage and on the effector.

But when i noticed, there was no backlash in the rod ends, i decided not to buy smaller ones but to adjust carriage and effector.

For the carriage I put a 4mm spacer between the two carriage-parts.

For the effector I made a completley new one out of 3 Aluminium-Sheets (1,5mm and 3mm) - slightly bigger than the orriginal one.

To mount the rod Ends on the effector I used the metal parts of wire terminals.

After setting the correct temperatures printing works realy fine, calibration seems OK.

But the endstop-mounts are really bad. I'll have to adjust them to a more rigid version, so calibration will stay good.

bought one of these sets too.

Like most of you I had the Problem, the rod-ends were simply to big on the carriage and on the effector.

But when i noticed, there was no backlash in the rod ends, i decided not to buy smaller ones but to adjust carriage and effector.

For the carriage I put a 4mm spacer between the two carriage-parts.

For the effector I made a completley new one out of 3 Aluminium-Sheets (1,5mm and 3mm) - slightly bigger than the orriginal one.

To mount the rod Ends on the effector I used the metal parts of wire terminals.

After setting the correct temperatures printing works realy fine, calibration seems OK.

But the endstop-mounts are really bad. I'll have to adjust them to a more rigid version, so calibration will stay good.

|

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 05:03AM |

Registered: 8 years ago Posts: 8 |

My Heatbed would not come up to temperature at all. (86Degrees instead of 110)

Larger wire (20 Amp) from Power supply to 12 volt relay the Thermister on the heatbed will cycle Ramps and then the relay to keep the temperature Correct and connect Ramps output to Relay to actuate

All heat problems on the ramps board disappear and full voltage can get to the heat bed.

Car relay is 30 Amps and cheap.

Larger wire (20 Amp) from Power supply to 12 volt relay the Thermister on the heatbed will cycle Ramps and then the relay to keep the temperature Correct and connect Ramps output to Relay to actuate

All heat problems on the ramps board disappear and full voltage can get to the heat bed.

Car relay is 30 Amps and cheap.

|

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 07:15AM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

I disagree with nebbians rubberband theory.

When the rubbers tension is unequal, the carriers will be dragged in one direction. As the tension changes, the carriers will be dragged the other way...

You'd get "forced wobble".

What if you use one string/fishing line and a spring instead of three rubbers?

The string would run through rollers and the tension would always be equal for all three carriers.

Just my 2cent

-Olaf

The problem with a string and spring is that you have a much higher variance in tension between when the carriages are level, vs when they're unequal. You really need a spring that is as long as you can possibly make it, to minimise tension variations. Rubber bands are a pretty good solution here. I haven't observed any forced wobble in practise, however I was getting noticeable overshoot on corners before the rubber band upgrade.

|

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 07:31AM |

Registered: 9 years ago Posts: 67 |

|

Re: Ebay SINTRON Kossel Mini full kit October 16, 2015 11:10PM |

Registered: 8 years ago Posts: 8 |

I to had this problem..cheap 30 Amp Car relay did the trick and 20 Amp wire (so it does not heat up and become resistive)

Aurduino board operates the relay with Thermister operating Arduino board so temp stays good and No more big Loads on the Ramps or Arduino

I still had to wind up the Power Supply to 13.6 volts to get 100 Degrees

Aurduino board operates the relay with Thermister operating Arduino board so temp stays good and No more big Loads on the Ramps or Arduino

I still had to wind up the Power Supply to 13.6 volts to get 100 Degrees

|

Re: Ebay SINTRON Kossel Mini full kit October 17, 2015 04:45AM |

Registered: 8 years ago Posts: 3 |

Sorry, only registered users may post in this forum.