Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 03:50PM |

Registered: 8 years ago Posts: 255 |

Quote

dc42

Quote

DRTak

So If I dont use an Arduino Ramps. How do I use my Kossel? What other system can run it.

Arduino/RAMPS has a number of issues, of which the lack of enough current from the 5V rail is the most frequently encountered. My recommendation is to use a modern 32-bit controller board such as Duet or Smoothieboard or one of their clones. These board are available from $50 + shipping including the drivers, although well-made ones not built in China cost more (just like Arduino and RAMPS).

For delta printers, I particularly recommend the Duet 0.8.5 which is available from Think3DPrint3D. It supports a fast auto delta calibration, segmentation-free delta movement, and a built-in web interface. See [miscsolutions.wordpress.com] for how I upgraded my delta from RAMPS to Duet. The calibration instructions in that series are out of date because it's completely automatic now if you have a Z probe.

If you want to spend less, you can get a Replikeo Duet 0.6 for $50 + shipping, although the quality seems to be variable.

If you want to continue using Arduino/RAMPS, see [forums.reprap.org] for how to work around the 5V power problem.

I second that, I got duet 0.8.5 from think3dprint3d and DC is my hero ;-) The only downside is that the printer is a bit louder now ;-) And I changed arduino/ramps that was working just fine for me, more or less all hardware/software problems resolved. Still, I'm a happier man now.

I'm thinking of upgrading the old i3 to smoothieboard now just for variety's sake.

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 04:16PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

So If I upgrade to a duet then I have to buy your Panel DUE to get LCD function right?

It seems so, though I'd be happy to hear about something cheap and basic that I can use. Right now I'm fine without LCD, but would love to have one. I only want to see things, don't want to control from LCD, network is okay with me.

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 04:20PM |

Registered: 10 years ago Posts: 14,672 |

Quote

DRTak

So If I upgrade to a duet then I have to buy your Panel DUE to get LCD function right?

Currently the only LCD supported by RepRapFirmware is the PanelDue. That's because when I sounded out Duet users about providing an LCD display, although I intended to do a low-cost mono graphics one, the overwhelming response I got was that folks would rather spend more and have a colour touch screen.

Alternatively, connect the Duet to your home network, then you can use a smartphone or tablet to control it via the web interface.

Edited 2 time(s). Last edit at 11/01/2015 04:21PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 04:48PM |

Registered: 8 years ago Posts: 104 |

I've just finished initial calibration of the printer and ready to continue with melting plastic.

Now I have more generic questions because I'm warring about hot-end jams (maybe I can read that topics somewhere?):

- How to do very first print? Just push filament to the nozzle and kick print button in Pronterface? Or the nozzle should be preheated before inserting the plastic?

- How to retract the filament (i.e. for replacement)? Is it enough to put another filament after that without nozzle cleaning? Again, is it cold operation or preheated?

- How to abort the print in emergency and do not get the jam in the nozzle after that?

- If hot-end is heated is it must to extrude something or is it safe to have melted filament in the nozzle without extrusion?

- Could someone share Slic3r config.ini for this printer?

Now I have more generic questions because I'm warring about hot-end jams (maybe I can read that topics somewhere?):

- How to do very first print? Just push filament to the nozzle and kick print button in Pronterface? Or the nozzle should be preheated before inserting the plastic?

- How to retract the filament (i.e. for replacement)? Is it enough to put another filament after that without nozzle cleaning? Again, is it cold operation or preheated?

- How to abort the print in emergency and do not get the jam in the nozzle after that?

- If hot-end is heated is it must to extrude something or is it safe to have melted filament in the nozzle without extrusion?

- Could someone share Slic3r config.ini for this printer?

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 06:15PM |

Registered: 8 years ago Posts: 319 |

Heat hotend to 190 ish for PLA. Then you can manually push filament through to see if it works.

The lcd screen has a panic switch which u can use to kill the process. I use this all the time

To replace filament. Heat hotend. Manually pull out old filament once hotend is up to the correct temp. and replace with different color.

The printer is basically a CNC machine with a glue gun attached to it. So yes you always have to heat the hotend just like u have to heat a gluegun to get it to work

The lcd screen has a panic switch which u can use to kill the process. I use this all the time

To replace filament. Heat hotend. Manually pull out old filament once hotend is up to the correct temp. and replace with different color.

The printer is basically a CNC machine with a glue gun attached to it. So yes you always have to heat the hotend just like u have to heat a gluegun to get it to work

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 06:17PM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

Quote

DRTak

So If I upgrade to a duet then I have to buy your Panel DUE to get LCD function right?

Currently the only LCD supported by RepRapFirmware is the PanelDue. That's because when I sounded out Duet users about providing an LCD display, although I intended to do a low-cost mono graphics one, the overwhelming response I got was that folks would rather spend more and have a colour touch screen.

Alternatively, connect the Duet to your home network, then you can use a smartphone or tablet to control it via the web interface.

DC. I think I'm going to have to buy your stuff. Lol. So the duet board. How do I input all of my config.h files from marlin into the duet? And do u sell your z probe on the think 3d website so i can buy everything at once

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 06:36PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 06:38PM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 06:46PM |

Registered: 9 years ago Posts: 445 |

Quote

hacker

Quote

DRTak

Hacker. Why is your kossel loudER now with duet?

I'd love to hear expert opinion myself. I attribute it to the lack of segmentation for now — after all it affects how it moves and therefore the sound it produces, but I'd love to hear expert opinion.

I chalk it down to the fact that they have implemented the "decay hack" on the drivers.

|

Re: Ebay SINTRON Kossel Mini full kit November 01, 2015 10:46PM |

Registered: 10 years ago Posts: 14,672 |

If the printer is louder since uograding to the Duet, the most likely explanation is that the motor currents are set higher. I haven't heard that the decay change makes any difference to noise when using A4982 drivers.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 04:08AM |

Registered: 8 years ago Posts: 255 |

Quote

dc42

If the printer is louder since uograding to the Duet, the most likely explanation is that the motor currents are set higher. I haven't heard that the decay change makes any difference to noise when using A4982 drivers.

That was my initial thought, but I didn't notice any change after changing currents both up and down. But it was all kinda "while I'm at it", so unless I dedicate some time to this issue, it's not conclusive.

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 04:17AM |

Registered: 9 years ago Posts: 445 |

Quote

dc42

If the printer is louder since uograding to the Duet, the most likely explanation is that the motor currents are set higher. I haven't heard that the decay change makes any difference to noise when using A4982 drivers.

I run mine at lower current with the duet than what I did with ramps and a4988 and 8825's, it's still louder + it got a different "singing" to it.

I have never modified any driver with the "decay" hack so I wouldn't really know what the difference in actual sound may be, that's probably why I chalked it down to that.

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 05:35AM |

Registered: 8 years ago Posts: 89 |

talking about currents... i just realise ive never even adjusted those. just plugged the drivers in, and started moving the printer. Is there a guide on how to find the best current for a delta printer and set the drivers accordingly? I dont even know what a too high a current or too low even does (except for frying your steppers, or overheating the drivers)

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 06:35AM |

Registered: 9 years ago Posts: 445 |

Quote

Tha_Reaper

talking about currents... i just realise ive never even adjusted those. just plugged the drivers in, and started moving the printer. Is there a guide on how to find the best current for a delta printer and set the drivers accordingly? I dont even know what a too high a current or too low even does (except for frying your steppers, or overheating the drivers)

You should adjust the current of your drivers to about 70-80% of your motors rated current but you should not exceed what your drivers can handle without overheating.

There's a "guide" in the wiki, try searching there by the name of your driver.

Do take note that you also have to look at your sense resistors to get the math correct.

(the Chinese manufactured driver-boards sometimes uses different resistors than what is mentioned in the wiki)

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 07:24AM |

Registered: 10 years ago Posts: 14,672 |

For the axis motors, set the current high enough so that you can get the acceleration you want, but low enough to minimise the damage caused if you get a gead crash etc. This will typically be between 50% and 80% of rated current, a higher percentage for short motors than for long ones. Too low a current may also cause the motor not to respond to jogging by small amounts sometimes.

For the extruder, set the current high enough to not skip steps during normal extrusion, but low enough to skip steps if the nozzle is obstructed, to avoid grinding a notch in the filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

For the extruder, set the current high enough to not skip steps during normal extrusion, but low enough to skip steps if the nozzle is obstructed, to avoid grinding a notch in the filament.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 07:43AM |

Registered: 8 years ago Posts: 104 |

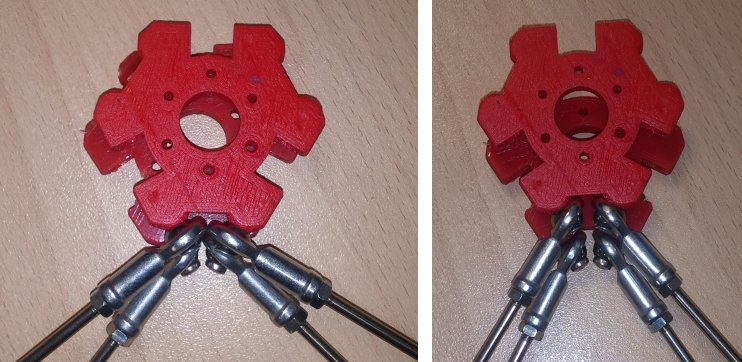

BTW... Sintron's guys sent me replacement parts which could match their large rod ends. I've received definitely larger belt clips (for roller cars) and rather the same effector plate. Rod end mounting hole on belt clip is moved to 1.5mm farther from carriage. But regarding the effector... I noticed the only change - it's 38.5-38.7mm (instead of 40mm) between mounting points for rods. In the same time belt clips are 40mm in width. So rods wont be parallel after mounting.

The original parts are on the left, the new - on the right (in each pair).

[EDIT]

With new effector rods can be spread wider, but they still interfere. Beside that the minimum angle is also increased a bit, that's not good.

Edited 5 time(s). Last edit at 11/02/2015 10:08AM by GrAndAG.

The original parts are on the left, the new - on the right (in each pair).

[EDIT]

With new effector rods can be spread wider, but they still interfere. Beside that the minimum angle is also increased a bit, that's not good.

Edited 5 time(s). Last edit at 11/02/2015 10:08AM by GrAndAG.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 09:50AM |

Quote

GrAndAG

BTW... Sintron's guys sent me replacement parts which could match their large rod ends. I've received definitely larger belt clips (for roller cars) and rather the same effector plate. Belt clips mounting hole moved to 1.5mm farther from carriage. But regarding the effector... I noticed the only change - it's 38.5-38.7mm (instead of 40mm) between mounting points for roads. In the same time belt clips are 40mm in width. So rods wont be parallel after mounting.

[attachment 65137 Sintron_larger_parts.jpg]

The original parts are on the left, the new - on the right (in each pair).

Got the same replacement parts to. - Useless.

I used 4mm spacers made out of a plastic plate for the carriage-parts and did my own effector out of Aluminium slightly bigger in size, but the same spacing as the carriages.

If you don't have the same spacing, the effector gets tilt and you won't be able to print correct dimmensions and angles!

EDIT:

Here you can find pictures of mine and the construction drawing for my effector (Forum is in german):

http://www.fingers-welt.de/phpBB/viewtopic.php?f=14&t=42&start=975#p107980

Edited 1 time(s). Last edit at 11/02/2015 09:53AM by Sir_Death.

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 10:02AM |

Registered: 8 years ago Posts: 255 |

Quote

GrAndAG

BTW... Sintron's guys sent me replacement parts which could match their large rod ends. I've received definitely larger belt clips (for roller cars) and rather the same effector plate. Rod end mounting hole on belt clip is moved to 1.5mm farther from carriage. But regarding the effector... I noticed the only change - it's 38.5-38.7mm (instead of 40mm) between mounting points for roads. In the same time belt clips are 40mm in width. So rods wont be parallel after mounting.

[attachment 65137 Sintron_larger_parts.jpg]

The original parts are on the left, the new - on the right (in each pair).

With new effector rods can be spread wider, but they still interfere. Beside that the minimum angle is also increased a bit, that's not good.

[attachment 65150 Sintron_effectors_comparison.jpg]

I didn't want to wait for them to ship, but wanted to try their original design first, so I printed out their STLs on the other printer. Indeed I could print, but the radius was like 50-60mm, so I went for traxxas rod ends…

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 10:05AM |

Registered: 8 years ago Posts: 255 |

Quote

dc42

For the axis motors, set the current high enough so that you can get the acceleration you want, but low enough to minimise the damage caused if you get a gead crash etc. This will typically be between 50% and 80% of rated current, a higher percentage for short motors than for long ones. Too low a current may also cause the motor not to respond to jogging by small amounts sometimes.

For the extruder, set the current high enough to not skip steps during normal extrusion, but low enough to skip steps if the nozzle is obstructed, to avoid grinding a notch in the filament.

Speaking of currents and other things, does anyone have *numbers* for this particular kit? Like, Olaf, have you got a config.g with nice currents, speeds, acceleration values, etc. values that are probably applicable not just to your assembly?

|

Re: Ebay SINTRON Kossel Mini full kit November 02, 2015 06:34PM |

Registered: 8 years ago Posts: 104 |

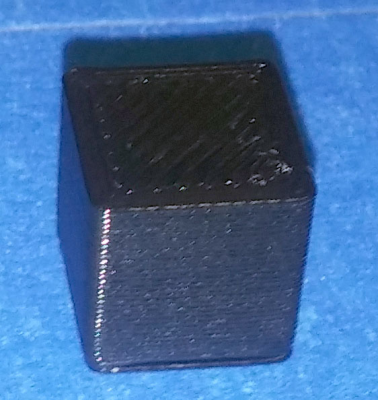

Today I did very first print. It works! Here it is the 1x1x1cm test cube:

The bottom layer is a bit junky because the filament was just inserted and the extrusion was not started at very beginning.

But why the corners are round a bit? Is it normal?

And it seems it over-extruded (but I calibrated extruder precisely: 100mm requested - 100mm got).

The settings was: PLA @ 200C, layer 0.3.

[EDIT]

And after the print I got a thin straight solid thread of plastic 20cm long from last printing point to the nozzle. Not enough retraction at the end? Or wrong temperature?

[EDIT2]

How to eliminate plastic threads while head is moving from object to object without printing?

Edited 2 time(s). Last edit at 11/03/2015 03:12AM by GrAndAG.

The bottom layer is a bit junky because the filament was just inserted and the extrusion was not started at very beginning.

But why the corners are round a bit? Is it normal?

And it seems it over-extruded (but I calibrated extruder precisely: 100mm requested - 100mm got).

The settings was: PLA @ 200C, layer 0.3.

[EDIT]

And after the print I got a thin straight solid thread of plastic 20cm long from last printing point to the nozzle. Not enough retraction at the end? Or wrong temperature?

[EDIT2]

How to eliminate plastic threads while head is moving from object to object without printing?

Edited 2 time(s). Last edit at 11/03/2015 03:12AM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 04:20AM |

Registered: 8 years ago Posts: 89 |

Quote

GrAndAG

The bottom layer is a bit junky because the filament was just inserted and the extrusion was not started at very beginning.

But why the corners are round a bit? Is it normal?

And it seems it over-extruded (but I calibrated extruder precisely: 100mm requested - 100mm got).

The settings was: PLA @ 200C, layer 0.3.

[EDIT]

And after the print I got a thin straight solid thread of plastic 20cm long from last printing point to the nozzle. Not enough retraction at the end? Or wrong temperature?

[EDIT2]

How to eliminate plastic threads while head is moving from object to object without printing?

I too have a bit rounded corners. Not as round as you. metbe your temp is too high, or overextrusion, that way there is too much filament being forced out on your corners.

So far i print my PLA at 190 deg first layer, 180 for the other layers. crazy low, but it gives me good results.

both the edit problems are because of oozing. you can battle that by using a fast retration of 5-6 mm at 60-100 mm/s ive read. didnt get around to testing those settings myself. 4mm retraction @ 40 mm/s still gives me a lot of oozing and stringing.

|

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 04:25AM |

Registered: 8 years ago Posts: 89 |

Sintron offered me a new PSU. I dint expect that. the service is really incredible for a HK seller. I asked if they could send a 20A version, and they agreed for 10 dollar more.

Good deal, good service. parts quality may not be premium grade (as should have been expected for this price), but i'm still happy i bought this set.

Good deal, good service. parts quality may not be premium grade (as should have been expected for this price), but i'm still happy i bought this set.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 05:06AM |

Quote

Tha_Reaper

Sintron offered me a new PSU. I dint expect that. the service is really incredible for a HK seller. I asked if they could send a 20A version, and they agreed for 10 dollar more.

Good deal, good service. parts quality may not be premium grade (as should have been expected for this price), but i'm still happy i bought this set.

More important is the ammount of power, the RAMPS is eating away from the heatbed.

Inputvoltage 11.97V Output RAMPS for Heatbed 9.46V - RAMPS gets very hot!

I don't want to discuss things with sintron anymore - just try to use a relay for heatbed and a PC-Powersupply (360W on +12V available)

But I have another strange behaviour:

I'm printig PLA with Nozzle 0.4mm

Layerheight 0,2mm

Hotend Temp 215°C (less temperature I won't get strong parts) - Temperature checked is 212°C

I can only achive 15mm/sec - seems much to low for me.... trying more Speed, extrudermotor jumps back - it can't push the Filament faster because it won't melt fast enough...

did the volumetric Speed test - only 1.3mm³/sek - read somewhere it should be over 5mm³/sek

So what are your values?

Edited 1 time(s). Last edit at 11/03/2015 09:12AM by Sir_Death.

|

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 06:32AM |

Registered: 8 years ago Posts: 89 |

thanks for the heads-up. I have never noticed the RAMPS to run very hot, but i only heated the heatbed to 60 degrees for PLA. Have not tried ABS yet before i can put stronger fans under my heatbed and i have kapton tape (painters tape probably wont like it if i heat the bed to 90 degrees for an extended amount of time. Anyone tried printing without any type of tape or adhesive on the bed by the way?Quote

Sir_Death

Quote

Tha_Reaper

Sintron offered me a new PSU. I dint expect that. the service is really incredible for a HK seller. I asked if they could send a 20A version, and they agreed for 10 dollar more.

Good deal, good service. parts quality may not be premium grade (as should have been expected for this price), but i'm still happy i bought this set.

More important is the ammount of power, the RAMPS is eating away from the heatbed.

Inputvoltage 11.97V Output RAMPS for Heatbed 9.46V - RAMPS gets very hot!

I don't want to discuss things with sintron anymore - just try to use a relay for heatbed and a PC-Powersupply (360W on +12V available)

But I have another strange behaviour:

I'm printig PLA with Nozzle 0.4mm

Layerheight 0,2mm

Hotend Temp 215°C (less temperature I won't get stron parts) - Temperature checked is 212°C

I can only achive 15mm/sec - seems much to low for me.... trying more Speed, extrudermotor jumps back - it can't push the Filament faster because it won't melt fast enough...

did the volumetric Speed test - only 1.3mm³/sek - read somewhere it should be over 5mm³/sek

So what are your values?

about the extrusion problem: maybe the current is set too low on the extruder, causing it to skip steps? just guessing, i dont know jack about currents and what the right current would be...

If you tell me how to perform the volumetric test, i will gladly try it and report the results back.

|

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 08:36AM |

Registered: 8 years ago Posts: 916 |

Quote

Sir_Death

I can only achive 15mm/sec - seems much to low for me.... trying more Speed, extrudermotor jumps back - it can't push the Filament faster because it won't melt fast enough...

did the volumetric Speed test - only 1.3mm³/sek - read somewhere it should be over 5mm³/sek

So what are your values?

I'm getting good prints at 60 mm/s, at 0.3mm and 0.1mm layer heights in PLA. 210 degrees first layer, 200 thereafter.

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

I found that I also had to wind the extruder spring tensioner right up, almost to the stop. Otherwise I was getting grinding of filament occasionally. This would show as occasional thin strings where it should have been a continuous flat sheet. Took me ages to figure out what was going wrong.

For ABS you don't need the extruder tension as high, but I just leave it there because I'm lazy.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 09:10AM |

Quote

Tha_Reaper

thanks for the heads-up. I have never noticed the RAMPS to run very hot, but i only heated the heatbed to 60 degrees for PLA. Have not tried ABS yet before i can put stronger fans under my heatbed and i have kapton tape (painters tape probably wont like it if i heat the bed to 90 degrees for an extended amount of time. Anyone tried printing without any type of tape or adhesive on the bed by the way?

about the extrusion problem: maybe the current is set too low on the extruder, causing it to skip steps? just guessing, i dont know jack about currents and what the right current would be...

If you tell me how to perform the volumetric test, i will gladly try it and report the results back.

Description of Extrusion rate = volumetric Speed (Name of the Parameter in slic3r)

http://www.extrudable.me/2013/04/18/exploring-extrusion-variability-and-limits/

I'm printing directly on the Sintron-Heatbed - works perfect.

Quote

nebbian

Quote

Sir_Death

I can only achive 15mm/sec - seems much to low for me.... trying more Speed, extrudermotor jumps back - it can't push the Filament faster because it won't melt fast enough...

did the volumetric Speed test - only 1.3mm³/sek - read somewhere it should be over 5mm³/sek

So what are your values?

I'm getting good prints at 60 mm/s, at 0.3mm and 0.1mm layer heights in PLA. 210 degrees first layer, 200 thereafter.

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

I found that I also had to wind the extruder spring tensioner right up, almost to the stop. Otherwise I was getting grinding of filament occasionally. This would show as occasional thin strings where it should have been a continuous flat sheet. Took me ages to figure out what was going wrong.

For ABS you don't need the extruder tension as high, but I just leave it there because I'm lazy.

I will do measurement of the Voltage/Current again.

Seems there are different types of PLA out there

http://reprap.org/wiki/PLA#Heater_Settings

some melting at 160°C some at 230°C....

Have to check back at distributor, which value is suitable for the Filament I bought....

My Extruder is not grinding away the filament, Stepper-driver ist jumping back with "Clonck, clonck, clonck,..."

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 10:17AM |

Quote

Sir_Death

I will do measurement of the Voltage/Current again.

Seems there are different types of PLA out there

http://reprap.org/wiki/PLA#Heater_Settings

some melting at 160°C some at 230°C....

Have to check back at distributor, which value is suitable for the Filament I bought....

My Extruder is not grinding away the filament, Stepper-driver ist jumping back with "Clonck, clonck, clonck,..."

Answer from the Distributor already here: I should use about 220°C

So my Printer seems to work already...

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 03:36PM |

Quote

nebbian

Quote

Sir_Death

I can only achive 15mm/sec - seems much to low for me.... trying more Speed, extrudermotor jumps back - it can't push the Filament faster because it won't melt fast enough...

did the volumetric Speed test - only 1.3mm³/sek - read somewhere it should be over 5mm³/sek

So what are your values?

I'm getting good prints at 60 mm/s, at 0.3mm and 0.1mm layer heights in PLA. 210 degrees first layer, 200 thereafter.

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

I found that I also had to wind the extruder spring tensioner right up, almost to the stop. Otherwise I was getting grinding of filament occasionally. This would show as occasional thin strings where it should have been a continuous flat sheet. Took me ages to figure out what was going wrong.

For ABS you don't need the extruder tension as high, but I just leave it there because I'm lazy.

Checked Motor driver current - perfect fit.

Increase Hotend temperature to 220/225/230°C - only more stringing, but not more extrusion....

I think, I'll use the Filament as it is, and maybe with next Filament, things get better...

|

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 04:34PM |

Registered: 8 years ago Posts: 104 |

Quote

Sir_Death

Increase Hotend temperature to 220/225/230°C - only more stringing, but not more extrusion....

I think, I'll use the Filament as it is, and maybe with next Filament, things get better...

Did you check if there is a jam in the nozzle and (possible) in the heat breaking tube? Overheating PLA can lead to jams.

BTW. I print PLA @ 200C (all layers) with bed @ 45C on blue tape. With 0.2mm layer it prints just perfect. Printing speed - 60mm/s, infill - 120mm/s, movement - 400mm/s.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 03, 2015 05:22PM |

Quote

GrAndAG

Quote

Sir_Death

Increase Hotend temperature to 220/225/230°C - only more stringing, but not more extrusion....

I think, I'll use the Filament as it is, and maybe with next Filament, things get better...

Did you check if there is a jam in the nozzle and (possible) in the heat breaking tube? Overheating PLA can lead to jams.

BTW. I print PLA @ 200C (all layers) with bed @ 45C on blue tape. With 0.2mm layer it prints just perfect. Printing speed - 60mm/s, infill - 120mm/s, movement - 400mm/s.

Nozzle was free before printing - could see through. PTFE tube is down all the way through heatbreake - there was a Problem after building the printer, so I had to disassemble and reassemble it, therefore I'm sure, how it is assembled now.

Sorry, only registered users may post in this forum.