Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 02:46AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 02:49AM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

Don't take the nozzle diameter for granted.

I got 0.3 nozzles from china, which are 0.4 and vise versa...

-Olaf

What's a good way to test this?

Also while we're on the subject, I read somewhere that you should have an extrusion width that is slightly larger than the nozzle size. I've always just used an extrusion width equal to the nozzle size. Can you confirm/deny?

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 03:24AM |

Quote

Sir_Death

Nozzle was free before printing - could see through. PTFE tube is down all the way through heatbreake - there was a Problem after building the printer, so I had to disassemble and

reassemble it, therefore I'm sure, how it is assembled now.

Nozzle was jammed this morning after unattended night-print...

I think - or at least hope - I found the problem. - The screw which is pressing the heatblock onto the heatcartridge broke in the middle, so it was not correctly pressing the two parts together anymore...

Will have to drill it out this afternoon and reassemble.

Nozzle got jammed, because PTFE-Tube got widened at the end, and so PLA crystalized..

(Thats why I started dissasembling, because cold pull did not work anymore - so I found the broken screw...)

(Thats why I started dissasembling, because cold pull did not work anymore - so I found the broken screw...)

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 03:32AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Quote

Sir_Death

Nozzle was free before printing - could see through. PTFE tube is down all the way through heatbreake - there was a Problem after building the printer, so I had to disassemble and

reassemble it, therefore I'm sure, how it is assembled now.

Nozzle was jammed this morning after unattended night-print...

I think - or at least hope - I found the problem. - The screw which is pressing the heatblock onto the heatcartridge broke in the middle, so it was not correctly pressing the two parts together anymore...

Will have to drill it out this afternoon and reassemble.

Nozzle got jammed, because PTFE-Tube got widened at the end, and so PLA crystalized..(Thats why I started dissasembling, because cold pull did not work anymore - so I found the broken screw...)

Broken screw should've reduced the thing's ability to heat, whereas overheating filament in supposedly cold areas sounds more like not enough cooling? (or decoupling of thermistor and therefore not knowing how hot we are). At any rate, you confuse me

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 03:44AM |

The PTFE Tube should reach down through the heatbreak until touching the back of the Nozzle (in the heatblock), so 1.75mm Filament is directed to the nozzle correctly.

So this is not an area to stay cold - because it is in the heatblock So now there is crysalized Filament with outer Diameter of the PTFE Tube at the End of the Heatbreak, and fresh filament has to pass through the crystalized one - which is only possible in melted condition... i think, this is one of the points why I had to use such great heat, but still not extruding very much. (second Point might be the broken screw)

So now there is crysalized Filament with outer Diameter of the PTFE Tube at the End of the Heatbreak, and fresh filament has to pass through the crystalized one - which is only possible in melted condition... i think, this is one of the points why I had to use such great heat, but still not extruding very much. (second Point might be the broken screw)

We will see, when I've cleaned it up and reassembled, if it works as it should...

Would it be a good Idea to apply some thermal compound on the heatcartridge to ensure best thermal Transfer to the heatblock?

So this is not an area to stay cold - because it is in the heatblock

So now there is crysalized Filament with outer Diameter of the PTFE Tube at the End of the Heatbreak, and fresh filament has to pass through the crystalized one - which is only possible in melted condition... i think, this is one of the points why I had to use such great heat, but still not extruding very much. (second Point might be the broken screw)

So now there is crysalized Filament with outer Diameter of the PTFE Tube at the End of the Heatbreak, and fresh filament has to pass through the crystalized one - which is only possible in melted condition... i think, this is one of the points why I had to use such great heat, but still not extruding very much. (second Point might be the broken screw)We will see, when I've cleaned it up and reassembled, if it works as it should...

Would it be a good Idea to apply some thermal compound on the heatcartridge to ensure best thermal Transfer to the heatblock?

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 04:19AM |

Registered: 8 years ago Posts: 104 |

Quote

nebbian

Quote

o_lampe

Don't take the nozzle diameter for granted.

I got 0.3 nozzles from china, which are 0.4 and vise versa...

-Olaf

What's a good way to test this?

Find a piece of wire which is 0.4mm (0.3, 0.5, etc) and just check if it fits. I used a bunch of packing wires (they usually used to pack device wires, such as mouses, computer cables, etc). I was able to found 0.3, 0.4, 0.45 and 0.5 wires and they are strong enough to push through the hole.

Quote

nebbian

Also while we're on the subject, I read somewhere that you should have an extrusion width that is slightly larger than the nozzle size. I've always just used an extrusion width equal to the nozzle size. Can you confirm/deny?

I left it as "auto" in slicer. Because, I think, the extrusion width also depends on layer height, at least.

Edited 1 time(s). Last edit at 11/04/2015 05:14AM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 04:50AM |

Registered: 8 years ago Posts: 104 |

I do not think that the problem is in not good heater contact. It can affect the time of heating and wasting energy to heat air. But if the head is able to reach desired temperature, which is measured by thermistor (which is still installed properly), it means the head has requested temperature.Quote

Sir_Death

Nozzle was jammed this morning after unattended night-print...

I think - or at least hope - I found the problem. - The screw which is pressing the heatblock onto the heatcartridge broke in the middle, so it was not correctly pressing the two parts together anymore...

If the filament is overheated, it starts melting not in the nozzle only, but higher, in heat-breaker tube and even in cold zone. At least it may to become wider due to softness on high temperature (PLA becomes soft @ 60C) on overly long distance and the friction will be too strong for extruder.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:00AM |

Desired temperature is one Thing (maybe not even reached while unattended printing) - but for melting, the transferable amount of energy is important.

If to low amount of heat energy is transferred, while keeping Extrusion up, Filament is getting squeezed (wider) and gets stuck. while stuck, heated and keeping preasure up, less melted Filament is brought forward. More melted Filament outside the main path will start to crystalize and slow down less melted Filament in the middle (main path) - perfect conditions for jammed...

If to low amount of heat energy is transferred, while keeping Extrusion up, Filament is getting squeezed (wider) and gets stuck. while stuck, heated and keeping preasure up, less melted Filament is brought forward. More melted Filament outside the main path will start to crystalize and slow down less melted Filament in the middle (main path) - perfect conditions for jammed...

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:11AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

The PTFE Tube should reach down through the heatbreak until touching the back of the Nozzle (in the heatblock), so 1.75mm Filament is directed to the nozzle correctly.

We will see, when I've cleaned it up and reassembled, if it works as it should...

Would it be a good Idea to apply some thermal compound on the heatcartridge to ensure best thermal Transfer to the heatblock?

I thought it ends halfway in the heatbreak? I need to check that once I'm home, because I happen to have original hotend lying around ready for disassembling

I'd say PTFT tube *is* kinda cold zone wherever it is, maybe not too cold ;-)

I'd say PTFT tube *is* kinda cold zone wherever it is, maybe not too cold ;-)Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink. And would triple check how well heatsink is colled.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:21AM |

Quote

hacker

Quote

Sir_Death

The PTFE Tube should reach down through the heatbreak until touching the back of the Nozzle (in the heatblock), so 1.75mm Filament is directed to the nozzle correctly.

We will see, when I've cleaned it up and reassembled, if it works as it should...

Would it be a good Idea to apply some thermal compound on the heatcartridge to ensure best thermal Transfer to the heatblock?

I thought it ends halfway in the heatbreak? I need to check that once I'm home, because I happen to have original hotend lying around ready for disassemblingI'd say PTFT tube *is* kinda cold zone wherever it is, maybe not too cold ;-)

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink. And would triple check how well heatsink is colled.

Consulting E3D Assembly Instruction at

http://wiki.e3d-online.com/wiki/E3D-v6_Assembly#1.75mm_Universal_.28with_Bowden.29´

it tells you:

"The tubing should be inserted from the top of the now assembled hotend and pushed as far down into the hotend as possible."

With the chinese hotend PTFE Tube is able to go down till the end of the heatbreak.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:23AM |

Registered: 8 years ago Posts: 104 |

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:26AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Quote

hacker

Quote

Sir_Death

The PTFE Tube should reach down through the heatbreak until touching the back of the Nozzle (in the heatblock), so 1.75mm Filament is directed to the nozzle correctly.

We will see, when I've cleaned it up and reassembled, if it works as it should...

Would it be a good Idea to apply some thermal compound on the heatcartridge to ensure best thermal Transfer to the heatblock?

I thought it ends halfway in the heatbreak? I need to check that once I'm home, because I happen to have original hotend lying around ready for disassemblingI'd say PTFT tube *is* kinda cold zone wherever it is, maybe not too cold ;-)

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink. And would triple check how well heatsink is colled.

Consulting E3D Assembly Instruction at

http://wiki.e3d-online.com/wiki/E3D-v6_Assembly#1.75mm_Universal_.28with_Bowden.29´

it tells you:

"The tubing should be inserted from the top of the now assembled hotend and pushed as far down into the hotend as possible."

With the chinese hotend PTFE Tube is able to go down till the end of the heatbreak.

You absolutely need to push it as far as possible, I was just hoping it's not all the way. Like it's not with E3D — [RAWING-V6-175-BREAK.png" target="_blank" rel="nofollow">wiki.e3d-online.com] According to what you say, it's not the case, though.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:26AM |

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:28AM |

Registered: 8 years ago Posts: 255 |

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

I'm not sure if it should be *that* hot there, but then I don't know for sure either.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:38AM |

Registered: 9 years ago Posts: 445 |

Quote

Sir_Death

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

Don't think you need to worry to much about it, where the fins are it shouldn't be such extreme temperatures.

It would be another matter if you tried putting thermal compound where the heatblock is (threads to nozzle, around heating cartridge).

E3D actually recommends putting thermal compound on the heatbreak where the fins are.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:49AM |

Registered: 8 years ago Posts: 255 |

Quote

Koenig

Quote

Sir_Death

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

Don't think you need to worry to much about it, where the fins are it shouldn't be such extreme temperatures.

It would be another matter if you tried putting thermal compound where the heatblock is (threads to nozzle, around heating cartridge).

E3D actually recommends putting thermal compound on the heatbreak where the fins are.

Oh yeah, sorry if I wasn't clear (and I almost wasn't), I meant heatbreak threading where it goes into heatsink, of course.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 05:54AM |

Registered: 9 years ago Posts: 445 |

Quote

hacker

Quote

Koenig

Quote

Sir_Death

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

Don't think you need to worry to much about it, where the fins are it shouldn't be such extreme temperatures.

It would be another matter if you tried putting thermal compound where the heatblock is (threads to nozzle, around heating cartridge).

E3D actually recommends putting thermal compound on the heatbreak where the fins are.

Oh yeah, sorry if I wasn't clear (and I almost wasn't), I meant heatbreak threading where it goes into heatsink, of course.

That would not be very smart to do that as you really want as little heat transfer between those two parts as possible.

It would be much better if there was a thermal insulator compound to put there.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 06:31AM |

Registered: 8 years ago Posts: 89 |

But you also don't want the heat to creep up to the PTFE tube and start melting plastic higher up...Quote

Koenig

Quote

hacker

Quote

Koenig

Quote

Sir_Death

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

Don't think you need to worry to much about it, where the fins are it shouldn't be such extreme temperatures.

It would be another matter if you tried putting thermal compound where the heatblock is (threads to nozzle, around heating cartridge).

E3D actually recommends putting thermal compound on the heatbreak where the fins are.

Oh yeah, sorry if I wasn't clear (and I almost wasn't), I meant heatbreak threading where it goes into heatsink, of course.

That would not be very smart to do that as you really want as little heat transfer between those two parts as possible.

It would be much better if there was a thermal insulator compound to put there.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 06:48AM |

Quote

Tha_Reaper

But you also don't want the heat to creep up to the PTFE tube and start melting plastic higher up...Quote

Koenig

That would not be very smart to do that as you really want as little heat transfer between those two parts as possible.

It would be much better if there was a thermal insulator compound to put there.

Some guys even apply PTFE foil on the part of the heatbreak going into the heatblock, to stop the heat from going into the heatbreak.

I was thinking of the possibility of appliying thermal compound on the heatcartridge - so the hottest place! - That's why I'm Little worried about thermal stability of the compound...

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 06:55AM |

Registered: 9 years ago Posts: 445 |

Quote

Tha_Reaper

But you also don't want the heat to creep up to the PTFE tube and start melting plastic higher up...Quote

Koenig

Quote

hacker

Quote

Koenig

Quote

Sir_Death

Quote

GrAndAG

Quote

hacker

Perhaps I'd try some thermal compound on heatbreak threading to improve thermal transfer to heatsink.

Just FYI.. Regular (usually for computer coolers) thermal compound is not designed for high temperature, such as in our case. It will degrade rapidly. But it worth to try, if it solves the problem (at least for short time) - you found the problem.

That is exactly the Point which worries me...

So first I'll just reassemble it, as it should be, and check again...

Don't think you need to worry to much about it, where the fins are it shouldn't be such extreme temperatures.

It would be another matter if you tried putting thermal compound where the heatblock is (threads to nozzle, around heating cartridge).

E3D actually recommends putting thermal compound on the heatbreak where the fins are.

Oh yeah, sorry if I wasn't clear (and I almost wasn't), I meant heatbreak threading where it goes into heatsink, of course.

That would not be very smart to do that as you really want as little heat transfer between those two parts as possible.

It would be much better if there was a thermal insulator compound to put there.

Not very likely to creep up the PTFE tube as it is a very poor thermal conductor, what you want to prevent is the heat creeping up the heatbreak so that plastic starts to melt higher up.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 07:38AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Quote

Tha_Reaper

But you also don't want the heat to creep up to the PTFE tube and start melting plastic higher up...Quote

Koenig

That would not be very smart to do that as you really want as little heat transfer between those two parts as possible.

It would be much better if there was a thermal insulator compound to put there.

Some guys even apply PTFE foil on the part of the heatbreak going into the heatblock, to stop the heat from going into the heatbreak.

I considered that, but I'm also worried that it might be a bit too hot for PTFE? Gotta do the research perhaps.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 08:01AM |

Registered: 8 years ago Posts: 104 |

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 08:04AM |

Quote

hacker

Quote

Sir_Death

Some guys even apply PTFE foil on the part of the heatbreak going into the heatblock, to stop the heat from going into the heatbreak.

I considered that, but I'm also worried that it might be a bit too hot for PTFE? Gotta do the research perhaps.

Wikipedia tells me PTFE has its melting Point at 327°C

https://de.wikipedia.org/wiki/Polytetrafluorethylen

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 01:45PM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Quote

hacker

Quote

Sir_Death

Some guys even apply PTFE foil on the part of the heatbreak going into the heatblock, to stop the heat from going into the heatbreak.

I considered that, but I'm also worried that it might be a bit too hot for PTFE? Gotta do the research perhaps.

Wikipedia tells me PTFE has its melting Point at 327°C

https://de.wikipedia.org/wiki/Polytetrafluorethylen

Oh, thanks for doing my homework! Yes, I don't think I'm going above that ;-)

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 03:14PM |

Registered: 8 years ago Posts: 104 |

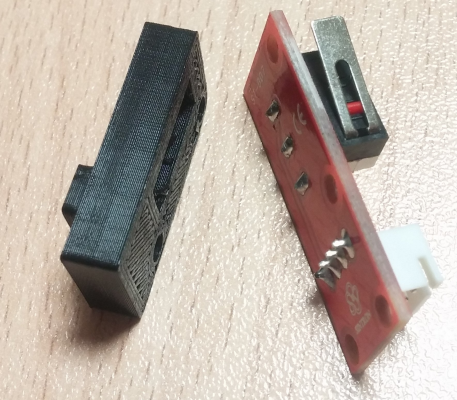

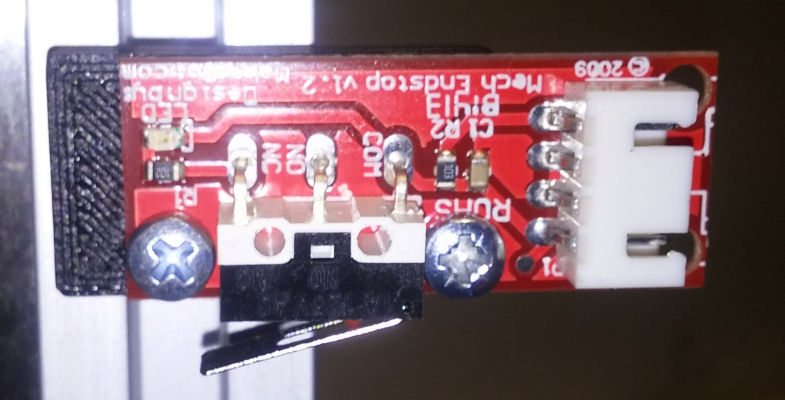

BTW, my design of endstops mount plate - [www.thingiverse.com]

It has cavern for soldered pins from back side of endstop PCB. And also has pin for precise mount.

It has cavern for soldered pins from back side of endstop PCB. And also has pin for precise mount.

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 04:57PM |

Registered: 8 years ago Posts: 89 |

Quote

nebbian

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

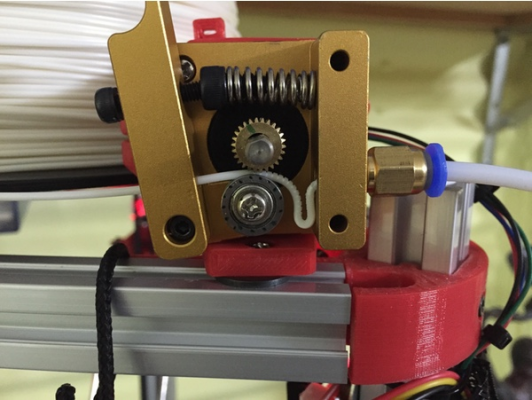

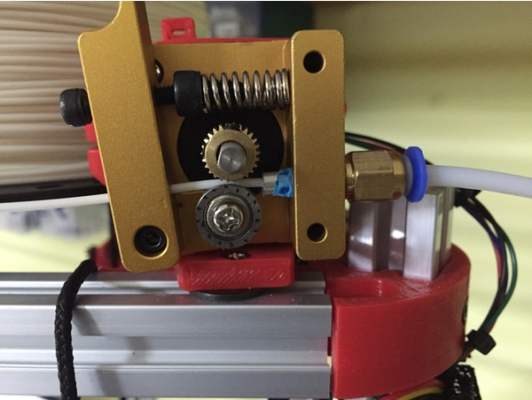

Checked mine, it was 0.3V. Had a lot of skipping so I cranked it up to 0.45v. Much less skipping, but now on a longer print my PLA bent inside the extruder after the gear and before the PTFE tube. Created an ugly mess... I suspect a hot extruder is at fault for making the PLA more plyable.

Any way to combat this?

|

Re: Ebay SINTRON Kossel Mini full kit November 04, 2015 07:30PM |

Registered: 8 years ago Posts: 916 |

Quote

Tha_Reaper

Quote

nebbian

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

Checked mine, it was 0.3V. Had a lot of skipping so I cranked it up to 0.45v. Much less skipping, but now on a longer print my PLA bent inside the extruder after the gear and before the PTFE tube. Created an ugly mess... I suspect a hot extruder is at fault for making the PLA more plyable.

Any way to combat this?

Like this?

Add some aluminium or PTFE tube like this:

|

Re: Ebay SINTRON Kossel Mini full kit November 05, 2015 12:46AM |

Registered: 8 years ago Posts: 89 |

Exactly! I just discovered it 30 minutes later, and it turned into a bird's nest up there.Quote

nebbian

Quote

Tha_Reaper

Quote

nebbian

Have you adjusted the motor driver currents? You stick a jewellers screwdriver in the little trimpot, and measure the voltage between the screwdriver and earth, while slowly nudging the screwdriver back and forth. Mine is set to 0.45V.

Checked mine, it was 0.3V. Had a lot of skipping so I cranked it up to 0.45v. Much less skipping, but now on a longer print my PLA bent inside the extruder after the gear and before the PTFE tube. Created an ugly mess... I suspect a hot extruder is at fault for making the PLA more plyable.

Any way to combat this?

Like this?

[attachment 65335 IMG_4506.jpeg]

Add some aluminium or PTFE tube like this:

[attachment 65336 IMG_4507.jpeg]

What's that part that you used? Can I buy that somewhere?

|

Re: Ebay SINTRON Kossel Mini full kit November 05, 2015 02:15AM |

Registered: 8 years ago Posts: 916 |

Quote

Tha_Reaper

Exactly! I just discovered it 30 minutes later, and it turned into a bird's nest up there.

What's that part that you used? Can I buy that somewhere?

That part is called "Bit of aluminium tube I had lying around".

I've since replaced it with a part called "1 cm offcut of PTFE tubing, exactly the same stuff as is in your bowden tube". The easiest way to do this is to press the little button on your extruder and pop off the bowden tube. Cut off 1 cm and replace. Now put some tape around that offcut and screw it into the threaded hole. You might have to take some parts of the extruder off to do this, because the idler bearing gets in the way. Then trim the tubing so that it's just proud of the gear and idler bearing.

Alternatively if you're feeling brave you could disassemble the push fit connector and drill it out the same as the one on the hotend, which would allow you to push the bowden cable all the way through the hole in the extruder until it's almost touching the extruder gear and idler bearing.

Edited 1 time(s). Last edit at 11/05/2015 02:18AM by nebbian.

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 05, 2015 03:41AM |

Quote

nebbian

Quote

Tha_Reaper

Exactly! I just discovered it 30 minutes later, and it turned into a bird's nest up there.

What's that part that you used? Can I buy that somewhere?

That part is called "Bit of aluminium tube I had lying around".

I've since replaced it with a part called "1 cm offcut of PTFE tubing, exactly the same stuff as is in your bowden tube". The easiest way to do this is to press the little button on your extruder and pop off the bowden tube. Cut off 1 cm and replace. Now put some tape around that offcut and screw it into the threaded hole. You might have to take some parts of the extruder off to do this, because the idler bearing gets in the way. Then trim the tubing so that it's just proud of the gear and idler bearing.

Alternatively if you're feeling brave you could disassemble the push fit connector and drill it out the same as the one on the hotend, which would allow you to push the bowden cable all the way through the hole in the extruder until it's almost touching the extruder gear and idler bearing.

I'm using a long 2,5mm² wire end ferrule...

But I'm thinking of removing it again, because this behavior appeared only, when trying to extrude at higher Speed than the nozzle can handle...

I got a really bad "jammed" with about 5mm Long crystalized PLA in the Heatbreak - had to drill it out yesterday...

Now Printer is working again - I've a strange roll of PLA - more than about 10-15mm/sek printing speed is not possible.. (Volumetric 1,3mm³/sek)..

But who cares.... printing slow gives good Quality...

Sorry, only registered users may post in this forum.