Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 08:58AM |

Registered: 8 years ago Posts: 17 |

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 09:15AM |

Registered: 8 years ago Posts: 255 |

Quote

MrPCatt

Thats what i tried in the first place. And this also worked for me the first time I had to unmount the noozle. Anyway, fortunately the parts and even the whole printhead is rather cheap. Maybe I should order also another one as spare, just in case.

Indeed, it's got clogged pretty early whether through the fault of mine or not, but it was kinda indication that it will be more problematic, so I didn't spend too much time on it, just put it aside (still lies around) and was happy to replace it with e3d hotend.

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 06:37PM |

Registered: 8 years ago Posts: 23 |

Quote

hacker

Quote

Bigkahuna2187

Haha "home" button in the GUI. I will double check but it appears everything is setup correctly according to the diagrams.

Thanks

I figured that, but couldn't resist ;-)

There are many diagrams around and although I'd expect them to be the same and show all motors the same way, you can just compare your X-motor wiring to Y and Z which move in the correct directions. You can often reverse the connector for X and Y motors, but you can't reverse sintron-supplied connectors for Z axis. And the only way you can plug Z in is actually reverse, so I had to reverse direction in firmware. But then again all my motors were moving in the same direction, so it does sound like you did flip one of those…

Here is video I took of the issue. I tried inverting with "true" under #define INVERT_X_DIR but that doesn't work. All my wiring appears correct. It looks like it starts going up but then begins to go down as the others hit the end stops.

[www.youtube.com]

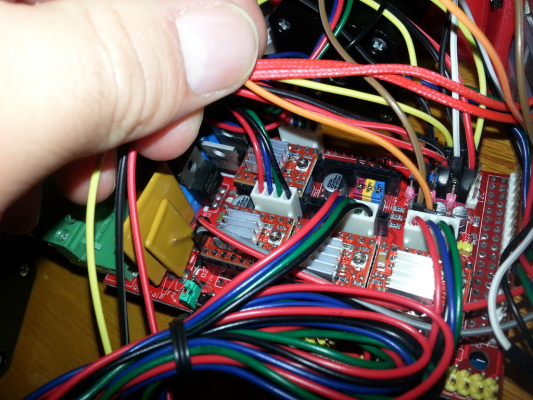

Wiring:

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 06:47PM |

Registered: 8 years ago Posts: 255 |

Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Haha "home" button in the GUI. I will double check but it appears everything is setup correctly according to the diagrams.

Thanks

I figured that, but couldn't resist ;-)

There are many diagrams around and although I'd expect them to be the same and show all motors the same way, you can just compare your X-motor wiring to Y and Z which move in the correct directions. You can often reverse the connector for X and Y motors, but you can't reverse sintron-supplied connectors for Z axis. And the only way you can plug Z in is actually reverse, so I had to reverse direction in firmware. But then again all my motors were moving in the same direction, so it does sound like you did flip one of those…

Here is video I took of the issue. I tried inverting with "true" under #define INVERT_X_DIR but that doesn't work. All my wiring appears correct. It looks like it starts going up but then begins to go down as the others hit the end stops.

[www.youtube.com]

Wiring:

This is beyond me, it actually starts moving in the correct direction but halfway it looks like it gets some mechanical problem, some obstacle, maybe rods interferring with each other, but then at the end it seems to be indeed moving the wrong way… Maybe someone more experienced will give you a sound advice, all I can suggest is that you lower the speed and try looking closely checking for mechanical issues…

And yes, your wiring looks like they should be moving at least in one direction unless you specifically invert a single axis in firmware.

Edited 1 time(s). Last edit at 11/10/2015 06:49PM by hacker.

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 07:19PM |

Registered: 8 years ago Posts: 23 |

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 07:21PM |

Registered: 9 years ago Posts: 67 |

@Bigkahuna2187

That could be a defect endstop, or endstop cable or noise on the endstop line.

The carriages go up until they receive a endstop hit. Then x starts to back up a short distance, tries a second touch, can't find the stop a second time, stops again (because the second move towards the endstop is only 1.5 times the backward move). Then things begin to go completely wrong. Have not analysed this completely but i guess the tower coordinate system is messed up in that case.

That could be a defect endstop, or endstop cable or noise on the endstop line.

The carriages go up until they receive a endstop hit. Then x starts to back up a short distance, tries a second touch, can't find the stop a second time, stops again (because the second move towards the endstop is only 1.5 times the backward move). Then things begin to go completely wrong. Have not analysed this completely but i guess the tower coordinate system is messed up in that case.

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 07:52PM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit November 10, 2015 09:13PM |

Registered: 8 years ago Posts: 23 |

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

Edited 1 time(s). Last edit at 11/10/2015 09:14PM by Bigkahuna2187.

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 03:18AM |

Registered: 8 years ago Posts: 89 |

hit and stay, unless you manually set endstop offsets with M666.Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 04:42AM |

Registered: 8 years ago Posts: 104 |

But after minute or so, drives go to idle mode and endstops have enough force tp push carriages a bit down. So, usually, when you hit print, printer goes home and starts heating the head. But minute is not enough to reach desired temperature, so it releases motors, they go down a bit and upon starting moving head the height is not accurate anymore. So, I added "M84 S180" to custom start g-code in slicer program to hold motors for 3 minutes instead of one.Quote

Tha_Reaper

hit and stay, unless you manually set endstop offsets with M666.Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 04:59AM |

Registered: 8 years ago Posts: 255 |

Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

Congrats ;-) But you're out of spare stepper drivers now ;-) So am I… My extruder stepper has died suddenly and I have no idea why.

I think it depends on firmware, I'm not sure what are Marlin's defaults. At the very least I Think it hits, goes back and then again up? I think you will have opportunity to worry about it later, just try getting things work now

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 02:14PM |

Registered: 8 years ago Posts: 23 |

Quote

hacker

Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

Congrats ;-) But you're out of spare stepper drivers now ;-) So am I… My extruder stepper has died suddenly and I have no idea why.

I think it depends on firmware, I'm not sure what are Marlin's defaults. At the very least I Think it hits, goes back and then again up? I think you will have opportunity to worry about it later, just try getting things work now

Thanks!

Did anyone have to invert their extruder direction? When I click Extrude in Pronterface the filament moves toward the extruder and when I click reverse the filament moves towards the hotend. Hoping my stepper isnt fried for this as well.

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 02:52PM |

Registered: 8 years ago Posts: 89 |

Thats normal. Marlin is stock setup for a geared extruder. This kit comes with a direct drive extruder, so you should set #define INVERT_E0_DIR in configuration.h to true. that way the extruder really extrudes when you tell it to instead of retracting.Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Quote

hacker

Quote

Bigkahuna2187

Looks like I had a bad stepper drive. Good thing the kit came with an extra!

Meaning you got it working?

Yes everything is working properly now. Glad it was an easy fix.

Now, when homing, are the carriages suppose to hit the endstops and stay or are they suppose to go down some?

Congrats ;-) But you're out of spare stepper drivers now ;-) So am I… My extruder stepper has died suddenly and I have no idea why.

I think it depends on firmware, I'm not sure what are Marlin's defaults. At the very least I Think it hits, goes back and then again up? I think you will have opportunity to worry about it later, just try getting things work now

Thanks!

Did anyone have to invert their extruder direction? When I click Extrude in Pronterface the filament moves toward the extruder and when I click reverse the filament moves towards the hotend. Hoping my stepper isnt fried for this as well.

|

Re: Ebay SINTRON Kossel Mini full kit November 11, 2015 10:16PM |

Registered: 8 years ago Posts: 23 |

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 01:14AM |

Registered: 8 years ago Posts: 104 |

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 04:56AM |

Registered: 8 years ago Posts: 8 |

1. I have a question regarding Printing time.

Printed a mobile phone stand took about 2 hours.

now I am using Cura because Pronterface does not want to work (AGAIN)

now it takes about 5 hours + to print the same thing.

I have played with a few settings but nothing much makes a big difference

I have gone to Default in Cura still slow. 0.1 Layer Height, 2mm shell 100mm/s print speed. 20% fill Density. still slower than before

2. I am a little concerned with the movement of the 3 wheel carrage truck

I thought a 4 wheel Carrage Truck and Delvin rollers would do the trick however Delvin rollers are M3 and Carrage Trucks are M4

I am not good in Cad so maybe I can sleeve them. Any one else Been Here ?

Printed a mobile phone stand took about 2 hours.

now I am using Cura because Pronterface does not want to work (AGAIN)

now it takes about 5 hours + to print the same thing.

I have played with a few settings but nothing much makes a big difference

I have gone to Default in Cura still slow. 0.1 Layer Height, 2mm shell 100mm/s print speed. 20% fill Density. still slower than before

2. I am a little concerned with the movement of the 3 wheel carrage truck

I thought a 4 wheel Carrage Truck and Delvin rollers would do the trick however Delvin rollers are M3 and Carrage Trucks are M4

I am not good in Cad so maybe I can sleeve them. Any one else Been Here ?

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 05:32AM |

Registered: 8 years ago Posts: 8 |

Electronics- Yes just reverse the leads on stepper motors take the plug off the ramps and turn it around if it is going in the wrong Direction.

Please put your Power supply output to 13.8 volts it will not over heat the regulators however definately blow a small fan over the ramps board.

Current (amps) is what will cook things the higher voltage helps with less current to give you the watts needed.

Put a heat sink on the Heatbed Tr also

Please put your Power supply output to 13.8 volts it will not over heat the regulators however definately blow a small fan over the ramps board.

Current (amps) is what will cook things the higher voltage helps with less current to give you the watts needed.

Put a heat sink on the Heatbed Tr also

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 05:41AM |

Registered: 8 years ago Posts: 255 |

Quote

theda1

1. I have a question regarding Printing time.

Printed a mobile phone stand took about 2 hours.

now I am using Cura because Pronterface does not want to work (AGAIN)

now it takes about 5 hours + to print the same thing.

I have played with a few settings but nothing much makes a big difference

I have gone to Default in Cura still slow. 0.1 Layer Height, 2mm shell 100mm/s print speed. 20% fill Density. still slower than before

2. I am a little concerned with the movement of the 3 wheel carrage truck

I thought a 4 wheel Carrage Truck and Delvin rollers would do the trick however Delvin rollers are M3 and Carrage Trucks are M4

I am not good in Cad so maybe I can sleeve them. Any one else Been Here ?

Without knowing what model we're talking about the time isn't of much help, but so far I can see that 0.1 layer is pretty thin and of course yields longer printing times, then there's a travel speed and acceleration to take into account. Check firmware speed and acceleration limits and perhaps raise it. And, well, arduino/ramps has its own limitations as to how much it can do within a given time. Not sure what limits you're bumping in.

Since you mention the difference between "pronterface" and cura, perhaps you may want to somehow look up the settings used for pronterface's slicer whatever slicer it uses, I think it's Slic3r?

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 06:17AM |

Registered: 9 years ago Posts: 445 |

Quote

hacker

Quote

theda1

1. I have a question regarding Printing time.

Printed a mobile phone stand took about 2 hours.

now I am using Cura because Pronterface does not want to work (AGAIN)

now it takes about 5 hours + to print the same thing.

I have played with a few settings but nothing much makes a big difference

I have gone to Default in Cura still slow. 0.1 Layer Height, 2mm shell 100mm/s print speed. 20% fill Density. still slower than before

2. I am a little concerned with the movement of the 3 wheel carrage truck

I thought a 4 wheel Carrage Truck and Delvin rollers would do the trick however Delvin rollers are M3 and Carrage Trucks are M4

I am not good in Cad so maybe I can sleeve them. Any one else Been Here ?

Without knowing what model we're talking about the time isn't of much help, but so far I can see that 0.1 layer is pretty thin and of course yields longer printing times, then there's a travel speed and acceleration to take into account. Check firmware speed and acceleration limits and perhaps raise it. And, well, arduino/ramps has its own limitations as to how much it can do within a given time. Not sure what limits you're bumping in.

Since you mention the difference between "pronterface" and cura, perhaps you may want to somehow look up the settings used for pronterface's slicer whatever slicer it uses, I think it's Slic3r?

A mobile phone stand doesn't sound very large, so it might be worth looking into "min. layer time" or some setting like that.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 09:47AM |

Registered: 8 years ago Posts: 15 |

Hi everyone,

first printer and first post in this forum. I finished building the Sintron Kossel kit yesterday, so today I will start with calibration. However before I start, I have some questions regarding the 'configuration.h' that comes with the Marlin firmware provided by Sintron. Please excuse if some of my questions have already been answered elsewhere...

My main question is: what parameters do I have to adjust and which parameters can be taken just as is?

Printer geometry

From reading this thread and several other sources regarding calibration of the Kossel Mini it seems as if DELTA_EFFECTOR_OFFSET and DELTA_CARRIAGE_OFFSET should be (as long as now modifications have been done to e.g. the carriages) the same for each and every Sintron Kossel printer out there, right? Still, do I have to touch these values in the Sintron 'configuration.h'? From what I understand I only have to adjust the DELTA_SMOOTH-ROD-OFFSET and the DELTA_DIAGONAL_ROD values according to my setup or am I wrong here?

I used a jig milled on my CNC router to assemble the rods using Traxxas joints:

Hence, DELTA_DIAGONAL_ROD length should almost perfectly be ~220mm for each rod. However, what I am currently scratching my head on is how to measure the DELTA_SMOOTH-ROD-OFFSET. From my understanding DELTA_SMOOTH-ROD-OFFSET should be affected by the endstop calibration. Hence, until I have not corrected for the endstop offsets adjusting the DELTA_SMOOTH-ROD-OFFSET parameter would not make any sense, right?

Motors

Obviously the DEFAULT_AXIS_STEPS_PER_UNIT are wrong in the Sintron 'configuration.h'. Do you think it makes sense to use a gauge to get the correct steps/mm; i.e. adjusting DEFAULT_AXIS_STEPS_PER_UNIT until a 1mm step on the z axis send via pronterface corresponds to 1mm measured by the gauge for each tower? As an alternative, would it be ok to just set each tower to 80 steps/mm?

Thank you for your help!!

first printer and first post in this forum. I finished building the Sintron Kossel kit yesterday, so today I will start with calibration. However before I start, I have some questions regarding the 'configuration.h' that comes with the Marlin firmware provided by Sintron. Please excuse if some of my questions have already been answered elsewhere...

My main question is: what parameters do I have to adjust and which parameters can be taken just as is?

Printer geometry

From reading this thread and several other sources regarding calibration of the Kossel Mini it seems as if DELTA_EFFECTOR_OFFSET and DELTA_CARRIAGE_OFFSET should be (as long as now modifications have been done to e.g. the carriages) the same for each and every Sintron Kossel printer out there, right? Still, do I have to touch these values in the Sintron 'configuration.h'? From what I understand I only have to adjust the DELTA_SMOOTH-ROD-OFFSET and the DELTA_DIAGONAL_ROD values according to my setup or am I wrong here?

I used a jig milled on my CNC router to assemble the rods using Traxxas joints:

Hence, DELTA_DIAGONAL_ROD length should almost perfectly be ~220mm for each rod. However, what I am currently scratching my head on is how to measure the DELTA_SMOOTH-ROD-OFFSET. From my understanding DELTA_SMOOTH-ROD-OFFSET should be affected by the endstop calibration. Hence, until I have not corrected for the endstop offsets adjusting the DELTA_SMOOTH-ROD-OFFSET parameter would not make any sense, right?

Motors

Obviously the DEFAULT_AXIS_STEPS_PER_UNIT are wrong in the Sintron 'configuration.h'. Do you think it makes sense to use a gauge to get the correct steps/mm; i.e. adjusting DEFAULT_AXIS_STEPS_PER_UNIT until a 1mm step on the z axis send via pronterface corresponds to 1mm measured by the gauge for each tower? As an alternative, would it be ok to just set each tower to 80 steps/mm?

Thank you for your help!!

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 10:14AM |

Registered: 8 years ago Posts: 255 |

Quote

HaGeEm

Hi everyone,

first printer and first post in this forum. I finished building the Sintron Kossel kit yesterday, so today I will start with calibration. However before I start, I have some questions regarding the 'configuration.h' that comes with the Marlin firmware provided by Sintron. Please excuse if some of my questions have already been answered elsewhere...

My main question is: what parameters do I have to adjust and which parameters can be taken just as is?

Printer geometry

From reading this thread and several other sources regarding calibration of the Kossel Mini it seems as if DELTA_EFFECTOR_OFFSET and DELTA_CARRIAGE_OFFSET should be (as long as now modifications have been done to e.g. the carriages) the same for each and every Sintron Kossel printer out there, right? Still, do I have to touch these values in the Sintron 'configuration.h'? From what I understand I only have to adjust the DELTA_SMOOTH-ROD-OFFSET and the DELTA_DIAGONAL_ROD values according to my setup or am I wrong here?

I used a jig milled on my CNC router to assemble the rods using Traxxas joints:

Hence, DELTA_DIAGONAL_ROD length should almost perfectly be ~220mm for each rod. However, what I am currently scratching my head on is how to measure the DELTA_SMOOTH-ROD-OFFSET. From my understanding DELTA_SMOOTH-ROD-OFFSET should be affected by the endstop calibration. Hence, until I have not corrected for the endstop offsets adjusting the DELTA_SMOOTH-ROD-OFFSET parameter would not make any sense, right?

Motors

Obviously the DEFAULT_AXIS_STEPS_PER_UNIT are wrong in the Sintron 'configuration.h'. Do you think it makes sense to use a gauge to get the correct steps/mm; i.e. adjusting DEFAULT_AXIS_STEPS_PER_UNIT until a 1mm step on the z axis send via pronterface corresponds to 1mm measured by the gauge for each tower? As an alternative, would it be ok to just set each tower to 80 steps/mm?

Thank you for your help!!

All in all, I think you're more experienced than I am (you've milled a cool jig, after al!), but I'll try ;-)

The horizontal dimension is based on the parts involved in the first place and is set to theoretical value and if you still have some concave/convex problems you adjust it during the calibration. I think that's one of the things that they got right in firmware.

I think 80mm is a pretty safe bet. You can put a mark on your column, then move carriage, calculate the distance and adjust your firmware values then. I ended up with 80 anyway. Watch out for motors directions! And try being slow and having a power switch off with initial attempts ;-)

I admire your patience, I'd go for calibrating and wouldn't be able to wait for a forum response ;-)

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 10:40AM |

Registered: 8 years ago Posts: 15 |

Thanks for your reply, hacker!

Regarding calibration of the printer geometry I guess I'll just adjust the rod length and keep all parameters as provided by Sintron for a first try.

Marking the carriage positions on each tower is a nice idea for adjusting the steps/mm. I'll give it a try instead of using a gauge (which might be more complicated to set up anyway).

Just another question came up. Currently I have put my RAMPS board below the heatbed. Although I have insulated the space below the heatbed using cardboard and aluminium foil, I currently do not have any fan or something installed to cool the stepper drivers. Do you think I can give it a try or do you think I should definitely cool the electronics before starting with calibration and test printing?

Regarding the jig I milled, if there is any interest I can upload the STL to thingiverse. Although I guess there are already some other jigs floating around there. Further I made an endstop holder, which fits quite nicely using the nuts provided in the kit. It is quite easy to mill/print (when milling/printing the spacers underneath separately) :

I can upload this also...

Edited 3 time(s). Last edit at 11/12/2015 10:55AM by HaGeEm.

Quote

hacker

The horizontal dimension is based on the parts involved in the first place and is set to theoretical value and if you still have some concave/convex problems you adjust it during the calibration. I think that's one of the things that they got right in firmware.

Regarding calibration of the printer geometry I guess I'll just adjust the rod length and keep all parameters as provided by Sintron for a first try.

Quote

hacker

I think 80mm is a pretty safe bet. You can put a mark on your column, then move carriage, calculate the distance and adjust your firmware values then.

Marking the carriage positions on each tower is a nice idea for adjusting the steps/mm. I'll give it a try instead of using a gauge (which might be more complicated to set up anyway).

Just another question came up. Currently I have put my RAMPS board below the heatbed. Although I have insulated the space below the heatbed using cardboard and aluminium foil, I currently do not have any fan or something installed to cool the stepper drivers. Do you think I can give it a try or do you think I should definitely cool the electronics before starting with calibration and test printing?

Regarding the jig I milled, if there is any interest I can upload the STL to thingiverse. Although I guess there are already some other jigs floating around there. Further I made an endstop holder, which fits quite nicely using the nuts provided in the kit. It is quite easy to mill/print (when milling/printing the spacers underneath separately) :

I can upload this also...

Edited 3 time(s). Last edit at 11/12/2015 10:55AM by HaGeEm.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 11:44AM |

Registered: 8 years ago Posts: 255 |

Quote

HaGeEm

Just another question came up. Currently I have put my RAMPS board below the heatbed. Although I have insulated the space below the heatbed using cardboard and aluminium foil, I currently do not have any fan or something installed to cool the stepper drivers. Do you think I can give it a try or do you think I should definitely cool the electronics before starting with calibration and test printing?

Regarding the jig I milled, if there is any interest I can upload the STL to thingiverse. Although I guess there are already some other jigs floating around there. Further I made an endstop holder, which fits quite nicely using the nuts provided in the kit. It is quite easy to mill/print (when milling/printing the spacers underneath separately) :

I can upload this also...

I have never installed electronics under the bed. Neither original arduino/ramps, nor the new duet (thinner and cooler) — for no reason ;-) I may get to that later. And my plan is to first measure how hot it is in there ;-) Actually, even on the table the original ramps heatbed fuse was overheating so badly that without fanning it I couldn't heat up bed. Though that was fixed by replacing the fuse.

Yeah, I was mostly referring to the fact that you have CNC mill, which kinda suggests you're into that kind of stuff ;-) And yes, I desired the endstop myself — [www.thingiverse.com] — (also earlier in this thread). For what I can tell by this thread pretty much everyone designs his own endstop for this kit. It sure is way too trivial to use someone else's design and the original part is hardly usable at all.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 11:54AM |

Registered: 8 years ago Posts: 89 |

As soon as you heat the bed, or you want to print for a longer period of time, I would make sure you have a fan under the bed blowing over the electronics. I calibrated my printer using an unheated bed since that works fine with PLA. No need to cool the electronics for that also because calibration prints are usually low speed so less chance to overheat your stepper drivers.

I would recommend putting a small heatsink on the 12v rail MOSFET by the way. Mine is acting up otherwise when I heat the bed.

Edited 1 time(s). Last edit at 11/12/2015 11:55AM by Tha_Reaper.

I would recommend putting a small heatsink on the 12v rail MOSFET by the way. Mine is acting up otherwise when I heat the bed.

Edited 1 time(s). Last edit at 11/12/2015 11:55AM by Tha_Reaper.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 12:55PM |

Registered: 8 years ago Posts: 15 |

Okay, I think I might have an old fan lying around. I'll try to cramp it in there. Tha_Reaper, are you using a specific heatsink for the MOSFET (which can be ordered somewhere)?

Yeah, at least I now some basic gcode commands and how to use CAD software Having a CNC mill is really nice especially for routing PCBs and so on. However, I hope that I can overcome some of the restrictions 2.5D milling has using the Kossel.

Having a CNC mill is really nice especially for routing PCBs and so on. However, I hope that I can overcome some of the restrictions 2.5D milling has using the Kossel.

Quote

hacker

Yeah, I was mostly referring to the fact that you have CNC mill, which kinda suggests you're into that kind of stuff ;-)

Yeah, at least I now some basic gcode commands and how to use CAD software

Having a CNC mill is really nice especially for routing PCBs and so on. However, I hope that I can overcome some of the restrictions 2.5D milling has using the Kossel.

Having a CNC mill is really nice especially for routing PCBs and so on. However, I hope that I can overcome some of the restrictions 2.5D milling has using the Kossel.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 01:00PM |

Registered: 8 years ago Posts: 23 |

I know this may be a very broad question, but any tips on printing for the first time since no .ini was supplied? Im attempting without setting up my auto probe retract which im not in a rush to setup. Can I auto level, go to 0,0,0 and begin printing with my .stl file after tweaking slic3r parameters?

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 01:30PM |

Registered: 8 years ago Posts: 89 |

I use a similar heatsink as you use for the stepper drivers. You can order like 50 of those for under 10 bucks if you search for heatsink MOSFET on ebayQuote

HaGeEm

Okay, I think I might have an old fan lying around. I'll try to cramp it in there. Tha_Reaper, are you using a specific heatsink for the MOSFET (which can be ordered somewhere)?

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 01:55PM |

Registered: 8 years ago Posts: 89 |

Quote

Bigkahuna2187

I know this may be a very broad question, but any tips on printing for the first time since no .ini was supplied? Im attempting without setting up my auto probe retract which im not in a rush to setup. Can I auto level, go to 0,0,0 and begin printing with my .stl file after tweaking slic3r parameters?

Here are my slic3r settings. they work for me, but are far from perfect. maybe a good starting point.

Slic3r_config_bundlesintronkossel.ini

I also made a M666 button in pronterface. i use that button before i start every print. after i replaced the tape on the bed, or removed the bed, i totally recalculate the M666 settings again. takes me about 2 minutes to get it manually right if i use my last M666 settings as a starting point.

Edited 1 time(s). Last edit at 11/12/2015 01:58PM by Tha_Reaper.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 02:51PM |

Registered: 8 years ago Posts: 319 |

Quote

HaGeEm

Thanks for your reply, hacker!

Quote

hacker

The horizontal dimension is based on the parts involved in the first place and is set to theoretical value and if you still have some concave/convex problems you adjust it during the calibration. I think that's one of the things that they got right in firmware.

Regarding calibration of the printer geometry I guess I'll just adjust the rod length and keep all parameters as provided by Sintron for a first try.

Quote

hacker

I think 80mm is a pretty safe bet. You can put a mark on your column, then move carriage, calculate the distance and adjust your firmware values then.

Marking the carriage positions on each tower is a nice idea for adjusting the steps/mm. I'll give it a try instead of using a gauge (which might be more complicated to set up anyway).

Just another question came up. Currently I have put my RAMPS board below the heatbed. Although I have insulated the space below the heatbed using cardboard and aluminium foil, I currently do not have any fan or something installed to cool the stepper drivers. Do you think I can give it a try or do you think I should definitely cool the electronics before starting with calibration and test printing?

Regarding the jig I milled, if there is any interest I can upload the STL to thingiverse. Although I guess there are already some other jigs floating around there. Further I made an endstop holder, which fits quite nicely using the nuts provided in the kit. It is quite easy to mill/print (when milling/printing the spacers underneath separately) :

I can upload this also...

DO NOT put the RAMPS below the heatbed. I did that and I fried my MOSFET. Why? Because you cannot see the fan moving and blowing air. Yes I installed a fan below the heatbed blowing onto my RAMPS. It looks amazing. All electronics hidden. But you cannot see or hear if the fan is on. If for some reason the fan is off. Your RAMPS will smoke and you will not know until it is too late. Also, I insulated the heatbed bottom. But you are still getting cool air below counteracting the heat above. So it takes longer for the heatbed to get hot. I instead did a different method and mounted a new RAMPS setup on the X axis rod. And if DC42 reads this. Yes I have not bought the Duet. Im trying not to spend the $150 to buy that board.

Also HaGeEm what CAD software are you using. I am using TurboCAD pro.

Edited 1 time(s). Last edit at 11/12/2015 02:52PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit November 12, 2015 03:18PM |

Registered: 8 years ago Posts: 89 |

Thats where this thing comes in handy: [www.thingiverse.com]Quote

DRTak

DO NOT put the RAMPS below the heatbed. I did that and I fried my MOSFET. Why? Because you cannot see the fan moving and blowing air. Yes I installed a fan below the heatbed blowing onto my RAMPS. It looks amazing. All electronics hidden. But you cannot see or hear if the fan is on. If for some reason the fan is off. Your RAMPS will smoke and you will not know until it is too late. Also, I insulated the heatbed bottom. But you are still getting cool air below counteracting the heat above. So it takes longer for the heatbed to get hot.

you can see when your fans are running. I use 2 of those, and 1 30mm fan inside of the frame. The 30mm fan is very, very noisy. as soon as its up to speed you can hear it above all the other printer sounds. Hard to miss when that thing is not on.

I know the risk of smoking the RAMPS is higher, but i still prefer this to external electronics (at least untill i tidied up the cable mess and i'm able to build a good case for the RAMPS)

Sorry, only registered users may post in this forum.