Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit November 15, 2015 07:38AM |

Registered: 8 years ago Posts: 89 |

I think this is indeed the problem... i tried trimming the plastic a bit, but now the hotend has a slight play in it. Not good...Quote

dc42

Quote

GrAndAG

If the effector moves without any tilt, you should have absolutely no problem even with non-vertical hot-end. Because this defect affects [X:Y] offset only, and it's constant. Which can be adjusted in Slic3r to make [0:0] point of the nozzle perfectly in center of the table if you wish. But it's absolutely not needed.

I'm sorry, I misunderstood. I don't think that tilt matters very much. I think it may be caused by the groove mount plate not being screwed tight up against the effector, so the effector is horizontal but the groove mount plate isn't.. May be there is a stray bit of plastic between them that needs to be trimmed off.

I'm going to try another version of the effector, this one should not have the same problem as it secures the hotend in another way: [www.thingiverse.com]

As an example of what i mean with overhang artefacts i'll show these 2 pictures:

Front of the object:

[www.dropbox.com]

Back of the object:

[www.dropbox.com]

you can see a lot of thick overhang issues on the back, while only a few on the front. My therory is that this is because of the tilted hotend...

|

Re: Ebay SINTRON Kossel Mini full kit November 15, 2015 12:00PM |

Registered: 8 years ago Posts: 104 |

Quote

Tha_Reaper

As an example of what i mean with overhang artefacts i'll show these 2 pictures:

Front of the object:

[www.dropbox.com]

Back of the object:

[www.dropbox.com]

you can see a lot of thick overhang issues on the back, while only a few on the front. My therory is that this is because of the tilted hotend...

Is it PLA or ABS? If PLA, the difference could be due to non-uniform cooling.

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 01:28AM |

Registered: 8 years ago Posts: 89 |

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 04:24AM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 04:53AM |

Registered: 8 years ago Posts: 17 |

good point actually.... does anybody have a good cooling solution for our kits (and hotends) ? Most solutions I found either are made for different heatsink diameters or are to big overall costing way to much printspace on the edges. Or both

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 05:04AM |

Registered: 8 years ago Posts: 255 |

Quote

MrPCatt

good point actually.... does anybody have a good cooling solution for our kits (and hotends) ? Most solutions I found either are made for different heatsink diameters or are to big overall costing way to much printspace on the edges. Or both

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

I have a solution combined from various parts available and some designed myself, but that's not of much use as I have different heatsink diameter, somewhat different mount and actually it does cost a bit more space than I'd want it to, so I'm still thinking… ;-)

But what I wanted to say is that it's best to cool nozzle as little as possible while cooling the extruded plastic well, but in reality you always compromise this way or another…

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 06:06AM |

Registered: 8 years ago Posts: 916 |

Quote

MrPCatt

good point actually.... does anybody have a good cooling solution for our kits (and hotends) ? Most solutions I found either are made for different heatsink diameters or are to big overall costing way to much printspace on the edges. Or both

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

It's best to have some control over the cooling.

I was having no end of trouble with a certain part (long and thin) curling up on me (ABS, with raft and PEI bed). Eventually after a dozen or so failures I figured out that the exhaust from the hot end fan was cooling the part too much. Rotating the part so that it was at 90 degrees to the airflow made a huge difference and now I'm getting perfect prints. I also put a small metal shroud to guide the airflow from the fan to past the heatsink, so it didn't go down to the bed.

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 12:02PM |

Registered: 8 years ago Posts: 319 |

Quote

MrPCatt

good point actually.... does anybody have a good cooling solution for our kits (and hotends) ? Most solutions I found either are made for different heatsink diameters or are to big overall costing way to much printspace on the edges. Or both

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

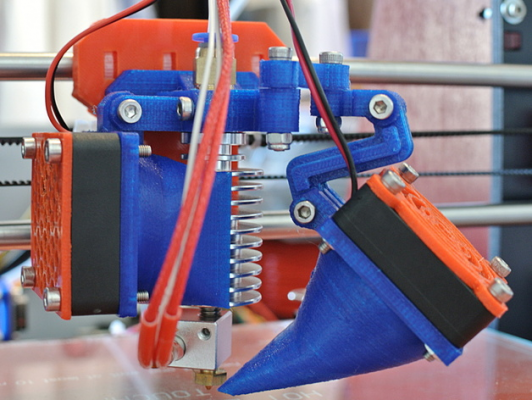

This is an exact fit for our kit. I downloaded this and use it. It works perfectly.

[www.thingiverse.com]

Remove fan. Place shroud. Put fan on shroud. screw in place. its an exact fit for our kossel.

I was having hot end cooling issues when using ABS. Now no more issues.

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 12:18PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Quote

MrPCatt

good point actually.... does anybody have a good cooling solution for our kits (and hotends) ? Most solutions I found either are made for different heatsink diameters or are to big overall costing way to much printspace on the edges. Or both

And does it matter having a fan blowing to the noozle? Or do I have to make sure only have the fan hitting the object itself?

This is an exact fit for our kit. I downloaded this and use it. It works perfectly.

[www.thingiverse.com]

Remove fan. Place shroud. Put fan on shroud. screw in place. its an exact fit for our kossel.

I was having hot end cooling issues when using ABS. Now no more issues.

Good thing, though it's only about heatsink cooling, not part cooling.

|

Re: Ebay SINTRON Kossel Mini full kit November 16, 2015 07:58PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 02:32AM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:13AM |

Registered: 8 years ago Posts: 104 |

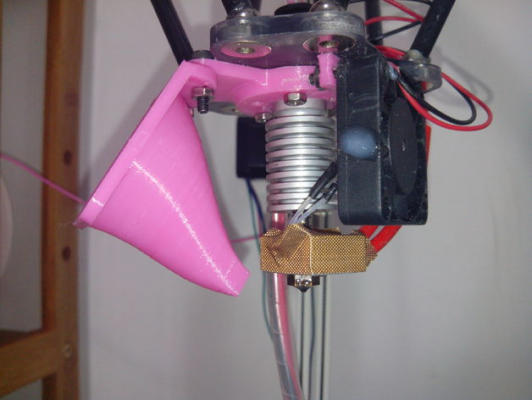

Ideally, you have to have 2 fans. One is permanently cooling the heatsink and connected directly to 12V contacts of PSU. And the second one (for PLA cooling) is blowing directly to area around the nozzle, which can be connected to D9 output of RAMPS for controlling from printing software (or from g-code).

Like this:

http://www.thingiverse.com/thing:540716

Or this:

http://www.thingiverse.com/thing:451667

Edited 1 time(s). Last edit at 11/17/2015 05:13AM by GrAndAG.

Like this:

http://www.thingiverse.com/thing:540716

Or this:

http://www.thingiverse.com/thing:451667

Edited 1 time(s). Last edit at 11/17/2015 05:13AM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:16AM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:18AM |

Registered: 8 years ago Posts: 17 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:25AM |

Registered: 8 years ago Posts: 255 |

Quote

MrPCatt

For the object fan we now just need a really space saving solution. Or at least a solution which does not collide with one of the towers.

There are also solutions like this one: [www.thingiverse.com]

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:29AM |

Registered: 8 years ago Posts: 104 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:32AM |

Registered: 8 years ago Posts: 15 |

Okay, I finished calibration and did some test prints using PLA yesterday evening. I used 0.3mm layer height for the first two layers and 0.2mm for the rest. Printing speed was 20mm/s for the external perimeters and 40mm/s for the infill (20%). I set the bed temperature to 60°C and hotend temperature to 195°C for the first layers and 185°C for the rest. First 10mm cube had corners bended upwards. After cooling the PLA on the heatbed using a (handheld) fan the cube dimensions were almost perfect. Both, X and Y exactly 9.98mm. However, Z height was 10.37mm.

Could someone point out what potentially causes this problem? Is it due to overextrusion? What I observed during printing was that the higher layers were more like a smear of PLA. Although I am new to 3D printing I guess this is not intended? I think there is also a post in this thread which states that Slic3er 1.2.9 has a problem with getting the extrusion width right. However, as X and Y width were almost perfect I guess this should not be a problem?

Thanks for your help!

Could someone point out what potentially causes this problem? Is it due to overextrusion? What I observed during printing was that the higher layers were more like a smear of PLA. Although I am new to 3D printing I guess this is not intended? I think there is also a post in this thread which states that Slic3er 1.2.9 has a problem with getting the extrusion width right. However, as X and Y width were almost perfect I guess this should not be a problem?

Thanks for your help!

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:41AM |

Registered: 8 years ago Posts: 17 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:49AM |

Registered: 8 years ago Posts: 104 |

HaGeEm,

I'm printing PLA @ 195C all layers, 0.2 thickness (all layers again). 60mm/s for perimeters (70% for outer), 80-90mm/s - infill, 60mm/s - top/bottom (15-20mm/s very first layer). But I heating up the bed is very bit - to 40C.

Even on default Slic3r settings (40mm/s, 200C, layer 0.3) I had my very first print (1cm cube) very decent. Could you show us yours?

I'm printing PLA @ 195C all layers, 0.2 thickness (all layers again). 60mm/s for perimeters (70% for outer), 80-90mm/s - infill, 60mm/s - top/bottom (15-20mm/s very first layer). But I heating up the bed is very bit - to 40C.

Even on default Slic3r settings (40mm/s, 200C, layer 0.3) I had my very first print (1cm cube) very decent. Could you show us yours?

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:56AM |

Quote

HaGeEm

Okay, I finished calibration and did some test prints using PLA yesterday evening. I used 0.3mm layer height for the first two layers and 0.2mm for the rest. Printing speed was 20mm/s for the external perimeters and 40mm/s for the infill (20%). I set the bed temperature to 60°C and hotend temperature to 195°C for the first layers and 185°C for the rest. First 10mm cube had corners bended upwards. After cooling the PLA on the heatbed using a (handheld) fan the cube dimensions were almost perfect. Both, X and Y exactly 9.98mm. However, Z height was 10.37mm.

Could someone point out what potentially causes this problem? Is it due to overextrusion? What I observed during printing was that the higher layers were more like a smear of PLA. Although I am new to 3D printing I guess this is not intended? I think there is also a post in this thread which states that Slic3er 1.2.9 has a problem with getting the extrusion width right. However, as X and Y width were almost perfect I guess this should not be a problem?

Thanks for your help!

Had the same Problem when printing to cold and / or to fast. - Gets even worse, the higher the printed object is ... - up to complete blockage of Hotend.

I'm printing at about 12-15mm/sec at 0,2mm Layer height and 215°C for PLA

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:57AM |

Registered: 8 years ago Posts: 15 |

Thanks for getting back to me! I will print a 20mm calibration cube to see if dimensions are still okay and then fiddle around with Slic3er settings...

I will try your settings, thanks!

Sure, I will take a picture of it later today, as I am not at home currently...

Quote

GrAndAG

I'm printing PLA @ 195C all layers, 0.2 thickness (all layers again). 60mm/s for perimeters (70% for outer), 80-90mm/s - infill, 60mm/s - top/bottom (15-20mm/s very first layer). But I heating up the bed is very bit - to 40C.

I will try your settings, thanks!

Quote

GrAndAG

Even on default Slic3r settings (40mm/s, 200C, layer 0.3) I had my very first print (1cm cube) very decent. Could you show us yours?

Sure, I will take a picture of it later today, as I am not at home currently...

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 05:59AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Had the same Problem when printing to cold and / or to fast. - Gets even worse, the higher the printed object is ... - up to complete blockage of Hotend.

I'm printing at about 12-15mm/sec at 0,2mm Layer height and 215°C for PLA

Could that be that it's just too slow for your heatsink cooling? The longer filament stays near the heated area the higher the heat creeps, the more likely it is to clog? And of course the higher the object is (the longer you print) the likelier it is to finally block the hotend?

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 06:00AM |

Registered: 8 years ago Posts: 15 |

Quote

Sir_Death

Had the same Problem when printing to cold and / or to fast. - Gets even worse, the higher the printed object is ... - up to complete blockage of Hotend.

I'm printing at about 12-15mm/sec at 0,2mm Layer height and 215°C for PLA

Mhm, your settings seem to be totally different from GrAndAG's. I think I will just have to experiment with different settings then...

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 06:10AM |

Registered: 8 years ago Posts: 15 |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 06:11AM |

Registered: 8 years ago Posts: 255 |

Quote

hacker

Quote

Sir_Death

Had the same Problem when printing to cold and / or to fast. - Gets even worse, the higher the printed object is ... - up to complete blockage of Hotend.

I'm printing at about 12-15mm/sec at 0,2mm Layer height and 215°C for PLA

Could that be that it's just too slow for your heatsink cooling? The longer filament stays near the heated area the higher the heat creeps, the more likely it is to clog? And of course the higher the object is (the longer you print) the likelier it is to finally block the hotend?

Oops, sorry, it sounds like the slowness actually solved your problem ;-)

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 06:45AM |

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 06:51AM |

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 08:30AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Correct - printing faster gave holes in the print, and nozzle got jammed after about 3-4cm printing height.

Slowing down to 12-15mm/sec (1,3mm³/sec volumetric speed), and printing is perfect....

Interesting… admittedly I use different hotend, but I can print PLA at about 100-120mm/s with no underextrusion at 215C…

Does your motor skip when printing faster? Could it be that it's underpowered?

12mm is the speed I use to lay the first layer of PETG…

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 08:51AM |

Quote

hacker

Interesting… admittedly I use different hotend, but I can print PLA at about 100-120mm/s with no underextrusion at 215C…

Does your motor skip when printing faster? Could it be that it's underpowered?

12mm is the speed I use to lay the first layer of PETG…

Vref is set correctly - double-checked (it was even set to 10% more - did not get better - motor just got hotter...)

I have the same Vref on the other three Motors (X/Y/Z) no Problem with skipping there.

Hotend is simply not melting fast enough. Coldend-Fan already has a Screen to not cool the hotend. - Made it much better (was even worse before...)

|

Re: Ebay SINTRON Kossel Mini full kit November 17, 2015 09:09AM |

Registered: 8 years ago Posts: 255 |

Quote

Sir_Death

Quote

hacker

Interesting… admittedly I use different hotend, but I can print PLA at about 100-120mm/s with no underextrusion at 215C…

Does your motor skip when printing faster? Could it be that it's underpowered?

12mm is the speed I use to lay the first layer of PETG…

Vref is set correctly - double-checked (it was even set to 10% more - did not get better - motor just got hotter...)

I have the same Vref on the other three Motors (X/Y/Z) no Problem with skipping there.

Hotend is simply not melting fast enough. Coldend-Fan already has a Screen to not cool the hotend. - Made it much better (was even worse before...)

I think extruder current is not necessarily the same as other motors, I think "correctly" means it doesn't skip when extruding, but skips with blocked hotend. Of course if it gets too hot that also adjusts the idea of correctness…

My currents configuration (duet board) is M906 X600 Y600 Z600 E1000 I0.6 meaning extruder current is higher than other axes — can't tell how current numbers translate to Vref, but I think I've seen the stepper driver details somewhere in this thread. The motor is a bit warm, but not too hot.

I don't think you (or I for that matter) need to go as high as 100mm/s, but 12-15 sounds a bit slow to me… Then I think someone on this thread reported he prints infill at 150mm/s and running stock hotend?

Sorry, only registered users may post in this forum.