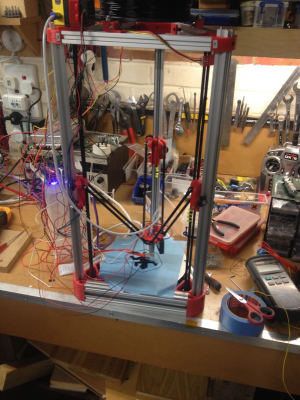

Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 03:00AM |

Registered: 8 years ago Posts: 104 |

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 03:30AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Right now I have a a heatsink fan on full. I only heat my hotend to 240 for PETG and it works fine. I have a 2nd thermistor on the heatsink itself and it reads 100deg C. Still hot but not that bad. The heatsink shroud is made of ABS so well below the metling point of ABS.

100С with fan shroud? IIRC, e3d docs say that even the lowest heatsink fins should be cold to touch at all times (and last time I checked they were). So yes, it looks like e3d does better job cooling. In itself it doesn't mean sintron's hotend isn't suited for the job, of course.

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 03:32AM |

Registered: 8 years ago Posts: 255 |

Quote

GrAndAG

Hm... My heatsink is about 45C, I think. Because I can easily touch it by hand and it's definitely colder than heat-bed @ 60C. And I do not have fan shroud (I use stock mount way).Quote

DRTak

I have a 2nd thermistor on the heatsink itself and it reads 100deg C.

Interesting. Maybe it's cold in your room?

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 02:03PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

GrAndAG

Hm... My heatsink is about 45C, I think. Because I can easily touch it by hand and it's definitely colder than heat-bed @ 60C. And I do not have fan shroud (I use stock mount way).Quote

DRTak

I have a 2nd thermistor on the heatsink itself and it reads 100deg C.

Interesting. Maybe it's cold in your room?

I see all the comments and yes. I think the only reason my heastink E3d combo works is that my room is cold. Its the basement and its around 65 deg.

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 04:08PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Quote

hacker

Quote

GrAndAG

Hm... My heatsink is about 45C, I think. Because I can easily touch it by hand and it's definitely colder than heat-bed @ 60C. And I do not have fan shroud (I use stock mount way).Quote

DRTak

I have a 2nd thermistor on the heatsink itself and it reads 100deg C.

Interesting. Maybe it's cold in your room?

I see all the comments and yes. I think the only reason my heastink E3d combo works is that my room is cold. Its the basement and its around 65 deg.

But I meant GrAndAG's room. ;-) His heatsink seems to be much colder than yours?

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 05:06PM |

Registered: 8 years ago Posts: 66 |

Hi. I just bought this kit a week ago and i now have it all built.

The fan doesn't seem to work.

I am folowing the calibration procedure they supplied in the pdf. I can set the maximum and minimum z axis coordinates. After that, i am asked to deploy the autoleveling probe. I manually deploy the probe. I home the printer and then i hit the g29 command. The print head, goes down almost till it thouches the print bed and starts the auto leveling process. It's doesn't actually touch the printbed and when it's moving from one point to another, it's going up. when it finishes the leveling, the printer is almost home again.

I guess something is not right, maybe some of the measurements. I noticed the if i go just above the print bed, a few mm above it, when moving on the Y axis away from the center, it also goes up. anybody faced this? what's the sollution?

The fan doesn't seem to work.

I am folowing the calibration procedure they supplied in the pdf. I can set the maximum and minimum z axis coordinates. After that, i am asked to deploy the autoleveling probe. I manually deploy the probe. I home the printer and then i hit the g29 command. The print head, goes down almost till it thouches the print bed and starts the auto leveling process. It's doesn't actually touch the printbed and when it's moving from one point to another, it's going up. when it finishes the leveling, the printer is almost home again.

I guess something is not right, maybe some of the measurements. I noticed the if i go just above the print bed, a few mm above it, when moving on the Y axis away from the center, it also goes up. anybody faced this? what's the sollution?

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 05:33PM |

Registered: 8 years ago Posts: 17 |

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 05:38PM |

Registered: 8 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 06:03PM |

Registered: 8 years ago Posts: 104 |

Quote

hacker

Quote

DRTak

Quote

hacker

Quote

GrAndAG

Hm... My heatsink is about 45C, I think. Because I can easily touch it by hand and it's definitely colder than heat-bed @ 60C. And I do not have fan shroud (I use stock mount way).Quote

DRTak

I have a 2nd thermistor on the heatsink itself and it reads 100deg C.

Interesting. Maybe it's cold in your room?

I see all the comments and yes. I think the only reason my heastink E3d combo works is that my room is cold. Its the basement and its around 65 deg.

But I meant GrAndAG's room. ;-) His heatsink seems to be much colder than yours?

Actually, I was wrong.

I have tried to measure heatsink temperature by pyrometer, and got values between 27° and 36° C. It's barely noticeable that it's warm when I'm touching it by fingers.

I have tried to measure heatsink temperature by pyrometer, and got values between 27° and 36° C. It's barely noticeable that it's warm when I'm touching it by fingers.Room temperature is 23°C. Printer settings for hot-end - 215°C.

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2016 11:12PM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 02:00AM |

Registered: 8 years ago Posts: 255 |

Quote

nebbian

Does anyone know which file I should use when printing a replacement effector?

Has anyone printed one that fits the hotend that Sintron provided?

I think I already posted one that sintron sent me in this thread, but finding it is beyond my capability ;-) Here it goes again.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 02:04AM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 04:24AM |

Registered: 8 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 07:04AM |

Registered: 8 years ago Posts: 916 |

Your probe or switch is sticking.

It took me ages to get my probe working smoothly, and even then I don't even use it now. Manual levelling is a pain but it's reliable.

I'd not worry too much about the probe just yet, just get everything printing properly and after a couple of months, then try getting your probe working.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 07:18AM |

Registered: 8 years ago Posts: 66 |

Thank you for your reply.

It's sticking... you mean that the probe's support shaft is to narrow, so the allen key isn't moving easely? It might be. That part was printed with wrong dimensions, at first the allen key wouldn't fit in there at all. i made it fit, with a knife, scraped the walls. might need a bit more.

i tried manual calibration, using this method. I adjusted the endstops offset fot near the pillars positions. Those 3 positions where good, then when i checked the center, it was lower than it should. according to the vid, i should lower the delta radius, but we have it as an equation in the sintron marlin firmware. so i got stuck at that, i don't know what to modify next.

Is there a better method for calibration?

It's sticking... you mean that the probe's support shaft is to narrow, so the allen key isn't moving easely? It might be. That part was printed with wrong dimensions, at first the allen key wouldn't fit in there at all. i made it fit, with a knife, scraped the walls. might need a bit more.

i tried manual calibration, using this method. I adjusted the endstops offset fot near the pillars positions. Those 3 positions where good, then when i checked the center, it was lower than it should. according to the vid, i should lower the delta radius, but we have it as an equation in the sintron marlin firmware. so i got stuck at that, i don't know what to modify next.

Is there a better method for calibration?

|

Anonymous User

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 07:20AM |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 07:48AM |

Registered: 8 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 08:38AM |

Registered: 8 years ago Posts: 5,232 |

Quote

CrisCG

... i should lower the delta radius, but we have it as an equation in the sintron marlin firmware. so i got stuck at that, i don't know what to modify next.

You can see the result of the equation in (pronterface-) bootscreen ( eg: M665 L250 R160 S200 ) where Rxxxx is the Delta Radius.

You can change the values as well and save them in eeprom with M500.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 08:55AM |

Registered: 8 years ago Posts: 916 |

Quote

CrisCG

i tried manual calibration, using this method. I adjusted the endstops offset fot near the pillars positions. Those 3 positions where good, then when i checked the center, it was lower than it should. according to the vid, i should lower the delta radius, but we have it as an equation in the sintron marlin firmware. so i got stuck at that, i don't know what to modify next.

Is there a better method for calibration?

Adjust the smooth rod offset, which will then go through the formula to adjust the delta radius.

Once you get more confident you'll eventually end up turning on the EEPROM as o_lampe suggests, but for now just adjust the smooth rod offset and be happy.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 10:17AM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 11:11AM |

Registered: 8 years ago Posts: 319 |

I agree with the rest. The probe is sticking or not deployed. I was able to get my probe to work correctly. I even fixed the issue when the probe cuts into the heatbed because it goes to low before auto retracting by adjusting the marlin firmware. However, I am now using IR probe.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 11:34AM |

Registered: 8 years ago Posts: 66 |

Thank you. Solved the probe. It works how it should now. It was sticking.

But after it autolevels, the hotend doesn't move parallel to the bed. When moving away from the center towards any of the pillars, it also moves up.

I played with the smooth rod offset, but i'm not getting it right. i measured 161.5mm. this value doesnt't work. also tried 159 to 175. no good. any suggestions?

But after it autolevels, the hotend doesn't move parallel to the bed. When moving away from the center towards any of the pillars, it also moves up.

I played with the smooth rod offset, but i'm not getting it right. i measured 161.5mm. this value doesnt't work. also tried 159 to 175. no good. any suggestions?

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 04:32PM |

Registered: 8 years ago Posts: 104 |

After adjusting smooth rod offset you have to re-calibrate end-stop offsets. Because actually the adjustment does not directly lower/upper effector in the center, but more likely uppers/lowers positions near towers.Quote

CrisCG

I played with the smooth rod offset, but i'm not getting it right. i measured 161.5mm. this value doesnt't work. also tried 159 to 175. no good. any suggestions?

So, actually, the very first calibration process is cyclic: adjusting end-stops - adjusting smooth rod offset - re-adjusting end-stops - re-adjusting smooth rod offset - and so on. Unless you have all 4 offsets (3 towers and center) the same. After that adjust total height to tune 0 height.

If you heed to recalibrate in future (i.e. because of re-leveling of bed), the adjusting of end-stops will be enough.

Edited 1 time(s). Last edit at 02/16/2016 04:33PM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 04:52PM |

Registered: 10 years ago Posts: 14,672 |

Quote

GrAndAG

After adjusting smooth rod offset you have to re-calibrate end-stop offsets. Because actually the adjustment does not directly lower/upper effector in the center, but more likely uppers/lowers positions near towers.

So, actually, the very first calibration process is cyclic: adjusting end-stops - adjusting smooth rod offset - re-adjusting end-stops - re-adjusting smooth rod offset - and so on. Unless you have all 4 offsets (3 towers and center) the same. After that adjust total height to tune 0 height.

If you heed to recalibrate in future (i.e. because of re-leveling of bed), the adjusting of end-stops will be enough.

No need to use that cyclical method any more, my delta calibration calculator works out the endstop adjustments, delta radius adjustment, and height at the same time. Also tower position offsets if you want. See [escher3d.com]. Two iterations should be enough.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit February 16, 2016 07:53PM |

Registered: 8 years ago Posts: 4 |

Got a SINTRON kit going with reasonable results:

(More prints attached)

The mechanics are pretty much as supplied, except for carbon rods & traxxas rod ends for arms.

The electronics have been replaced with a Duet 0.85 - I knew I was going to do this - the Mega 2650 & RAMPS board are destined for a TinyG setup elsewhere.

Notable things during build:

- ALOT of fettling of the frame corners to get the extrusions and nuts to sit well - mainly slump at botttom layers, and clearance for T nuts.

- Rather than measuring angles - I made a gauge for setting up the frame - a piece of 4mm steel rod with flat ends that was used to set distance between towers. It was cut to ~1mm longer than the longest side - and all edges were set to that length.

- Cleared a lot of swarf out of extrusion channels.

- Lots of filing to get rod end spacing equal - wound up taking it down to 38mm everywhere, then putting washers between ball ends and their attachements.

- Made a jig for arm rods and ends - 3mm rods into MDF plank - used drill press to get them square.

- Didn't bother with ice water for rod ends - just used hot air gun to soften plastic parts. Used silicone grrase on balls. If they every get any slop, I'll get at them with hot air gun again - With a bit of care, they can be shrunk back to fit. (Used to do this on model helis).

- EDIT: Added a washer between top idler bearings, and made sure stepper pulley, carriage slot, and idlers were all same distance from tower.

- Added a steel washer to effector to support supplied hot end.

- Cleaned swarf out of hot end!! (That would not have gone well if I had started printing like that)

- Made sure nozzle/heatbreak fit was ok (was actually pretty good as supplied).

- Made sure probe operated cleanly - file/drill and silicone grease. I haven't bothered trying to get automatic deploy retract working yet.

- Built RepRapFormware_dc42 dev branch from source (and wrote Makefile because I am a masochist and would like to tinker with implementation)

- Took a few hours learning how to set up probe and successfully run automatic calibration.

- Using the heated bed (55C) + blue tape worked well with PLA.

- Noticed that having the extruder too tight caused it to skip steps

Since getting it to work, I have now:

- Swapped out power supply for 24V - Probably not necessary, but I wanted fast bed heat up, and had both PSU and fans already - so only needed a new hot end heater.

- Printed fan shrouds and added 2nd fan.

- Printed better end stop mounts.

- Experimented with MK8 extruder gear (Would like to print faster, but it looks like I'lll need to do more than just swap the gear.)

Overall, I am very happy with it - but it did need care and attention to get going.

Edited 1 time(s). Last edit at 02/16/2016 08:01PM by samlittlewood.

(More prints attached)

The mechanics are pretty much as supplied, except for carbon rods & traxxas rod ends for arms.

The electronics have been replaced with a Duet 0.85 - I knew I was going to do this - the Mega 2650 & RAMPS board are destined for a TinyG setup elsewhere.

Notable things during build:

- ALOT of fettling of the frame corners to get the extrusions and nuts to sit well - mainly slump at botttom layers, and clearance for T nuts.

- Rather than measuring angles - I made a gauge for setting up the frame - a piece of 4mm steel rod with flat ends that was used to set distance between towers. It was cut to ~1mm longer than the longest side - and all edges were set to that length.

- Cleared a lot of swarf out of extrusion channels.

- Lots of filing to get rod end spacing equal - wound up taking it down to 38mm everywhere, then putting washers between ball ends and their attachements.

- Made a jig for arm rods and ends - 3mm rods into MDF plank - used drill press to get them square.

- Didn't bother with ice water for rod ends - just used hot air gun to soften plastic parts. Used silicone grrase on balls. If they every get any slop, I'll get at them with hot air gun again - With a bit of care, they can be shrunk back to fit. (Used to do this on model helis).

- EDIT: Added a washer between top idler bearings, and made sure stepper pulley, carriage slot, and idlers were all same distance from tower.

- Added a steel washer to effector to support supplied hot end.

- Cleaned swarf out of hot end!! (That would not have gone well if I had started printing like that)

- Made sure nozzle/heatbreak fit was ok (was actually pretty good as supplied).

- Made sure probe operated cleanly - file/drill and silicone grease. I haven't bothered trying to get automatic deploy retract working yet.

- Built RepRapFormware_dc42 dev branch from source (and wrote Makefile because I am a masochist and would like to tinker with implementation)

- Took a few hours learning how to set up probe and successfully run automatic calibration.

- Using the heated bed (55C) + blue tape worked well with PLA.

- Noticed that having the extruder too tight caused it to skip steps

Since getting it to work, I have now:

- Swapped out power supply for 24V - Probably not necessary, but I wanted fast bed heat up, and had both PSU and fans already - so only needed a new hot end heater.

- Printed fan shrouds and added 2nd fan.

- Printed better end stop mounts.

- Experimented with MK8 extruder gear (Would like to print faster, but it looks like I'lll need to do more than just swap the gear.)

Overall, I am very happy with it - but it did need care and attention to get going.

Edited 1 time(s). Last edit at 02/16/2016 08:01PM by samlittlewood.

|

Re: Ebay SINTRON Kossel Mini full kit February 17, 2016 06:15AM |

Registered: 8 years ago Posts: 66 |

Well done samlittlewood. I'm still trying to calibrate it. That z probe isn't giving good results, even now that it's working.

I'm trying to enter endstop adjustments with the m666 comand. I type in the adjustment value, like M666 y-1.6 for example, then when i hit m501, endstop adjustments is 0. I tried using the m500 command, but it's the same. Any ideas?

I'm trying to enter endstop adjustments with the m666 comand. I type in the adjustment value, like M666 y-1.6 for example, then when i hit m501, endstop adjustments is 0. I tried using the m500 command, but it's the same. Any ideas?

|

Re: Ebay SINTRON Kossel Mini full kit February 17, 2016 07:14AM |

Registered: 8 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit February 17, 2016 09:19AM |

Registered: 8 years ago Posts: 66 |

|

Re: Ebay SINTRON Kossel Mini full kit February 17, 2016 09:21AM |

Registered: 8 years ago Posts: 255 |

Quote

CrisCG

Now i'm having some issues printing a first test. The printhead moves, but the PLA comes out too slow, no enough flow for the printing speed.

Also, the fan doesn't spin. Just makes a buzzing sound. Anyone else had problems with the fan?

Can't tell what could it be with the fan, maybe plugged wrong way? But I'd recommend that you don't even try to heat the hotend until you fix the fan issue.

|

Re: Ebay SINTRON Kossel Mini full kit February 17, 2016 10:14AM |

Registered: 8 years ago Posts: 66 |

I've heated the hotend, but not longer than 20-25 minutes, everything seems ok. I tried to switch the wires for the fan, but it's the same.

Now i see that i also have the issue with the rod ends rubbing against each other. I don't understand why they ship those metal rods, if they know there are problems with them. They should exchange them with traxxas. i didn't know about this until i ordered the kit.

Now i see that i also have the issue with the rod ends rubbing against each other. I don't understand why they ship those metal rods, if they know there are problems with them. They should exchange them with traxxas. i didn't know about this until i ordered the kit.

Sorry, only registered users may post in this forum.