Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit April 06, 2016 11:43AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Quote

hacker

Quote

DRTak

Yeah. just changing material.

But on another note. I am having major issues printing in PLA. For me PETG is easier to print with. It seems that I cant get enough heated filament out of the nozzle. Doesnt make sense.

Oddly, this is a new nozzle and is exactly 0.4mm. My older hotend I mistakenly bore out too much and it was like a 1mm hole. Of course with that nozzle I was able to run my extruder at full speed. Now with my new hotend I am stuck figuring out new settings.

Interesting. In my experience PETG is slower to print than PLA… It is easier to print without adequate object cooling, though.

Yes for PETG it is slower than PLA. But with my new nozzle so far. I have to print PLA at the same speed as PETG. And even then it is too fast?

This is weird. What is the speed/nozzle d/layer height and temp?

|

Re: Ebay SINTRON Kossel Mini full kit April 07, 2016 06:51AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit April 07, 2016 06:55AM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit April 07, 2016 10:18AM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Quote

hacker

Quote

DRTak

Yeah. just changing material.

But on another note. I am having major issues printing in PLA. For me PETG is easier to print with. It seems that I cant get enough heated filament out of the nozzle. Doesnt make sense.

Oddly, this is a new nozzle and is exactly 0.4mm. My older hotend I mistakenly bore out too much and it was like a 1mm hole. Of course with that nozzle I was able to run my extruder at full speed. Now with my new hotend I am stuck figuring out new settings.

Interesting. In my experience PETG is slower to print than PLA… It is easier to print without adequate object cooling, though.

Yes for PETG it is slower than PLA. But with my new nozzle so far. I have to print PLA at the same speed as PETG. And even then it is too fast?

This is weird. What is the speed/nozzle d/layer height and temp?

15 to 30 mm/sec for nozzle speed. Temp is now at 220 deg c. Layer height is .4mm first layer and then .35mm second. I think the issue is that the machine has issues pushing out 200% first layer in slic3r. But after that it works better.

Going back to Sintron. I have done some math finally.

Kossel from Sintron: Roughly $350 USD

My Upgrades to the Sintron Machine:

Aluminum corners: $75

Duet 0.6: 150

Carbon fiber rods: 50

Metal effector: 50

New Hotend: 50

ABS Molded Carriages: 50

Total upgrades: $400

Total cost of machine right now is $750 give or take $50 (misc screws and nuts)

Now if you were to build Sintron Kossel from Scratch you would have to add these parts to the list:

Nema motors: $58

GT2 belts: 14

2020 Extrusion: 50

Total for those: $122

So if you were NOT to buy the sintron for $350, you can have a fully upgraded Kossel made by yourself for $400 + 122 = $522.

Summary: Sintron Machine which I have had to completely remake: $350

Sintron Machine like if you made it yourself with all the upgrades: $522

Difference: $172

|

Re: Ebay SINTRON Kossel Mini full kit April 08, 2016 04:48AM |

Registered: 8 years ago Posts: 5,232 |

Quote

hacker

Quote

o_lampe

Warping parts made of ABS is related rather to a bigger expansion coefficient than melting temp differences ( compared to PETG.)

Yeah, thought of that too. Are you dead sure or do you hypothesize?

It's a known fact that ABS has a high expansion coefficient. That's why we put ( heated ) enclosures around the printer to keep the temp difference as low as possible.

The rest is wild guessing...

|

Re: Ebay SINTRON Kossel Mini full kit April 08, 2016 04:51AM |

Registered: 8 years ago Posts: 255 |

Quote

o_lampe

Quote

hacker

Quote

o_lampe

Warping parts made of ABS is related rather to a bigger expansion coefficient than melting temp differences ( compared to PETG.)

Yeah, thought of that too. Are you dead sure or do you hypothesize?

It's a known fact that ABS has a high expansion coefficient. That's why we put ( heated ) enclosures around the printer to keep the temp difference as low as possible.

The rest is wild guessing...

Yes, I meant the exact thing with effector warping. The guess makes perfect sense to me, I just thought maybe you know for sure it applies. Anyway, I think I shouldn't print cooling duct in ABS

|

Re: Ebay SINTRON Kossel Mini full kit April 08, 2016 09:45PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

o_lampe

Quote

hacker

Quote

o_lampe

Warping parts made of ABS is related rather to a bigger expansion coefficient than melting temp differences ( compared to PETG.)

Yeah, thought of that too. Are you dead sure or do you hypothesize?

It's a known fact that ABS has a high expansion coefficient. That's why we put ( heated ) enclosures around the printer to keep the temp difference as low as possible.

The rest is wild guessing...

Yes, I meant the exact thing with effector warping. The guess makes perfect sense to me, I just thought maybe you know for sure it applies. Anyway, I think I shouldn't print cooling duct in ABS

Well either way, the plain fact in my usage is that ABS warps from heat creep of the heatsink. PETG does not. I assume at a higher temp. Maybe beyond 260 deg C that PETG would start to warp.

|

Re: Ebay SINTRON Kossel Mini full kit April 09, 2016 08:50AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Well either way, the plain fact in my usage is that ABS warps from heat creep of the heatsink. PETG does not. I assume at a higher temp. Maybe beyond 260 deg C that PETG would start to warp.

This plain fact is what I was aiming at, because I was under impression that printed effector is no good, not ABS effector. You didn't really say that. Now I have some picture…

I understand the difference between ABS and PETG is not just temperature, but that while PETG just softens at some temps, ABS warps. I'm fine with my PLA effector so far, but I think I should print a spare

|

Re: Ebay SINTRON Kossel Mini full kit April 09, 2016 02:43PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Well either way, the plain fact in my usage is that ABS warps from heat creep of the heatsink. PETG does not. I assume at a higher temp. Maybe beyond 260 deg C that PETG would start to warp.

This plain fact is what I was aiming at, because I was under impression that printed effector is no good, not ABS effector. You didn't really say that. Now I have some picture…

I understand the difference between ABS and PETG is not just temperature, but that while PETG just softens at some temps, ABS warps. I'm fine with my PLA effector so far, but I think I should print a spare

Yeah. I would say PLA < ABS < PETG < NYLON < Metal effector would be my guess as to the least likely to warp.I think the benefit of Nylon and PETG would be that it would be more forgiving if you had a bed crash. Right now if I get a rare bed crash it puts stress on the carbon rods which are the weakest link.

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 05:39AM |

Registered: 8 years ago Posts: 104 |

You are saying about melting(soften) points. But I can't agree that it's correlates with warping. At least I can say about PLA. I'm using cooling duct mounted on effector to cool objects during the printing. The end of it is almost touching heater block (2mm away I can say). And there is no a single sign of warping despite on the fact that I often print with cooler fan off. And it's in black, so it should absorb heat very well. I even thought that it must be melted in seconds if its cooling fan is off, but it's still ok for more than 4 months.Quote

DRTak

I would say PLA < ABS < PETG < NYLON < Metal effector would be my guess as to the least likely to warp.

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 06:03AM |

Registered: 8 years ago Posts: 255 |

Quote

GrAndAG

You are saying about melting(soften) points. But I can't agree that it's correlates with warping. At least I can say about PLA. I'm using cooling duct mounted on effector to cool objects during the printing. The end of it is almost touching heater block (2mm away I can say). And there is no a single sign of warping despite on the fact that I often print with cooler fan off. And it's in black, so it should absorb heat very well. I even thought that it must be melted in seconds if its cooling fan is off, but it's still ok for more than 4 months.Quote

DRTak

I would say PLA < ABS < PETG < NYLON < Metal effector would be my guess as to the least likely to warp.

Indeed I doubt PLA is worse than ABS in terms of warping. And I still have no experience with nylon… I've heard it's a bit more elastic, that's not necessarily good for effector and I've heard it's very sensitive to humidity? Though, so is PLA, but PLA is quite manageable, is nylon harder to store/handle than PLA in terms of absorbing water?

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 11:37AM |

Registered: 8 years ago Posts: 319 |

Ok. I see your argument for PLA warping or not.

I do not have experience with nylon. My assessment is based on the melting point of nylon. I also I have only read about nylon's issues with humidity and water absorption. No experience with it personally. I dont want to pay the extra for nylon bridge. I have read my reviews and PETG and nylon bridge are comparible. Both are somewhat flexible. But nylon is way stronger.

With PETG and PLA my spools are contained in dessicant. However, I didnt use dessicant when I first started and PLA was very brittle before and after a print. PETG I heard is worse than PLA with water absorption but I again am not taking any chances and store my PETG in a vat of dessicant.

I do not have experience with nylon. My assessment is based on the melting point of nylon. I also I have only read about nylon's issues with humidity and water absorption. No experience with it personally. I dont want to pay the extra for nylon bridge. I have read my reviews and PETG and nylon bridge are comparible. Both are somewhat flexible. But nylon is way stronger.

With PETG and PLA my spools are contained in dessicant. However, I didnt use dessicant when I first started and PLA was very brittle before and after a print. PETG I heard is worse than PLA with water absorption but I again am not taking any chances and store my PETG in a vat of dessicant.

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 11:42AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

With PETG and PLA my spools are contained in dessicant. However, I didnt use dessicant when I first started and PLA was very brittle before and after a print. PETG I heard is worse than PLA with water absorption but I again am not taking any chances and store my PETG in a vat of dessicant.

I'm trying to store my stuff with dessicant, but I'm not good at being very consistent in these practices. I rarely had any issues with PLA (though I did have a problems with one spool that became totally unusable, perhaps due to absorbed water) and I have never properly stored PETG at all… Haven't had any problems with it yet, but maybe the thing is that I haven't heard it's worse than PLA

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 01:06PM |

Registered: 8 years ago Posts: 319 |

Ive been hoarding dessicant from food products. They have them in protein shake jugs, candy, etc. I put like 10-20 packs of those in an "air" tight tupper ware bowl and toss in the spool of PLA/ PETG. I doubt the tupperware or ziploc container is really air tight. But it does the trick. I have noticed that some of the dessicant pellets turning yellow. So moisture is being absorbed.Quote

hacker

Quote

DRTak

With PETG and PLA my spools are contained in dessicant. However, I didnt use dessicant when I first started and PLA was very brittle before and after a print. PETG I heard is worse than PLA with water absorption but I again am not taking any chances and store my PETG in a vat of dessicant.

I'm trying to store my stuff with dessicant, but I'm not good at being very consistent in these practices. I rarely had any issues with PLA (though I did have a problems with one spool that became totally unusable, perhaps due to absorbed water) and I have never properly stored PETG at all… Haven't had any problems with it yet, but maybe the thing is that I haven't heard it's worse than PLA

|

Re: Ebay SINTRON Kossel Mini full kit April 10, 2016 02:49PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Ive been hoarding dessicant from food products. They have them in protein shake jugs, candy, etc. I put like 10-20 packs of those in an "air" tight tupper ware bowl and toss in the spool of PLA/ PETG. I doubt the tupperware or ziploc container is really air tight. But it does the trick. I have noticed that some of the dessicant pellets turning yellow. So moisture is being absorbed.

Okay, I'm worse than I thought. When I think I'm doing well I'm using ziploc bags

(that was regarding your doubts, the bigger problem is that I don't always put them in bags).

Edited 1 time(s). Last edit at 04/10/2016 02:50PM by hacker.

|

Re: Ebay SINTRON Kossel Mini full kit April 11, 2016 09:44AM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Ive been hoarding dessicant from food products. They have them in protein shake jugs, candy, etc. I put like 10-20 packs of those in an "air" tight tupper ware bowl and toss in the spool of PLA/ PETG. I doubt the tupperware or ziploc container is really air tight. But it does the trick. I have noticed that some of the dessicant pellets turning yellow. So moisture is being absorbed.

Okay, I'm worse than I thought. When I think I'm doing well I'm using ziploc bags

(that was regarding your doubts, the bigger problem is that I don't always put them in bags).

Thats the funny thing. Who would print something and then break it? Well my kids do. They test the printed toys to the limit. The PLA that has too much moisture breaks very easily (with some force). The PLA with dessicant is a little tougher. So I can tell if the PLA was sitting too long outside of the container.

|

Re: Ebay SINTRON Kossel Mini full kit April 11, 2016 09:49AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Thats the funny thing. Who would print something and then break it? Well my kids do. They test the printed toys to the limit. The PLA that has too much moisture breaks very easily (with some force). The PLA with dessicant is a little tougher. So I can tell if the PLA was sitting too long outside of the container.

;-) I can't. My kids would break things if I printed steel..

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 09:35AM |

Registered: 8 years ago Posts: 319 |

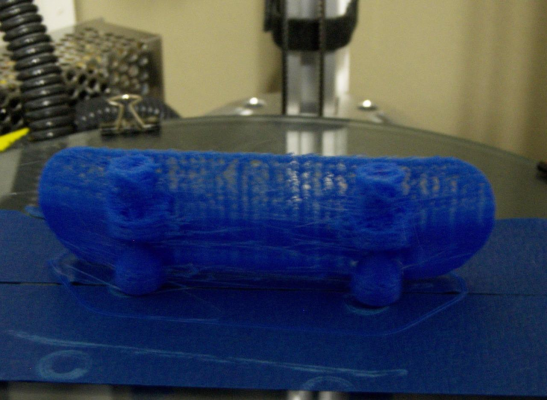

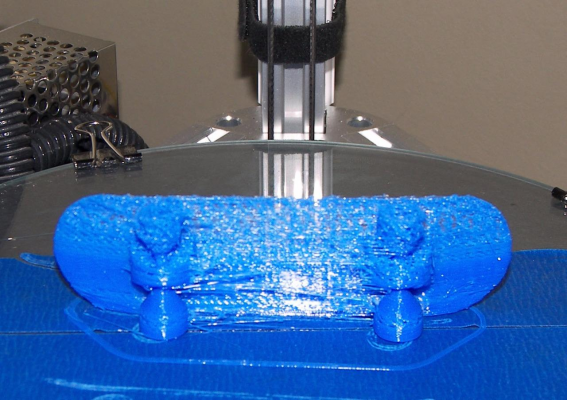

Need help. I was printing a large file. 6hrs long. It printed fine in PLA. But now when I go to print anything it prints like below? The bottom is perfect so to speak. But I would say 30min into any print, the top part gets choppy like the picture and see through? I dont understand. I can only assume the nozzle is clogged or partially clogged. But I checked the flow and it looks great. I am at a complete loss.

HELP!!!!

HELP!!!!

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 09:52AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Need help. I was printing a large file. 6hrs long. It printed fine in PLA. But now when I go to print anything it prints like below? The bottom is perfect so to speak. But I would say 30min into any print, the top part gets choppy like the picture and see through? I dont understand. I can only assume the nozzle is clogged or partially clogged. But I checked the flow and it looks great. I am at a complete loss.

HELP!!!!

It does look like you start underextruding halfway. I think I've experienced that before, but can't fully remember what it was. I'd first try to rule out the bad filament and then would go about cleaning the nozzle. I'd also see if the extruder motor/driver overheats or for any other reason starts to have problems extruding filament for long enough… Not sure if that was helpful, but that's all I could come up with that quick ;-)

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 10:24AM |

Registered: 8 years ago Posts: 916 |

I agree with Hacker, it looks to me like your extruder driver is heating up too much, and not driving the way it should. Are you cooling the driver boards with a fan? Have you checked the driver currents with a multimeter? Have you put your finger on the extruder motor after half an hour and felt how hot it is?

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 10:27AM |

Registered: 8 years ago Posts: 255 |

Quote

nebbian

I agree with Hacker, it looks to me like your extruder driver is heating up too much, and not driving the way it should. Are you cooling the driver boards with a fan? Have you checked the driver currents with a multimeter? Have you put your finger on the extruder motor after half an hour and felt how hot it is?

DRTak has duet, IIRC, I haven't had anything overheating-like with the drivers even though I don't cool electronics, but that makes me think that double checking the motor current in the config may not be a bad idea.

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 12:04PM |

Registered: 8 years ago Posts: 319 |

I dont understand how it can be my extruder motor. I have not had this problem before. It only occured after I finished printing the 5 to 6hr print. After that all of my other prints with PLA have looked like that picture. If I do the print for say 3hrs. It will have bands. Starts off good. Then under extrusion. The good. Then finishes with under extrusion.

How do I check the current in config?

I will start a print again and check the temp of the extruder motor after an hour and see.

I have a fan on a on/off switch blowing air over the duet board. The fan is directly on the motor drivers of the duet. I tested with it on and off and get the same results.

Edited 1 time(s). Last edit at 04/25/2016 12:05PM by DRTak.

How do I check the current in config?

I will start a print again and check the temp of the extruder motor after an hour and see.

I have a fan on a on/off switch blowing air over the duet board. The fan is directly on the motor drivers of the duet. I tested with it on and off and get the same results.

Edited 1 time(s). Last edit at 04/25/2016 12:05PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 04:03PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

I dont understand how it can be my extruder motor. I have not had this problem before. It only occured after I finished printing the 5 to 6hr print. After that all of my other prints with PLA have looked like that picture. If I do the print for say 3hrs. It will have bands. Starts off good. Then under extrusion. The good. Then finishes with under extrusion.

How do I check the current in config?

I will start a print again and check the temp of the extruder motor after an hour and see.

I have a fan on a on/off switch blowing air over the duet board. The fan is directly on the motor drivers of the duet. I tested with it on and off and get the same results.

First, we obviously don't know what we're talking about we're just coming up with guesses. Second, motor currents are set with M906 command in your config and seen on the Settings/Machine Properties (at least in RepRapFirmware 1.11) tab. My extruder motor, for instance is set to 1000mA (though I thought it's lower).

I'd check the temps, also I'd check the hotend cooling, thermal contact between heatbreak and heatsink and the state of PTFE tube on the hotend side, could be that after a while heat gets where it shouldn't… What else could that be… Could also have to do with a lot of long retractions… But then you say it wasn't the case before, so it's some property that changes over time… Cleaning nozzle also sounds like a nice thing to do…

I'm out of ideas again ;-)

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 05:23PM |

Registered: 8 years ago Posts: 319 |

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 05:28PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Checked the config file and the x y and z motors come up as 1000mA. I do not see any reading for the E motor?

In config, it's E axis (perhaps it's default if it's not there) and in machine properties it's the first drive after axes. But all in all probably you need to look elsewhere, temps, etc…

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 06:36PM |

Registered: 10 years ago Posts: 14,672 |

All the currents default to zero in RepRapFirmware, so you must be setting the extruder current somewhere. Typically you would have a line in config.g something like M906 X1000 Y1000 X1000 E1000.

If you run M906 with no parameters, it will report what the currents are set to.

Can you see or hear the extruder motor skipping steps when the problem occurs?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you run M906 with no parameters, it will report what the currents are set to.

Can you see or hear the extruder motor skipping steps when the problem occurs?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit April 25, 2016 07:10PM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

All the currents default to zero in RepRapFirmware, so you must be setting the extruder current somewhere. Typically you would have a line in config.g something like M906 X1000 Y1000 X1000 E1000.

If you run M906 with no parameters, it will report what the currents are set to.

Can you see or hear the extruder motor skipping steps when the problem occurs?

I was using the Duet Webbased info to see the current of the motors.

Yes. I hear skipping constantly. I dont know why. I loosened the tension and it doesnt help. I changed the temp from 190 all the way up to 230 deg. Didnt help. Its like it wants to extrude more but cant. I paused the print and I can easily feed filament into the hotend? Resume the print and it prints fine for 5min. Then it starts up again with the odd prints.

I changed filaments. Didnt help.

I checked all the connections. The wires are all connected.

I felt the extruder motor after 30min. Not Hot at all.

I did upgrade to the newest duet firmware and newest Web interface.

Here is a cut and paste of my config. I did find the m906 command in it:

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R108.99 L215.00 H237.63 B110.00 X-0.78 Y0.65 Z0.00 ;122.16 set delta radius, diagonal rod length, printable radius and homed height

M666 X0.21 Y0.27 Z-0.47 ; put your endstop adjustments here, or let auto calibration find them

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E500 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E3600 ; Maximum speeds (mm/min)

M566 X1200 Y1200 Z1200 E1200 ; Maximum instant speed changes mm/minute

M579 X1.001 Y1.03

; Thermistors

;*** If you have a Duet board stickered "4.7K", change R1000 to R4700 to the following M305 commands

M305 P0 T10000 B3950 R1000 H-10 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction

M305 P1 T100000 B4066 R1000 H5 L-30 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction

M305 P2 T100000 B3950 R1000 H10 L-30 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

M570 S180 ; Hot end may be a little slow to heat up so allow it 180 seconds

; Tool definitions

M563 P0 D0 H1 ; Define tool 0

;M563 P1 H2 D1

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a dual-nozzle build, un-comment the next 2 lines

;M563 P1 D1 H2 ; Define tool 1

;G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E100:100 ; Set extruder steps per mm

Here is what the web interface console reads after I type M906

7:39:22 PMM906

Axis currents (mA) - X:1000, Y:1000, Z:1000, E:500:500:500:500:500:500, idle factor 60%

Edited 5 time(s). Last edit at 04/25/2016 08:40PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit April 26, 2016 02:38AM |

Registered: 10 years ago Posts: 14,672 |

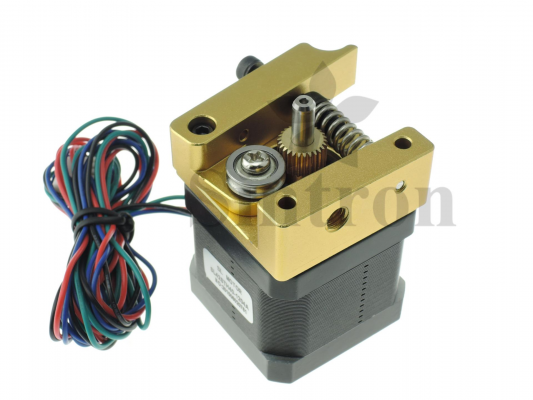

You have the extruder current set to just 500mA, which is very low especially as you have an un-geared extruder. It's the E500 parameter in the M906 command. Try increasing it to E1000 or E1200. What is the specification of your extruder stepper motor?

Edited 3 time(s). Last edit at 04/26/2016 02:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 3 time(s). Last edit at 04/26/2016 02:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit April 26, 2016 10:00AM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

You have the extruder current set to just 500mA, which is very low especially as you have an un-geared extruder. It's the E500 parameter in the M906 command. Try increasing it to E1000 or E1200. What is the specification of your extruder stepper motor?

I do not know what the extruder is. Sintron claims its a MK8. But then on their ebay ad, they say its a modified NEMA 17.

[www.ebay.com]

I assume its a NEMA 17? There are no stickers or engravings on it. I took it off the Kossel. I cant tell who makes it etc. I can only go by what Sintron listed on ebay.

I will increase the E to 1000 as you stated.

Edited 1 time(s). Last edit at 04/26/2016 10:01AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit April 26, 2016 10:17AM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Quote

dc42

You have the extruder current set to just 500mA, which is very low especially as you have an un-geared extruder. It's the E500 parameter in the M906 command. Try increasing it to E1000 or E1200. What is the specification of your extruder stepper motor?

I do not know what the extruder is. Sintron claims its a MK8. But then on their ebay ad, they say its a modified NEMA 17.

[www.ebay.com]

I assume its a NEMA 17? There are no stickers or engravings on it. I took it off the Kossel. I cant tell who makes it etc. I can only go by what Sintron listed on ebay.

I will increase the E to 1000 as you stated.

I don't have the original sintron stepper in the printer, but I have a few steppers laying around. I *think* the sintron has a sticker SL42STH40-1204A. I think that means 1.2A rated current? But again, I'm not 100% positive it's sintron's stepper.

Sorry, only registered users may post in this forum.