Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit February 02, 2017 06:26PM |

Registered: 9 years ago Posts: 91 |

Ok, I admit defeat. I am printing undersize and not getting proper circles?

On a cylinder 6mm tall and 25mm diameter, I am getting appx 4.4 tall and 22.5 diameter.

One side of the cylinder is squared off, rather than a maintaining the radius around the circumference.

New glass bed fitted, first time I have been able to test it properly.

#define DELTA_SEGMENTS_PER_SECOND 120

#define DELTA_DIAGONAL_ROD 215 // mm

#define DELTA_SMOOTH_ROD_OFFSET 162 // mm

#define DELTA_EFFECTOR_OFFSET 30 // mm

#define DELTA_CARRIAGE_OFFSET 20 // mm

I have tried DELTA_DIAGONAL_ROD 215 - 220 (they are 220mm when measured) but that made minimal difference.

The motor steps are set up as

#define XYZ_FULL_STEPS_PER_ROTATION 200

#define XYZ_MICROSTEPS 16

#define XYZ_BELT_PITCH 2

#define XYZ_PULLEY_TEETH 20

#define XYZ_STEPS (XYZ_FULL_STEPS_PER_ROTATION * XYZ_MICROSTEPS / double(XYZ_BELT_PITCH) / double(XYZ_PULLEY_TEETH))

#define DEFAULT_AXIS_STEPS_PER_UNIT {79, 79, 79, 760}

>>> g28

SENDING:G28

>>> M114

SENDING:M114

X:0.00 Y:0.00 Z:242.00 E:0.00 Count X: 425.52 Y:425.52 Z:425.52

>>> G1 Z4

SENDING:G1 Z4

Then bringing the head down to paper thickness = 242

>>> M114

SENDING:M114

X:0.00 Y:0.00 Z:0.20 E:0.00 Count X: 183.72 Y:183.72 Z:183.72

MANUAL_Z_HOME_POS: 242-0.20= 241.80

Does anyone know where I should be looking to increase the radius of printed circles, and the height? The print quality is ok, things are looking level, it's just the size??

On a cylinder 6mm tall and 25mm diameter, I am getting appx 4.4 tall and 22.5 diameter.

One side of the cylinder is squared off, rather than a maintaining the radius around the circumference.

New glass bed fitted, first time I have been able to test it properly.

#define DELTA_SEGMENTS_PER_SECOND 120

#define DELTA_DIAGONAL_ROD 215 // mm

#define DELTA_SMOOTH_ROD_OFFSET 162 // mm

#define DELTA_EFFECTOR_OFFSET 30 // mm

#define DELTA_CARRIAGE_OFFSET 20 // mm

I have tried DELTA_DIAGONAL_ROD 215 - 220 (they are 220mm when measured) but that made minimal difference.

The motor steps are set up as

#define XYZ_FULL_STEPS_PER_ROTATION 200

#define XYZ_MICROSTEPS 16

#define XYZ_BELT_PITCH 2

#define XYZ_PULLEY_TEETH 20

#define XYZ_STEPS (XYZ_FULL_STEPS_PER_ROTATION * XYZ_MICROSTEPS / double(XYZ_BELT_PITCH) / double(XYZ_PULLEY_TEETH))

#define DEFAULT_AXIS_STEPS_PER_UNIT {79, 79, 79, 760}

>>> g28

SENDING:G28

>>> M114

SENDING:M114

X:0.00 Y:0.00 Z:242.00 E:0.00 Count X: 425.52 Y:425.52 Z:425.52

>>> G1 Z4

SENDING:G1 Z4

Then bringing the head down to paper thickness = 242

>>> M114

SENDING:M114

X:0.00 Y:0.00 Z:0.20 E:0.00 Count X: 183.72 Y:183.72 Z:183.72

MANUAL_Z_HOME_POS: 242-0.20= 241.80

Does anyone know where I should be looking to increase the radius of printed circles, and the height? The print quality is ok, things are looking level, it's just the size??

|

Re: Ebay SINTRON Kossel Mini full kit February 14, 2017 05:17PM |

Registered: 9 years ago Posts: 91 |

The Final Chapter....I got back to working on the configuration and straight off the bat managed a first test print that is better than expected. For the record, I simply assembled what was in the box, never checked angles, lengths or anything else, just made sure that the rods were all identical. Configuring it was a pain as tracking down the info that I needed sent me down a few blind alleys. I swapped the heated bed for a glass one, but that is the only thing that is non standard.

This is what I printed, complete with measurements.

Test Print video and measurements

This is what I printed, complete with measurements.

Test Print video and measurements

|

Re: Ebay SINTRON Kossel Mini full kit February 15, 2017 01:18AM |

Registered: 7 years ago Posts: 60 |

|

Re: Ebay SINTRON Kossel Mini full kit February 25, 2017 01:12PM |

Registered: 8 years ago Posts: 40 |

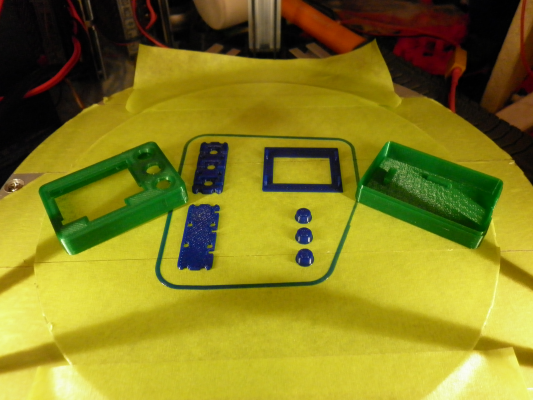

Well hey, would you look at that. Replace all of Sintrons frame with cheap moulded parts and magically it prints perfectly!

No more over-extrusion, holes slightly too small, large, scraping or having to level the bed every print. It only took 8 hours of setup to get it to work properly as opposed to the mess that was the other frame. When I first started the rebuild I wasn't expecting much, but now I have a fully functional printer that is accurate to within 0.05mm.

You can take the glass plate on and off, bump it, move it, pick it up with one hand and store it sideways. Prints perfectly every time.

The kit I used is just one of those Chinese black plastic frame sets with carriages and roller wheels for $120. The parts aren't threaded but they don't mind being undone and done up a few times.

Very happy with the printer now!

No more over-extrusion, holes slightly too small, large, scraping or having to level the bed every print. It only took 8 hours of setup to get it to work properly as opposed to the mess that was the other frame. When I first started the rebuild I wasn't expecting much, but now I have a fully functional printer that is accurate to within 0.05mm.

You can take the glass plate on and off, bump it, move it, pick it up with one hand and store it sideways. Prints perfectly every time.

The kit I used is just one of those Chinese black plastic frame sets with carriages and roller wheels for $120. The parts aren't threaded but they don't mind being undone and done up a few times.

Very happy with the printer now!

|

Re: Ebay SINTRON Kossel Mini full kit February 25, 2017 02:06PM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit February 25, 2017 02:23PM |

Registered: 9 years ago Posts: 91 |

Good to hear that someone else has got theirs up and running. I amazed at how fast this thing prints, my Smartrap+ has the slight edge on quality but then it does have an E3D hotend, but the Kossel will finish a job in a lot less time. Just wish it had a bigger print bed. Since discovering extra firm hairspray (on glass, no heated bed, PLA) I can print 1mm thick sheets that are 100mm+ square on either printer with no lifting, I am over the moon.

Only slight problem yet to fix, the hotend over extrudes occasionally, I have stripped it down, cleaned it right out, redrilled the nozzle, the extrusion rate is bang on 100mm, but every now and then....gloop....?

Only slight problem yet to fix, the hotend over extrudes occasionally, I have stripped it down, cleaned it right out, redrilled the nozzle, the extrusion rate is bang on 100mm, but every now and then....gloop....?

|

Re: Ebay SINTRON Kossel Mini full kit February 25, 2017 02:26PM |

Registered: 8 years ago Posts: 255 |

Quote

Wibbles

Good to hear that someone else has got theirs up and running. I amazed at how fast this thing prints, my Smartrap+ has the slight edge on quality but then it does have an E3D hotend, but the Kossel will finish a job in a lot less time. Just wish it had a bigger print bed. Since discovering extra firm hairspray (on glass, no heated bed, PLA) I can print 1mm thick sheets that are 100mm+ square on either printer with no lifting, I am over the moon.

Only slight problem yet to fix, the hotend over extrudes occasionally, I have stripped it down, cleaned it right out, redrilled the nozzle, the extrusion rate is bang on 100mm, but every now and then....gloop....?

Maybe pressure accumulated in bowden tube? Especially if it prints this fast, you may be trying to extrude faster than it actually can?

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 10:00AM |

Registered: 8 years ago Posts: 40 |

Quote

Only slight problem yet to fix, the hotend over extrudes occasionally, I have stripped it down, cleaned it right out, redrilled the nozzle, the extrusion rate is bang on 100mm, but every now and then....gloop....?

Are you adding an offset on the end of Delta Radius to make the effector travel flat?

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 10:09AM |

Registered: 9 years ago Posts: 91 |

I've never come across that before, how is this achieved? It prints very well, amazingly well in fact, considering the bad press that Chinese hotends get. I was getting a blocked nozzle so stripped it apart and found a tiny length of tube in the throat that I assume they but in to reduce heat transfer, but discovered that it was a very tight fit on the filament, after removing it no more glooping.

I also tried slowing it down which seems to have cured it, it now runs at 80% instead of 100%. I am also trying to get that infernal clicking eradicated on the extruder mechanism. I have slowed the rate down by 60% using the lcd which doesn't affect the print quality at all, but it still has that annoying racket going on, if anyone knows how to smooth it please post up the solution. I know from my other printer that it shouldn't be doing that, as that one feeds filament silently.

I also tried slowing it down which seems to have cured it, it now runs at 80% instead of 100%. I am also trying to get that infernal clicking eradicated on the extruder mechanism. I have slowed the rate down by 60% using the lcd which doesn't affect the print quality at all, but it still has that annoying racket going on, if anyone knows how to smooth it please post up the solution. I know from my other printer that it shouldn't be doing that, as that one feeds filament silently.

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 10:41AM |

Registered: 8 years ago Posts: 104 |

If motor clicks (skips the steps) it can mean 2 things: over-extrusion or under-power. As you already tried decreasing feedrate and it was not helped, so it can be the second cause. You could try to increase power by adjusting little "+" thing on the corresponding driver board.Quote

Wibbles

I also tried slowing it down which seems to have cured it, it now runs at 80% instead of 100%. I am also trying to get that infernal clicking eradicated on the extruder mechanism. I have slowed the rate down by 60% using the lcd which doesn't affect the print quality at all, but it still has that annoying racket going on, if anyone knows how to smooth it please post up the solution. I know from my other printer that it shouldn't be doing that, as that one feeds filament silently.

When I tried (as an experiment) to print at 300 mm/s my extruder was also clicked. But in my case it was because the hot end was supplied with plastic at 2x faster speed than it could physically melt.

Edited 1 time(s). Last edit at 02/27/2017 10:47AM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 10:47AM |

Registered: 8 years ago Posts: 40 |

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 10:58AM |

Registered: 9 years ago Posts: 91 |

I use my printers to make model parts that I can't buy as no one makes them. Once configured properly my guess is that any printer will deliver the goods, it's a matter of fixing things so that they are running as nature intended. Getting the right settings in the firmware, and on the slicer software all make a difference, on top of assembling the things properly.

I can print 0.5mm sheets on both printers, though the Smartrap+ that I have is better with the really detailed stuff. The Kossel is amazingly quick though, and is what I use for the bigger items.

I can print 0.5mm sheets on both printers, though the Smartrap+ that I have is better with the really detailed stuff. The Kossel is amazingly quick though, and is what I use for the bigger items.

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 11:36AM |

Registered: 7 years ago Posts: 60 |

Very cool

Try swapping around the extruder driver with one of the others and see if it changes anything.

If your extruder runs cool, then you can up the current.

My extruder begins to grind the filament before it clicks, because either I have set the hot end temp too low, so it cant melt it fast enough, or there is a feed proplem, like the spool is stuck, of there is too much resistance in the bowden setup, or some kind of blockage in the hot end somewhere. Oy, if my first layer is too close to build plate.

you can try and just heat up the hotend, and just manualy feed the filament throght the hotend without the extruder, and get a feel for the resistance.......

Try swapping around the extruder driver with one of the others and see if it changes anything.

If your extruder runs cool, then you can up the current.

My extruder begins to grind the filament before it clicks, because either I have set the hot end temp too low, so it cant melt it fast enough, or there is a feed proplem, like the spool is stuck, of there is too much resistance in the bowden setup, or some kind of blockage in the hot end somewhere. Oy, if my first layer is too close to build plate.

you can try and just heat up the hotend, and just manualy feed the filament throght the hotend without the extruder, and get a feel for the resistance.......

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 02:45PM |

Registered: 8 years ago Posts: 40 |

Just to note, adjusting the feedrate on the front LCD slows the whole process down not just the rate at which filament is fed. The filament rate should scale perfectly up and down regardless of the speed.

I just viewed the video and it is definitely trying to overextrude, what is the value you have set for DEFAULT_AXIS_STEPS_PER_UNIT for the extruder in your firmware?

I have some suggestions for you too:

This depends on your filament but you can usually get away with 2-4 perimeters and still have a fair amount of strength, you may save on filament that way.

Also, honeycomb infill is the fastest mode to use for most builds when printing on a delta, it tries to avoid retracts and to complete large sections at once saving a lot of time. Prusa's Slic3r is a very good program that includes good infill settings. Set infill speed to about 80mm/s as it involves a lot of reversing direction.

You can get Prusa's Slic3r here: Prusa's Slic3r Github

I just viewed the video and it is definitely trying to overextrude, what is the value you have set for DEFAULT_AXIS_STEPS_PER_UNIT for the extruder in your firmware?

I have some suggestions for you too:

This depends on your filament but you can usually get away with 2-4 perimeters and still have a fair amount of strength, you may save on filament that way.

Also, honeycomb infill is the fastest mode to use for most builds when printing on a delta, it tries to avoid retracts and to complete large sections at once saving a lot of time. Prusa's Slic3r is a very good program that includes good infill settings. Set infill speed to about 80mm/s as it involves a lot of reversing direction.

You can get Prusa's Slic3r here: Prusa's Slic3r Github

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 02:57PM |

Registered: 9 years ago Posts: 91 |

This is my setting, the printer was doing exactly 100mm when I originally set it up, but slowing the rate down on the lcd didn't affect the print quality.

I went down in steps from 350 to 160, but still get the micro retracts, not as bad, but I can't get rid of them altogether.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 350}

#define DEFAULT_MAX_FEEDRATE {200, 200, 200, 200} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,9000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E ma

I went down in steps from 350 to 160, but still get the micro retracts, not as bad, but I can't get rid of them altogether.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 350}

#define DEFAULT_MAX_FEEDRATE {200, 200, 200, 200} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,9000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E ma

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 03:12PM |

Registered: 8 years ago Posts: 255 |

Quote

Wibbles

This is my setting, the printer was doing exactly 100mm when I originally set it up, but slowing the rate down on the lcd didn't affect the print quality.

I went down in steps from 350 to 160, but still get the micro retracts, not as bad, but I can't get rid of them altogether.

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 350}

#define DEFAULT_MAX_FEEDRATE {200, 200, 200, 200} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,9000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E ma

IIRC, sintron's extruder has something around 100 steps (I have changed it a number of times, so I can't tell you for sure now). You probably want to calibrate it — [reprap.org] (there are a lot of guides how to do that, actually). Or was that 100mm you were referring to?

Edited 1 time(s). Last edit at 02/27/2017 03:13PM by hacker.

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 03:46PM |

Registered: 7 years ago Posts: 4 |

The following are what I have set. They are the defaults, but I actually did do the calculations to verify them.

//

// MOVEMENT SETTINGS

// @section motion

//

// default settings

// delta speeds must be the same on xyz

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 94} // default steps per unit for Kossel (GT2, 20 tooth)

#define DEFAULT_MAX_FEEDRATE {500, 500, 500, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 3000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

//

// MOVEMENT SETTINGS

// @section motion

//

// default settings

// delta speeds must be the same on xyz

#define DEFAULT_AXIS_STEPS_PER_UNIT {80, 80, 80, 94} // default steps per unit for Kossel (GT2, 20 tooth)

#define DEFAULT_MAX_FEEDRATE {500, 500, 500, 25} // (mm/sec)

#define DEFAULT_MAX_ACCELERATION {9000,9000,9000,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot.

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E acceleration in mm/s^2 for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration in mm/s^2 for retracts

#define DEFAULT_TRAVEL_ACCELERATION 3000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 03:50PM |

Registered: 9 years ago Posts: 91 |

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 04:01PM |

Registered: 8 years ago Posts: 104 |

|

Re: Ebay SINTRON Kossel Mini full kit February 27, 2017 05:52PM |

Registered: 9 years ago Posts: 91 |

What can I say? Thanks a million, problem solved. Strangely, I lowered the setting on the LCD all the way down to 50 before the clicking stopped, and then wound it back up 10 at a time to see when it came back...it didn't, I have left it on 95 and it still has a silent extruder. I did a test run of a detailed part at high speed to see whether it under extruded and it ran perfectly. A bit of stringing but that was to be expected under the test, but it all scraped off to zero residue.

Video demo - can't get the link to work from the icon, just click below

[youtu.be]

Edited 1 time(s). Last edit at 02/27/2017 06:23PM by Wibbles.

Video demo - can't get the link to work from the icon, just click below

[youtu.be]

Edited 1 time(s). Last edit at 02/27/2017 06:23PM by Wibbles.

|

Re: Ebay SINTRON Kossel Mini full kit March 30, 2017 03:06AM |

Registered: 7 years ago Posts: 32 |

I got to comment this a little bit

I made this kind of a circuit and tried it and my irf540 got so f#%} HOT that I could cook sausages on it..

I had good conversation with one profesional and he said that this IRF540 is NOT a proper choise for this setup

because IRF540 needs to have 10volts for gate to get fully open and ramps gives only 5 volts so it is not fully open and if you got lucky threshold voltage is 4 volts so there is only 1 voltage to play with.. and thats why this IRF540 gets hot..

a better solution would be logic level N-channel FET instead of this IRF540..

Quote

Sir_Death

Quote

GrAndAG

I can suggest buying solid state relay to connect heating bed via it. It will eliminate all problems with mosfet and fuse overheating.

Much cheaper (and easier) way is to just solder a wire to the Gate Signal of the internal MOSFET and place a IRF540Z external - connect Heatbed there....

Wire from RAMPS to GATE of MOSFET

"-" from Powersupply to SOURCE of MOSFET

"+" from Powersupply to Heatbed, other Wire from Heatbed to DRAIN of MOSFET

(Configuration is called "Low Side Switch")

IRF540Z does not need any cooling for up to 10Amps.. - I have no FAN blowing on it, and no Heatsink mounted.

Heatbed gets hot verry fast, IRF540 stays absolute cool, RAMPS stays cool too.

And with this config, you can easily change heatbed to 24V - just make sure "-" from both Powersupplies are connected together, and connect +24V direct to Heatbed like mentioned above...

I made this kind of a circuit and tried it and my irf540 got so f#%} HOT that I could cook sausages on it..

I had good conversation with one profesional and he said that this IRF540 is NOT a proper choise for this setup

because IRF540 needs to have 10volts for gate to get fully open and ramps gives only 5 volts so it is not fully open and if you got lucky threshold voltage is 4 volts so there is only 1 voltage to play with.. and thats why this IRF540 gets hot..

a better solution would be logic level N-channel FET instead of this IRF540..

|

Re: Ebay SINTRON Kossel Mini full kit March 30, 2017 04:50AM |

Registered: 8 years ago Posts: 916 |

Quote

OG

I made this kind of a circuit and tried it and my irf540 got so f#%} HOT that I could cook sausages on it..

I had good conversation with one profesional and he said that this IRF540 is NOT a proper choise for this setup

because IRF540 needs to have 10volts for gate to get fully open and ramps gives only 5 volts so it is not fully open and if you got lucky threshold voltage is 4 volts so there is only 1 voltage to play with.. and thats why this IRF540 gets hot..

a better solution would be logic level N-channel FET instead of this IRF540..

I've used IRF540 before in this sort of application, it worked fine. You just need to:

1) Connect the gate to +V via a 680 ohm resistor

2) Use a small NPN transistor to switch the gate to ground.

Obviously this means more components on the board, and you need to get your logic inversion right, but it does work. This solution gives good gate drive voltage, and high current. Another FET to check out is SUP53P06-20 which is P channel as well, but it has really good on-resistance.

|

Re: Ebay SINTRON Kossel Mini full kit April 08, 2017 09:09AM |

Registered: 7 years ago Posts: 1 |

After four months of silently participating of your knowledge, i would like to give something back. I made two enhancements for the sintron delta kossel which might provide useful solving some adjustment issues.

(1) a Carriage with adjustable screw for 2020 Kossel Delta Mini Thingiverse

and

(2) a Solid Endstop Holder for 2020 Kossel Delta Mini Thingiverse

In combination, these parts make precise heigth adjustment fairly easy.

Have fun!

(1) a Carriage with adjustable screw for 2020 Kossel Delta Mini Thingiverse

and

(2) a Solid Endstop Holder for 2020 Kossel Delta Mini Thingiverse

In combination, these parts make precise heigth adjustment fairly easy.

Have fun!

|

Re: Ebay SINTRON Kossel Mini full kit April 08, 2017 10:26AM |

Registered: 9 years ago Posts: 91 |

|

Re: Ebay SINTRON Kossel Mini full kit May 05, 2017 04:19PM |

Registered: 6 years ago Posts: 3 |

Hi all,

I need some help with my setup for my sintron kossel mini. I've painstakingly set up marlin, calibrated the kinematics, and various other settings, and went for my first print (xyz calibration cube!). I load it into Slic3r, get the gcode and load that into pronterface. I press print and the effector placed itself near the bed (ready for print I assumed), then after about 30 seconds just shot over into one of the pillars. Some plug pulling later and I'm somewhat lost as to why/how this happened, and what to do now?

I've attached my config.h file, I would greatly appreciate any advice/guidance/feedback anyone can provide (of course if any other info is needed let me know).

Cheers

Sean

I need some help with my setup for my sintron kossel mini. I've painstakingly set up marlin, calibrated the kinematics, and various other settings, and went for my first print (xyz calibration cube!). I load it into Slic3r, get the gcode and load that into pronterface. I press print and the effector placed itself near the bed (ready for print I assumed), then after about 30 seconds just shot over into one of the pillars. Some plug pulling later and I'm somewhat lost as to why/how this happened, and what to do now?

I've attached my config.h file, I would greatly appreciate any advice/guidance/feedback anyone can provide (of course if any other info is needed let me know).

Cheers

Sean

|

Re: Ebay SINTRON Kossel Mini full kit May 05, 2017 05:26PM |

Registered: 9 years ago Posts: 91 |

Just a suggestion, but have you set Slicr up as a circular print bed? I have two printers, one is a Mini Kossel, the other is a Smartrap. If I forget which printer I am supposed to be sending the Gcode to, it will do exactly what yours just did. I use Cura so its only a couple of clicks to change the printer that I have selected, but when it happens all hell breaks loose.

|

Re: Ebay SINTRON Kossel Mini full kit May 05, 2017 06:02PM |

Registered: 6 years ago Posts: 3 |

I had done, however I realised I had an older version of slicer (1.17), so upgraded to 1.29, again made sure all settings were right(ish), and it printed (huzzah!). Strangely though, when I pulled to gcode into pronterface, it placed it outside the build area (but printed fine). Now it's on to calibration, have done 2 XYZ cubes now, first one better than the second (I updated the kinematics, made them more precise, made it worse oddly). Have just notice the effector is not perfectly level, seems one of the arms is loosey goosey, so in the morning will redo that. Think I need to slow down the homing speed too, is pretty quick so I think slight imbalance will come from that. Given (I assume) we have all the same printer (more or less), is there an accepted, community created set of marlin settings?

|

Re: Ebay SINTRON Kossel Mini full kit May 05, 2017 06:46PM |

Registered: 9 years ago Posts: 91 |

Glad that you are on the right track, these printers take some understanding but all of a sudden, everything is right and they print like a dream. Amazing quality.

The basic Marlin settings are pretty much what is provided by Sintron, the bit that is unique to each printer is all of the measurements and offsets, though it sounds like you have sorted that. The rest is fine tuning, and if it helps there is a tool online

Tool

The basic Marlin settings are pretty much what is provided by Sintron, the bit that is unique to each printer is all of the measurements and offsets, though it sounds like you have sorted that. The rest is fine tuning, and if it helps there is a tool online

Tool

|

Re: Ebay SINTRON Kossel Mini full kit May 06, 2017 08:03AM |

Registered: 6 years ago Posts: 3 |

Cheers for the info dude, tis much appreciated, out of curiousity what do some of these relate too? or do I only need to fill a few of them in? Rod length/radius/printable radius all seem straightforward, others I'm not so sure about.

Steps/mm (for Repetier only):

Initial endstop corrections:

X:

Y:

Z:

Initial diagonal rod length:

Initial delta radius:

Initial homed height:

Initial tower angular position corrections:

X:

Y:

Z:

Printable bed radius:

Number of probe points:

7

Number of factors to calibrate:

6

Normalise endstop corrections?

Steps/mm (for Repetier only):

Initial endstop corrections:

X:

Y:

Z:

Initial diagonal rod length:

Initial delta radius:

Initial homed height:

Initial tower angular position corrections:

X:

Y:

Z:

Printable bed radius:

Number of probe points:

7

Number of factors to calibrate:

6

Normalise endstop corrections?

|

Re: Ebay SINTRON Kossel Mini full kit May 06, 2017 08:23AM |

Registered: 9 years ago Posts: 91 |

Sorry, only registered users may post in this forum.