Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit March 11, 2016 10:32AM |

Registered: 8 years ago Posts: 916 |

Quote

Electric ant

Hi guys,

I am just about to strip my printer down and rebuild it with all the right angles this time.

I have got a digital angel finder and a good spirit level, can anyone give me some tips on the best way to achieve 3 x 60 degree corners and how to get the towers perfectly upright.

This time I want to build it right, with the angles all being correct because now all my prints lean to the left slightly, and the top edge of my print bed (in front of the Z tower) is 1.2mm lower than the rest if it.

I have a dremel in case I need to hack away at anything.

What would be the best way to put it all back together when I start the rebuild ?

Thanks guys

You don't need to strip it down, just loosen the screws, adjust, and tighten again.

For 60 degrees, forget the angle finder. Instead measure with a set of calipers using their depth gauge function the distance between towers, at both the bottom and the top of the towers. If all values are the same, then all your angles will be at 60 degrees, and your towers parallel. Mine are within 0.02mm or so of each other.

To get the towers upright, get your angle finder, and set it at exactly 90 degrees with a large carpenters square, then tighten the screw to lock it there. Then use the bed as a reference surface to get each tower at 90 degrees to the bed. That will get you non-skewed.

To get twist out is tricky, you need to get your 90 degree square and ensure that each tower is at 90 degrees to both bottom horizontal frame pieces.

Once you've done that... then ensure that each pair of diagonal rods are the same distance apart (top vs bottom).

That will get you most of the way there.

|

Re: Ebay SINTRON Kossel Mini full kit March 11, 2016 10:36AM |

Registered: 8 years ago Posts: 319 |

Quote

Electric ant

Hi guys,

I am just about to strip my printer down and rebuild it with all the right angles this time.

I have got a digital angel finder and a good spirit level, can anyone give me some tips on the best way to achieve 3 x 60 degree corners and how to get the towers perfectly upright.

This time I want to build it right, with the angles all being correct because now all my prints lean to the left slightly, and the top edge of my print bed (in front of the Z tower) is 1.2mm lower than the rest if it.

I have a dremel in case I need to hack away at anything.

What would be the best way to put it all back together when I start the rebuild ?

Thanks guys

Well, I just did what you said. You might want to wait. I just did some testing. I have an IR z probe. I think there was not enough light getting to the IR. I turned on an incandescent flood light to a low setting. Then redid the calibration. Turns out it fixed out the Z height issues I was having .ie It thought that the z tower was higher than it really is. So the z height would be way off. Might be a totally different issue with a mechanical z probe.

Regardless, I have replaced my corners with aluminum ones. I like the look and the extra height it gave me off of the ground. It elevated the Kossel higher off the ground. But I lost Z height due to how it was made. I used an analog crown moulding angle finder to get 60 deg on all sides. For the vertical towers I used a speed squared. However, it is all left to speculation if the angles were right since it wasnt digital measurements.

|

Re: Ebay SINTRON Kossel Mini full kit March 11, 2016 02:45PM |

Registered: 8 years ago Posts: 66 |

Thank you nebbian, i will try that.

I changed to nozzle and now i'm back to printing. I now know what happened. I printed ABS, than switched back to PLA and heated it to 250 degrees. I guess the PLA staied too long at this temperature and got stuck in there, creating a partial clog.

Is there a way to save this nozzle? Or trash can and that's it??

I changed to nozzle and now i'm back to printing. I now know what happened. I printed ABS, than switched back to PLA and heated it to 250 degrees. I guess the PLA staied too long at this temperature and got stuck in there, creating a partial clog.

Is there a way to save this nozzle? Or trash can and that's it??

|

Re: Ebay SINTRON Kossel Mini full kit March 11, 2016 03:23PM |

Registered: 8 years ago Posts: 319 |

Quote

CrisCG

Thank you nebbian, i will try that.

I changed to nozzle and now i'm back to printing. I now know what happened. I printed ABS, than switched back to PLA and heated it to 250 degrees. I guess the PLA staied too long at this temperature and got stuck in there, creating a partial clog.

Is there a way to save this nozzle? Or trash can and that's it??

For clogs get a .4 mm drill bit or wire and ream out the nozzle once it is heated up to 190 deg for PLA. try and extrude. If it works then you are good to go. If it doesnt then you need to take the nozzle off heatblock. I found that my clog was because the PTFE tubing inside was melted along with the PLA.

|

Re: Ebay SINTRON Kossel Mini full kit March 11, 2016 03:23PM |

Registered: 8 years ago Posts: 319 |

Quote

CrisCG

Thank you nebbian, i will try that.

I changed to nozzle and now i'm back to printing. I now know what happened. I printed ABS, than switched back to PLA and heated it to 250 degrees. I guess the PLA staied too long at this temperature and got stuck in there, creating a partial clog.

Is there a way to save this nozzle? Or trash can and that's it??

For clogs get a .4 mm drill bit or wire and ream out the nozzle once it is heated up to 190 deg for PLA. try and extrude. If it works then you are good to go. If it doesnt then you need to take the nozzle off heatblock. I found that my clog was because the PTFE tubing inside was melted along with the PLA. I actually use a thin wire to ream out the nozzle tip. You can also use a very small needle.

Once you have the nozzle out you can look in and see if there is any blockage. For me I saw melted white stuff (PFTE). I also had a lot of built up PLA. I used a small drill to make a hole in the center. Then used pliers to pull out the clot.

Edited 1 time(s). Last edit at 03/11/2016 04:47PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit March 12, 2016 05:25PM |

Registered: 8 years ago Posts: 319 |

I have a new question. Since I have owned my Sintron. The system has always thought that the center of the bed is off b 40mm. When I home the nozzle the nozzle is in the center. But when I try and calibrate manually, I notice that the probe arcs 40mm towards the XY axis. This occured with the Ramps setup and now the Duet. What I am saying is that the system has issues with the center of the Concave or Convex center of the arc. My system has shifted the center of the arc to be way off from real center. So when I was messing with Delta Smooth Rod offset with the Ramps setup, the center was toward the XY and therefore the nozzle would be very close to the glass plate on one end and very high off the plate on the other end. Ie the arc was not centered. Now with the Duet the arc is still off and it helps very little if I adjust the delta radius. The escher calculator does help but where did I go wrong the 2nd time I built my system. The first time I can assume it was being a noob. The second time I built it, I measured all of the sides and angles when I put in the aluminum corners.

|

Re: Ebay SINTRON Kossel Mini full kit March 13, 2016 08:13AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit March 13, 2016 11:34AM |

Registered: 8 years ago Posts: 319 |

Quote

o_lampe

@DrTak

I think, this is related to the real endstop height. Place them in equal height and keep the M666 values as small as possible.

o lampe. thanks for your help. I manually adjusted the Z endstop and noticed an immediate improvement. I then made sure that all the towers are the same height. Adjusted those. Came back to the z endstop and made it 2mm lower than the rest. Did a auto calibration and this is what the calculator now says.

M666 X0.04 Y-0.07 Z0.03

Doing multiple auto calcs to make sure its all good. But its a dramatic improvement. Before my M666 Z value was -2.57

|

Re: Ebay SINTRON Kossel Mini full kit March 13, 2016 10:54PM |

Registered: 8 years ago Posts: 916 |

Just a note on endstop placement:

I've found that having about 2mm of travel after homing (the value in the M66 command) works well. This means that you can adjust the endstops up to 2mm before running out of adjustment.

When I do the first print of the day I always watch the thickness of the lines, and often have to adjust the values in the M666 command by 0.03 - 0.05mm. Occasionally if I've moved the printer I might have to adjust this up to 0.1mm. This is now that my printer is nicely bedded in. Previously, when still adjusting everything, I was glad of that 2mm adjustment range.

I had to play with my manual z home position until the values plugged into M666 were about 2 mm.

I've found that having about 2mm of travel after homing (the value in the M66 command) works well. This means that you can adjust the endstops up to 2mm before running out of adjustment.

When I do the first print of the day I always watch the thickness of the lines, and often have to adjust the values in the M666 command by 0.03 - 0.05mm. Occasionally if I've moved the printer I might have to adjust this up to 0.1mm. This is now that my printer is nicely bedded in. Previously, when still adjusting everything, I was glad of that 2mm adjustment range.

I had to play with my manual z home position until the values plugged into M666 were about 2 mm.

|

Re: Ebay SINTRON Kossel Mini full kit March 14, 2016 12:04PM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Just a note on endstop placement:

I've found that having about 2mm of travel after homing (the value in the M66 command) works well. This means that you can adjust the endstops up to 2mm before running out of adjustment.

When I do the first print of the day I always watch the thickness of the lines, and often have to adjust the values in the M666 command by 0.03 - 0.05mm. Occasionally if I've moved the printer I might have to adjust this up to 0.1mm. This is now that my printer is nicely bedded in. Previously, when still adjusting everything, I was glad of that 2mm adjustment range.

I had to play with my manual z home position until the values plugged into M666 were about 2 mm.

Im not as savy as you. But I think I know what you are saying. For me I made this change in firmware

M208 S1 Z-2

|

Re: Ebay SINTRON Kossel Mini full kit March 14, 2016 05:53PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Quote

hacker

Quote

DRTak

So my Sintron Kossel cracked. I was auto leveling the bed and for some reason it decided to ram itself into the glass bed. I hit stop. But I heard something snap. I looked and couldnt find the issue. I tried to auto level and noticed the z side was messed up. I looked at the upper corner frame and the Z corner cracked. For now I have tightened the screw as much as possible but its still loose. I can print but not that well. I have ordered aluminum corners. Soon to be delivered. So another list in my Sintron upgrades. One of the only things left are the E3D hotend replacement and upgrading to a metal effector.

Upgrades now:

Changed from Ramps 1.4 to duet 0.6

Changed from Sintron Rods to Traxxas carbon rods

Changed from Sintron carriages to ABS molded carriages and wheels

Changed Sintron Gt2 belts to aftermarket Gt2 belts

Plastic Sintron Printed Frame corners to aluminum machined corners.

Analog Z probe to Dc42 IR probe

LCD 2004 by Sintron to PanelDUE by dc42 touch screen

Upgrades to Go:

Metal effector

New hotend?

Metal effector bottom plate

Obviously, it would be cheaper to order parts and build it from scratch, but I know I wouldn't do that ;-) Though I still have original corners and carriages… Actually, I have a lot — movement motors, belts and pulleys, endstops, heatbed, bolts and nuts.

If my corner cracked I'd probably glue it and print one (or more likely — three) in PETG

Well knowing what I know now, I could build one from scratch and it would likely be cheaper.

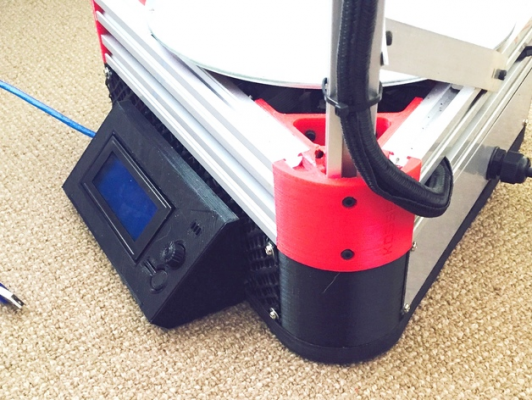

So my metal corners finally came in. I slowly put them together. Checked for the corners to be 60 deg from each other. I didnt do this the first time I made it. Then made sure the vertical parts are 90 deg. Printed the new endstop holders in PETG. Attached that. Then decided to make another change. Move all electronics below the bed and have a dedicated fan blowing over the chips.

So I analyzed the Sintron printed parts after removing them. The Z and Y upper corners were cracked were the screws were. The z bottom corner was cracked where the screws were. All bottom corner parts were warped where the NEMA motors connect to it. I assume the motors got too hot and melted the plastic. It then allowed for the motor tilt upward with the plastic giving the pulley a very slight tilt.

I also made sure that I used the pronterface axis orientation when putting the motors down. I made sure that they are x, Z, y going clockwise. Close to starting to print. Will shoot pics of my "NEW" Sintron machine soon.

Indeed you can build one for cheaper now, what Sintron does well for its money is teaching us things ;-)

Interesting things have happened to your corners. I wonder if the same happened to mine and for whatever reason I can't see it (I've just tried to check without disassembling and they seem to be intact.

And yes, I'm not sure how you move your electronics under the bed, but, just in case, this is what I've done — [www.thingiverse.com] (in case duet 0.6 has the same dimensions like 0.8.5 may be useful for you).

Hacker you win. Im going to print out your feet and duet holder. I was printing out a new effector. It was over half done and the duet auto shut off. This happened before on another print. When I checked the thermal readings it was 54 deg C under the heatbed where the duet was sitting. I assume it was the same temp just now. So the duet shut off and didnt finish the effector. I can only assume it gets way to hot below a heated hotbed. So I will temporarily elevate the kossel with bricks. Place fans all around the unit to cool the duet. Try and print the 4 holder parts and the 3 feet. Then have a taller cooler kossel

|

Re: Ebay SINTRON Kossel Mini full kit March 14, 2016 06:31PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Hacker you win. Im going to print out your feet and duet holder. I was printing out a new effector. It was over half done and the duet auto shut off. This happened before on another print. When I checked the thermal readings it was 54 deg C under the heatbed where the duet was sitting. I assume it was the same temp just now. So the duet shut off and didnt finish the effector. I can only assume it gets way to hot below a heated hotbed. So I will temporarily elevate the kossel with bricks. Place fans all around the unit to cool the duet. Try and print the 4 holder parts and the 3 feet. Then have a taller cooler kossel

Uh, I never had duet shut off yet and I never fan it.What's your bed temperature and do you any thermal insulation between the bed and the duet?

|

Re: Ebay SINTRON Kossel Mini full kit March 14, 2016 06:35PM |

Registered: 10 years ago Posts: 14,672 |

Quote

DRTak

When I checked the thermal readings it was 54 deg C under the heatbed where the duet was sitting. I assume it was the same temp just now. So the duet shut off and didnt finish the effector. I can only assume it gets way to hot below a heated hotbed. So I will temporarily elevate the kossel with bricks. Place fans all around the unit to cool the duet. Try and print the 4 holder parts and the 3 feet. Then have a taller cooler kossel

If you mount electronics under a heated bed - whether Duet, RAMPS or anything else - then it is highly recommended to:

1. Use insulation under the bed heater. Thick cork or triple-skin corrugated cardboard will do.

2. Use a fan to blow air over the electronics, especially over the drivers on both sides of the PCB. Make sure that the hot air can escape and be replaced by cool air from outside the base of the printer.

I published a design for mounting a Duet and cooling fan in the base of a delta printer at [www.thingiverse.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ebay SINTRON Kossel Mini full kit March 14, 2016 08:47PM |

Registered: 8 years ago Posts: 916 |

Quote

DRTak

Im not as savy as you. But I think I know what you are saying. For me I made this change in firmware

M208 S1 Z-2

Oooh nice, I didn't know about that one! What was that about being savvy? Thanks for the tip

btw here's the pedestal I designed, I've been using it constantly since putting it together (3 months or so), I find that it works really well:

[www.thingiverse.com]

As DC mentioned, you need to put some insulation under your heatbed, and have a fan that blows air across your electronics. I used cardboard and aluminium roofing tape as insulation, others have used cork with good success.

Edited 2 time(s). Last edit at 03/14/2016 08:50PM by nebbian.

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 11:01AM |

Registered: 8 years ago Posts: 319 |

Quote

dc42

Quote

DRTak

When I checked the thermal readings it was 54 deg C under the heatbed where the duet was sitting. I assume it was the same temp just now. So the duet shut off and didnt finish the effector. I can only assume it gets way to hot below a heated hotbed. So I will temporarily elevate the kossel with bricks. Place fans all around the unit to cool the duet. Try and print the 4 holder parts and the 3 feet. Then have a taller cooler kossel

If you mount electronics under a heated bed - whether Duet, RAMPS or anything else - then it is highly recommended to:

1. Use insulation under the bed heater. Thick cork or triple-skin corrugated cardboard will do.

2. Use a fan to blow air over the electronics, especially over the drivers on both sides of the PCB. Make sure that the hot air can escape and be replaced by cool air from outside the base of the printer.

I published a design for mounting a Duet and cooling fan in the base of a delta printer at [www.thingiverse.com].

dc42, nebbian, and hacker.

Thanks for the input. My goal was to put ALL of the electronics below the bed. Nebbian your print is what I was looking for. Actually, I might mix prints. I might use hackers brackets and nebbians feet. I just have to reassemble the unit to print.

On another note when I was able to print. I have never had such great prints with one adjustment. All I had to do was increase the 1st layer thickness for PETG to be .4mm. This corrected bed sticking issues and made my less than 30 min prints perfect. Before in some areas of my bed, the nozzle was off by .25 mm no matter how many times I auto calibrated. So when the first layer went down, The PETG would just curl up on the heatbed and not stick. Now a thick layer coats the bed base. The rest of the print is perfect.

DC42, I was using a 40mm fan blowing through the small slit in the space between the bars to cool the duet. Obviously this was a bad idea. Not enough air going into it. So what I will do now is elevated the bed with the feet. And use my noisy 60mm Superred fan. Possibly one blowing into it and another blowing air out. The reason I was hesitant was that the darn thing sounds like an airplane taking off.

Nebbian. I do not see the STL file for the screen you have on the front of the kossel. The black mesh thing?

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 12:39PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Thanks for the input. My goal was to put ALL of the electronics below the bed. Nebbian your print is what I was looking for. Actually, I might mix prints. I might use hackers brackets and nebbians feet. I just have to reassemble the unit to print.

I'm not sure if my brackets are good for hiding *all* electronics under the bed. It puts duet right in the middle, meaning there's no room left for power supply. My power supply is ATX hanging on printed brackets under the desk, it wouldn't fit under the bed anyway.

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 02:23PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Thanks for the input. My goal was to put ALL of the electronics below the bed. Nebbian your print is what I was looking for. Actually, I might mix prints. I might use hackers brackets and nebbians feet. I just have to reassemble the unit to print.

I'm not sure if my brackets are good for hiding *all* electronics under the bed. It puts duet right in the middle, meaning there's no room left for power supply. My power supply is ATX hanging on printed brackets under the desk, it wouldn't fit under the bed anyway.

Well I have an idea. I have a lot of granite laying around. I might make granite feet. I have tested it and I elevated the Kossel 90mm off the ground with granite tile. Its enough room to fit the power supply below the unit. Its also enough height that I could attach a 80mm fan directly below the unit. I also put aluminum tape like u said below the heatbed along with layers and layers of that and PVC tape.

Edited 1 time(s). Last edit at 03/15/2016 02:27PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 02:29PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Well I have an idea. I have a lot of granite laying around. I might make granite feet. I have tested it and I elevated the Kossel 90mm off the ground with granite tile. Its enough room to fit the power supply below the unit. Its also enough height that I could attach a 80mm fan directly below the unit.

Sounds like a plan. If you have some marble maybe you will also want change columns to some corinthian ones ;-)

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 03:27PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

Well I have an idea. I have a lot of granite laying around. I might make granite feet. I have tested it and I elevated the Kossel 90mm off the ground with granite tile. Its enough room to fit the power supply below the unit. Its also enough height that I could attach a 80mm fan directly below the unit.

Sounds like a plan. If you have some marble maybe you will also want change columns to some corinthian ones ;-)

Funny you say that. I have 2 marble phineals laying around. But only 2 not 3. So it wont work for legs. LOL

|

Re: Ebay SINTRON Kossel Mini full kit March 15, 2016 11:21PM |

Registered: 8 years ago Posts: 916 |

Quote

DRTak

Nebbian. I do not see the STL file for the screen you have on the front of the kossel. The black mesh thing?

Ha ha that's because it's too big to print on a Sintron Kossel Mini!

I just used gutter guard:

[www.bunnings.com.au]

You can use any mesh you have lying around. On the back panel I used a solid metal panel, so that I could firmly clamp the power cord. I don't like the idea of 240 volts floating around if you accidentally pull the power cord hard.

|

Re: Ebay SINTRON Kossel Mini full kit March 16, 2016 10:52AM |

Registered: 8 years ago Posts: 39 |

Hi folks,

I have finished my partial strip down and rebuild now, and it has made more of a difference than I expected.

I couldn't get all my corners on the bottom rail to exactly 60 degrees. 1 is at 60, 1 is at 60.05 and 1 is at 59.95

The top frame is all at 60 degrees, it's at the same height all way round and there is equal distance between all 3 towers now.

All 3 towers were off centre but 2 are now right and the other is within 0.5 degree of upright, both forward to backward and left to right.

Still haven't printed anything large yet but what I have done is now straight up and not leaning to the left anymore.

Everything I print always ends up being bigger than it should be, e.g. a 20mm hollow cube is 20.2 x 20.2 x 20.6, what settings do I need to change to fix this ?

I was hoping someone with more experience than me might know, and there seems to be a few people with more experience than me on this thread.

A few pages back there is a link to a calibration video where the Z axis goes below zero position (as if it is going lower than the print surface).

I would like to follow this video but I cannot get my Z axis to go below zero. Is this something you can only do with Repetier or can I do it with Marlin ?

Everything else I have tried fails to level my print bed accurately.

I have another little problem and I have no idea what is causing it.

In the first picture of the 30mm blue cube you can see that layer 2 seems to be offset from layer 1, but then returns for layer 3,and in the second picture the first 12mm or so (with the exception of layer 2) has printed very well, but for some reason it seems to have offset itself in the opposite direction to layer 2 and the quality gets really bad.

Blue 30mm Cube-Pic 1

Blue 30mm Cube-Pic 2

In the first pic of the grey 20mm cube there is a skirt around the bottom edge of the top horizontals. and the second pic is taken upside down to show the state of the span between the uprights.

Grey 20mm Cube-Pic 1

Grey 20mm Cube-Pic 2

I want to print a case for my lcd screen but until I get my bed level that will have to wait.

I am going to design a little case to slide a small LED strip into for the bottom of the axis to illuminate the bed.

Until I get my bed level and the size accuracy right, I should be able to reduce the scale in Slic3r to get something to fit.

Hope someone can help, I'm almost there and I can't wait for my first big print.

Thanks guys.

Ant

I have finished my partial strip down and rebuild now, and it has made more of a difference than I expected.

I couldn't get all my corners on the bottom rail to exactly 60 degrees. 1 is at 60, 1 is at 60.05 and 1 is at 59.95

The top frame is all at 60 degrees, it's at the same height all way round and there is equal distance between all 3 towers now.

All 3 towers were off centre but 2 are now right and the other is within 0.5 degree of upright, both forward to backward and left to right.

Still haven't printed anything large yet but what I have done is now straight up and not leaning to the left anymore.

Everything I print always ends up being bigger than it should be, e.g. a 20mm hollow cube is 20.2 x 20.2 x 20.6, what settings do I need to change to fix this ?

I was hoping someone with more experience than me might know, and there seems to be a few people with more experience than me on this thread.

A few pages back there is a link to a calibration video where the Z axis goes below zero position (as if it is going lower than the print surface).

I would like to follow this video but I cannot get my Z axis to go below zero. Is this something you can only do with Repetier or can I do it with Marlin ?

Everything else I have tried fails to level my print bed accurately.

I have another little problem and I have no idea what is causing it.

In the first picture of the 30mm blue cube you can see that layer 2 seems to be offset from layer 1, but then returns for layer 3,and in the second picture the first 12mm or so (with the exception of layer 2) has printed very well, but for some reason it seems to have offset itself in the opposite direction to layer 2 and the quality gets really bad.

Blue 30mm Cube-Pic 1

Blue 30mm Cube-Pic 2

In the first pic of the grey 20mm cube there is a skirt around the bottom edge of the top horizontals. and the second pic is taken upside down to show the state of the span between the uprights.

Grey 20mm Cube-Pic 1

Grey 20mm Cube-Pic 2

I want to print a case for my lcd screen but until I get my bed level that will have to wait.

I am going to design a little case to slide a small LED strip into for the bottom of the axis to illuminate the bed.

Until I get my bed level and the size accuracy right, I should be able to reduce the scale in Slic3r to get something to fit.

Hope someone can help, I'm almost there and I can't wait for my first big print.

Thanks guys.

Ant

|

Re: Ebay SINTRON Kossel Mini full kit March 16, 2016 11:02AM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Quote

DRTak

Nebbian. I do not see the STL file for the screen you have on the front of the kossel. The black mesh thing?

Ha ha that's because it's too big to print on a Sintron Kossel Mini!

I just used gutter guard:

[www.bunnings.com.au]

You can use any mesh you have lying around. On the back panel I used a solid metal panel, so that I could firmly clamp the power cord. I don't like the idea of 240 volts floating around if you accidentally pull the power cord hard.

Well nebbian you win. The Granite tiles are too wide that I have. They are also very slippery when trying to repair or move the Kossel. So much so that when I moved the kossel to put the x endstop wires back in after I put in hackers bottom duet brackets, 2 tiles slipped and cracked in half. So I was going to print out your corners but 90mm high. Then decided its now worth taking the chance on a 5hr print. So Im going with your original file. Ill likely do what u did and attach the power supply to the kossel back frame.

Edited 1 time(s). Last edit at 03/16/2016 11:04AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit March 16, 2016 11:51AM |

Registered: 8 years ago Posts: 255 |

Quote

Electric ant

I am going to design a little case to slide a small LED strip into for the bottom of the axis to illuminate the bed.

It's just a couple of leds instead of a led strip, but this is how I illuminate my printer: [www.thingiverse.com]

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 06:41AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 07:16AM |

Registered: 9 years ago Posts: 67 |

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 08:15AM |

Registered: 8 years ago Posts: 39 |

Thanks for the info guys, that gives me more stuff to play about with now.

I can understand how the rod length could affect the print size now that someone else has said it, that was my initial thought.

I started a print of a screen cover but the size was way off, so I stopped it. The hole for the screen should have been 97mm x 39mm, mine came out at 100mm x 42mm.

The overall size however was only 2mm bigger than it should have been.

That was before the partial strip down and rebuild though, now my prints are closer to the mark but still not quite right.

Any thoughts on what's happening with the blue 30mm hollow cube in the pics above, because it didn't do it with a 20mm grey cube. And layer 2 even stayed where it should be.

Sorry to sound Noob-ish, but I am. This is my first 3D printer, but already I have all the parts (except plastic pieces, I hope to print them myself) for a Prusa i3 already ordered and on the way to me.

I have about a week to get my Delta working at a level capable of printing the i3 plastics, so the sizing is the most important thing now.

Would I be right thinking that every time I change the delta_rod_length I have to recalibrate and do a test print as well ? That's not a 5 minute job.

Thanks for the help guys.

I can understand how the rod length could affect the print size now that someone else has said it, that was my initial thought.

Quote

o lampe

You should print bigger parts to measure dimensions

I started a print of a screen cover but the size was way off, so I stopped it. The hole for the screen should have been 97mm x 39mm, mine came out at 100mm x 42mm.

The overall size however was only 2mm bigger than it should have been.

That was before the partial strip down and rebuild though, now my prints are closer to the mark but still not quite right.

Any thoughts on what's happening with the blue 30mm hollow cube in the pics above, because it didn't do it with a 20mm grey cube. And layer 2 even stayed where it should be.

Do you mean the feed rate of the plastic during the print ?Quote

AnHardt

0.1 - 0.2mm to large - can be caused by over extrusion

Sorry to sound Noob-ish, but I am. This is my first 3D printer, but already I have all the parts (except plastic pieces, I hope to print them myself) for a Prusa i3 already ordered and on the way to me.

I have about a week to get my Delta working at a level capable of printing the i3 plastics, so the sizing is the most important thing now.

Would I be right thinking that every time I change the delta_rod_length I have to recalibrate and do a test print as well ? That's not a 5 minute job.

Thanks for the help guys.

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 09:34AM |

Registered: 8 years ago Posts: 319 |

Quote

Electric ant

Thanks for the info guys, that gives me more stuff to play about with now.

I can understand how the rod length could affect the print size now that someone else has said it, that was my initial thought.

Quote

o lampe

You should print bigger parts to measure dimensions

I started a print of a screen cover but the size was way off, so I stopped it. The hole for the screen should have been 97mm x 39mm, mine came out at 100mm x 42mm.

The overall size however was only 2mm bigger than it should have been.

That was before the partial strip down and rebuild though, now my prints are closer to the mark but still not quite right.

Any thoughts on what's happening with the blue 30mm hollow cube in the pics above, because it didn't do it with a 20mm grey cube. And layer 2 even stayed where it should be.

Do you mean the feed rate of the plastic during the print ?Quote

AnHardt

0.1 - 0.2mm to large - can be caused by over extrusion

Sorry to sound Noob-ish, but I am. This is my first 3D printer, but already I have all the parts (except plastic pieces, I hope to print them myself) for a Prusa i3 already ordered and on the way to me.

I have about a week to get my Delta working at a level capable of printing the i3 plastics, so the sizing is the most important thing now.

Would I be right thinking that every time I change the delta_rod_length I have to recalibrate and do a test print as well ? That's not a 5 minute job.

Thanks for the help guys.

There is a lot that goes into calibrating for size. I gave up on that whole idea.

But when you change the rod length. You have to recalibrate and I do a test print to see what it looks like. But in the end, I got a 10mm cube that looked perfect. However, it will change for a larger print. Say a 50mm cube. The measurements may be off at the larger size. I printed dozens of calibration cubes. But again, it will all change when you print a larger object.

Also, for cases, I have issues with the inner and outer diameters. For me the outer length of the case is perfect. But for some reason the inside is too small by 0.2- 1.0mm. So the LCD screen might fit in my printed case, but the screw holes on the inside of the case are too narrow. I make do by angling the screw to the mounting spot.

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 09:39AM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Quote

DRTak

Nebbian. I do not see the STL file for the screen you have on the front of the kossel. The black mesh thing?

Ha ha that's because it's too big to print on a Sintron Kossel Mini!

I just used gutter guard:

[www.bunnings.com.au]

You can use any mesh you have lying around. On the back panel I used a solid metal panel, so that I could firmly clamp the power cord. I don't like the idea of 240 volts floating around if you accidentally pull the power cord hard.

Nebbian, repetier was way off in its calculation. A single corner of your pedestal takes 4.5 hrs. [www.thingiverse.com]

Repetier told me 2.5hrs. So I googled what to do. I had to adjust the ADD TO COMP PRINT TIME in settings. I had to increase it to 75%. Now it says print time is 4hrs 21min. Which I think is correct.

Needless to say, I am printing the final corner today. 4.5hrs x 3 = 13.5hrs total print time. Wow this is a labor of love. I am glad I didnt print the 90mm high pedestal.

I will also have to go to the hardware store and buy a tap and die set. Ream out the hole in the bottom of the Kossel for an M6 bolt. Then put that bolt in that you mentioned in your article. Hopefully, they sell that large of a metric bolt. In the USA they are not that prevelant.

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 12:03PM |

Registered: 8 years ago Posts: 4 |

> Hi guys,

> I am just about to strip my printer down and rebuild it with all the right angles this time.

> I have got a digital angel finder and a good spirit level, can anyone give me some tips on the best way to achieve 3 x 60 degree corners and how to get the towers perfectly upright.

> This time I want to build it right, with the angles all being correct because now all my prints lean to the left slightly, and the top edge of my print bed (in front of the Z tower) is 1.2mm lower than the rest if it.

> ...

Rather than measuring angles, I made a gauge from a spare piece of steel rod, and then used that to get the distance between towers the same when assembling the top and bottom triangles. To make the gauge, I assembled the corners 'tightly' and then cut it 1mm longer than the longest edge. Having got that, I relaxed all the edges so that the gauge was a slip fit between the corners of the tower along each triangle edge.

Also, when assembling the corners, I made sure the top of the extrusion was flush & flat with top of the corner piece - assemble upside down on a flat surface. (did require a bit of cleaning up corners to get things to sit well).

I also didn't bother with a spirit level. I worked from a flat reference surface:

- Set top surface of bottom triangle to same distance from reference surface all the way around (I have some 5mm of towers poking out below bottom corners).

- Set top surface of top triangle to same distance from reference surface.

Now, there should be the two equilateral triangles parallel to the reference surface - what remains is twist and shear:

- Find a good big framing square (um, that is SQUARE - don't ask ) and find a good way of setting it on reference surface and against the towers.

) and find a good way of setting it on reference surface and against the towers.

I had a nice parallel metal box that was slightly higher than the bottom corners, so the square could be set against the towers easily.

- Loosen the T nuts furthest away from the corners to allow the corners to twist a bit

- Check all the towers and figure how the top triangle should be move to get the towers vertical

- Apply force - it is one those situations where it needs some overshoot as there will be some elasticiity.

- Iterate - it took me 4 or 5 times around with decreasing (ish) nudges.

- Carefully tighten all T nuts.

Finally:

- Set bed to equal height from reference surface - I wound up have the bed screws tightened to the point where the springs were pretty much fully compressed.

- Set endstops to equal height from reference surface.

S

Edited 1 time(s). Last edit at 03/17/2016 12:05PM by samlittlewood.

> I am just about to strip my printer down and rebuild it with all the right angles this time.

> I have got a digital angel finder and a good spirit level, can anyone give me some tips on the best way to achieve 3 x 60 degree corners and how to get the towers perfectly upright.

> This time I want to build it right, with the angles all being correct because now all my prints lean to the left slightly, and the top edge of my print bed (in front of the Z tower) is 1.2mm lower than the rest if it.

> ...

Rather than measuring angles, I made a gauge from a spare piece of steel rod, and then used that to get the distance between towers the same when assembling the top and bottom triangles. To make the gauge, I assembled the corners 'tightly' and then cut it 1mm longer than the longest edge. Having got that, I relaxed all the edges so that the gauge was a slip fit between the corners of the tower along each triangle edge.

Also, when assembling the corners, I made sure the top of the extrusion was flush & flat with top of the corner piece - assemble upside down on a flat surface. (did require a bit of cleaning up corners to get things to sit well).

I also didn't bother with a spirit level. I worked from a flat reference surface:

- Set top surface of bottom triangle to same distance from reference surface all the way around (I have some 5mm of towers poking out below bottom corners).

- Set top surface of top triangle to same distance from reference surface.

Now, there should be the two equilateral triangles parallel to the reference surface - what remains is twist and shear:

- Find a good big framing square (um, that is SQUARE - don't ask

) and find a good way of setting it on reference surface and against the towers.

) and find a good way of setting it on reference surface and against the towers.I had a nice parallel metal box that was slightly higher than the bottom corners, so the square could be set against the towers easily.

- Loosen the T nuts furthest away from the corners to allow the corners to twist a bit

- Check all the towers and figure how the top triangle should be move to get the towers vertical

- Apply force - it is one those situations where it needs some overshoot as there will be some elasticiity.

- Iterate - it took me 4 or 5 times around with decreasing (ish) nudges.

- Carefully tighten all T nuts.

Finally:

- Set bed to equal height from reference surface - I wound up have the bed screws tightened to the point where the springs were pretty much fully compressed.

- Set endstops to equal height from reference surface.

S

Edited 1 time(s). Last edit at 03/17/2016 12:05PM by samlittlewood.

|

Re: Ebay SINTRON Kossel Mini full kit March 17, 2016 10:10PM |

Registered: 8 years ago Posts: 916 |

Quote

DRTak

Nebbian, repetier was way off in its calculation. A single corner of your pedestal takes 4.5 hrs. [www.thingiverse.com]

Repetier told me 2.5hrs. So I googled what to do. I had to adjust the ADD TO COMP PRINT TIME in settings. I had to increase it to 75%. Now it says print time is 4hrs 21min. Which I think is correct.

Needless to say, I am printing the final corner today. 4.5hrs x 3 = 13.5hrs total print time. Wow this is a labor of love. I am glad I didnt print the 90mm high pedestal.

I will also have to go to the hardware store and buy a tap and die set. Ream out the hole in the bottom of the Kossel for an M6 bolt. Then put that bolt in that you mentioned in your article. Hopefully, they sell that large of a metric bolt. In the USA they are not that prevelant.

Krrrrist!! I don't remember it taking that long to print mine. Maybe about 2 hours each for the ones that I posted? Are you printing at 0.3mm layer height? Anyway, I'm glad that my solution is helping you out.

You don't necessarily need to use 6mm, I think you might be able to use 1/4". Aluminium is soft, I don't think you'd have many problems tapping it out to a slightly larger diameter than 6mm.

Sorry, only registered users may post in this forum.