Carriage crashing into base

Posted by Joeybane

|

Carriage crashing into base September 17, 2015 06:40AM |

Registered: 8 years ago Posts: 12 |

Hello.

I have recently gotten a Folgertech kossel 2020.

I have built it, and calibrated it, so now the nozzle is a papers width over every part of the heatbed.

Have printed a calibration cube, and the xy direction is too big.

The problem is that sometimes when i manually move x and y, one of the carriages just continues down and crashes into the base. This has wore out my rod ends, and there is now a lot more slack than there used to be

The problem was worse when i set the #define DELTA_DIAGONAL_ROD to 230, which is the length of my rods. I set it to the default of 216, and the problem got a lot better. It still is there though.

I have recently gotten a Folgertech kossel 2020.

I have built it, and calibrated it, so now the nozzle is a papers width over every part of the heatbed.

Have printed a calibration cube, and the xy direction is too big.

The problem is that sometimes when i manually move x and y, one of the carriages just continues down and crashes into the base. This has wore out my rod ends, and there is now a lot more slack than there used to be

The problem was worse when i set the #define DELTA_DIAGONAL_ROD to 230, which is the length of my rods. I set it to the default of 216, and the problem got a lot better. It still is there though.

|

Re: Carriage crashing into base September 17, 2015 01:56PM |

Registered: 8 years ago Posts: 396 |

I know this is going to sound funny but im going to say... Stop manually moving x and y

Here is why.

On a cartesian printer each axis is independent and you can freely move one alone.

A delta printer is not so. All three axis work in unison to put the nozzle on a point in 3 dimensional space.

You therefore have to move all three at once.

So here is what I did to help my brain remember this.

In repetier host or prontrface i created buttons to issue a G1 command with all three x y z numbers. This i setup for each tower. Now when I manually calibrate i press X tower button and it goes to the same point every time.

Avoid moving just one axis because the machine was not designed to understand a single axis horizontal movement.

Cheers!

Edited 1 time(s). Last edit at 09/17/2015 01:56PM by thetazzbot.

Here is why.

On a cartesian printer each axis is independent and you can freely move one alone.

A delta printer is not so. All three axis work in unison to put the nozzle on a point in 3 dimensional space.

You therefore have to move all three at once.

So here is what I did to help my brain remember this.

In repetier host or prontrface i created buttons to issue a G1 command with all three x y z numbers. This i setup for each tower. Now when I manually calibrate i press X tower button and it goes to the same point every time.

Avoid moving just one axis because the machine was not designed to understand a single axis horizontal movement.

Cheers!

Edited 1 time(s). Last edit at 09/17/2015 01:56PM by thetazzbot.

|

Re: Carriage crashing into base September 17, 2015 03:34PM |

Registered: 8 years ago Posts: 12 |

Thanks for the reply.

I'm not moving a single tower, just using repetier and moving it by clicking the buttons.

The firmware stops the movement in some directions, but in others it crashes.

When the firmware bstops it, the coordinates in repetier is off, and i have to home it again.

the problem first appeared when i calibrated the flatness at these points:

g0 x0 y0 z5

g0 x0 y105 z5

g0 x-90.23 y-52.5 z5

g0 x90.23 y-52.5 z5

If my maths is correct, this should be the tower positions for a 210mm circle.

It worked at first, but when i tried setting diagonal rod length to the measured one was when this happened.

But now the x-y axes is printing oversized, which i understand is related to the rod length in firmware.

when calibrating flatness, i just mechanically moved the endstops, don't know if that is the correct way to do it, but i don't know another way without making an adjustable heatbed. (all i would need is 3 springs.

I checked the frame, and it is symmetrical.

Delta printers are really a lot of headache! This is my first printer

This is my first printer

I'm not moving a single tower, just using repetier and moving it by clicking the buttons.

The firmware stops the movement in some directions, but in others it crashes.

When the firmware bstops it, the coordinates in repetier is off, and i have to home it again.

the problem first appeared when i calibrated the flatness at these points:

g0 x0 y0 z5

g0 x0 y105 z5

g0 x-90.23 y-52.5 z5

g0 x90.23 y-52.5 z5

If my maths is correct, this should be the tower positions for a 210mm circle.

It worked at first, but when i tried setting diagonal rod length to the measured one was when this happened.

But now the x-y axes is printing oversized, which i understand is related to the rod length in firmware.

when calibrating flatness, i just mechanically moved the endstops, don't know if that is the correct way to do it, but i don't know another way without making an adjustable heatbed. (all i would need is 3 springs.

I checked the frame, and it is symmetrical.

Delta printers are really a lot of headache!

This is my first printer

This is my first printer

|

Re: Carriage crashing into base September 17, 2015 06:52PM |

Registered: 8 years ago Posts: 916 |

|

Re: Carriage crashing into base September 18, 2015 03:44AM |

Registered: 8 years ago Posts: 5,232 |

Your rods are 230mm long from balljoints center to center?

Many people have their effector_offset set wrong, which would lead to a wrong delta_radius.

Effector_offset is NOT the distance from effector center to one of the balljoints.

Think of a virtual axis between two corresponding rods and measure the distance from the axis´ middle to the center of the effector.

Sorry my English math term dictionary is very limited, I can´t explain better

-Olaf

Many people have their effector_offset set wrong, which would lead to a wrong delta_radius.

Effector_offset is NOT the distance from effector center to one of the balljoints.

Think of a virtual axis between two corresponding rods and measure the distance from the axis´ middle to the center of the effector.

Sorry my English math term dictionary is very limited, I can´t explain better

-Olaf

|

Re: Carriage crashing into base September 18, 2015 09:39AM |

Registered: 8 years ago Posts: 12 |

|

Re: Carriage crashing into base September 18, 2015 02:55PM |

Registered: 8 years ago Posts: 12 |

I figured it out. sort of.

The 230mm rods are not long enough to reach the advertised 210mm build area!

I set the radius to 75, loosing a lot of build volume in the process.

I also had set repetier up for 210mm build area.

However, the xy distance is something i'm still working on. I took all the measurements and plugged it in the newest version of marlin (with G30 autotune)

Calibrating flatness again, will se how the xy behaves after that.

Edit: Yup, now XY is spot on

Now to tinker with auto level and/or extruder calibration

Edit 2: Just found out i had slic3r set to 3mm filament on the first cube i printed. It prints beautifully now It prints faster than my hotend can heat! Now i need a fan shroud

It prints faster than my hotend can heat! Now i need a fan shroud

Edited 3 time(s). Last edit at 09/18/2015 05:32PM by Joeybane.

The 230mm rods are not long enough to reach the advertised 210mm build area!

I set the radius to 75, loosing a lot of build volume in the process.

I also had set repetier up for 210mm build area.

However, the xy distance is something i'm still working on. I took all the measurements and plugged it in the newest version of marlin (with G30 autotune)

Calibrating flatness again, will se how the xy behaves after that.

Edit: Yup, now XY is spot on

Now to tinker with auto level and/or extruder calibration

Edit 2: Just found out i had slic3r set to 3mm filament on the first cube i printed. It prints beautifully now

It prints faster than my hotend can heat! Now i need a fan shroud

It prints faster than my hotend can heat! Now i need a fan shroudEdited 3 time(s). Last edit at 09/18/2015 05:32PM by Joeybane.

|

Re: Carriage crashing into base September 19, 2015 03:21AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Carriage crashing into base September 19, 2015 06:52AM |

Registered: 8 years ago Posts: 12 |

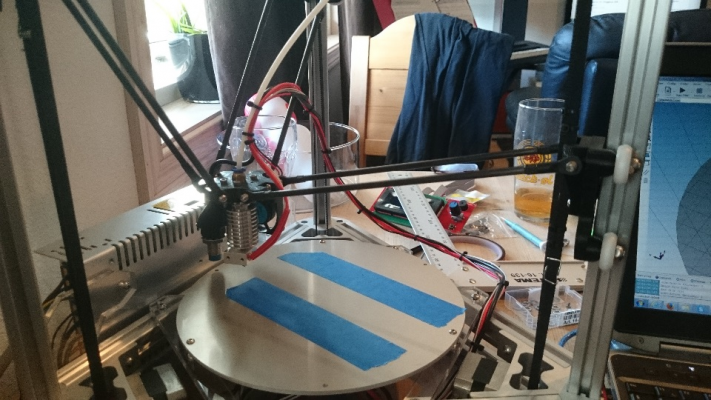

Well, this is how it looks like at x-75, not much more to go on.

In the other direction I can go all the way over the edge of the heatbed if i want.

I may buy some 250mm rods eventually 250mm rods

Edited 1 time(s). Last edit at 09/19/2015 06:53AM by Joeybane.

In the other direction I can go all the way over the edge of the heatbed if i want.

I may buy some 250mm rods eventually 250mm rods

Edited 1 time(s). Last edit at 09/19/2015 06:53AM by Joeybane.

|

Re: Carriage crashing into base September 19, 2015 07:14AM |

Registered: 10 years ago Posts: 14,672 |

I think your print bed is under-sized for the frame you are using. To put it another way, the towers are too far away from the edges of the bed. It appears to me that in the other direction, you could move the nozzle some way off the edge of the bed before the print head fouls the belts.

You definitely need longer rods to reach the far edge of the bed, and you could also get a larger bed too to increase the print area.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

You definitely need longer rods to reach the far edge of the bed, and you could also get a larger bed too to increase the print area.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Carriage crashing into base September 20, 2015 04:14AM |

Registered: 8 years ago Posts: 5,232 |

What´s the length of the horizontal extrusions? I´m afraid with 250mm rods you are still not using the whole printable area. ( If you are willing to spend $$ for a bigger bed, too )

OTOH, longer rods will cause less print height.

BTW, where is the nozzle at x0 y0? Is it at the center of the bed?

-Olaf

OTOH, longer rods will cause less print height.

BTW, where is the nozzle at x0 y0? Is it at the center of the bed?

-Olaf

|

Re: Carriage crashing into base September 20, 2015 12:17PM |

Registered: 8 years ago Posts: 12 |

The extrusions are 300mm.

I'm thinking of using countersunk screws on the bed and using a glass plate on top(already bought a borosilicate glass plate)

I should be able to use all the build area if I then put on longer rods and move the powersupply.

How long rods would i need to utilize the full build area on this machine?

I may win some build height back if i use an effector like this one: Infill 3d effector

I may put a bigger plate on in the future, but i might need a 24V powersupply for it. This one barely reaches 100 *C, will maybe be easier if i insulate it.

Edited 1 time(s). Last edit at 09/20/2015 12:19PM by Joeybane.

I'm thinking of using countersunk screws on the bed and using a glass plate on top(already bought a borosilicate glass plate)

I should be able to use all the build area if I then put on longer rods and move the powersupply.

How long rods would i need to utilize the full build area on this machine?

I may win some build height back if i use an effector like this one: Infill 3d effector

I may put a bigger plate on in the future, but i might need a 24V powersupply for it. This one barely reaches 100 *C, will maybe be easier if i insulate it.

Edited 1 time(s). Last edit at 09/20/2015 12:19PM by Joeybane.

Sorry, only registered users may post in this forum.