backlash eliminating star

Posted by o_lampe

|

backlash eliminating star October 17, 2015 04:30AM |

Registered: 8 years ago Posts: 5,232 |

Hi guys,

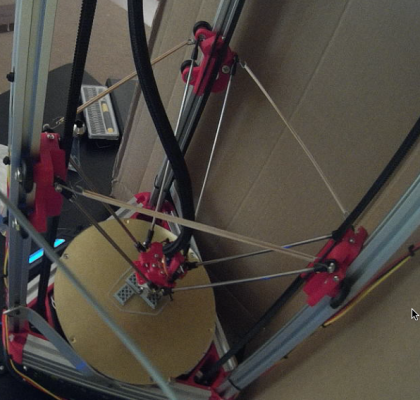

inspired by nebbians rubberband anti wobble hack, I sketched up a version that eliminates backlash in the rod ends as well as any play in the carriers.

It combines the well known "anti-backlash spring" between the rods and nebbians approach to eliminate wobble and play in the v-slot rollers.

Now the pulling force on the carrier-wheels is always aiming to the center-ring. No "forced wobble" anymore.

#see attachment

-Olaf

inspired by nebbians rubberband anti wobble hack, I sketched up a version that eliminates backlash in the rod ends as well as any play in the carriers.

It combines the well known "anti-backlash spring" between the rods and nebbians approach to eliminate wobble and play in the v-slot rollers.

Now the pulling force on the carrier-wheels is always aiming to the center-ring. No "forced wobble" anymore.

#see attachment

-Olaf

|

Re: backlash eliminating star October 17, 2015 06:29AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: backlash eliminating star October 17, 2015 02:07PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: backlash eliminating star October 17, 2015 02:29PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: backlash eliminating star October 18, 2015 04:06AM |

Registered: 8 years ago Posts: 5,232 |

I've mounted my extruder in half height onto the x-tower. Others have mounted their stepper on the top horizontal struts... There is no standard answer to that.

The installation with springs and center ring are halfway up on the rods. In my case it would have a clearance of 12cm to the effector. The ring might never get in contact with the Bowden tube, we'll see.

-Olaf

The installation with springs and center ring are halfway up on the rods. In my case it would have a clearance of 12cm to the effector. The ring might never get in contact with the Bowden tube, we'll see.

-Olaf

|

Re: backlash eliminating star October 18, 2015 10:27AM |

Registered: 9 years ago Posts: 1,159 |

Quote

o_lampe

I've mounted my extruder in half height onto the x-tower. Others have mounted their stepper on the top horizontal struts... There is no standard answer to that.

The installation with springs and center ring are halfway up on the rods. In my case it would have a clearance of 12cm to the effector. The ring might never get in contact with the Bowden tube, we'll see.

-Olaf

Ah the halfway up the rods is the missing piece I thought you were going to attach at the upper carriage point 12 cm above the effector would work I reckon will be interesting to see your result's

Fortunatly I don't have the problem so don't need to stabilise it (I use openBuilds Mini V-Wheels on there Vee slot extrusion and use a custom slider block with eccentric spacers to allow for adjustment and use 4 wheels on each carriage (tho that could be reduced to 3 if needed).

On more resent builds I have used Robotdigg Alloy corners,Carriages,Effector and Linear rails which totally eliminates all of the problems with Backlash also now using IGUS rod ends which are really nice. Unfortunately all this comes at a cost.

Current build (For a Customer) is coming out at around £650 for a Kossel XL with 300mm diam bed 260mm height AC Bed Heater Duet Controller and PanelDue 5 inch display and bulldog XL Extruder

|

Re: backlash eliminating star October 18, 2015 12:02PM |

Registered: 10 years ago Posts: 14,672 |

Dougal, which Igus rod ends do you use, and where do you get them from?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: backlash eliminating star October 18, 2015 12:41PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Dougal, which Igus rod ends do you use, and where do you get them from?

They are the IGUS KBRM-03 direct from IGUS They wont supply individual's (Unless your liberal with the truth Lol) only Businesses they come in at 1.92 + for quantities above 10 see KBRM-03 Rod Ends.

I have a second set in the post and Carbon Tube can be got from Carbon Tube

HTH

Doug

|

Re: backlash eliminating star October 18, 2015 02:07PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

Quote

dc42

Dougal, which Igus rod ends do you use, and where do you get them from?

They are the IGUS KBRM-03 direct from IGUS They wont supply individual's (Unless your liberal with the truth Lol) only Businesses they come in at 1.92 + for quantities above 10 see KBRM-03 Rod Ends.

I have a second set in the post and Carbon Tube can be got from Carbon Tube

HTH

Doug

Thanks!

Do you find the 5mm x 3mm tube rigid enough? My 6mm x 4mm tube bends a little more than I would like, and I was thinking of going up to 8mm. But all the Igus joints I have found use the same hole and thread sizes.

Is there a reason why you chose the woven tube instead of the pulltruded tube?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: backlash eliminating star October 18, 2015 02:22PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

Quote

dougal1957

Quote

dc42

Dougal, which Igus rod ends do you use, and where do you get them from?

They are the IGUS KBRM-03 direct from IGUS They wont supply individual's (Unless your liberal with the truth Lol) only Businesses they come in at 1.92 + for quantities above 10 see KBRM-03 Rod Ends.

I have a second set in the post and Carbon Tube can be got from Carbon Tube

HTH

Doug

Thanks!

Do you find the 5mm x 3mm tube rigid enough? My 6mm x 4mm tube bends a little more than I would like, and I was thinking of going up to 8mm. But all the Igus joints I have found use the same hole and thread sizes.

Is there a reason why you chose the woven tube instead of the pulltruded tube?

Woven should be stiffer than Pulltruded as the thread weave is more multidirectional as far as I can ascertain whereas pulltruded all the thread's are in the longitudal direction I think that the 3x5 should be plenty stiff enough at a push you could use 3x5 on the ends and the use that in a 7x5 tube if you needed something stiffer (Both are available in pulltruded and woven styles).

Robotdigg also do a 3x6 Pulltruded tube set at 300 long (Assembled they come out at 343 centre to centre of the ends which could easily be spaced out to 350+ by use of a couple of Nuts at each end (I use one on each end anyway to stop the Epoxy gluing the end so I can re-use them if need be).

I will need to PM you next week for another mini sensor and a panel Dueboard as well so if you could put me one of each to one side it would be appreciated.

Have you got anywhere with the hall sensor boards yet?

Doug

|

Re: backlash eliminating star October 18, 2015 09:58PM |

Registered: 8 years ago Posts: 916 |

Quote

o_lampe

Now the pulling force on the carrier-wheels is always aiming to the center-ring. No "forced wobble" anymore.

It's good to see someone improve my 'quick hack' :-)

Your centre ring will still move around when the carriages move up and down (it won't stay centred), and because the springs are shorter than the rubber bands, the difference in force between retracted and extended will be higher than the rubber bands. All this means that you'll still have 'forced wobble' with your system.

All of this is moot though, because the main issue with the current design is the top roller. The other two don't have much force on them, and if they wobble then they don't affect the effector very much if at all. It's only the top roller that causes the most issue. And either system (rubber bands or star arrangement) will preload the bearing on that top roller just fine. Granted, the rubber band system doesn't preload the rod ends, but mine don't have any slop in them at all so I didn't see it being necessary.

I'm getting really precise results out of mine now, hard to measure but it's probably around 50 microns. Not bad for window rollers.

Edited 1 time(s). Last edit at 10/18/2015 09:59PM by nebbian.

|

Re: backlash eliminating star October 19, 2015 04:55AM |

Registered: 8 years ago Posts: 5,232 |

My first carriers based on cheap shower door rollers but I replaced them with the t3d dual bearing rollers soon. So nebbians idea was a bit late for me

I also turned around my carrier, so that the rods are closer to the center roller. I've lost some z-height but it's playfree now. After 2kg of filament I start to hear some noise coming from the effector at turning points. Can't feel any excessive play, but I guess, the Traxxas joints start to loosen a bit.

I wonder if the play in dougals Igus ball joints is adjustable by tightening the screw that holds the ball?

-Olaf

@nebbian, what do you mean with window rollers?

I also turned around my carrier, so that the rods are closer to the center roller. I've lost some z-height but it's playfree now. After 2kg of filament I start to hear some noise coming from the effector at turning points. Can't feel any excessive play, but I guess, the Traxxas joints start to loosen a bit.

I wonder if the play in dougals Igus ball joints is adjustable by tightening the screw that holds the ball?

-Olaf

@nebbian, what do you mean with window rollers?

|

Re: backlash eliminating star October 30, 2015 12:32AM |

Registered: 10 years ago Posts: 169 |

Quote

dougal1957

Fortunatly I don't have the problem so don't need to stabilise it (I use openBuilds Mini V-Wheels on there Vee slot extrusion and use a custom slider block with eccentric spacers to allow for adjustment and use 4 wheels on each carriage (tho that could be reduced to 3 if needed).

Dougal1957 ....I'd sure like to see pictures of your v-slot mini wheel carriage set up. I'm using the same components for the enclosed delta I'm building. I went with the magnet ball/carbon rods setup from Werner Berry. His rods measure 9.5mm dia.

|

Re: backlash eliminating star October 30, 2015 03:24AM |

Registered: 9 years ago Posts: 1,159 |

Quote

simspeed

[attachment 64970 Carriage.JPG][attachment 64971 Carriageside.JPG][attachment 64972 Carriagerear.JPG]Quote

dougal1957

Fortunatly I don't have the problem so don't need to stabilise it (I use openBuilds Mini V-Wheels on there Vee slot extrusion and use a custom slider block with eccentric spacers to allow for adjustment and use 4 wheels on each carriage (tho that could be reduced to 3 if needed).

Dougal1957 ....I'd sure like to see pictures of your v-slot mini wheel carriage set up. I'm using the same components for the enclosed delta I'm building. I went with the magnet ball/carbon rods setup from Werner Berry. His rods measure 9.5mm dia.

Actually it is not dissimilar to yours except that my Sliders are printed in ABS (Your's are probably better being in Alloy) and I then have Kossel Carriages mounted to them where the Traxas Joint's are at the centre point this reduces print height but IMHO improve on stability and cross loading on the sliders ( Mine are 10mm thick). I would think that you might be better moving your Ball mounts to be more on the centre line of the wheels because where you have them (AS far as I can make out in the Photos) will induce a rotation force on the wheels which will wear them quicker.

There are photo's of it on here somewhere if you search on my previous post's I am sure you will find them.

Hope this makes sense

Doug

|

Re: backlash eliminating star October 31, 2015 09:12AM |

Registered: 10 years ago Posts: 169 |

|

Re: backlash eliminating star October 31, 2015 05:04PM |

Registered: 8 years ago Posts: 22 |

|

Re: backlash eliminating star November 02, 2015 03:53AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Billhc83

Those igus rod ends list max range @ 30* I am assuming this would make a total of 60* range of motion, how does that compare to the Traxxas joints?

Traxxas joints have around 22 degrees (Best I could measure with a protractor could not find any data sheet for them) the big advantage of the Igus ones in my mind are that they are preassembled have no noticeable backlash in the joint's themselves but they are a little more bulky than a traxxas joint so I have to shave a little of part of them at the effector end as the bind slightly if left intact but we are only talking about rounding about a 0.5 mm off the edges that contact each other so no big deal.

Doug

|

Re: backlash eliminating star December 23, 2015 05:28PM |

Registered: 9 years ago Posts: 1,035 |

Quote

o_lampe

Hi guys,

inspired by nebbians rubberband anti wobble hack, I sketched up a version that eliminates backlash in the rod ends as well as any play in the carriers.

It combines the well known "anti-backlash spring" between the rods and nebbians approach to eliminate wobble and play in the v-slot rollers.

Now the pulling force on the carrier-wheels is always aiming to the center-ring. No "forced wobble" anymore.

-Olaf

Is this still an in-progress idea? I never saw any pictures Olaf of your final/any solution. I am thinking to add springs to the traxxas diagonal rods on my Overlord and was researching for any lateral ideas on the backlash/wobble issue.

BTW is this applying only to extrusion/roller carriages? I have copper bushings on steel rod so any backlash I see is in the traxxas themselves.

Edited 1 time(s). Last edit at 12/23/2015 05:30PM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: backlash eliminating star December 23, 2015 06:39PM |

Registered: 8 years ago Posts: 3,525 |

|

Re: backlash eliminating star December 23, 2015 06:42PM |

Registered: 9 years ago Posts: 1,035 |

Quote

DjDemonD

Seems like a good idea. Makes me wonder if I am inadvertently achieving the same effect with a flying extruder since the extruder is attached by elastic to each of the carriages effectively pulling them towards the centre of the printer.

That's a good observation

... it would be cool to have killed two birds with one stone. I am also contemplating at a flying extruder.

... it would be cool to have killed two birds with one stone. I am also contemplating at a flying extruder.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: backlash eliminating star December 23, 2015 07:01PM |

Registered: 8 years ago Posts: 916 |

For those that are wondering...

My original rubber band hack did work quite well, although I've now moved to linear bearings. They work better Although it has to be said, I can't see any difference in print quality between rollers with the rubber band hack, and linear bearings, at least at this stage.

Although it has to be said, I can't see any difference in print quality between rollers with the rubber band hack, and linear bearings, at least at this stage.

I have been chasing a particular print issue for months, where external perimeters outside of infilled areas would be wider. In my case this resulted in a 'lip' around the outside of the part near the top. I thought that this might be due to slop when the effector turns the corner, hence the rubber bands and linear bearings. However that turns out not to be the case. The issue is to do with the long bowden cable. When you extrude at high pressure for infill (going fast), then extrude at low pressure (going slow around the perimeter), some pressure is still built up in the bowden tube and so you end up with a wider perimeter when you've just laid down solid infill. This results in that damn lip.

I'm now getting nice prints now that I've dropped the infill speed to slower than the perimeter speed. Yes I know this seems weird but I swear it's repeatable.

Needless to say, like others on here I'm investigating either a flying extruder, or a flex3drive system to do away with that big long stretchy bowden cable.

My original rubber band hack did work quite well, although I've now moved to linear bearings. They work better

Although it has to be said, I can't see any difference in print quality between rollers with the rubber band hack, and linear bearings, at least at this stage.

Although it has to be said, I can't see any difference in print quality between rollers with the rubber band hack, and linear bearings, at least at this stage.I have been chasing a particular print issue for months, where external perimeters outside of infilled areas would be wider. In my case this resulted in a 'lip' around the outside of the part near the top. I thought that this might be due to slop when the effector turns the corner, hence the rubber bands and linear bearings. However that turns out not to be the case. The issue is to do with the long bowden cable. When you extrude at high pressure for infill (going fast), then extrude at low pressure (going slow around the perimeter), some pressure is still built up in the bowden tube and so you end up with a wider perimeter when you've just laid down solid infill. This results in that damn lip.

I'm now getting nice prints now that I've dropped the infill speed to slower than the perimeter speed. Yes I know this seems weird but I swear it's repeatable.

Needless to say, like others on here I'm investigating either a flying extruder, or a flex3drive system to do away with that big long stretchy bowden cable.

|

Re: backlash eliminating star December 24, 2015 04:01AM |

Registered: 8 years ago Posts: 5,232 |

Combining the flying extruder with my star idea is only working when you mount the rubbers halfway down the rods-length. ( If possible )

I'm afraid the PTFE tube will then be too short and causes the extruder to shake too much.

OTOH, if you mount them on carrier height, the rubbers wont eliminate slack in the rod ends.

I skipped the idea, because I sold my delta and didn't want to leave experimental marks on the rods. ( You have to fix the rubbers somehow )

-Olaf

I'm afraid the PTFE tube will then be too short and causes the extruder to shake too much.

OTOH, if you mount them on carrier height, the rubbers wont eliminate slack in the rod ends.

I skipped the idea, because I sold my delta and didn't want to leave experimental marks on the rods. ( You have to fix the rubbers somehow )

-Olaf

Sorry, only registered users may post in this forum.