Bigger 3d delta printer size

Posted by harsh

|

Re: Bigger 3d delta printer size October 23, 2015 02:18PM |

Registered: 10 years ago Posts: 14,672 |

hercek, thanks for that. Where do you get your steel core belts from?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Bigger 3d delta printer size October 23, 2015 03:17PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

hercek, thanks for that. Where do you get your steel core belts from?

Dave

Found these and ordered some

PU GT2 with Steelcore

HTH

Doug

|

Re: Bigger 3d delta printer size October 23, 2015 03:28PM |

Registered: 9 years ago Posts: 445 |

Quote

dougal1957

Quote

dc42

hercek, thanks for that. Where do you get your steel core belts from?

Dave

Found these and ordered some

PU GT2 with Steelcore

HTH

Doug

Same as I ordered, only I got it $1.39 cheaper, probably due to ordering via their app.

(They run some promotions to use their app sometimes)

Edited 1 time(s). Last edit at 10/24/2015 12:58AM by Koenig.

|

Re: Bigger 3d delta printer size October 23, 2015 05:09PM |

Registered: 10 years ago Posts: 732 |

Well, I use T2.5 steel core belts. These are a bit worse than GT2 steel core. And I should get higher quality pulleys (which match the bets more tightly). I got them here: [www.reprap.cc]Quote

dc42

hercek, thanks for that. Where do you get your steel core belts from?

Notice the shop does not specify what kind of core the belt uses. I would verify it with them through email before buying. But most T2.5 belts bought from 3dPrinter shops which have core unspecified will have actually steel core. Most GT2 belts bought from 3dPrinter shops which have core unspecified will have actually glass core.

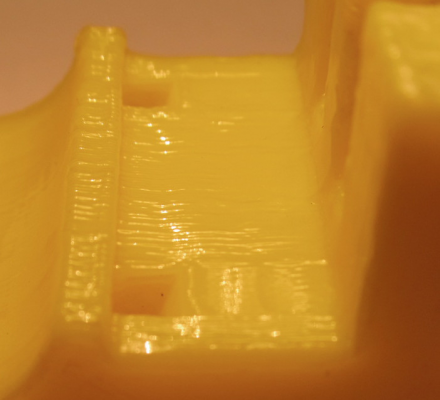

At the time I bought I was not even aware about many 3d printer gotchas. I only started to take interest in what could be reasons of different kinds of print errors when I saw them in my prints. Here is an example of the waves caused by springy belts or bending smooth rods. You can see two nice waves behind the bottom zip tie hole. Typically I can see also a very faint third one. But it is not visible here since the part surface direction changes. The part is already treated with acetone, so it is "shiny".

Anyway, people posted GT2 steel core sources. If they deliver then they are better since they give you TG2 steel core.

Edited 1 time(s). Last edit at 10/23/2015 05:10PM by hercek.

|

Re: Bigger 3d delta printer size October 26, 2015 02:41PM |

Registered: 10 years ago Posts: 469 |

My delta has a hair over 2m worth of belt. I cannot help but notice one thing. ~1/3 or maybe 1/4 of the belt is there for no good reason.

I have run my larger delta at speeds that approach 160mm/s and even as high as 200mm/s in testing. (found some missed steps at anything over 160mm/s, seems like my nema 17's cant cope with the weight of the carriage and the 340mm/rods....

Here are the findings.

The belt stretch can be mitigated with proper pretentioning of the belts.

Smooth pulleys at the extremities introduce more error than belt stretch.

The motors should be on top with toothed pulleys about 1/4 way up from the bottom. This needs careful calculation as the arms must not bottom out at the bottom of the stroke at the extremity of the bed.

I have also noticed that at least my cheap belts have the following characteristics.

They need about 2-3 hours of run-time to break in and should be retentioned, there should be no observable belt wobble when at full swing.

The belts will need another 2-3 hours of run-time if you plan on using a heated chamber. I run my chamber at 55c when doing big parts. The belts were retentioned after a print job while the belts were still warm. I use the Ultimaker style belt tentioners I 3d printed to do this. I only run 1 per belt on the bottom of the carriage.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

I have run my larger delta at speeds that approach 160mm/s and even as high as 200mm/s in testing. (found some missed steps at anything over 160mm/s, seems like my nema 17's cant cope with the weight of the carriage and the 340mm/rods....

Here are the findings.

The belt stretch can be mitigated with proper pretentioning of the belts.

Smooth pulleys at the extremities introduce more error than belt stretch.

The motors should be on top with toothed pulleys about 1/4 way up from the bottom. This needs careful calculation as the arms must not bottom out at the bottom of the stroke at the extremity of the bed.

I have also noticed that at least my cheap belts have the following characteristics.

They need about 2-3 hours of run-time to break in and should be retentioned, there should be no observable belt wobble when at full swing.

The belts will need another 2-3 hours of run-time if you plan on using a heated chamber. I run my chamber at 55c when doing big parts. The belts were retentioned after a print job while the belts were still warm. I use the Ultimaker style belt tentioners I 3d printed to do this. I only run 1 per belt on the bottom of the carriage.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Bigger 3d delta printer size October 26, 2015 06:48PM |

Registered: 10 years ago Posts: 732 |

What kind of belts do you use? (GT2, T2.5, T5, ...)Quote

jaguarking11

Smooth pulleys at the extremities introduce more error than belt stretch.

Did you try to twist the belts so that the smooth side of the belt touches the smooth pulley? The point is, I do not understand how smooth pulley can introduce an error if you run smooth part of the belt over it.

Edit:

Also belt stretch (rod bend) depends more on accelerations than on the final maximum speed. The maximum speed only needs to be big enough so that the maximum acceleration will be applied long enough for the full stretch/bend to develop (i.e. long enough path is traveled under full acceleration). How did you change the accelerations when testing different speeds?

Edited 1 time(s). Last edit at 10/26/2015 06:53PM by hercek.

|

Re: Bigger 3d delta printer size October 27, 2015 11:47AM |

Registered: 10 years ago Posts: 469 |

MY belts are running tooth side on the idler. It will introduce some errors.

The rods themselves in my configuration are stretched and do not bear the belt tension. The rods are placed and adjusted for optimal movement and then streched via threading the rods and placing nuts on them. There are some alu tubes on the sides that are under compression providing frame rigidity.

The belts are GT2 with glass reinforcement. My next upgrade will be 20T pulleys on a rod with bearings. This should reduce the errors a bit.

Edited 1 time(s). Last edit at 10/27/2015 11:48AM by jaguarking11.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

The rods themselves in my configuration are stretched and do not bear the belt tension. The rods are placed and adjusted for optimal movement and then streched via threading the rods and placing nuts on them. There are some alu tubes on the sides that are under compression providing frame rigidity.

The belts are GT2 with glass reinforcement. My next upgrade will be 20T pulleys on a rod with bearings. This should reduce the errors a bit.

Edited 1 time(s). Last edit at 10/27/2015 11:48AM by jaguarking11.

My Personal Blog. Build blog.

[engineerd3d.ddns.net]

Modicum V1 sold on e-bay user jaguarking11

|

Re: Bigger 3d delta printer size October 27, 2015 04:50PM |

Registered: 10 years ago Posts: 732 |

I agree. And the smaller the idler diameter the bigger the error. Also the bigger the belt pitch the bigger the error. If you can twist the belt then you will get rid of this error. I twisted my belts. It's working fine.Quote

jaguarking11

MY belts are running tooth side on the idler. It will introduce some errors.

Sorry, only registered users may post in this forum.